Leaderboard

Popular Content

Showing content with the highest reputation on 05/24/15 in Posts

-

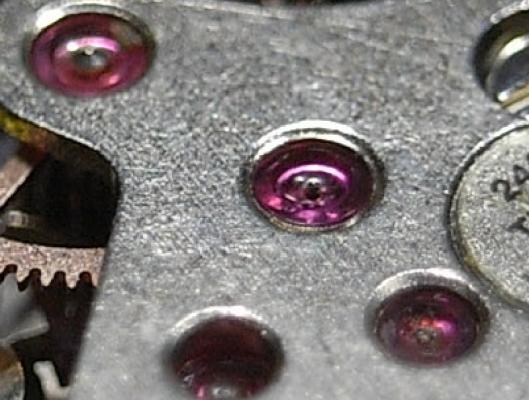

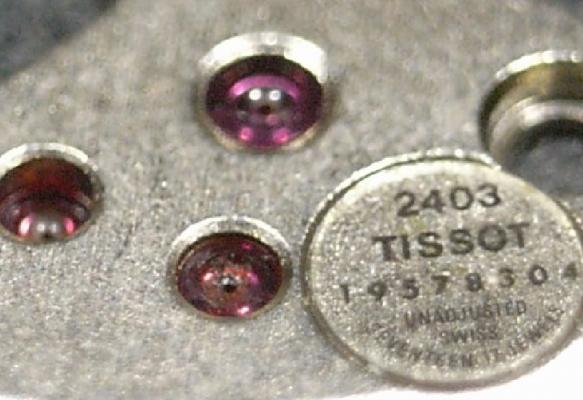

Tissot 2403 Service Walkthrough What is it with me and small movements?! I seem to attract them in absurd numbers. Oh well, here's another one to push my Zeiss optics to the limit, a Tissot 2403. My brother's father-in-law found this at the local rubbish tip, thrown away and unloved :( Upon initial inspection the condition looked dirty but not marked up, Canon Pinion felt good when setting the hands, and it seemed to wind smoothly. But alas it wasn't running at all. So to the bench I go, and de-case this little gem of a find. It removes like many ladies fashion watches, with the movement cradled in the Caseback. I removed it from the Caseback, and it looked remarkably clean. So I gave it a close inspection to see if there was something obvious that was stopping the movement. First thing that stood out, and is common on these types of movements, is the lack of a Crown Seal. As you can see there is a lot of contamination along the Stem, including nylon fibres ... perhaps from the sleeve of a sweater. I continued to look and found more of these fibres near the Balance. Continuing my inspection it was obvious that this watch was in desperate need of a complete service. Note the condition of the jewels. But besides a strip and clean, I couldn't see anything else wrong with it. No rust, nothing bent or broken; just some contamination stopping it from running. It's sad to see we live in such a throw away society today, 50 or 60 years ago this would have never been discarded on a tip. Ok, time to bring this watch back to life. First step as always, release the tension from the Mainspring, and remove the Balance and Pallets. Now the Balance and Pallet Fork safe, we can remove the Keyless Work. Start by removing the Hour Wheel, then the Setting Lever Spring. Then remove the Yoke and Setting Lever. Be sure to secure the Yoke Spring with Pegwood and note is orientation. Then remove the Minute Wheel and Setting Wheel. Then pull the Stem, and remove the Sliding Pinion and Winding Pinion. Flip it over and remove the Ratchet Wheel and Crown Wheel. Then you can remove the Mainspring and Train Bridges. As you can see, even if this watch was running, it would have not been giving accurate time. All the jewel holes are filthy! Here is a reference shot of the train on the 2403. Now, if you had good eyes you might have seen it. The object that stopped this watch from running. You guessed it ... a nylon fibre has found it's way into the wheels of the train, and gotten jammed between the Intermediate and Third Wheel. So know the mystery is solved, it's just a simple matter of cleaning and re-assembly. To Be Continued ......5 points

-

Avoid the WD40 - only good for tractors. Try heating a little with a fine tip soldering iron, put a dab of watch oil on while still warm & hopefully this will creep into the threads.3 points

-

I've just sold my entire collection to the Sheikh of Oman for £20,000,000... Damn! I'll have to start all over again...3 points

