Leaderboard

Popular Content

Showing content with the highest reputation on 06/08/23 in all areas

-

Some time ago Mark was asking members if anyone member would like to become a moderator. I had been a member for some time so I put my name forward. A far as I can remember as far as I know the moderators at that time had a vote and I was voted in.2 points

-

Thats exactly how i see it. I meant the hole is increasing in size but not symmetrical, growing gradually as the cutter makes its way around the circumference of the hole. I think everything has been covered now haha2 points

-

Even with a high performance CNC lathe there's a lot of other work involved in making a staff. My actual cutting time in the lathe (manual lathe) for a staff is maybe 30 minutes; the rest of the time is taking the initial measurements*, heat treating, and finishing. 300 is a good price (I'm around there, and other watchmakers tell me I should double it, haha). *The measuring is a big deal. For example, I have an old Longines in from a watchmaker friend. He had removed the old staff but found that the hole in the balance had been enlarged so the new (and correct) staff was way too loose to fit correctly. In addition, the old staff was longer than original, and the mainplate had been "pipped" to raise the balance cock a bit. After removing the pips, the cock sat at the right height for the original staff length. The jewel in the mainplate had been replaced with one with far too large of a hole, so that got straightened out. The old staff was slightly oversize for the roller table, which had been broached to fit, so that was corrected on the new staff dimensions. Basically, for old stuff, even if you have the original drawing from the factory, it's no guarantee that it will work correctly. Everything has to get measured (and we're talking microns making a difference on certain fits), verified, then made to those dimensions. The actual cutting, which is what the CNC would do, is a fraction of the total work. The older the watch, the higher the chance that things have gotten screwed up over time- and the lower the chance of finding spare parts, which if found, might still not fit .2 points

-

Perhaps we are talking the same? In my virtual brain picture the asymmetrically doesn't increase, it is constant but shifting its position during the rotation, provided you ream with the same downwards pressure, i.e. the thickness of the shaving stays constant. In fact, the asymmetrically decrease towards the cylindrical part of the reamer, where the reamer tapers off. The "problem" with this type of reamer is that the back-side of the reamer (the non-cutting) leans against the borehole whereas the cutting side digs in, enlarging the hole. One could see it a bit as following an increasing spiral predominantly in the horizontal plane. Correct. I do agree that there are nicer, perhaps better ways to enlarge a hole. Reaming with a one sided cutting action reamer seems crude, but, in the end of the day, if it works, it works. I drool over Nickelsilvers machines, but those I may get in my next life For now, and to me having solved the initial question, I can ream with these Seitz-reamers, when following the correct procedure, and be confident that I'll end up with a nice, in center and cylindrical hole. Crude, cheap but effective. I thank you all for your input ....... I think this was a thoroughly enjoyable and interesting discussion2 points

