Leaderboard

Popular Content

Showing content with the highest reputation on 06/08/15 in Posts

-

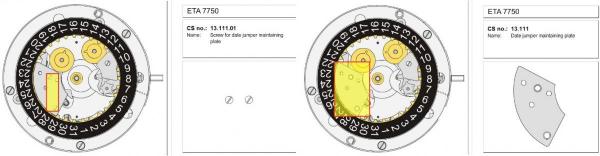

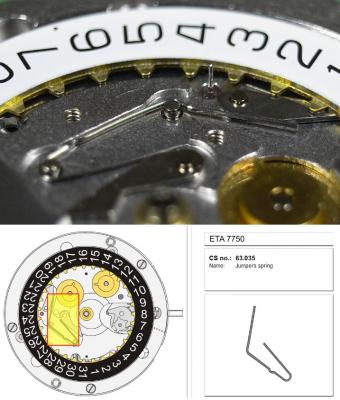

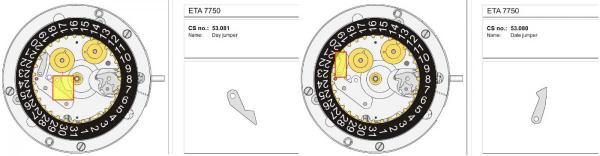

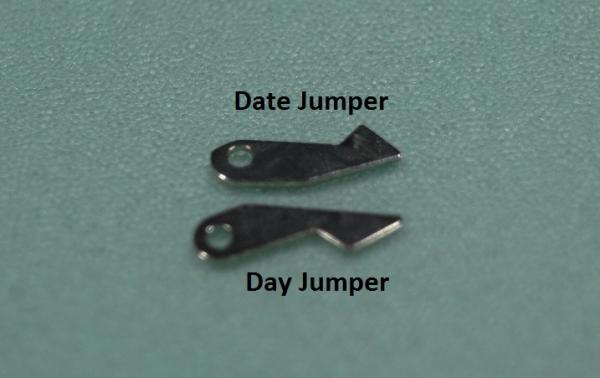

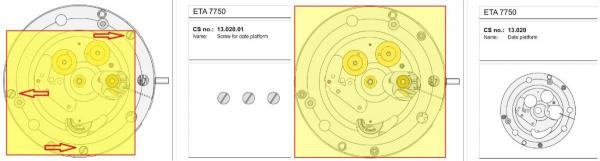

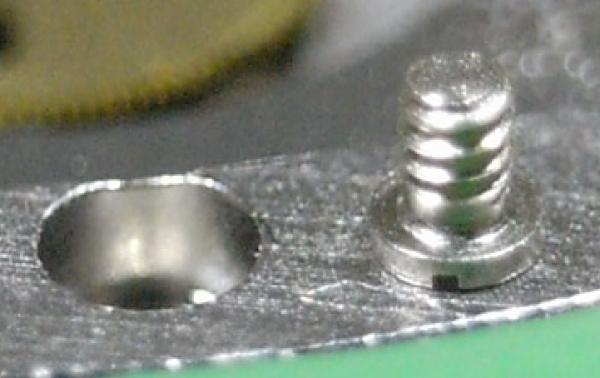

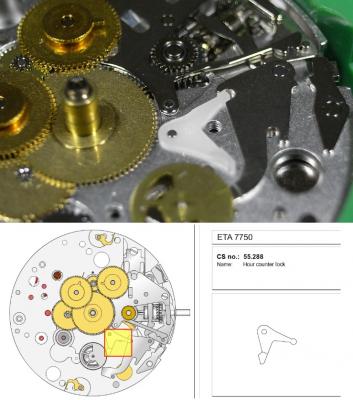

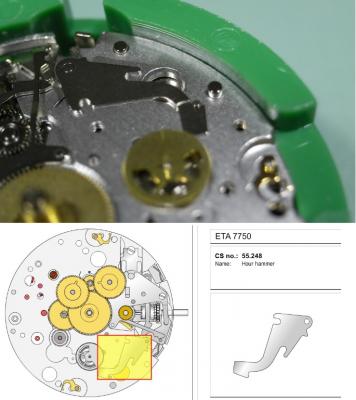

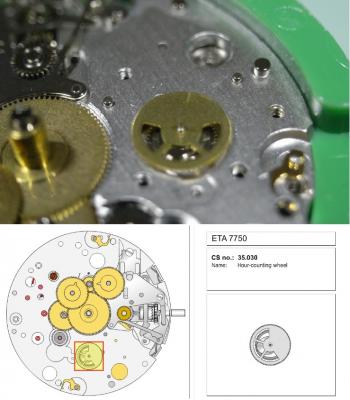

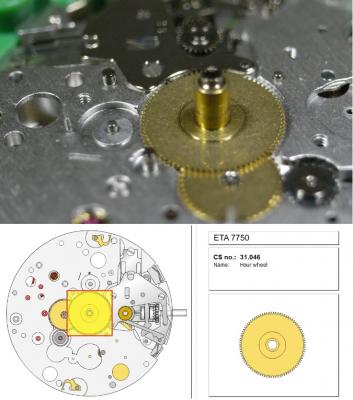

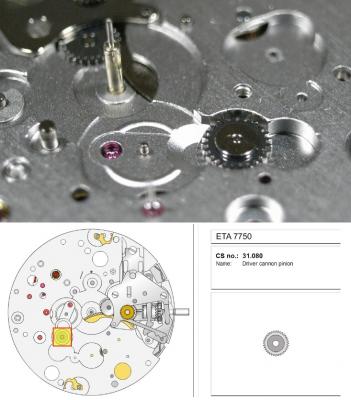

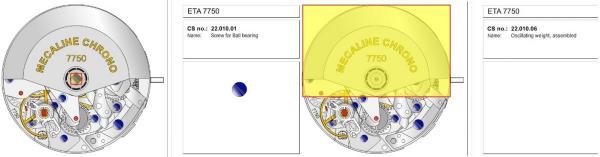

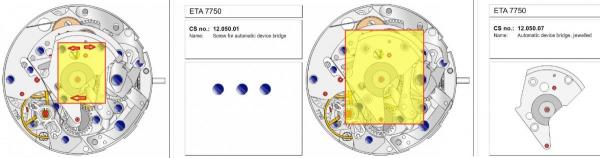

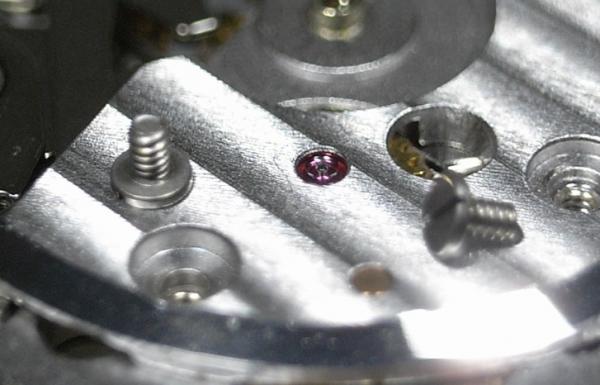

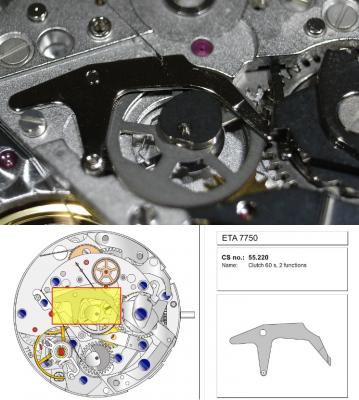

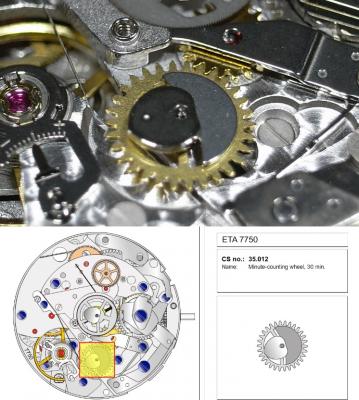

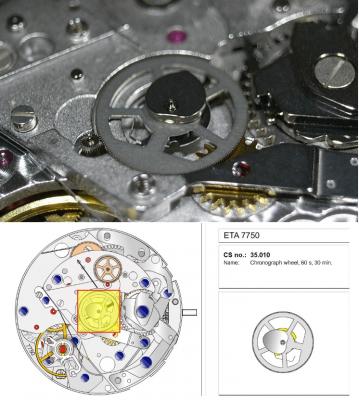

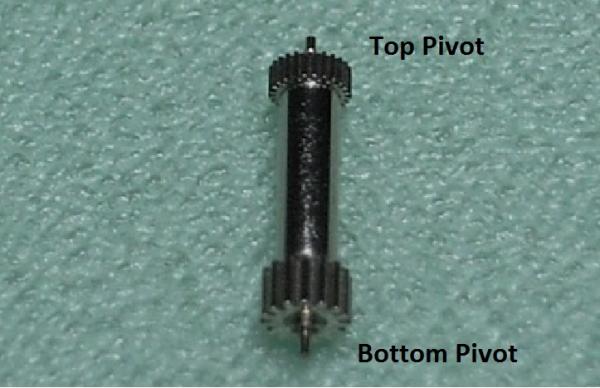

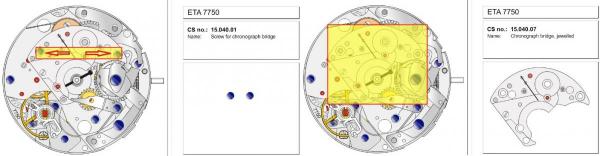

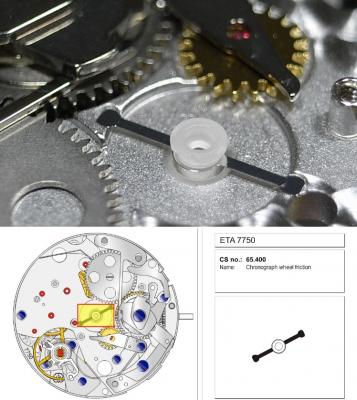

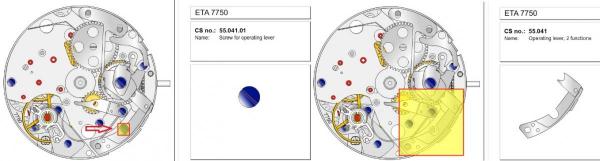

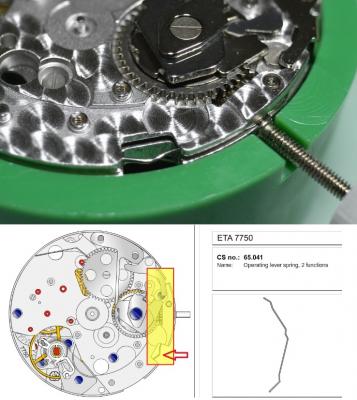

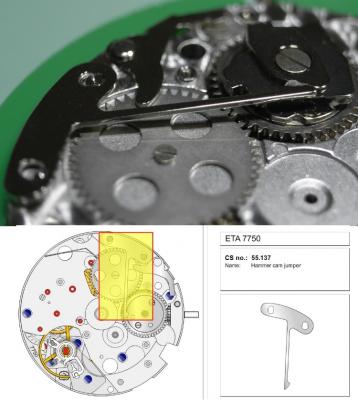

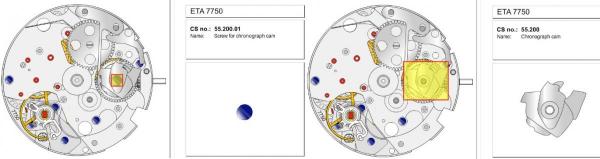

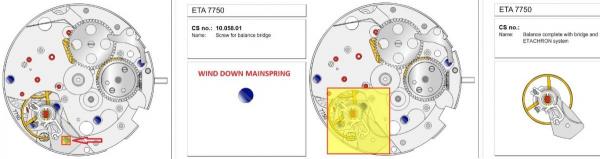

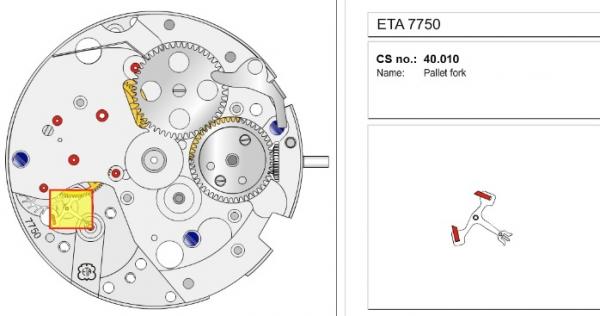

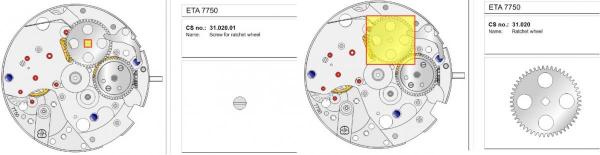

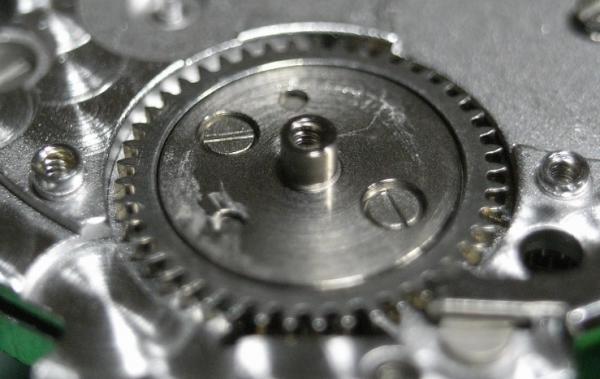

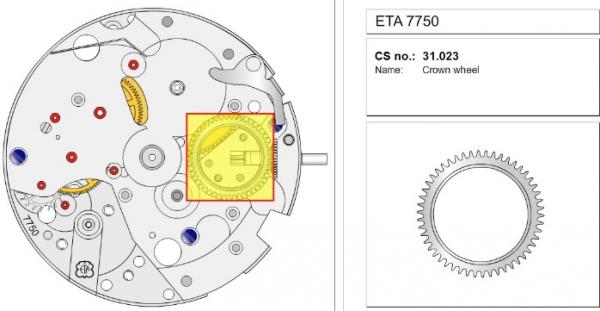

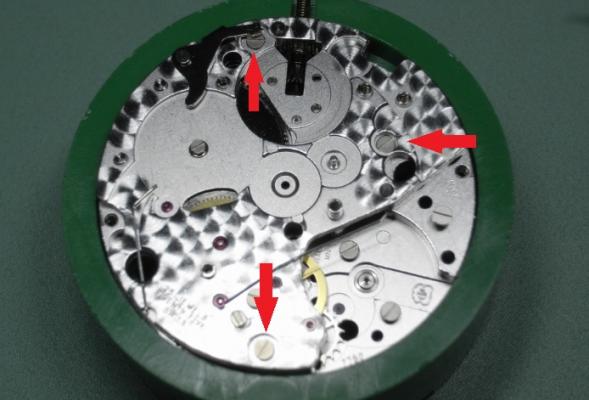

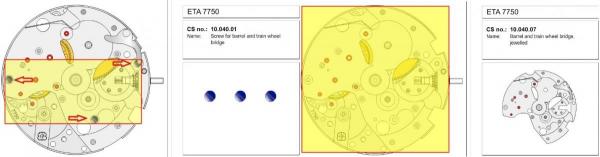

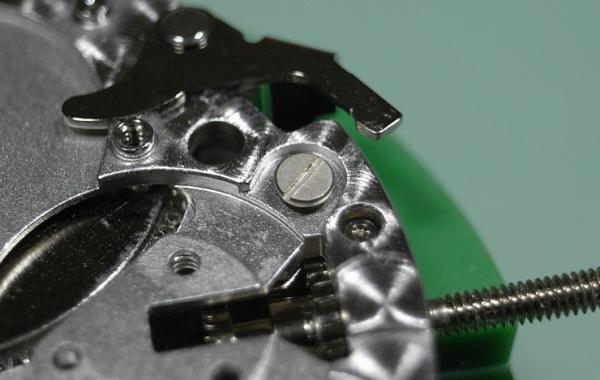

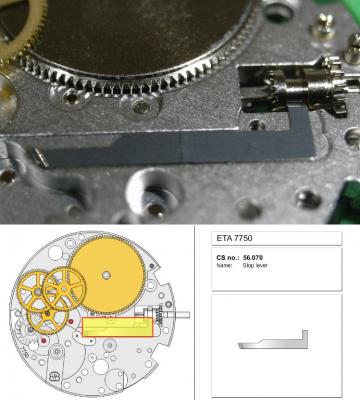

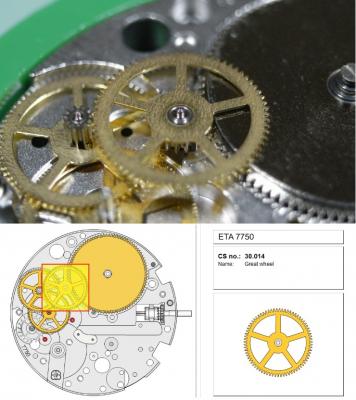

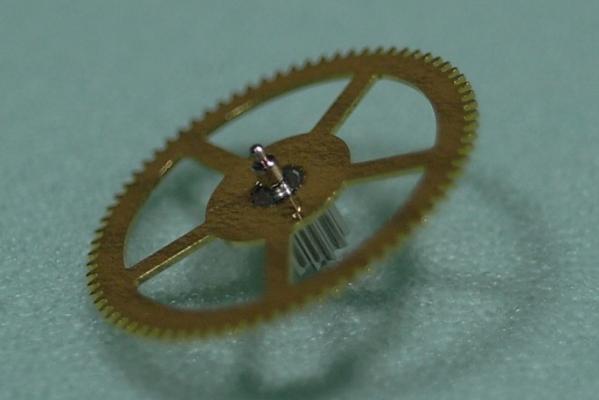

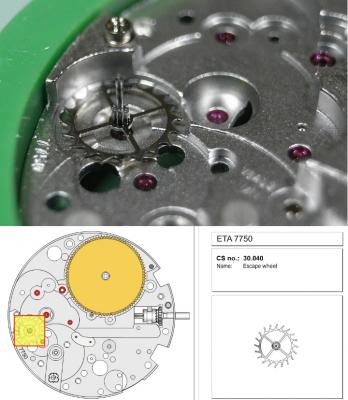

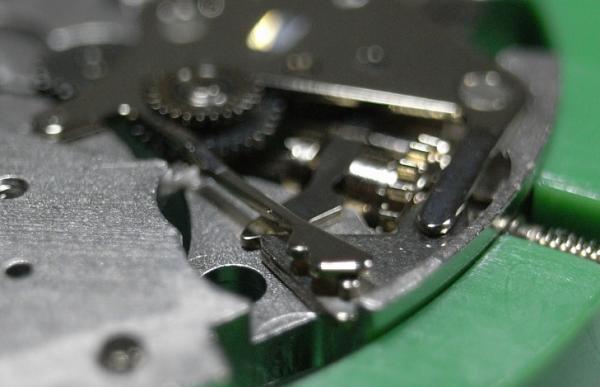

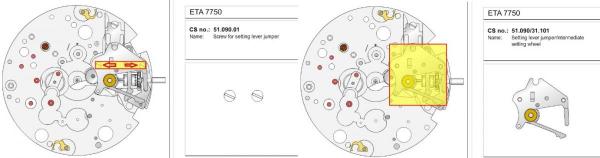

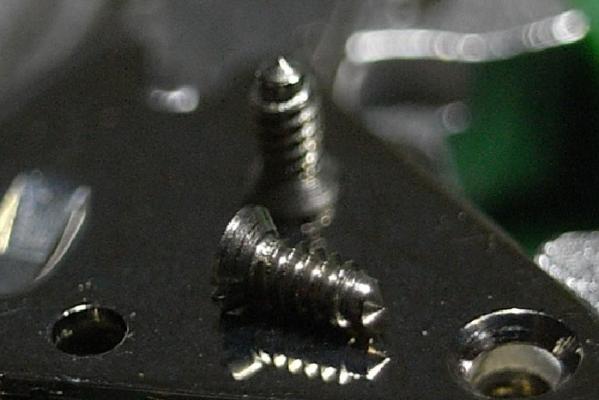