-

... continued. Lever pins replaced. I will not post details here about the replacing process itself because children might read these posts, however, clockboy was right suggesting that it is not simple. It is done now. The setting clutch was, as I guessed: a friction clutch on the bottom of the barrel. I did not need to disassemble this joint just used stake to push it/loosen it. It works but I am not sure how long it will hold the right tension, it is brass tube/on brass. Assembled at first the escapement was: 1. Lever to close to the escapement wheel - there is fine adjustment which moves the lever in and out. 2. Balance was jamming on one side of the swing. It turned out that the safety pin (which is on the balance) was not aligned with the roller. That was difficult to find but easy to fix. All assembled and the watch is working (balance had 90 degrees swing at one winder turn) full wind gives it little over 180 degrees (maybe 200) which is not so good is it? I cannot find data about a pin lever escapement in this or similar Roscopf. The watch seems very happy - what is interesting is the unusual ticking sound, completely different from the Swiss escapement. Set 9pm it for adjustment so will see tomorrow. After one hour (no second hand) seems good. :-)2 points

-

2 points

-

One of my first lauching was a spring from a Duofix. Removal is by moving the common leg away from the chaton and then reversing the movement to free the other two legs simultaneously and without tension. Being a newbie, I did not do it that way. Those things are so small you would not even hear it hit the (wooden) floor. I knew the general direction of the path and started looking in the area for a long time. After awhile I became methodical in looking. Searching in grids, looking at a slant so as to cover a larger area with a narrower angle. Finally, just to get an idea of what it looks like from a distance, I cut a piece of Rodico about the same size as the spring and put it on the floor and stood back to get an idea of the size. Well, a shiny sliver of metal, the spring, was only inches away from where I had placed the Rodico. That's my first search and recovery mission. The lesson for me, think first before you do.2 points

-

Well a follow on from my post yesterday regarding a bodged hands. You sometimes just get that gut feeling that all is not well especially when a watch/clock repairer had returned it with "to knackered to fix". I had added some pics of the service & poor workmanship I put right. The hand issue is on my previous post. The minute wheel is attached to most carriage clocks with a screw/post. When I opened the case the wheel was at an acute angle. It was fitted with this. The shaft that supports the wheel was very loose the screw/post was bent at the tip the head was also bent & whoever made this one had calculated the length incorrectly so made it fit with a brass bushing.Also the thread had been stripped on the screw & also on the case plate. So I had to make another. I also had to re-tap the plate. Sorry guys but did not take pics while making the part also some of the pics are out of focus but here are a few after making the screw/post. I tapped the case with a 1.4mm thread which was worry because I only had a cheap die so very very gently when cutting the thread. Drilling Tapping Cutting screw head slot Finished Part Testing all fits & runs smooth Some pics of polishing & burnishing the pivots Job done> The job is not perfect the balance wheel is kinked but to risky to fix. It has been up and running for the last hour keeping good time . I have made a small vid1 point

-

Well it's been some time since I was last here. Work has been busy. Update on this watch: Just the other day I took another look at it. It ran for a minute or so when I manipulated the balance wheel. Everything looked in order from what I could see, so I set about removing the balance bridge and removed the balance. I cleaned up the bottom pivot hole, oiled it with a little anchor oil. Then I oiled the jewel. Reinstalled it and it fired up straight away. This was last night at 9pm. I synced the time to my iphone and just compared it 30 or so minutes ago. It's still spot on to the minute after over 24 hrs. Quite surprising really for such an old watch! I'm over the moon it's working. I kind of wish I'd stripped it completely to clean and oil it. I just ordered a new strap for it, black with orange stitching.1 point

-

Okay, those shoes you've got on at the moment are horrendous! Get youself some Nikes! Oh, and a mohican! See where I'm going with this? If anyone says anything, tell 'em that it was repaired by Winston Churchill after he gave it a whack whilst laying some bricks. Or, it belonged to a Spitfire pilot and the old one was shot off!1 point

-

Thanks Ishima. That makes sense because the problem seems to have occurred since I fitted the calendar and dial. Something to do tomorrow!1 point

-

Ha-ha! Sorry Josip, I misunderstood! I said about ESC because nobody had answered your post. I wondered where they all were and I said that I thought they were all watching ESC on TV because here in the UK, for many people (men), the ESC is an embarrassing joke. The real answer is that they were all out at their favourite bar. :-)1 point

-

I am loving this staking set! I don't know why I waited so long to get one. Replaced the staff in the Elgin again. Thus time I only used the calipers with the holes for the pivots. Tried up and installed. Then a whole bunch of other problems reared their ugly head. I think I inherited another amateurs problems and mistakes. I am guessing that is the case because the watch was clean as a whistle. Like it was just serviced. But it had a broken balance staff. I think someone was messing with it and finally gave up and sold it. The staff was way to tight between the balance jewels. I double and triple checked that I had the correct staff and it measured up correctly. My guess is someone pressed the jewel in further trying to make a broken staff fit. So I decided to press the jewel in the balance cock out a fraction. I chose that jewel as it looked I had a little more room on that side. After that I reinstalled the balance and she started ticking away. It's been running for 2 days so I did a test and she us holding within a min over a 24hr period. I'm very happy with that. It's great to have this one up and running as its my favorite of my pocket watches. Here are some pics. And I thank everyone for the help provided in answering all my question. Elgin 18s 17 Jewels B.W. Raymond Grade 116 18951 point