-

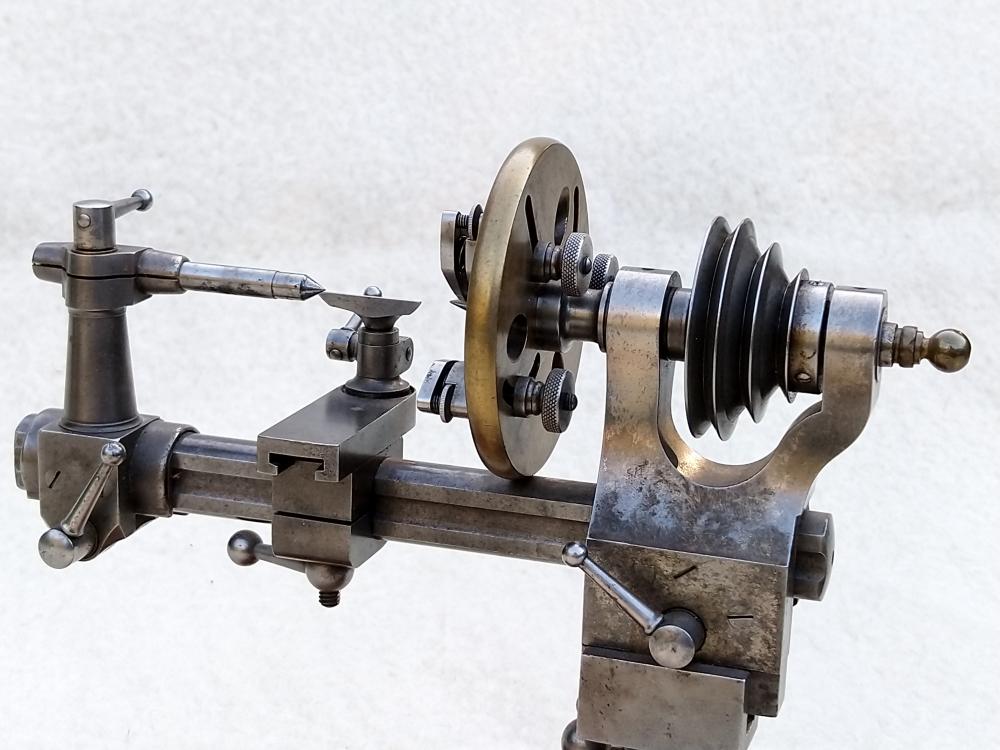

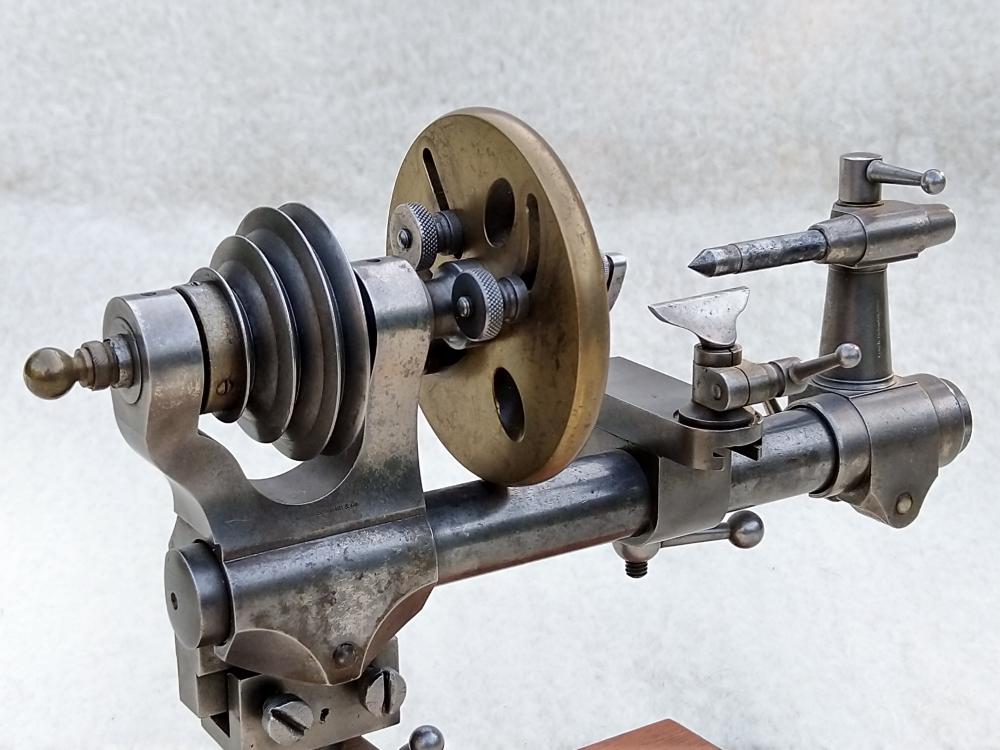

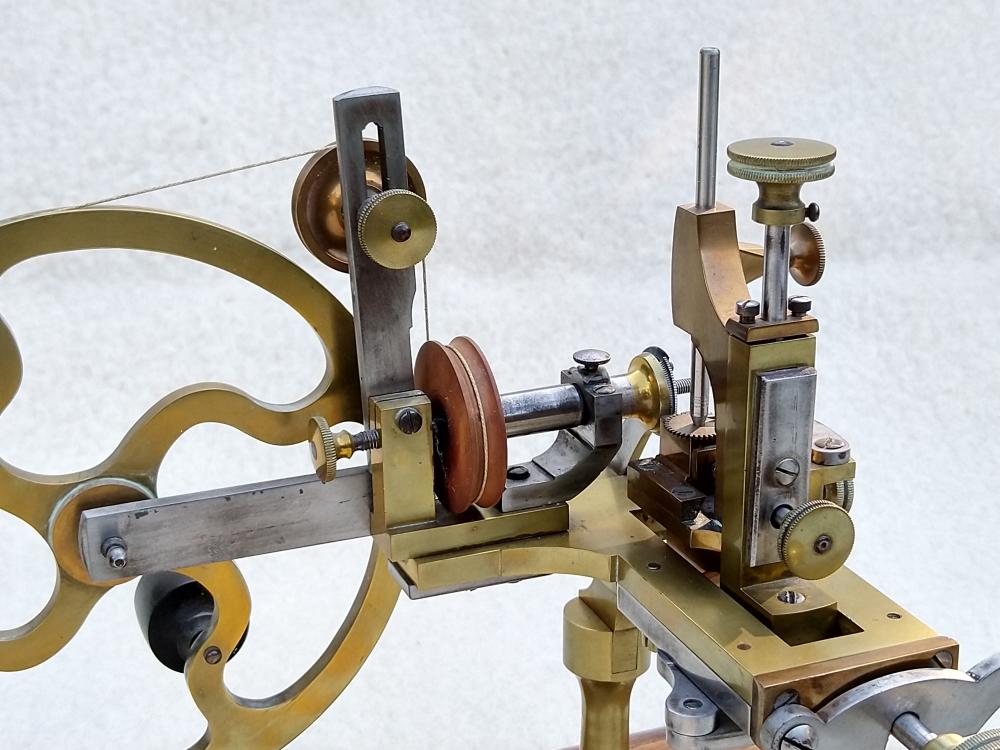

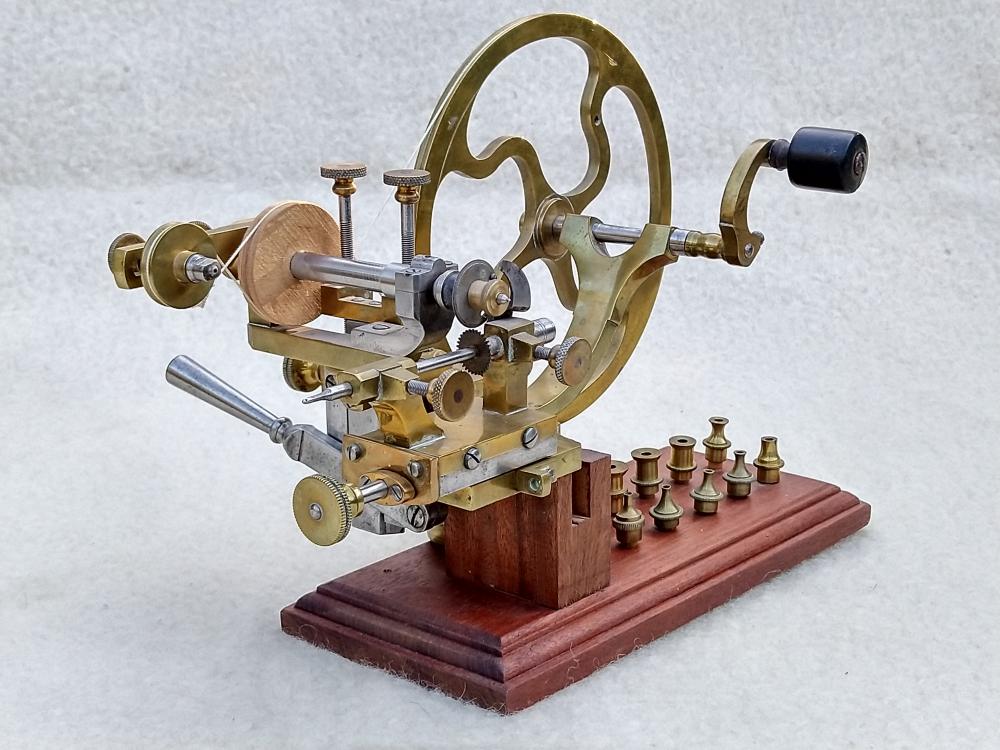

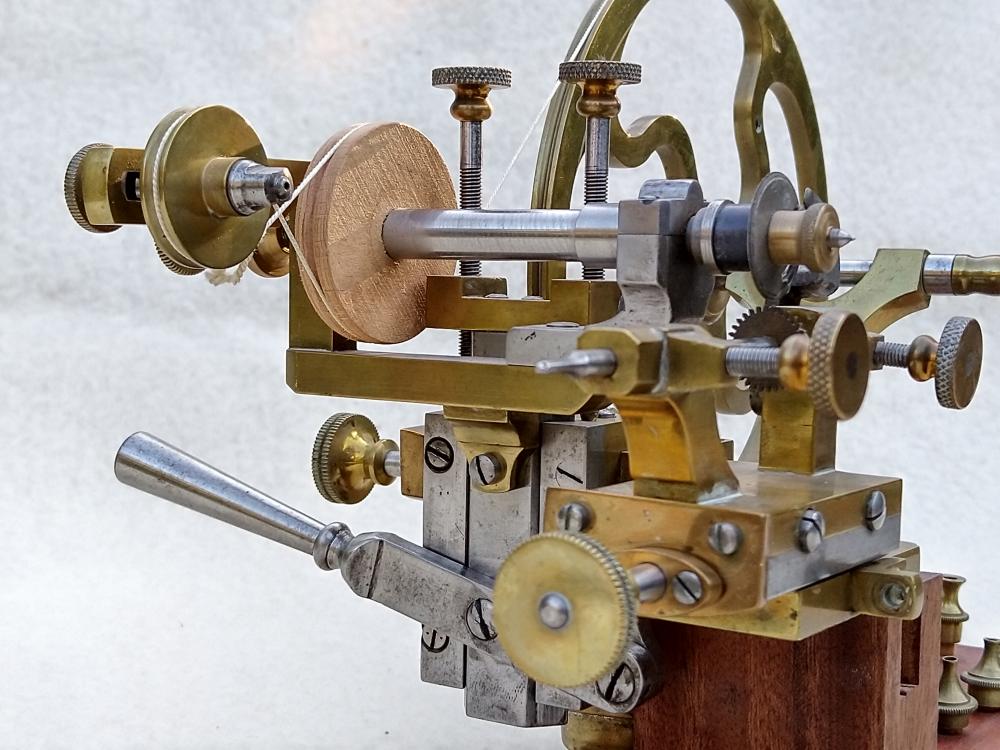

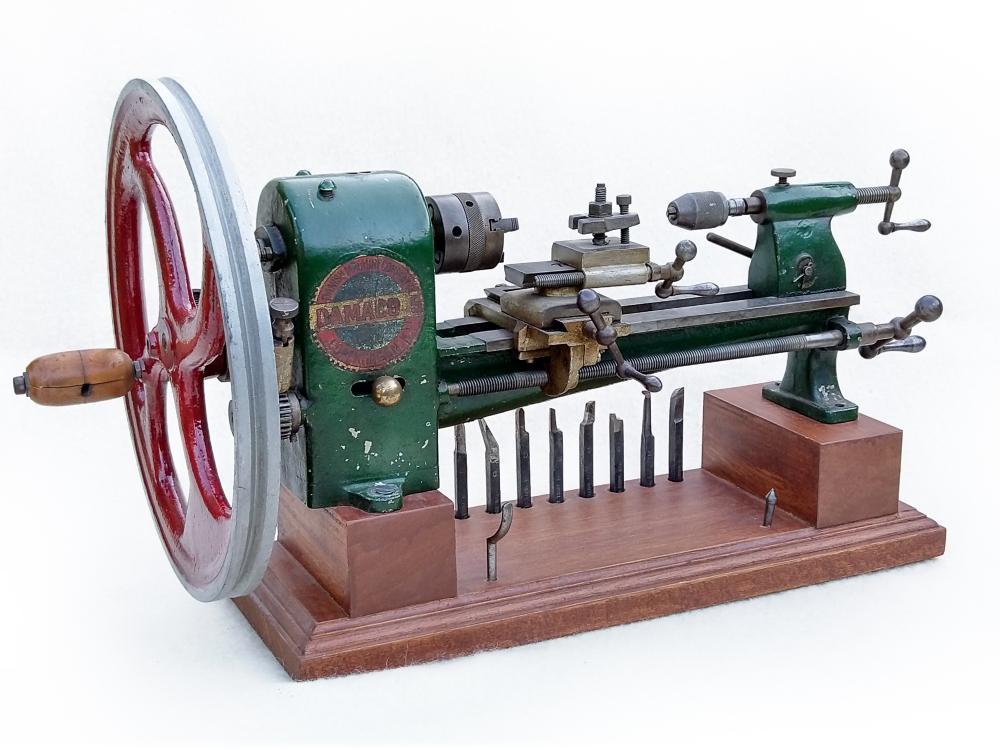

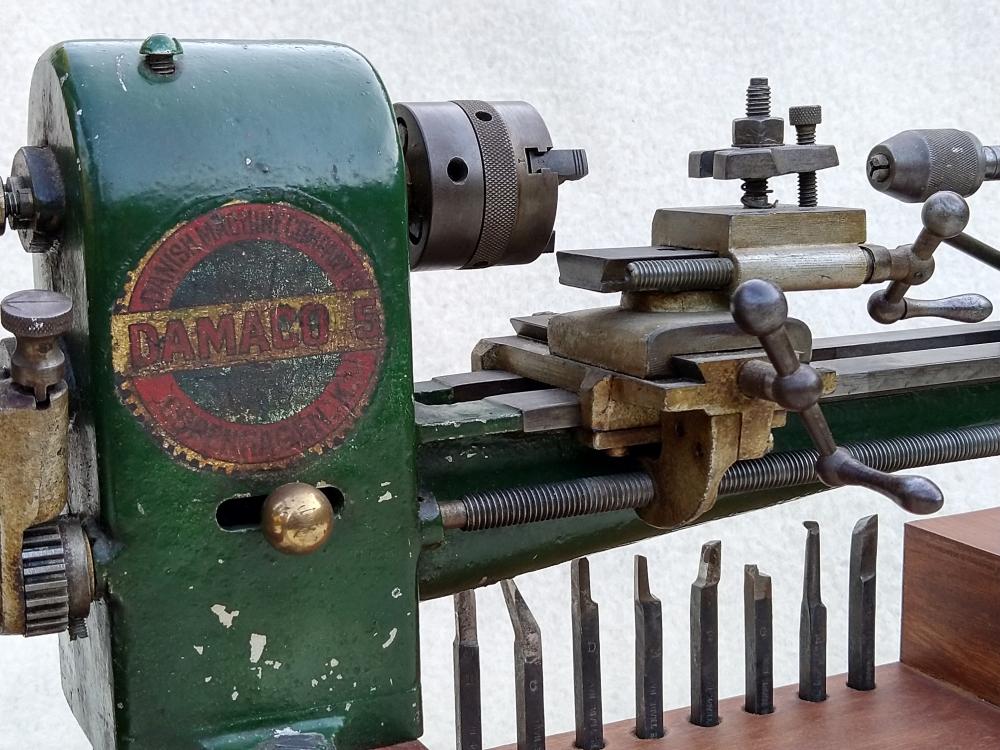