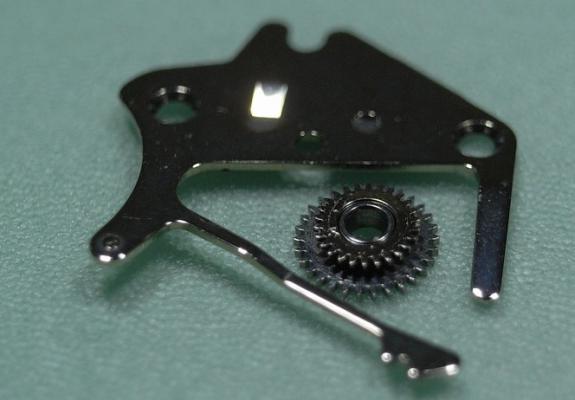

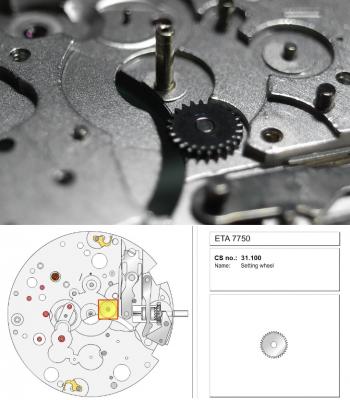

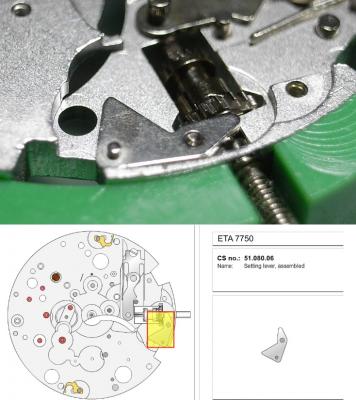

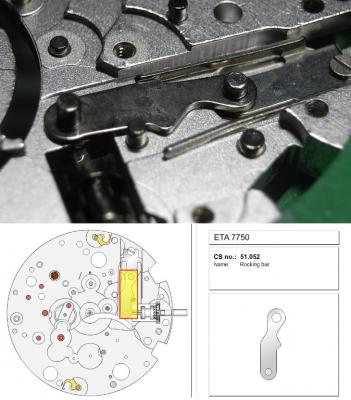

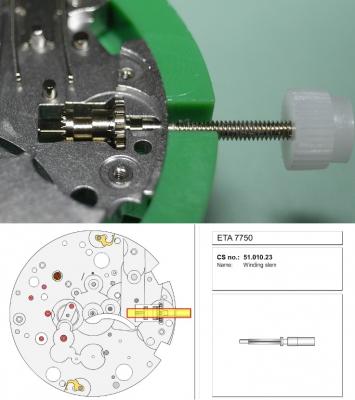

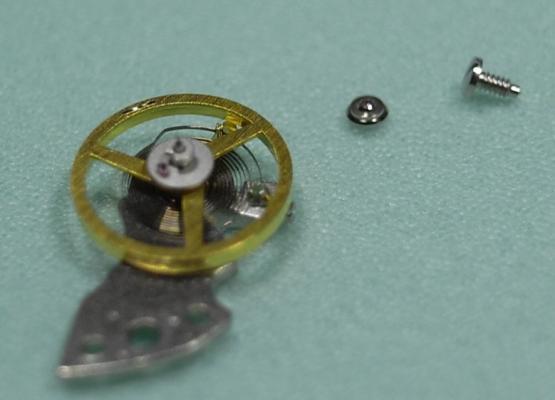

ETA 7750 Service Walkthrough The 7750 was first available in 1974, having been one of the first movements to be designed with the aid of a computer. It's hard to believe that the 7750 is still the industry standard movement for chronographs considering it's history. It was developed over 40 years ago by Valjoux, who was then a legendary movement maker that was part of the giant ASUAG conglomerate. But by the end of 1975 production was stopped due to the onslaught of the Quartz Era, and the 7750, along with many other mechanical calibers, was abandoned. Industry demand for this movement was so low that the stock produced in that 1 year manufacturing lasted until 1982! Such was the devastation of cheap Japanese produced quartz watches to Swiss manufactures. History may have forgotten the 7750 except for the local management at Zenith who ignored the orders by Valjoux to destroy the dies and equipment used to manufacture the 7750, instead hiding the equipment away from corporate eyes. You can find many more fascinating facts about this caliber online, and it's well worth the read. ................................................... This walkthrough will be very detailed, and I hope this will give people the courage to tackle this movement. I've serviced quite a few calibers, and this is one of the most beautiful, with a very logical layout. ETA7750 Tech.PDF If you have built your skills with basic movements, and become