Leaderboard

Popular Content

Showing content with the highest reputation on 04/15/15 in Posts

-

All sourced in the UK. 10" pressure vessel is on Ebay...... 301329458121 ....... go for the 3/4" ports Schrader valve...... courtesy of Kwik Fit 3/4" to 1/2" reducing bush (Plumb Center) 1/2" to 1/4" " " (Plumb Center) PTFE tape 1 roll (Plumb Center) 3/4" lever valve Male (for releasing pressure) ........ (Plumb Center) 6mm Stainless Tube Ebay ..... 111625454690 ..... Foot pump, any one that is capable of 10 Bar Hope that helps. Keith2 points

-

Hang around here long enough and learn from others. Basically if you are mechanically inclined you should be able to pick it up with pointers from the others to help you along. By mechanically inclined I mean that you have no problems tearing things cars and household appliances apart to see if you can it working (or at least put it back the way it was before). If you find assembling a flat-pack piece of furniture a challenge then a more structured course is advisable. Anil2 points

-

Russian watches... excellent, robust movements, let down by poor cases... Anil2 points

-

Hi Just signed up and thought I'd say hello. Don't quite know how it has happened but I think I have the bug. I find I am spending lots of my time tinkering with watches, reading about people tinkering with watches, and then watching people like Mark who actually know what they are doing. I find it fascinating and have lots to learn. But, I have quite a bit of free time now as I was lucky enough to be able to retire quite early from my job as an hgv mechanic. I do miss the spanners (a bit) though and need something to pull apart and put back together. As I don't have the space to park an articulated tractor unit on the drive, somehow I became interested in the workings of watches and bought one or two to experiment with. And now I seem to be hooked and am rapidly running out of space as parcels containing one thing or another keep dropping throught the letterbox fairly frequently. The postie is now a family friend. Anyway I will be lurking around here now trying to absorb some of the wisdom and knowledge and am sure to have one or two questions some time or other. Many thanks in advance Dave1 point

-

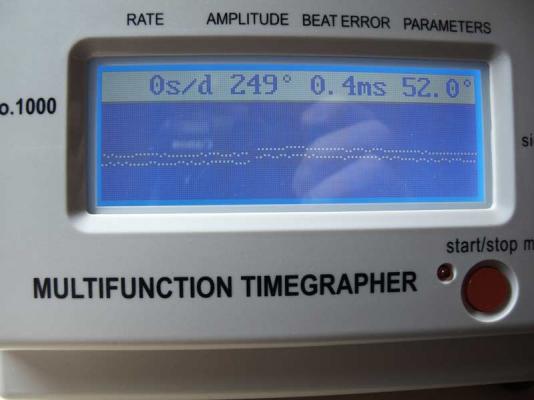

I finaly managed to get a Connie to complement my Omega collection, it is a Gold Cap model from 1966 with a 561 movement. I went against recommended practice of " get high definition pictures and ask to see the movement". The pictures were not at all good, and the seller said that he had no means of opening the back. I'm sure this put off a few folk, but luckily my offer was accepted and it turned out well. I did know that the crown was incorrect when I bought it. After a couple of small adjustments it is holding 0 to +2 seconds on the timegrapher. :) Here are some pictures I've just taken. A service should smooth out the graph a bit.1 point

-

That's good Roger, it sounds like the spring was just needing to catch properly. :)1 point

-

don't interfere with it, I think it will be OK when you reassemble the movement and fit the ratchet wheel. If there is an issue deal with it then.1 point

-

Take a look at this, see if it helps https://www.youtube.com/watch?v=S_S8oA9HdlY this guys channel is just fabulous, almost as good as Marks.... :-)1 point

-

I have used the rodico trick on a Seiko 6139B for a tricky pinion on the chrono bridge. The bridge incorporates a spring which makes sitting it down tricky with a wheel that has a long lower pinion shaft, so tends to tip over. I used very small pieces of rodico to hold th edges of the wheel to the bridge. Care needed to ensure that all rodico is removed afterwards!1 point

-

I hope you made him stand in the corner and think about what he'd done! Never mind, it'll give you the opportunity to try the Rodico trick - if it works we'll be famous!1 point

-

1 point

-

Would you believe it, the last thing I say to my pal is.............IT'S NOT SHOCK RESISTANT, well you know what's coming next. He had it sitting on top of my stone fireplace, and down it went and broke the balance staff. It lasted all of fifteen hours! luckily I found a spares or repair runner on Ebay this morning and it does have a shock resist balance, so it will be back to the fiddly pivots again next week. ARRRRRGH!1 point

-

I heated one of my screw drivers, pushed in tight, and waited a few seconds for the at to transfer inside the case tube. With light force, I was able to untried it out. No damage. How was it done with the tweezers?1 point

-

Geo you've got great taste. I love the Omegas from the 50's and 60's. In fact they were my very first watches in my collection watches before I got into all the other crazy watches of the 70's. I have many omegas but I will share these two with you so that I don't hijack your post! My 561 is a fantastic runner and the 504 is somewhat of a rarity with its arrow head markers and low production number. Enjoy the connie "convex" Pie-Pan and wear it well buddy!1 point

-

Geo, I'll have you know that a well-put-together locomotive is just like a watch! Just a bit heavier!1 point

