All Activity

- Past hour

-

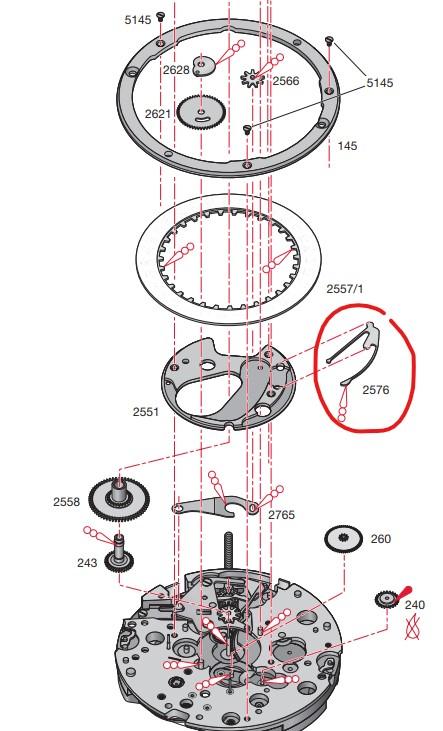

I have a Record 525 which is in a pretty bad way. From what I can see it is based on a cal 650 with an automatic bridge and centre seconds pinion under the rotor retaining stud. There are additional bearings in the train bridge for the bottom pivots of the automatic works. Of these, on has come out of the bridge completely, one is a bit mangled with an egg shaped pivot hole and one is half in, half out. I've made bearings from scratch on the lathe before, but only for pocket watch pivots (i.e. considerably bigger than these!) and these bearings are either plated or not brass, to match the bride plate, I would guess. I could not find a bridge on eBay so I started digging. I checked new Ranfft site (not help, but the new one seldom is) then the cousins download centre but I could not find a document for a cal 525. I did, however find one for the 650 and, scribbled on the page are the words "= Longines 701". So, obvious next step (or so I thought) would be to check the docs for Longines cal 701 and then see if there is maybe a cal close by, based on that cal with a rotor. I checked, no 701 in the downloads section. I did find some Longines 701 parts on eBay, which look similar to the 650 (i.e. the train bridge looks to be the same) but I feel I have hit a dead end. I have added some pictures that you may find helpful and I have photographed the entire strip down so I have more, if needed. I feel I have few options: 1. Close the brewing holes up and reinsert the loose bearings. Close up the pivot hole on the 3rd bearing and hope that does the trick. 2. Make some new bearings (doable but tricky and will look wrong) 3. hold out for a 525 bridge to come up online. I get the feeling this is a rare movement though (all the more a shame it is in such a bad condition) 5. See if there is a Longines equivalent and either use that, or transplant the bearings from that bridge to the Record. Any help identifying the Longines equivalent (if it exists) would be appreciated. Any suggestions on the alternatives I have discussed are also welcome

- Today

-

Elgin Grade 315: Runs/stops with dial down/up

mbwatch replied to docrpm's topic in Fault Finding / Fault Diagnosis

Really you paid that little for a legit Trupoise? -

Elgin Grade 315: Runs/stops with dial down/up

Neverenoughwatches replied to docrpm's topic in Fault Finding / Fault Diagnosis

An amazing way with words, I laughed so loud the neighbour's dog started barking . At last we have a new term for " watch breakers " curtesy of John........." Prior Idiots "...I think it is perfectly fitting, I can't wait to use it -

Elgin Grade 315: Runs/stops with dial down/up

Nucejoe replied to docrpm's topic in Fault Finding / Fault Diagnosis

Yes, attempts for undoing prior idiots wrong doing, in inexpensive watches is common. Regs -

Elgin Grade 315: Runs/stops with dial down/up

Neverenoughwatches replied to docrpm's topic in Fault Finding / Fault Diagnosis

It's not, but it can be. I have a few of them, I don't think I paid more than £35 for any of them. -

Elgin Grade 315: Runs/stops with dial down/up

JohnR725 replied to docrpm's topic in Fault Finding / Fault Diagnosis

Exact factory specifications does not require a shim. Bending of the balance bridge is only required if prior idiots bent the bridge for you and you need to restore it back to where it's supposed to be. Which unfortunately is quite common on American pocket watch repair. Oh and what about the Swiss tool that I mentioned above why would the Swiss have a tool? Or even more important why would a school like wostep use such a evil barbaric tool as that is actually how I know about the tools existence there must've been a reason why? So yes in absolute perfect world you would never bend the bridge. You would also never use a shim as typically that's a sign of poor manufacturing skills ideally you would adjust the balance pivots and do a proper repair. Unless of course the repair requires you to restore the bridge back to where it was supposed to be in the first place. -