proficient in servicing them, I would highly recommend this movement to be your first chronograph to tackle. Lets begin. DEMAGNETIZE THE MOVEMENT BEFORE DISASSEMBLY. Remove the Day Indicator and store it in a safe place where it won't be damaged. Unscrew (0.8 Driver) the Jumper Maintaining Plate and remove it. Do the same for the Date Indicator Maintaining Plate Carefully remove the Jumpers Spring, holding it with a piece of pegwood so it doesn't ping away. Next remove the jumpers for the day and date. The jumpers differ from one another, so here is a reference photo so you can see the difference. Remove the Date Indicator and place it in a safe place where it won't be damaged. The last piece to remove on the Date Platform is the Double Corrector Now unscrew (1.4 Driver) the Date Platform and gentle pry it from the movement. Be careful when removing this plate, as there is a fine spring pressed into the plate that can be easily damaged. Here is a reference photo of the screws that hold the Date Platform. Remove the Hour Hammer Spring, once again using the pegwood to hold the spring while removing the tension. Here is a reference photo of the correct orientation of the spring. Remove the Hour Counter Lock. Remove the Hour Hammer Operating Lever. Next is the Hour Hammer, be careful when removing this item so as not to damage the Hour-Counting Wheel. Now remove the Hour-Counting Wheel. Remove the Date Indicator Driving Wheel Remove the Day Star Driving Wheel Then remove the Intermediate Calendar Driving Wheel Remove the Hour Wheel Then the Minute Wheel Remove the Cannon Pinion, which does not require a puller. The last component to be removed on this side of the Main Plate is the Driver Cannon