-

Good evening Craig, I don't think I've had the pleasure of communicating with you before, so hi from scotland. That's a really nice looking watch and I agree with all that has been said before. Regarding it increasing in value, if it's new, and I asume it is, it will probably take a fair old time to increase in value. When it does inflation in general might mean that in real terms, it hasn't increased. I suppose it's all down to make, rarity and demand. Just buy it because you like it. :)1 point

-

One of the main obstacles to overcome in learning any new art or science is getting to know the components of the art/science and the language that describes those components. Learning the language of watchmaking is, in some ways, easier than learning a language (for example), because: most mechanical watches are designed, put together and work on common principles the watch comes apart and each component can be examined - either in a book or in the flesh each component has a name which is pretty standard from one mechanical watch to another So, the more you read and look - even without trying to do anything - the more you absorb the language and the science behind the mechanics of a watch movement. One of the most useful and basic videos I've ever seen, which explains the principles of a mechanical watch beautifully, is a superb Hamilton Watch Co. film from the 1940s. You'll find it referenced here: http://www.willswatchpages.com/the-mechanism.html And apologies if I'm being too basic and simplistic for you - you're probably at this level already - but the visual content in a wide range of videos which show watches being stripped and reassembled, with commentary, can be invaluable. As you say, finding out what's actually wrong with a mechanism, such that it won't work, can be a real problem. I'm lucky in that I have a friend who repairs watches for a hobby. He's been doing it for 40 years and is very experienced. I've taken many watches to him over the years to be fettled - amateur tinkerer that I am - and observed him at work, chatted to him, discussed problems and solutions, etc. That has been invaluable. In a sense, this forum is like that friend of mine - except it's many friends and many experiences - which is why we're all here!1 point

-

My goodness you know your stuff Anil! I appreciate your post very much it clears the doubts I've had. The 'Jewel' instead of Cyrylic seems so obvious but I never look at it (My eye glass was most pro0bably too dusty :-) ). Thank you. The watch will be serviced, I will replace the crystal but it will stay worn. I guess I will treat watches like antique furniture - leave some wear and tear. :bow: Z1 point

-

Hi Zenon, No real way out of this one.. I assume the front is OK? In that case I would just use it as it is...not so much a daily wearer but more of an 'evening out' watch. You can replate a watch but the resulting finish is no way comparable to how a 'gold-filled' or 'rolled gold' (same thing) looks almost like the real thing! As for the movement... it could be a) from a different factory or b)from a different period. The Russian were not too bothered about copyright and they production was based on capacity. In your example with the extra word/numbers.. the figures inside the Pentagram would be for the 1st Moscow Watch factory. The ones from Minsk had a more rounded cartouche. Since there is no cartouche it could be from either factory (or even a totally different one!). This movement was made for around 20 years so anything goes! One thought.. since they used the word 'jewel' instead of the Cyrillic equivalent could it have been an export model? The example with the russian wording also has bevelled edges on the bridges whereas yours has a stepped edge. The bevelled edge is cosmetically nicer but this should not affect the running of the watch. The 2209 movement is one of the nicer movements from the former USSR, most of them come in gold filled cases and I believe they were at the top of the food-chain back in the day! It was originally made in the 1st Moscow Watch Factory at Kirova. Production was later transferred to the Minsk, Belarus. Personally I love this watch, especially how silky smooth it winds!..Only two things bug me, firstly I wish it had a Breguet overcoil..most Russian one have these, even the cheap ones, but I believe it was left out here in the pursuit of slimness. Secondly, on most of the watches I've seen, the second hand is too short! I believe this was due to the low dome crystal originally fitted but it doesn't look 'right'. Anil1 point

-

Like Gotwatch, I too am self taught and started this as a hobby about four years ago after working in mechanical engineering for forty six years. Bill3, I strongly recommend you purchase this book http://www.amazon.com/Practical-Watch-Repairing-Donald-Carle/dp/1602393575it may be a copy of an old book, but the information and quality illustrations is excellent. Also take time to work through Mark's Videos, you will soon get a good understanding of what this game is all about. http://www.watchrepairtalk.com/page/watch_repair_videos.html above all, do not be frightened or embarrassed to ask any questions no matter how simple, you will get a civil answer and guidance. You will make a few mistakes on the way, but you will get there. Purchase a cheap movement from the likes of EBay to practicing servicing, this will allow you to develop the delicate touch required. Make sure that you get one that is running to begin with, at this stage you do not want to be trouble shooting faults, that is another thing altogether.1 point

-

Well I would definitely start with Moebius 9010 (for train wheels and balance endstones) and 9020 (for train wheels) if you are working on Pocket Watches. Moebius 9415 is a must for Pallet/Escape wheel teeth. A quality silicon grease. Moebius D5 is essential (barrel arbor, motion work). Molycote DX or Moebius 9501 grease for keyless work. Moebius 9501 or 9504 for high friction (e.g. Cannon pinion, Setting lever spring and anything at high friction). Moebius 8200 grease for mainspring. Moebius 8217 for barrel wall (automatic watches) It's a lot but at a minimum get 9010, 9415, D5 and 8200 I hope this helps. Recommended Lubricants for Getting Started.pdf Moebius_Oil_Chart.pdf1 point