Leaderboard

Popular Content

Showing content with the highest reputation on 04/26/15 in all areas

-

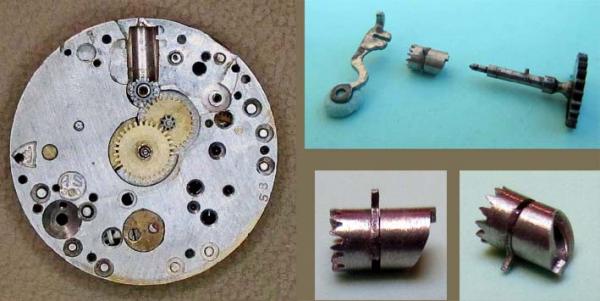

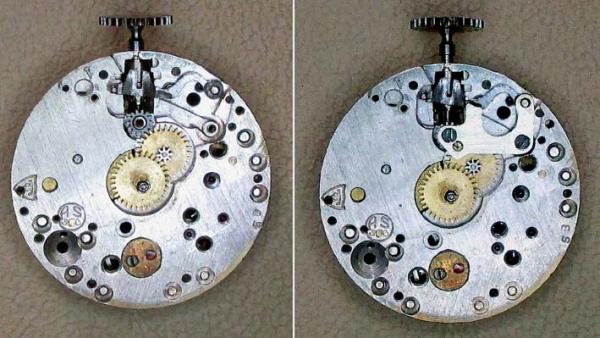

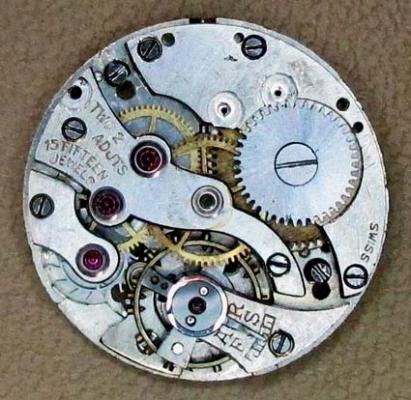

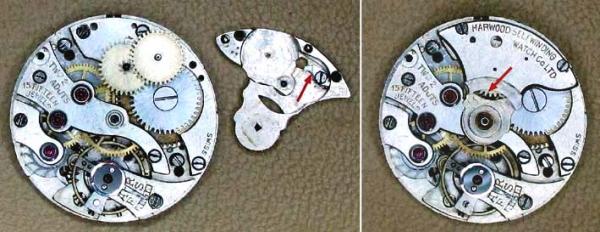

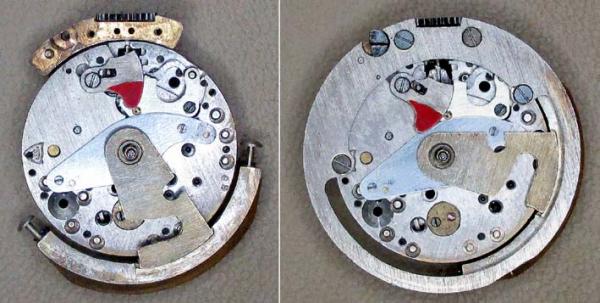

This Harwood base movement has been stripped down, cleaned and oiled. The mainspring looks good. It is the A.Schild 8.75 lignes, 15 jewels 2 adjustments, used by Harwood from 1925 as a base for his first automatic watch. This automatic movement was an early one since the it does not have either the UK or Swiss patent numbers on the winding bridge. Later examples with these numbers can be viewed on the Ranfft site at: http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Harwood You will see later on this assembled movement that in place of the patent number Harwood stamped: 'HARWOOD SELFWINDING WATCH Co. LTD', copying the inscription on the bumper (but with LTD instead of JLC)). I start the photo re-assembly from here to illustrate only the features particular to the Harwood. From its condition I suspect that it was either a prototype or a movement that has been used many times for demonstrations. Screw heads damaged and plating missing on some of the Harwood parts. The base movement A. Schild 8.75 lignes. No conventional stem for setting. Left: the winding wheels in place Middle: the uni-directional winding bridge (clic arrowed) Right: the bridge in place. (assembled by placing the movement down onto the upturned bridge with wheels and clic engaged). A little clockwise turn of the exposed gear wheel (arrowed) and the balance turns. Left the basic movement with intermediate wheel in place. Right: The setting gear. The large toothed wheel on the stem engages with teeth under the watch bezel and it is rotated by turning the bezel. Then the small pin set into the stem engages the cam face on the outer end of the castle wheel (Harwood calls it the crown wheel). This also has a rotating inset pin (as shown) that engages the lever to move a red flag (see later) that indicates the position of the castle wheel. The castle wheel moves inwards until the stem pin meets the protruding stop (see photo). The hand setting can the be completed. A short back-wind of the bezel releases the castle wheel. Left: The three parts of the setting mechanism in place together with the flag lever return spring. Right: The cover plate in position Left: The red flag in place. Right: The dial-side bearing plate and stud for the bumper arm. Left: The bumper in place with the end stops through which the stem is now inserted. The red flag is in the running position. Right: the frame that holds the bumper stops and setting stem to the movement. The red flag is in the setting position. Left: Back to the movement side showing the screw holding the stem in place. Right: the bumper and frame added. Left: The winding wheel (arrowed) in place. Centre: the underside of the winding bridge showing the pawl that turns the uni-direction wheel. Right: the winding bridge in place. The winding lever has a slipping clutch at the centre (arrowed) that prevents over-winding With a dial on the movement. Left: The red flag in the dial window indicates the running position. Right: The setting position. The watch is set by rotating the bezel in either direction. Then a back-turn corresponding to just 5 minutes of setting releases the crown wheel and the red flag appears in the window. The beat error was 0.1 ms and the timing error some second per day.2 points