Pinion. To lift the Driver Cannon Pinion I used what Mark used, a set of hand lifter from Horotec (MSA05.007); but you can also use a Presto Tool (30636-1) which will also work well. The dial side of the movement is now complete disassembled. Flip the movement over and unscrew (1.5 Driver) the Oscillating Weight. To remove the Hammer Spring lift it up gently over the automatic work and move it inwards. This will move the tail of the spring in a clockwise motion to the opening in the slots, which will free the spring. Slide out the Clutch Spring. Here is a reference photo of this spring, and it's orientation. Remove the screws (1.4 Driver) for the Automatic Device Bridge, and gently pry it loose. Here is a reference photo of these screws for the bridge. Once the Automatic Bridge has been removed, the two wheels for the automatic work are able to be removed. Below is a reference photo of how the sit inside the bridge. We now begin to disassemble the chronograph section of this movement. Begin with removing the Hammer, 2 Functions. Next remove the Clutch 60s, 2 Functions. Then remove the Minute-counting Wheel, 30min. Remove the Chronograph Wheel 60s, 30min. Gently lift out the Oscillating Pinion, 60s. Here is a reference photo of the orientation of this pinion. Unscrew (1.4 Driver) the Chronograph Bridge and gently pry it off the Train Wheel Bridge. Remove the Ratchet Driving Wheel. Remove the Chronograph Wheel Fiction. Unscrew (1.4 Driver) the Operating Lever, 2 Functions. Unscrew (1.4 Driver) the Lock, 2 Functions. Next remove the Minute-counter Driving Wheel, 30min. Slide out the Operating Lever Spring, 2 Functions. This spring can be fitting in both directions; but only 1 way is correct. Here