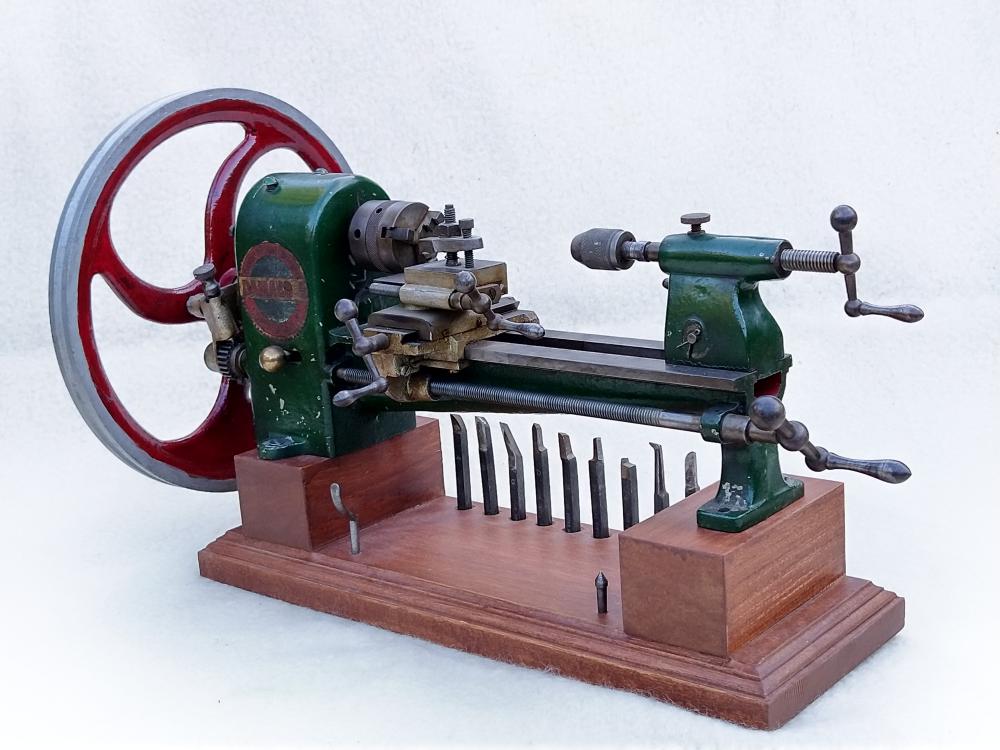

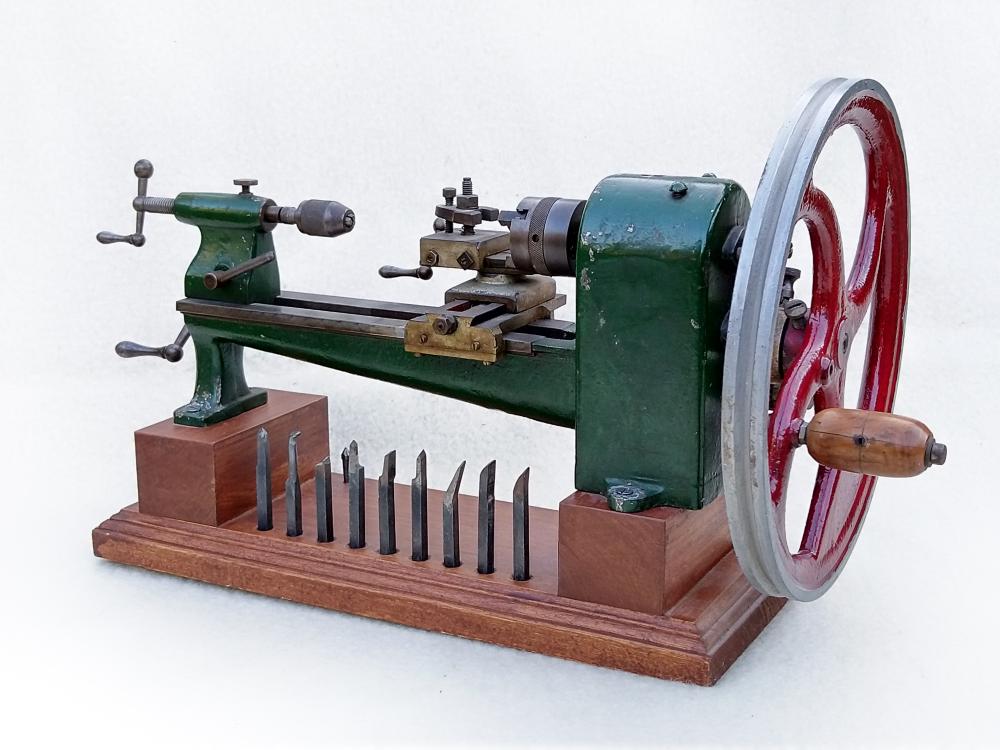

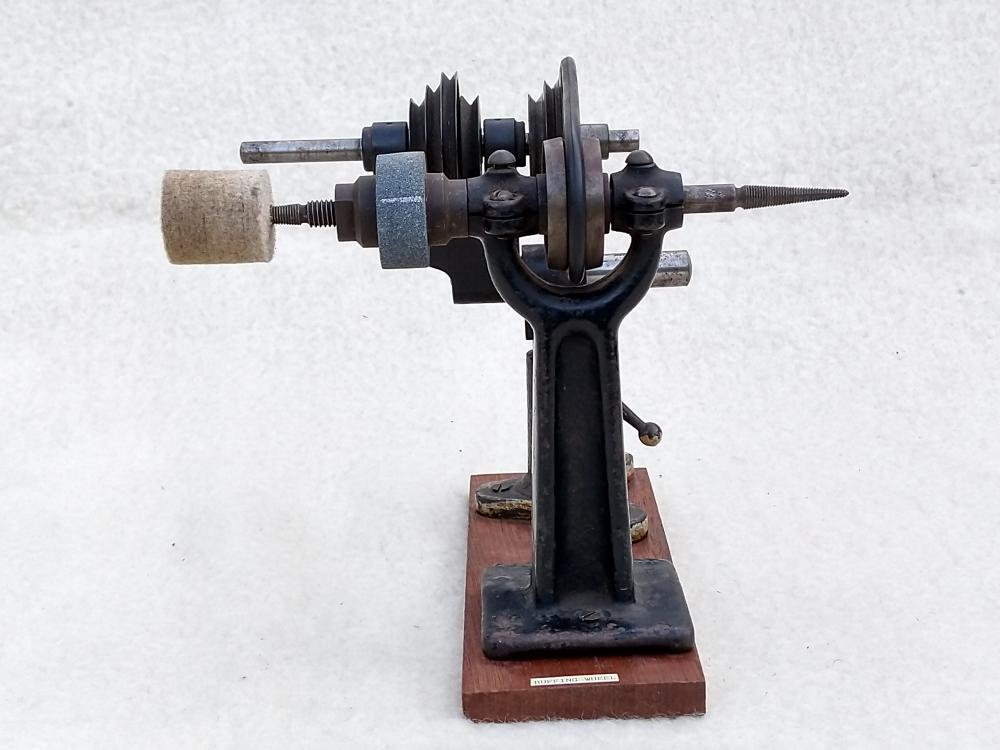

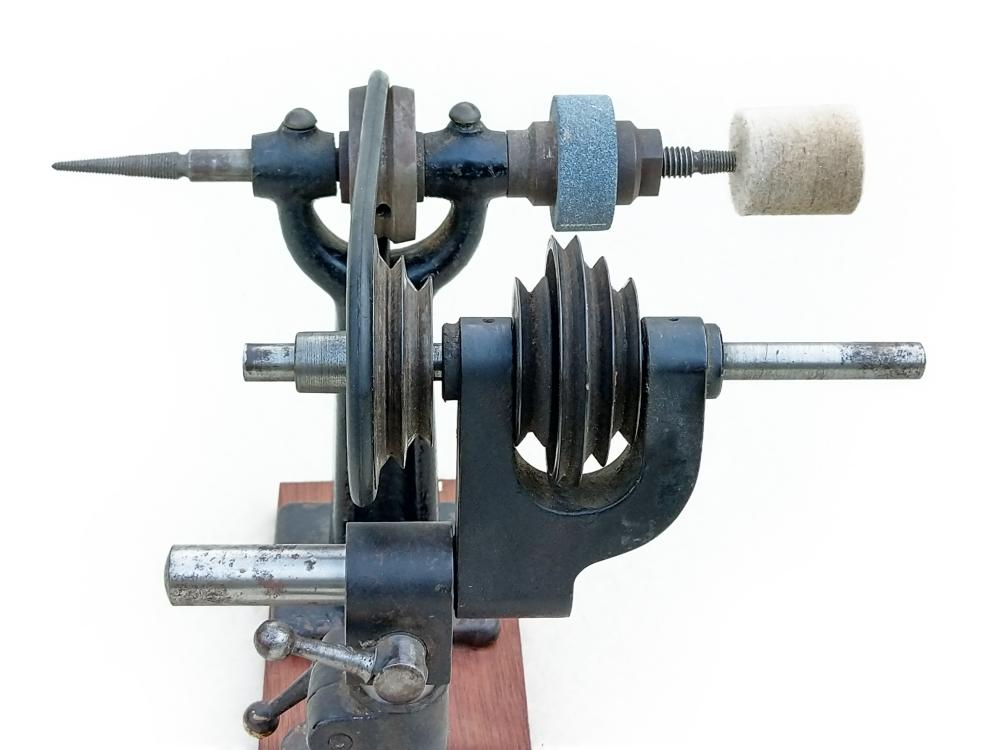

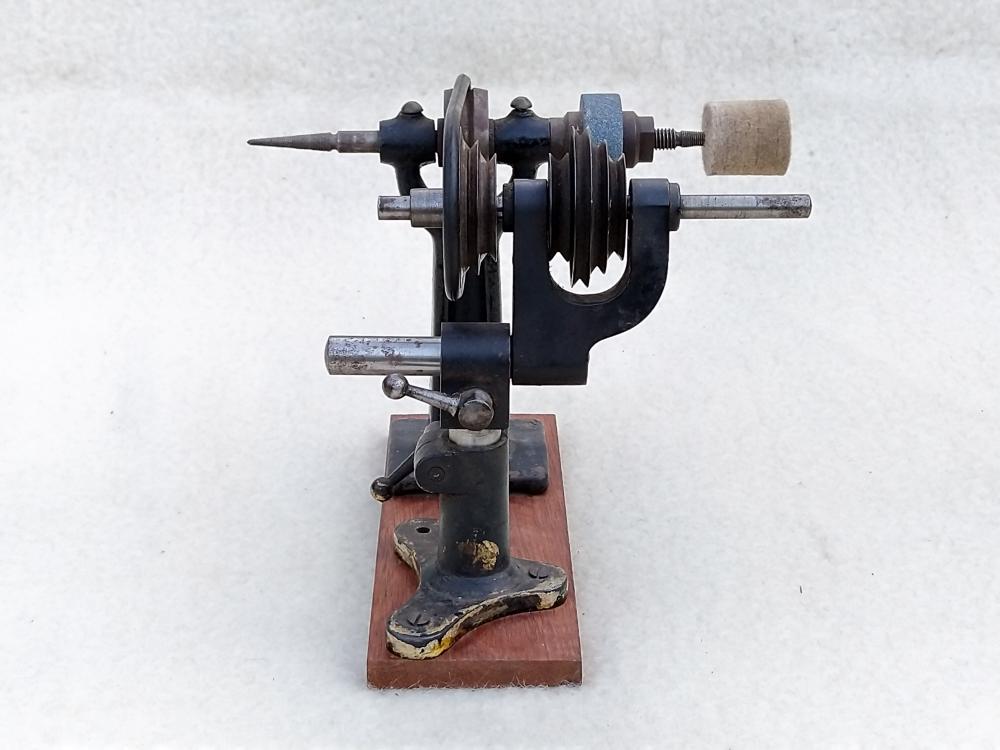

2 points

-

1 point

-

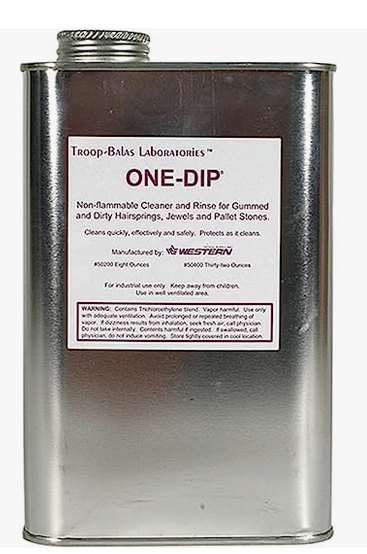

This is what I use. I also wipe a very thin layer of silicone grease around the rim of the lid. When I used to work in a lab we would also use Parafilm around the junction of the lid and jar to seal and help stop evaporation.1 point

-

Nice to find a virgin movement unravaged, to my mind if you break it then you fix it. Oh the unawareness of the complexities of a watch, it must be absolute bliss. Rant almost over, Mr. Delivery man has brought be treats1 point

-

The work horse Rolex caliber of that era, yes? …and how are you at timing screws? Haha… Yes I have my share of Fleabay specials, too. The experience more of a watch rescue situation. Gratifying most if the time, I feel. In the case of said Rolex it is fresh from the country auction house- showing its age but managed to avoid the oil dunkers…1 point

