Leaderboard

Popular Content

Showing content with the highest reputation on 04/20/15 in Posts

-

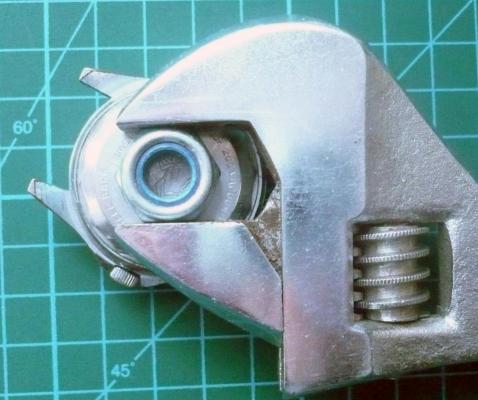

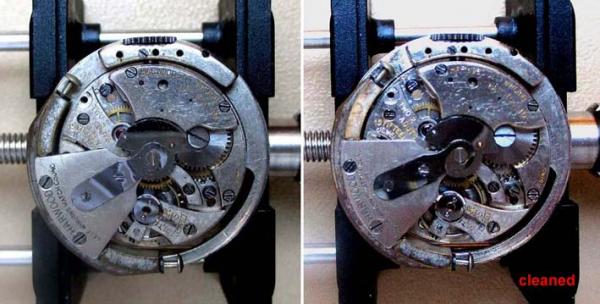

Right, here we go! And before anyone says so, yes, I should be ashamed of mistreating a watch this way. All I can say is I was young and careless! Well, it worked! I stuck the nut to the watch back and left the watch on a sunny window sill where it warmed up nicely. After an hour I put it, nut side down, on some frozen sausages that were defrosting in the kitchen. Yes, I forgot to photograph the sausages! :rolleyes: Anyhoo, with a slight temperature differential case to back, I applied the spanner (wrench for our colonial brethren) and good ol' Bob was my uncle! Thanks Bob! The innards turned out to be a Brevets SIC39 movement and were remarkably clean given that the stem was bent, see the photos, and rusted internally and the seal in the crown was just black goo. (Anil, I swear I haven't had acetone anywhere near the watch!) The main gasket was split into three or four sections through shrinkage but not too gooey so cleaning won't be too much of a problem. There it is! Another watch for me to play with when I get a proper bench set up. Thanks to all who contributed and encouraged.3 points

-

I have a particular, somewhat private, association with Douglas Isle of Man (hence my second initial, D). And being born and bred a Lancastrian the story of John Harwood of Bolton, Lancs, and his watches has always facinated me. For those who do not follow me read: http://www.harwood-watches.com/en/history/index.html I have collected three fine Harwoods, from left to right rolled-gold, silver and a 9 Ct gold cased versions with a selection of dial designs. The gold model has this very fine pearled movement. I had also a spare non-working movement, But after a bath in Bergeon One Dip within a small glass jar, immersed in my ultra sonic tank, it came to life and now keeps good time. See below. The keen-eyed observer will note that in the cleaned movement the balance wheel is oscillating. If there is any interest I could do a complete clean and oil with all stages in pictures.2 points

-

Is it in beat? significant beat error will cause rate deviations in positions and require a kick to get it going. It can also result in a less than confident oscillation.2 points

-

2 points

-

I have been working on clocks for about 12 years now and am ready to try my hand a watches. I don't have any watch tools. Can you all give me some ideas about what I need to get started? Looking online and in my jeweler's supply catalogs, I am overwhelmed with all the choices. What are some good brands and price ranges? Thanks! Matthew Condon Trafalgar, Indiana, USA1 point

-

NICE!! Congratulations on a job well done!! John that movement looks like a BFG 158 31/7 of which I have many many spare parts of every sort (including balances). You've already mentioned it was a SIC 39? I've never heard of that particular movement in a Sicura, but who knows? It sure does look like a Baumgartner 158 31/7 with 25 jewels which means they've included some jewel caps for the pivots and probably a jeweled rotor bearing for the auto-winder. If I could see the balance I could tell for sure--Does it have a KIF shock system? It is shaped like a little triangle. In any case, If you need any parts, just send me a picture of it and you can have it for free--just pay the shipping. I have entire movements so every little screw, spring, and lever is available!1 point

