Leaderboard

Popular Content

Showing content with the highest reputation on 10/07/14 in all areas

-

2 points

-

1 point

-

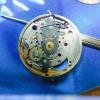

Here one of my Omegas that I rarely wear because its old and I don't want to put too much wear on it. It keeps phenomenal time--I mean, really spot on throughout the day. I wore it today in the house just to give it some wrist time, but its raining out and I won't wear it when I step outside later. JC1 point

-

Hi everyone! I'm new to watch repair! Wanted to know if anyone knows about what type of oil and grease I need to use in a Oris 649 ETA 2836-2? I purchased this watch with slight water damage. Along with a few parts that are missing! If anyone could help me it would be great! Look forward to hearing from you!!!1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Thanks for such a quick reply! I can't seem to get the link to work? I'm on a iPhone! Would that maybe why the link didn't work? Best Regards!1 point

-

You are welcome. That's what this forum is for, helping each other in our common watchmaking endeavors. Check out this link: http://www.watchrepairtalk.com/links/category/1-watch-clock-repair-suppliers/1 point

-

WOW! Thank you so much! That is so amazing of you to help me out! Do you know where I can buy parts from, and get some oil brush's and other types of tools?1 point

-

I've just bought a Seiko chronograph that requires a few things to get it up and running. I will strip the movement and give it a good clean and lube to see if I can get it firing on all cylinders. A new stem is required, but unfortunately they seem in the same storage location as hens teeth; the hunt is on!1 point

-

Wowers!! I've glad someone bumped this post. My hat is off to you Geo, that is a quality restoration my friend ... true craftsmanship.1 point

-

1 point

-

I mean the rounded part that wraps around the barrel arbor. It has a hole near the end which hooks onto the arbor. If its way too big then it cannot possibly be designed for the 2824 as the 2824 has a very small diameter arbor. The ones I have ordered in the past have had the correct size hook. I usually purchase by the GR reference. Hope this helps :)1 point

-

Hi and welcome to the forum. Whoever supplied that - it's unacceptable in my opinion. I would complain. The proper 2824 mainsprings will have a hook that fits the barrel arbor. The Swiss GR reference for the mainspring is: GR3149X But you can buy genuine ETA and the reference at Cousins is ETA28201801. However if you do want to close it - you have quite a gap there, I have reduced them before but obviously the larger the gap the greater the risk of snapping the spring. I would say it's 50/50 - it could go either way. Good luck - and let us know how you get on :)1 point

-

I second Jim in the suggestion about the screws. It seems to me that once loosened, the movement should rotate in such a way that the screw at 11 will be positioned at the gap at 12. Then it is a matter of lifting the movement. Of course, it is not confirmed so proceed with caution. Taking measurements is definitely good!1 point

-

Finished at last. It required a lot more than I originally thought. 1) Stem with spring, bezel gear and crown. Many thanks to Roger "Autowind" for supplying this. 2) Pusher springs. The springs were missing. 3) Balance assembly and bridge. The stud was broken off the hairspring making timing impossible. 4) Delecate repair to bezel teeth. Damaged at some pint due to stem gear not engaging properly. 5) Required movement retaining ring and spring. It had been abused at some time and was cracked. 6) Replaced minute counter hand. A replacement had been fitted but was the wrong shape. 7) Replaced and lubricated all seals. 8) Totaly re-finished case. 9) Fitted new replacement strap. 10 Enjoying wearing it! There is slight abrasion to the coloured outer bezel, I may replace it at a later date.1 point

-

Horotec make a jig for hollow grinding screwdrivers for about £250. Presumably they do the screwdrivers as well but I haven't found anyone selling them. I did see a set marketed by Cas-Ker, equally expensive though. To be honest if you take a little time to work out what angles best suit your own use, and then carefully maintain them properly, straight sided blades are just as good. There is a lot of debate on the internet about the relative merits of straight versus hollow ground, and I reckon there are as many opinions about it as there are watchmakers. One thing that I have found useful is to keep two sets of screw drivers (at least the most common sizes), one set ground slightly thinner than the other. Not all screw slots are the same width although they tend to be consistent within a given movement. A quick appraisal of the screws before I start work and I can select the screw drivers that best fit the situation. The result is less risk of slipping and less risk of damaging the screw. Add to that making sure that you always use the right size blade for the screw, and of course plenty of practise, and don't rush, and straight ground blades work fine.1 point

-

I decided to clean the whole thing again including pegging all of the jewels. I used peg wood and also a smoothing broach. When I was cleaning the upper great wheel jewel, I heard a faint noise and noticed some debris. What I thought was dried oil turned out to be flaked jewel. I am not sure if the broach caught on something or what why it didn't happen when I did it before. I didn't see any dried oil or debris under a 60X scope. But here is the broken jewel. I had to order a new jewel and pressed it in with my jewel press and checked the end shake. I also decided to replace the great wheel since the jewel cracked and I saw some minor scoring. After all of that was done, all of the train wheels were truly free. Whew! After oiling it again and doing some minor adjustments, I was able to get these results. I still don't know why the amplitude isn't higher since I see 290-300 degrees frequently in magazine articles. But I also don't know how old this particular movement is. Overall, I am pretty happy with an average amplitude, a delta of 6 seconds, and an average rate of +1.3 seconds. Thanks for looking!1 point