-

Ive had this problem myself 100's of times with pocket watches so i feel your pain :( My favoured method which by no means is the only one just the one that works for me..... Soak parts in clock oil/penetrant or similar and leave in tub in warm area ( such as clothing closet next to boiler or warm radiator ), i leave them for a few days allowing metal to expand and let in oils ( the thinner the oil the better ). I then clean off with soapy "WARM"( to keep metal expanded ) water before firstly trying to slightly tighten screw then untighten. The reason i try to tighten slightly first is that this usually ( 7/10 ) breaks the seal and allows it to be unscrewed. You may find sometimes that short quick knocking/tapping the screw head with a small watchmakers hammer ( the small ones NOT claw hammer type lol ) against a hard surface or metal block for example can help break the thread rust as the vibrations pass through the screw and cause it to come loose. Worth noting not to smack it to death just moderate tapping to send vibrations through screw. There are other methods im sure but this has worked for me on so many Omega pocket watches with rusted rachet screws. But this is only my method so approach it with caution :)1 point

-

1 point

-

Hello and Welcome Stuart. I think of my brain more like an old hard disk and unfortunately I now have some dodgy areas and need a good defragging but tinkering with watches settles me down nicely. Like clock watcher says pics are good for us but also on your work at every stage before removing something a pic can be invaluable for reference later and saves you from the "where the hell does this go or where the hell should that have gone" moments. Cheers, Vic1 point

-

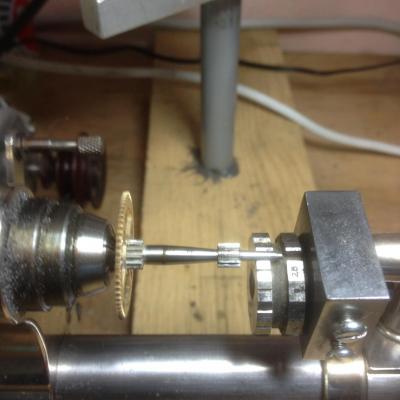

I posted a separate post (another senior moment) with the finished job. Some of the pics are poor though. The point being I could not have fixed this clock without the aid of a lathe. Also very often my Jacot tool is to small for clock pivots so have to use my lathe for polishing/burnishing.1 point

-

I've had springs on my cheek, eyebrows, elbows ... what happens when something goes flying is...... I freeze and then scan the desk with my eyes.. followed by my shirt/lap....then my arms and hands including between the fingers (cap jewels usually are found here) then my face. If this fails then its on the floor I go. My workroom is not carpeted and we dont usually wear shoes indoors in Malaysia so after checking the soles of my feet (if the part is a light spring) its broom and dustpan time. Its quite alarming the amount (and type) of crap you find on the floor of a room ...! The strange thing is I can spend more than a few minutes looking for a part without finding it, having given it up for lost, it turns up sometime later! Sometimes a few days later..now I keep a missing persons list on my desk. Currently MIA are a bridge screw from a Kif 414, Seiko diashock spring, date jumper spring and an ETA case clamp. The biggest thing to go AWOL was a barrel from an Enicar 167.. not the barrel arbor..the barrel! Took a few days to find it (replacing it was not an option as these movts are thin on the ground!) and finally located it in the unzipped pocket of a bag which was a few feet away! I had checked the bag earlier but since earlier searches were negative I had begun to systematically go thru every thing with the proverbial fine toothed comb! TIP... when dealing with springs or gripping something hard with a pair of tweezers, keep your free hand cupped around the movement so that it prevents any parts from flying away from you. If your desk is like mine, the area immediately in front will be a bit cluttered and this saves you from an unscheduled housekeeping session. Anil1 point

-

I'm not familiar with Benrus movements, but a thought occurs to me. If the second hand moves when the watch is wound clockwise - and remains still when the watch is wound anti-clockwise - then this just may be a way to set the time exactly to the second. Some watches have a hack function, which allows the second hand to be stopped when the crown is pulled out - thus allowing exact time to be set. So, on your Benrus - when fully wound down - you could pull out the stem, wind clockwise until the second hand is set to the 12 position, then wind anti-clockwise to set the hour and minute hands. Result? Time set exactly. This is just a theory - I don't know the watch in question - might just be a (useful) fault!1 point