-

Here is the Seiko 6602 with a different dial and watchband along side a Vintage Hamilton Pan Europ I am working on . A new crystal is on the way for that one and I am thinking of sending the dial to someone for a professional refinish . Excuse my inferior pics . I will have to get a better lighting set-up .1 point

-

For most jobs i use medium hard felt wheels with either SteelCut ( for deep scratches ) or Dialux Grey/Cannings Blue Steel compound for more minor scratches. If you use a rotary tool then slower speed = longer sweeps /// faster speeds = shorter sweeps. You want to build up heat just to the point where it is bearable to the hand or fingers ( this varies from person to person ), you also want to ensure the felt wheel is aligned in the same path as the curve or shape of the casing. If removing damage you need some prep work such as... 400/600/800/1000 Grit paper or Ready made grit sponge pads of same grade> Start with the most co**BLEEP** grade 400 then repeat through to 1000, you can use some 3in1 oil to help. Do not go back and forth, one smooth motion in the direction of the grain of the metal, lift and repeat. Going back and forth with papers can lead to flat spots and an uneven finish. Prep time on a deep scratch can take between 30-60 minutes or more. After grit papers, move onto compounds, but always wash casings before each step to avoid contamination. Start with a cutting grade compound ( Dialux grey e.g ) again do not go back and forth, one single motion. Once scratches appear to smooth out , move onto next compound washing thoroughly between each compound. Time for this step can be 30-90 minutes Final polishing only once damage is removed, use Dialux Green with cotton polishing wheels ( i only use chamois wheels to remove scratches from glass ). So in terms of a stage tree it is like this for me ( simplified version ) > 400Grit>600>800>1000>WASH>Grey Comp>WASH>Blue Comp>WASH> Green Comp> WASH > Polishing Cloth PS If you do get bench polisher don't forget the safety glasses !!1 point

-

A few points to note about " polishing ", if you are trying to remove damage to a casing or bracelet you don't polish it out ( unless very minor scratches ). Polishing is a means to finish a piece, not to repair damage. When you want to remove deep scratches and dents it is called buffing, after you remove the damage and need to finish the metal ( either mirror or satin etc ) it then becomes polishing. It is important to note that when you want to remove damage you don't want to remove the metal you merely want to heat up and manipulate the metal back into the desired shape, almost like moving really hard playdoh. There are several means to achieving the result you need but you must run through some questions to establish how to proceed. 1) What metal am i working with ? Seems obvious enough but each metal reacts differently to different treatments and what works for one may not work for another. Some metals are softer than others ( even between different grades of steel ) so choosing the right product/s for the job will make the result better and also less hard work for you. 2) Is the metal plated or solid ? Sounds obvious again but some casings are made from a base metal ( such as brass ) and then plated ( nickel chrome & gold plating are most common ). Over polishing on these types of casings will result in a rather nasty surprise and a case that will end up worse than when you begin :( If you can establish the casing is plated then the utmost care should be taken in polishing or buffing as removing the plating is all too easy and unsightly damage is even easier still. This isn't to say that plated casings can not be polished back to good order, it just requires a good judgement and experience to know how to proceed. 3) Which compounds / polishing pastes shall i use ? Again this varies depending on the materials hardness and type but luckily there are lots of easily available products that can help to restore that beaten up old casing. There are lots of easily available polishing compounds( dialux, autosol,peek,braso etc ), but if you want to remove deep scratches to Steel/Stainless Steel then id recommend SteelCut by Cannings or similar high/medium grit compound. Steelcut is a high grit compound that will act like sandpaper when used with a rotary tool, but be aware the compound if used too aggressively will easily damage and mis-shapen steel casing & bracelets. The ideal use for this is either via a bench mounted polishing/buffing wheel or a rotary type tool such as a dremel. To apply the compound you would need soft to medium hard felt wheels. The key to removing damage and keeping the original shape comes down to using the correct tool with the correct compound or material and also more importantly....heat. As i said earlier , to remove damage you don't want to remove metal but merely soften the existing metal and manipulate it back to the original shape, this is where heat plays a big role. By using a rotary tool and felt wheel with the right compound ( for example ) you can gently heat the metal up and slowly re shape it back to a smooth finish. The technique is not easy to pick up but with practice you will soon see how metal can be worked. You dont want to press too hard or too softly, and you don't want to keep the felt wheel in the same spot. To retain the casing or bracelets original shape will require learning techniques in buffing ( there are some videos online which can aid you with this ). Fine finishing or mirror polishing is an art form in itself and there are several methods that can be used. Since ive rattled on long enough i will leave a list below of the compounds and products i use for my work, im sure the other guys here will have some great tips of their own :) Removing Damage - SteelCut ( various grits ), Dialux Gris ( Grey ), Abrasive 3M Paper 80-3000 Grit, Silicone Carbide powder, High Micron Diamond paste. General Polishing - Dialux Blue,Red Green , Autosol, Peek, Medium Diamond pastes, Selvet Cloths, High Grit 3M Papers 1200-3000+ Mirror Polishing - Pegwood, Orange Wood, Pith Wood, Beech ( each wood has great polishing properties so experiment ! ), Lavender Oil + Fine Diamond paste 0.25 micron or less, Various Fish Oils, Lavender oil + Flat Zinc plate, Olive Oil , various burnishing tools, polished metal scraps Most important of all .....patience !1 point