-

Thank you, I appreciate the comment. To make my watch shiny I simply do the shower with them :)2 points

-

Just finished refurbing a tired Smiths TY believed to be from 1965: Before: After: Case, dial & hands cleaned. Crystal polished. Movement serviced & broken click spring replaced (thanks to John at Obsolete Clock & Watch Parts). New strap. The timegrapher readings were a little variable, however it kept good time all weekend. I am getting a bit of a thing for Smiths (the watches, not the designer-misery band from the 1980's) and have got myself a 1960 Astral to do after the next Seiko.1 point

-

Hi all, I'm a watch noob but sometimes I read something on watches, I bought a timegrapher because I like having my watches working at their best. I bought the Weishi NO. 1000 Timegrapher, a cheap one (250€ with shipping) but very functional. The Weishi NO.1000 has all the main features you may want: 1) possibility to adjust the sensibility of the microphone 2) possibility to set the lift angle 3) it shows the beat rate 4) it shows the amplitude 5) it shows the beat error 6) it keeps track of four average beat rate during the measurement (this feature is available in new software version only) Let's see how it looks: and here a photo of all the tool I used to regulate my watch without any scratch. As you can see in the photo below I have used: 1) watch case opener, I prefer the 2pins one over the three pins Jaxa, very easyer to use and IMHO very easier to not scratch the case with 2pins. 2) a simple loop, a 3x one 3) a watch case holder, it is mandatory to open the case without scratching it 4) a little screwdriver (0.9mm) 5) silicon grease for lubricating gaskets 6) the timegrapher 7) a little of patience Here the watch case holder in action: And here the watches I calibrated. Seiko Black Monster SRP307J1 with a Seiko 4R36A caliber And a classy Seiko SARB033 with a 6R15C caliber. Both calibers are similar sharing some components and some features. They beat at 21600bph, the lift angle is 53° on both calibers, they both hack and handwind, same automatic winding mechanism. The acceptable daily rate for the 4R36 is: -35/+45 seconds a day, +/- 30 seconds day isochronism fault, +/- 30 maximum positional variation, 40 hours power reserve (SPRON110 mainspring). The acceptable daily rate for the 6R15 is: -15/+25 seconds a day, +/- 10 seconds day isochronism fault, +/- 15 maximum positional variation, 50 hours power reserve (SPRON510 mainspring). Thanks to the 6R15 the SARB is less prone to positional variation and less prone to isochronism fault. The difference in performance once calibrated and when calibrating is big. The better mainspring and the better hairspring does a good job here. Let's start calibrating the Seiko Monster. Here what I have done in the correct order (I post an image just to show you the parts where I worked on): 1) I rotated the regulator pin counterclockwise in order to FIX the mainspring inside the regulator pin 2) I adjusted the beat error by moving the stud support, checking the timegrapher on every move, I tried to get 0.0ms beat error at least in one position 3) I adjusted the beat rate by moving the regulator, always checking the timegrapher on every move, I adjusted the rate by taking an average of the six positions. My job consists on working at the PC so my watch daily position is quite always the same. This are the Monster's results before calibration with a daily rate that varies between +9 to +14 seconds (this watch was regulated before by a professional watchmaker) and this are the results after the calibration: now the daily rate varies between -3 to +2 seconds a day, I don't need to reset the watch often ;) Now let's calibrate the Seiko SARB033 doing the same things: This are the Spirit's results before calibration with a daily rate that varies between +9 to +14 seconds (the watch is new and never calibrated before that doesn't done an excellent job) and this are the results after the calibration: now the daily rate varies between 0 to +1 seconds a day. The 6R15 on the SARB is really easier to calibrate and the beat rate is really more consistent than the 4R36 in the monster. The 6R15 beat rate is really constant when the watch is laying in the same position, the beat rate of the 4R36 fluctuates a lot more. This is the proof on how consistent is the rate of the SARB, no fluctuations at all. The Monster rate fluctuates a bit also when the watch is laying in the same position. That's all ;)1 point