Elgin Grade 315: Runs/stops with dial down/up

Nucejoe replied to docrpm's topic in Fault Finding / Fault Diagnosis

Disagree with Neven and JohnR, bending the bridge or cock is simply bad watch repair. Would you bend a cock in patek Phillip or audemars piguet watch? Good watch repair is one that conforms to exact factory specification. -

ecyobleoj changed their profile photo

-

Elgin Grade 315: Runs/stops with dial down/up

JohnR725 replied to docrpm's topic in Fault Finding / Fault Diagnosis

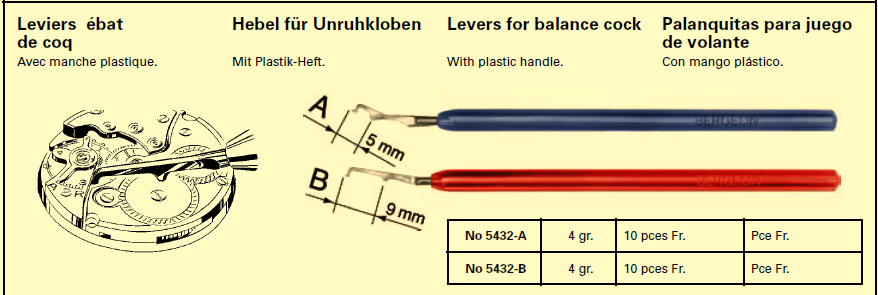

Personally I prefer to bend the balance bridge when it's out of the watch. Although typically I'm doing American pocket watches and it actually takes quite a lot of force to bend the bridge. But if you would like a lever and it's a wristwatch or something smaller than a pocket watch the Swiss have you covered as they have a lever or two. I remember somebody pointed this out to me and I looked at the tool and can't remember why but I was not impressed. I suppose the real question is why do we either method? In other words the watch left the factory without a shim unless of course it's a Russian watch and then it definitely had one plus a few other companies also had them but typically the watch doesn't need them at all. But with anything of vintage things have happened things have well things aren't always where there supposed to be. Then people change balance staffs and don't realize that pivots can be shortened. I saw a picture of a Russian balance staff and noticed they have extremely long pivots but apparently nobody has a lathe Or fail to grasp why the pivots are so long and shimming. But it would really be best if you didn't have to. Then for doing any of the things like we talk about you really should be practicing on a practice watch. Or even pieces of watches you don't even need a complete watch you just need the balance wheel on the bridge in the main plate see them practice bending things and see how much worse it takes to break etc. As everything requires practice and practicing on a watch you want to keep when you have no experience isn't necessarily what you want to do as it will lead to probably what were seeing where things are going to get much much worse before they hopefully get better hopefully Then I'm attaching a PDF on balance wheel truing. If you work on American pocket watches with bimetallic balance wheels your destiny will be to always have to true them. Typically there almost always out of flat or they been squeezed which has undesirable timing consequences and really screws up the poise. Plus typically American pocket watches have just had a lot of undesirable repairers over the years. Joseph Bulova School of Watch Making - Unit 2 balance wheel truing.pdf -

ecyobleoj joined the community

-

Elgin Grade 315: Runs/stops with dial down/up

SwissSeiko replied to docrpm's topic in Fault Finding / Fault Diagnosis

Get a piece of brass plate stock and mark on it where the indicating pins on the balance cock are, and drill them out. Then mark out where the screw would go, then drill and tap it. Then do as nev said, and bend the cock gently. In my opinion, shimming is an unacceptable repair, as its only a timesaving method. Too many bad previous repairs I've seen, I'd rather do it right the first time. Maybe that's why I have the clients watch now, and not the repairman who shimmed the balance. -

Accutron 700 meter

JohnR725 replied to ManSkirtBrew's topic in Watch Timing & Testing Equipment / Timegraphers