-

1 point

-

Hi Frank, Did it run before? How was the shape of the main spring? Did you give the barrel a wind before fitting the pallet fork to see if it really ran down all the way? A movement which was not properly cleaned or has 'issues' will wind down and stop but when you nudge the escape wheel a bit, it will run for a bit longer... this will happen a few times before it is really wound down. If it ran before did you mess with hairspring stud? (the bit where the end of the hairspring fits)... as Marc said, this will affect the running of the watch.. Do this.... ...with the movement out of the case you should be able to see the barrel teeth along the edge of the movement. Use a pegwood sharpened to a screwdriver shape, help the barrel along its path.. just some light presure..not really a push. If this helps and the watch runs more ' confidently" (love the term BTW) then you may need a new mainspring. Using a lot of pressure here will almost guarantee it will get galloping no matter what the issuing is but is not really helpful in making a diagnosis. Anil1 point

-

That's an interesting collection indeed. I remember the fad for biorhythms - we all did them - about the time the Certina was made! Oddly enough I've never gone for dive watches. I don't care for watches with chunky bezels - don't mind ladies with chunky bezels though...1 point

-

Check if it has enough 'throw'. The pallets should 'snap' when you help it a little with a clean oiler. Also check the train of wheels moves freely - try blowing air on the escape wheel.1 point

-

Great stuff CJT2, that sounds an absolutely cracking deal. You could pay more for the parts alone. Only one criticism........we need to see pictures!! :)1 point

-

Try using a stick ball, it's amazing how often it has worked for me in the past, and I wouldn't be without it today. If your watch is as old as you say it is, the ball may not cope, but it's still worth a try. Here's mine! Failing that, superglue a 17mm nut to the case back and use a spanner, you can remove the nut by soaking the back in acetone afterwards to dissolve the superglue.1 point

-

The Bergeon one should do the job just fine Gareth. I have one by another name and it's one of the best tools in the box, it gets used every time and ensures safe removal.1 point

-

1 point

-

Hi Ferdinand, there have been many post relating to polishing. I recommend you go to the top right hand side of the screen there is a box marked "search" and type in "polishing" and you will probably find what you are looking for. Here is one of my earlier posts. "I tend to do it the hard way myself to retain the original profile and the edges nice and sharp. I use various grades of wet or dry abrasive paper from 400 grit to 1200 to get rid of the deep scratches and then Solvol Autosol metal polish on peg wood. A light buff with Solvol on a micro fibre cloth finishes off the job." I forgot to add on this post that I use a "proprietary silver polishing cloth" for the final finish on all metals except titanium. I also use this cloth to maintain the finish on my watches.1 point