-

1 point

-

1 point

-

Thanks Bob, the Watch you are referring to is actually a modded Seiko. The mod is based on the Tudor Black Bay. Regards. Jon1 point

-

Definitely an amazing one! Our plans for WORLD DOMINATION are panning out! :D Nice of you Maurice! And thank you for the pic. Now you got quite a tool there! @Geo: That is a very classy bow there Geo. I feel like thanking you for the nice gesture and it is not even for me! PS. Do you actually need a lathe for the Jacot tool? Sorry for my ignorance but I've never used/had one...only seen a couple of pics/videos. Never the whole process/set up, etc.1 point

-

Here are my Tuning Fork Watches by Bulova, I hope you like them, the last two at the bottom right are Omega F300's1 point

-

as you can see in the official Seiko tech guide: http://service.seiko.com.au/i/seiko/documents/technicalguides/6R15B.pdf seiko suggest the minimal clearance... please see page 15 of the linked guide. I hope to see a Mark video on this. can we ask him this?1 point

-

1 point

-

Douglas, from a quick scan of your workings I'd say that the value for Theta needs multiplying by a factor of 0.066* to account for the thrum angle inherent in the final circular portion of the spring. Also you need to take into account the infinitesimal surface hardening which can vary over the entire length and give unintended consequences. I ran a theoretical vector diagram for the final portion of an annular spring in a railway buffer and forgot to account for the interaction between the grease and the rust, which gave me a wildly innacurate figure, so beware! Aside from that, the doctor says I'm coming along nicely!1 point

-

1 point

-

Hi Stephen, I'm only going by the part that Cousins references. If you go onto "watch parts" "watch parts branded" "AS" Then look up 1950 in the calibre box and select "all parts" in the Swiss part description box, then click "search for items", it lists everything that they have or can easily get for that movement. Then scroll down to the Incabloc entry and it gives the reference number. Cousins are a pretty good reference for this sort of information even if you don't end up buying from them (although they do have a price match policy). Hope this helps, Marc.1 point

-

Cousins order code INCA97503, £2.92 for a pack of 5. Currently out of stock but should be available after 30 June. Alternatively search eBay for Incabloc 975.03. I found this one; 201321869822, more expensive but I guess it depends on how much of a hurry you are in. Good luck :-)1 point

-

1 point

-

Hi chadders, Are you in UK? Otherwise, if in USA, I would recommend ofrei.com and this: http://www.ofrei.com/page615.html#23549... just in case any of them fit? I don't know how to go about this without the service data/part number, sorry! I hope another member can offer better help! Cheers, Bob1 point

-

I have now posted 'Harwood First Automatic Wristwatch Assembly Walkthrough' in the 'Watch Servicing and Walkthroughs' section of the forum.1 point

-

Not an answer to this post but thought the following link may be useful to all members as it is the most comprehensive I have come across (not found a tree though!). http://mikrolisk.de/show.php1 point

-

For practise, try to get a watch advertised as running. Do an ebay seach for handwinds under USD25 (with free shipping!), there are a lot of garish watches from India which although hard on the eyes, represent good value for a beginner watchbreaker maker. If you can take it apart and get it back together and running then thats a big motivational boost for you! If you start with a watch which is not running you may be stuck and lose heart thru no fault of yours. For a simple handwind you'd need A simple caseback opener A loupe (10 x ) A pair of decent tweezers (*) Some decent screwdrivers (*) A bottle of Zippo fluid (or equivalent) for cleaning watch parts. Some Rodico (funky green plasticine which watchmakers use) Some watch oil (*) mainspring winder parts organisor Misc tubs and containers. For Items marked with (*) try to buy quality stuff as poor tools will make your work so much more difficult. Anil1 point