is a reference photo of it's correct orientation. Remove the Switch. Here I digress from the order the SwissLab document illustrates the order of removal. They show to remove the Chronograph Cam before removing the Hammer Cam Jumper. This in my opinion is not the best way, as all the force from the jumper is pressing on the cam whilst your trying to remove it, and could lead to damage. Instead I move the Chronograph Cam until it reaches the notch as shown in the photo below. Then lift the Hammer Cam Jumper up to the top of the Chronograph Cam, which will release it's tension. Then, just as you removed the previous hammer, rotate the jumper to the opening in the slots, which will free the spring. Now you can unscrew (1.4 Driver) and remove the Chronograph Cam safely without tension on it. RELEASE THE MAINSPRING TENSION Once the tension has been released, unscrew (1.4 Driver) and remove the Balance Cock. Then unscrew (1.4 Driver) the Pallet Bridge and remove the bridge and Pallets. Unscrew (1.2 Driver) and remove the Ratchet Wheel. Then remove the Crown Wheel. Unscrew (1.4 Driver) the Train Wheel Bridge and gently pry it off the Main Plate. Note that one of the screws is under the Operating Lever. This needs to be moved out of the way to access this screw. The last level of this movement contains the train. Here is a reference photo of the wheel locations. Remove the Stop Lever. Remove the Great Wheel. Here is a reference photo of the underneath of this wheel. Remove the Third Wheel. Here is a reference photo of the underneath of this wheel. Remove the Second Wheel. Here is a reference photo of the underneath of this wheel. Note this has the long lower pivot. Remove the Escape Wheel. Here