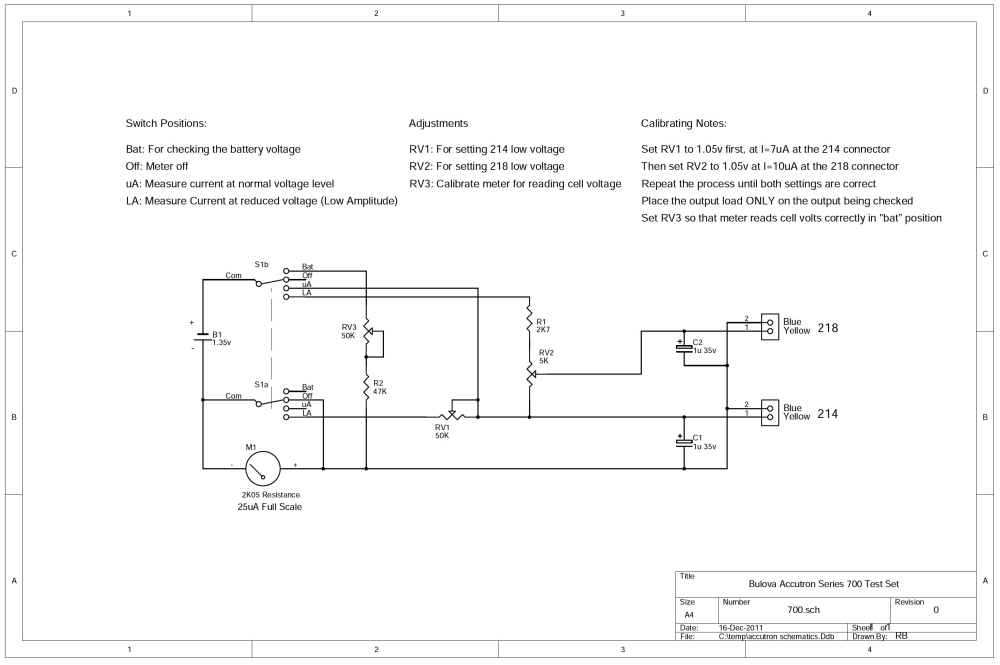

What makes you think that your meter needs to be restored does it have a problem? Unfortunately I don't have time to do this but I'll have to come back to the discussion and restore the links because it looks like the links up above are broken and I think they do exist they are just not pointing to where they need to point Then it's good that you gave the number there's actually two separate meters I believe is a 600 and a 700. The preferred approach today is not to restore but to modify with the simplest modification to change the meter to working with silver cell batteries which have a higher voltage than Mercury cell batteries. But a preferred approach would be to make use of the meter movements because that is a very nice analog meter which works really well for tuning fork watches and to produce a variable voltage power supply to use with your very sensitive microamp meter. I did find the missing links from up above their down below and on one of the links if you poke around far enough you will find the schematic for your meter but just in case. Is Then the link to how to properly phase with silver cells although what's interesting is that Bulova actually did check their watches at a much higher voltage. In a case here's one of the ways the phase at a higher voltage Which is I believe one of the broken links up above https://www.accutronwatchpage.com/accphs.htm Here's a webpage where someone modifies their meter which is a wild guess is probably the same person who drew the schematic up above based on his name and the initials on the schematic https://www.accutronwatchpage.com/700meter/700meter.html I really hate websites that do not link to their home page but here's the homepage L notice that both links above are actually on this website https://www.accutronwatchpage.com/ -

One thing that I struggle with is visualising sizes without seeing it, yes I can get out and tape measure but I would prefer to see it in person. The toolbox is smaller than I thought but will suffice, mops etc currently at work, will add tomorrow.

-

Hairspring Manipulation Practice !

Nucejoe replied to dnhb's topic in Your Current Projects and Achievements

mike your skill have constantly improved from the start. Manipulating tiny coils is just another level of improvement, must say its painstaking. When you feel ready to attack the next tiny coil, be confident your dexterity is practically on the improve and you will get proficient at it, and come to give good advice. Best regards. -

Elgin Grade 315: Runs/stops with dial down/up

Nucejoe replied to docrpm's topic in Fault Finding / Fault Diagnosis

Your approach limits your adjusting to integer number of folds. One fold Two folds, ......so on. You don't have 1.3 or 1.3758 folds. Just insert one fold under the cock, then moving the foil with respect to cock screw, gives you infinite slopes of the cock, and shoot for the smallest end shake. In practice, smallest end shake is, one that, if cock screw is 99% tightened !! balance is not free to turn. But When fully 100% tightened, balance frees up to turn. It is a very practical approach. Mark teaches it in one of his videos. Regs -

Elgin Grade 315: Runs/stops with dial down/up

LittleWatchShop replied to docrpm's topic in Fault Finding / Fault Diagnosis

The clamping is brilliant. The jewels holding the pivot are spring loaded and retract as you tighten on to the arms. -

mikepilk started following Hairspring Manipulation Practice !