is a reference photo of the underneath of this wheel. Then remove the Barrel. This completes the removal of the train. Flip the movement over so we can complete the disassembly by removing the keyless work. Firstly, release the tension from the Setting Lever Jumper. Then unscrew (1.2 Driver) and remove the Setting Lever Jumper. These are unique screws with pointed ends, and below is a reference photo of them. This will also remove the Intermediate Setting Wheel. Next remove the Setting Wheel Then remove the Yoke. Remove the Setting Lever. Remove the Rocking Bar. Now pull out the Stem. Once the Stem is removed the Winding and Sliding Pinion should fall out of the movement onto your work mat. Disassembly of the 7750 is now complete If you've come this far, congratulation on completing the disassembly. Make sure you pegwood all the jewels and reinstall the Balance back onto the movement for cleaning. Assembly of the movement will be posted as soon as I complete the write-up.2 points

-

The movement service is complete, and I'm doing the write-up now. But just as a teaser, here's how the movement looks on the Timegrapher straight after I'd finished the service .... totally UNADJUSTED :) I'll adjust the timing to COSC standards another day ... I wanna get the assembly write-up posted tonight if possible.2 points

-

Thanks mate :) But all praise goes to my Lord and Saviour, Jesus Christ, for giving me the gift of being able to do this work and write-ups for you guys. My hope is that they inspire others to "give it a go" like I did 11 months ago, and not be fearful of a challenge. The reward that comes from succeeding and seeing a movement come to life are hard to put into words.2 points

-

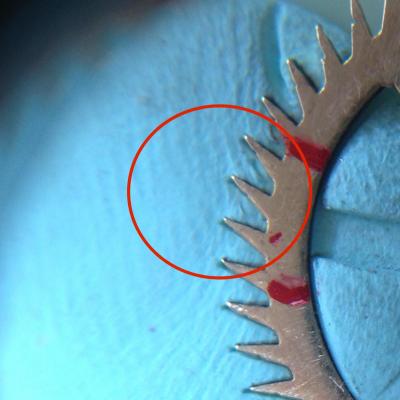

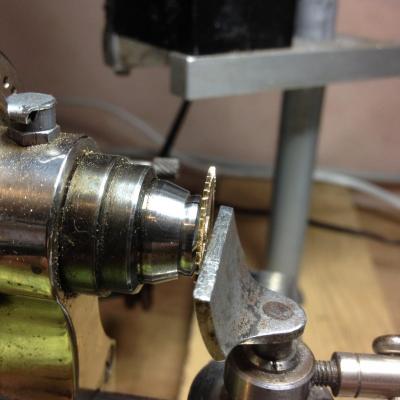

This 1920,s gravity clock that has a really simple movement required a lot of work to restore. Every bushing had to be changed with some of the bushes I had to custom make. The escape was very badly worn & the escape wheel was misshapen with many teeth out of true and all of the teeth had wear. I straighten the obvious teeth with small smooth nose pliers and every tooth was treated to a smoothing with a fine escapement file. Then see below I had to check all teeth where true, the wheel was true & all teeth where exactly the same height. See pics & short vid. Making a mould with Rodico to find them elusive mis aligned teeth Four tips of teeth mis shaped found Checking round & bending to get running true Running on the lathe with a gentle rub with a flat escapement file to get all exactly the same height Job done1 point

-

Perhaps its me I don't understand why the movement still has the Ronda logo. If it is a smiths then this page might be the one you require http://www.windingstems.com/smith.php You will have to have a measure to double check "click on more info"1 point

-

Definitely a Smiths TY, these were made in 1,5,7 & 21 jewel versions. Not too sure when production of this model was started - it was a replacement for the RY movement and was later replaced by the Streamline movement in 1966. The Anglo Celtic Watch Co. was a joint venture between Smiths & Ingersoll from 1947 until 1969 when Ingersoll pulled out of the venture. The factory carried on under Smiths until final closure in 1980. Watches from this factory with Smiths movements will be marked Made in Great Britain. If you can produce a photo of the complete watch, I may be able to give a rough date for the watch.1 point