-

Hairspring Manipulation Practice !

mikepilk replied to dnhb's topic in Your Current Projects and Achievements

I thought I was getting OK at hairspring manipulation until I tried to detangle one on an Omega cal 455 - ladies automatic movement (with sweep second) just 16mm diameter (very small and fiddly movements - best avoided). The hairspring was just 3.5mm diameter. Even with my sharpest tweezers working under the microscope I had to admit defeat and find a new balance. In the 'flat' I could correct errors, but trying to make vertical twists was beyond me. -

Elgin Grade 315: Runs/stops with dial down/up

nevenbekriev replied to docrpm's topic in Fault Finding / Fault Diagnosis

Yes, I understand. But one has to try, only this way the fear of the unknown disappears. I promise it will be not so hard to do and of course, if bending is too much, then lift it with some lever (bend it up) and with several iterations everything will be perfect. Never try to lift or bend down when the balance is in place, this is the important rule. If you have some useless movement, try and exercise on it. -

No images showing

Neverenoughwatches replied to VWatchie's topic in Help & Support With This Website

There are facebook groups ....but another forum that stores information from threads All we can do is wait and see what happens. -

Hairspring Manipulation Practice !

dnhb replied to dnhb's topic in Your Current Projects and Achievements

Good luck. Interested to hear what lessons it teaches/reinforces..... -

Elgin Grade 315: Runs/stops with dial down/up

docrpm replied to docrpm's topic in Fault Finding / Fault Diagnosis

@LittleWatchShop I've seen one of those Trupoise tools on the ChronoGlide YouTube channel...Pretty amazing tool, but I went looking for one, and there were none on offer. It strikes me as similar to one of those JKA Feintaster bench micrometers: really neat, really expensive. @nevenbekriev Regarding shimming v. bending the balance cock, the permanence of the solution is something that I hadn't considered. It totally makes sense if one is going to be removing and replacing the balance cock more than once or twice. I'm just not sure (a) how I would go about bending and (b) how I wouldn't bend it too much. It seems like an approach best left to the professionals. -

Willem1961 started following Seiko 5M42-0E60/69 4GM7-BA 20 mm rubber strap

-

Hello WRT members in my last post I mentioned about maybe try doing 3m22-0d39 straps. I got a request for this model so gave it a try. We kept the openings closed and we found out the strap would be much stronger. Gonna show you the result with the metal armor mounted on the strap. I fixed 2 3m22’s on request. A earlier project was a 5j22-0a70 with a broken rubber strap insert.

-

I have decided to go for the spray lacquer as I'm rubbish with a brush. Keep thinking I've missed a bit so I go over it again and again. Where do you get Mohawk from @Dell?

-

Sassman started following PANERAI OPIII DATE ADVANCES ONLY HALF DAY

-

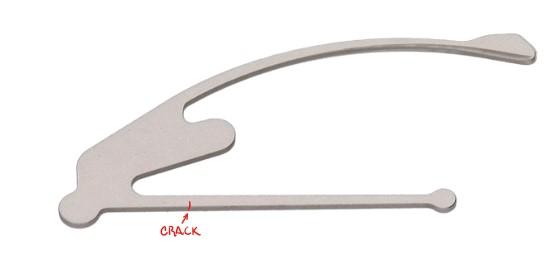

I was able to diagnose an odd issue with my Panerai and thought I would share in case anyone ever experiences it also. After I performed a full service on my pam00091, which uses the OPIII movement. The OPIII is a modified Valjoux 7750/7765. After reassembly I noticed the date wheel would only advance half a day. Showing half of the previous day and next day. After verifying everything was properly lubricated I studied in more depth the way the date advance operated. Noticing something a bit strange I put it under the microscope. Low and behold there was a tiny microscopic crack in the date jumper. It appears as if it was in the original part as the chrome plating follows the crack and may have been just enough to hold it together. Cleaning or bending it to reinstall looks to have been more than it could take. I have to imagine a fault in a part of this type is rare, but maybe not. Hope this helps someone in their search for a similar fault.