-

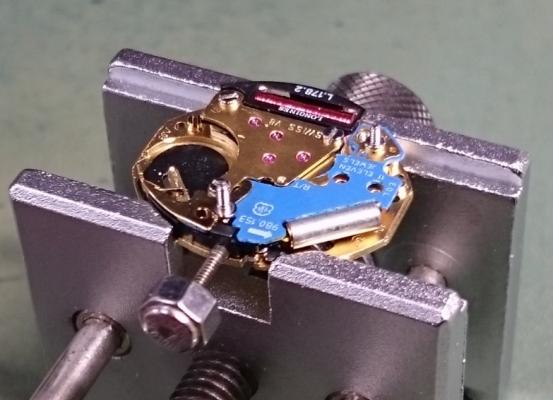

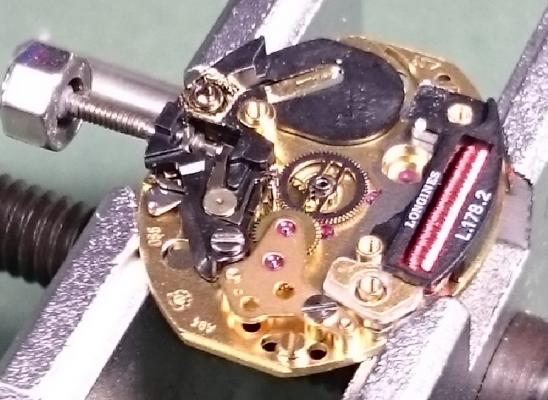

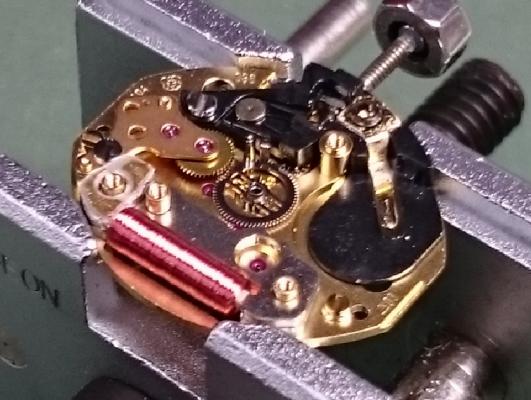

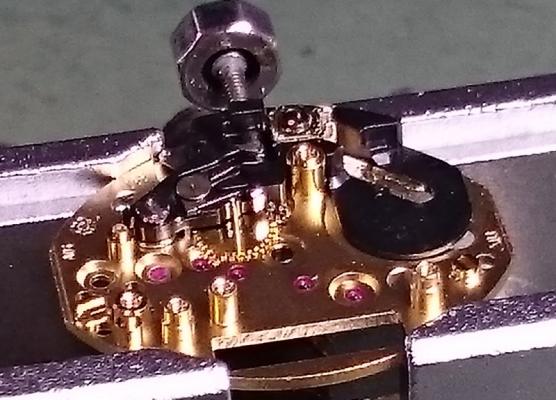

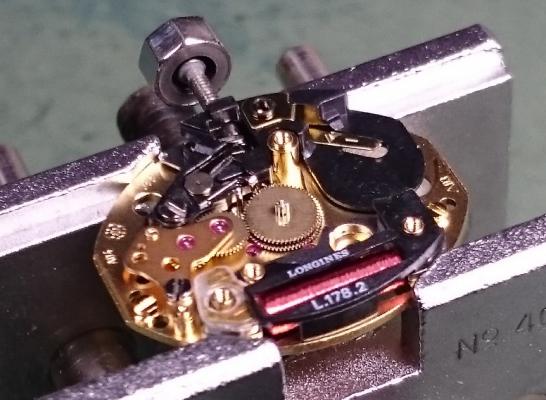

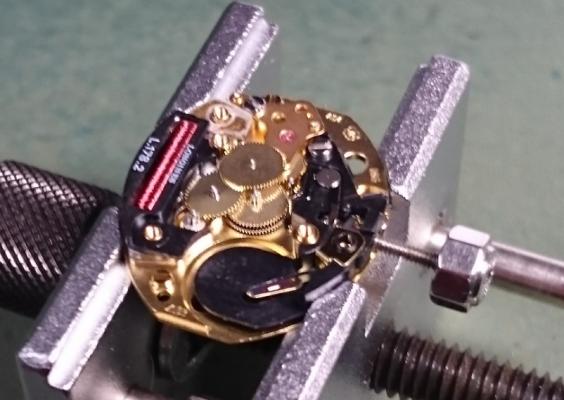

ETA 980.153 Service Walkthrough The ETA 980 Caliber is used mostly in ladies high-end quartz watches. The iteration for this walkthrough is the 980.153, which has the seconds subdial. ETA 980.153 - Technical Communication.PDF I thought this one would interest many of you, as it has a primary and secondary train bridge. Once the Hands are removed, turn the movement over and turn the fastening screws for the Dial Feet (circled in orange) until the flats are towards the feet. This will allow you to easily remove the Dial. Once the Dial is removed, you can take off the Hour Wheel. This is the only item to be removed from the dialside of the movement. Place your movement in the holder and unscrew the two screws holding the Circuit. Note they are two different lengths. Remove the Circuit and Battery Contacts and place the Circuit immediately somewhere safe. Next remove the three screws on the primary Train Bridge, and remove the bridge. Here are some reference shots of the primary train. Once the wheels are removed, you'll be able to see the Canon Pinion. DO NOT try and remove it at this stage! As you can see, it's slightly under the wheels in the secondary train for the seconds sub-dial. This will have to be removed before extracting the Canon Pinion. Before we get to removing the secondary train we must first remove the Coil. Remove the Coil Protector, then carefully lift out the Coil along with the Stator. Next remove the secondary train bridge. This is held in place with a single screw and two locating pins. The locating pins can be a little tight fitting, so very gently rock the bridge and work it slowly off these pins to avoid breaking a pivot or jewel. Now you can remove the two wheels under this bridge and the Canon Pinion. On to the plastic housing that the Swiss lovely refer to as the "Electronic Module Distance Piece" ... yeah, whatever! :rolleyes: Make sure the crown is pushed in, and NOT in the hand setting position, then undo the single screw and lift out the "Black Chuck of Plastic Module Thingie" :P Once this is removed, you can get to the Keyless Work and the Minute Wheel. You can then pull the Yoke, Sliding Pinion, Setting Lever and Stem out for cleaning. The disassembly is complete. After cleaning assembly is just the reverse operation. Here are some reference photos to help you along... I hope this has been an interesting walkthrough, and helps those wishing to tackle this wonderful little movement jam packed with wheels and bridges :)1 point

-

1 point

-

If I'm not mistaken that looks like a Smiths TY movement made by the Anglo Celtic Watch Co. Try John at http://www.obsoletewatchandclockparts.com for parts.1 point

-

If the kit is genuine Bergeon you have done OK Roger. Regarding the oil:- "Moebius 8141 This is a medium-weight, non-synthetic lubricant often specified for train wheels and highly recommended for mainsprings. This is an essential for mainsprings, but I usually use Synt-A-Lube 9020 on the higher-torque train wheels. FB-929 $16.95 "1 point

-

Tissot 2403 Service - Part 2 Tissot 2400,2401,2403,2404.pdf All the parts are now cleaning and ready to be assembled. I have to say that those Nylon fibres were everywhere!! Took me a long while to remove them off all the parts with an old piece of Rodico before cleaning, and even then, I STILL found tiny fibres after cleaning that I'd missed ... so my cleaning solution is now contaminated and needs to be changed @!#*%^# Arrgh!! :roadrage: Ok, I've clamed down :P ... on with the service. Secure the Main Plate in your movement holder and replace the Train. Then replace the Train Bridge and gently worry the wheels into their jewels. Then with a piece of Pegwood to hold the bridge in place tighten down the screws. Always continue re-checking that the train is running free as you secure the screws. It's good to see those jewel holes are now nice an clean. Once you've oiled with Mainspring and placed it back into the Barrel, replace it onto the Main Plate. Replace the Barrel Bridge, and Click. Replace the Click Spring, Ratchet Wheel and Crown Wheel. Then carefully place the Pallet Fork and Pallet Cock back into it's respective place. Once the Pallet is in place, give the Ratchet Wheel a few turns and check that the Pallet is operating correctly. Next the Balance and Incablocs need to be cleaned in Lighter Fluid. Once clean replace the Balance and Incablocs Now give the Ratchet Wheel a couple of good winds and check the oscillation of the Balance. It's now time to start on the dial side of the movement. Oil up your Winding Pinion and Sliding Pinion. Replace the Winding and Sliding Pinion, Setting Lever, Yoke and Yoke Spring. Replace the Canon Pinion, Minute Wheel and Intermediate Wheel. Then replace the Setting Lever Spring and secure it down. Replace the Dial and Hands, and your done :) Nothing left to do then adjust the timing and case it up. I hope these reference photos help those looking at servicing this movement, and I must say that it was a lovely movement to work on. Another watch saved from the rubbish tip.1 point