-

I've made a number of staffs and even vibrated hairsprings for that caliber .1 point

-

I had not thought of it this way but have been experiencing this in practice. I've recently cleaned up what could be a lovely Rolex cal 700 with horrible positional error. Before I try to adjust I've been looking for some 'safety net' replacement parts but have turned up nothing. I'm considering leaving it be as kinetic art rather than a timekeeper...1 point

-

It does feel like this market for repairing watches, not just for us hobbyists but for professionals alike, is going to get more and more difficult as time goes on. If its not current Swiss manufacturers restricting parts except for the very professional then its an ever decreasing amount of old stock. There will come a time when no more parts are available. So unless you are on the # i am completely independent and can make any part i need # professional side, the hobbyist and basic repairer for a living is going to come to an end. And its actually makes me quite sad to say i think that the blame for the diminishing parts lays heavily on the hobbyist using them up to repair what they break. Sobering thought that makes me feel guilty about the ones I've damaged.1 point

-

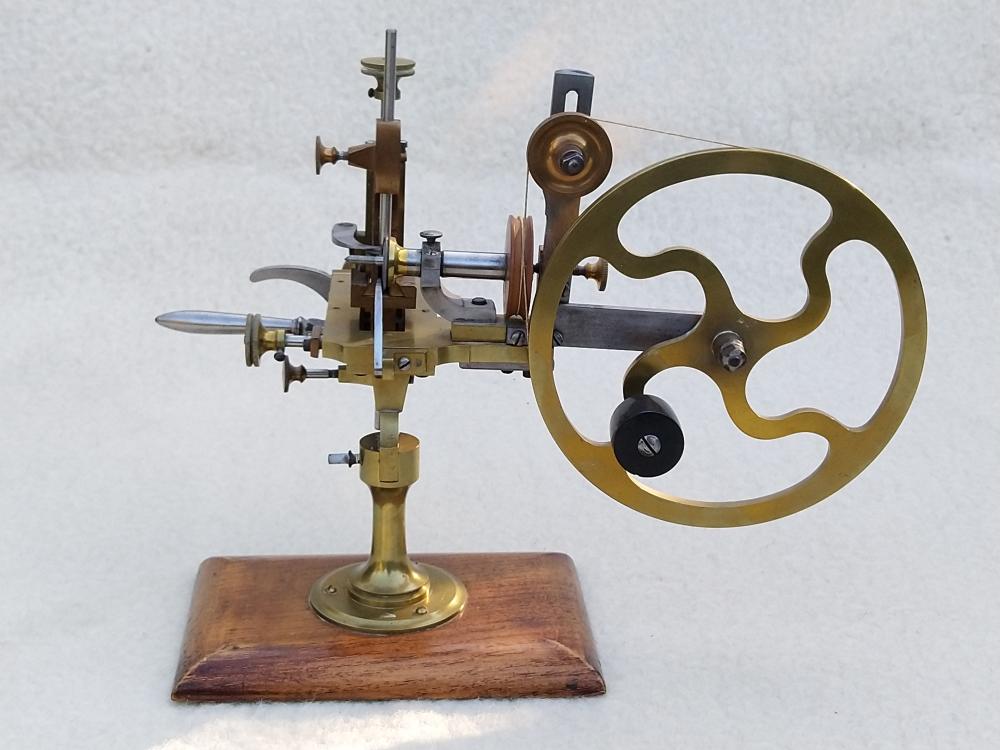

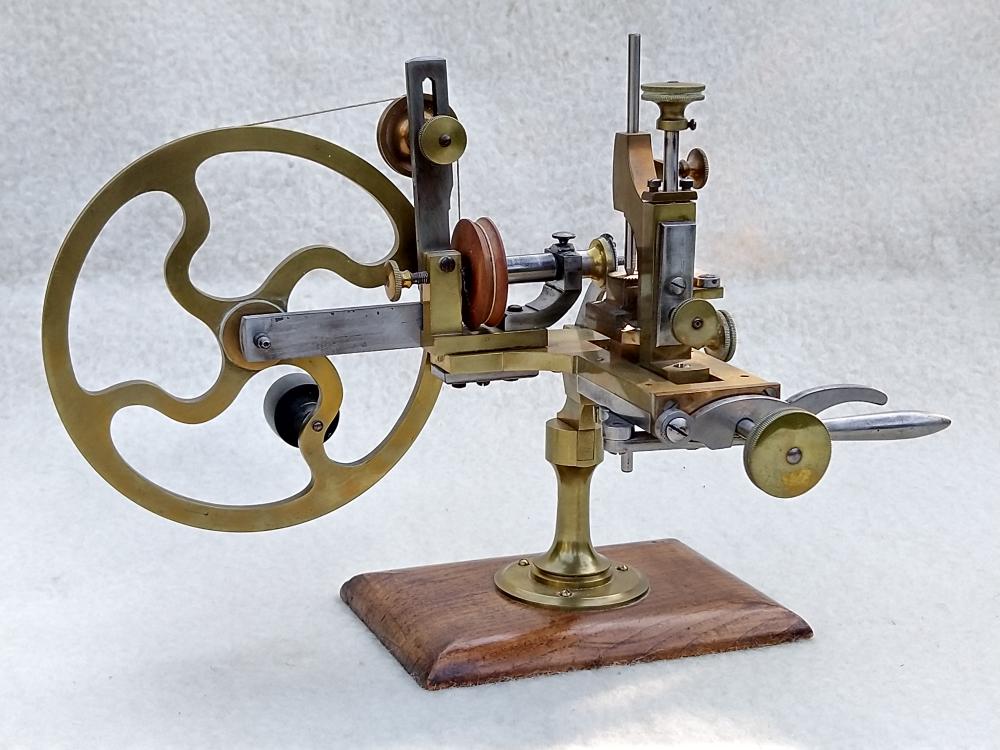

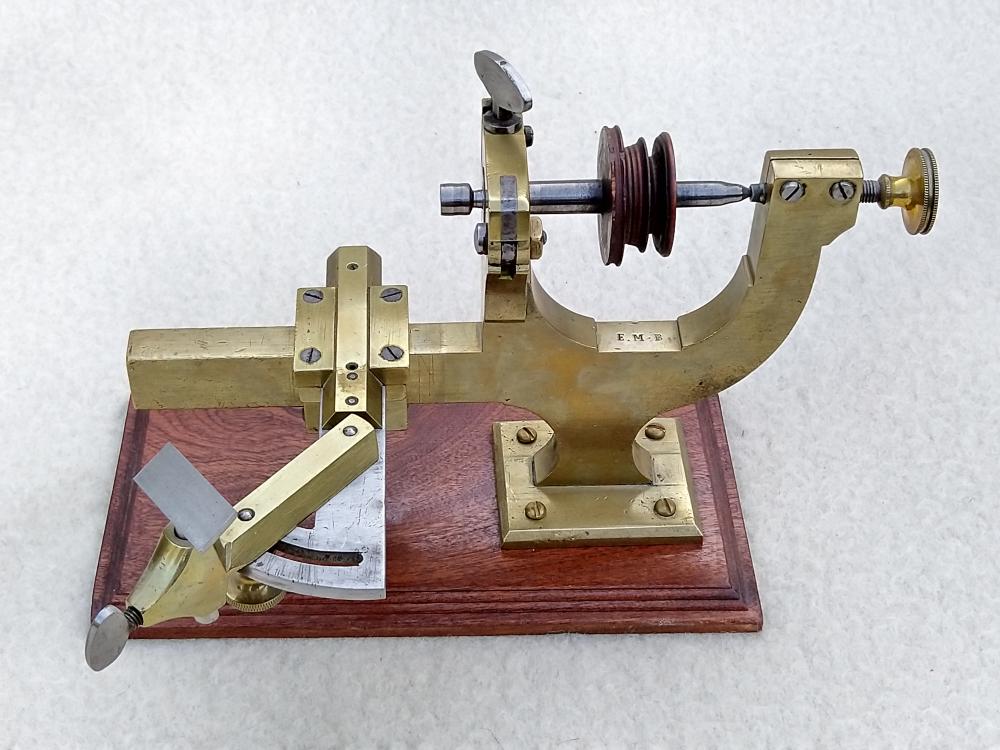

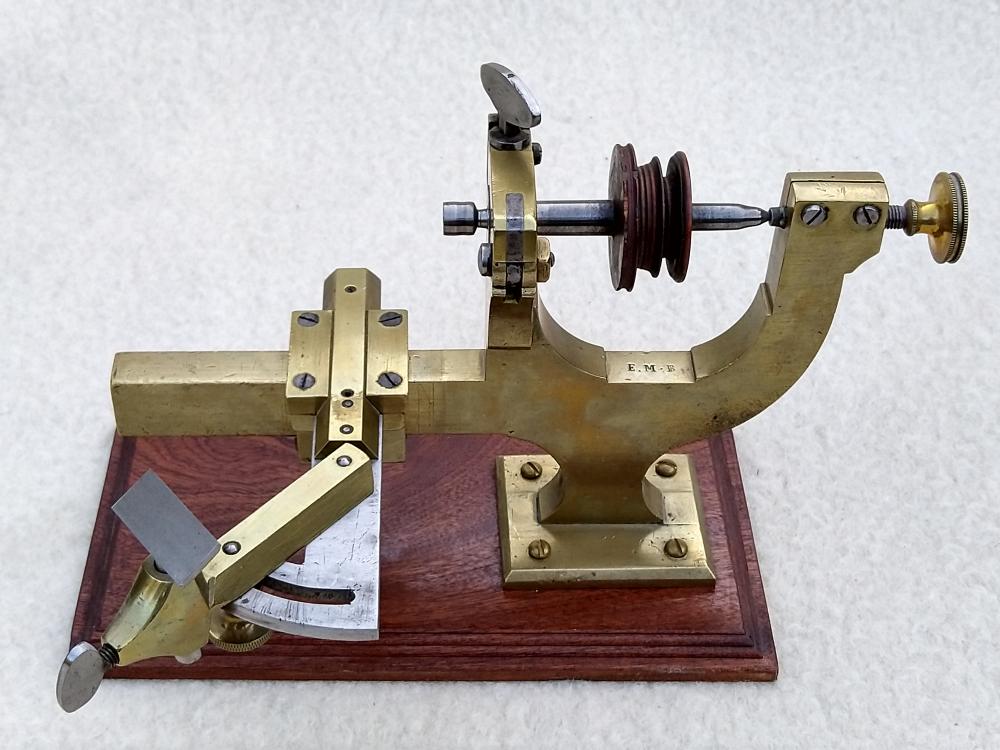

1 point

-

Thanks WW that was something i found elsewhere while looking for a method to straighten an extended pivot 3rd wheel. The device just seems like a nice flat solid wheel clamp to work some clever bending from. I did think at first it could be used as a press if the wheel could be inserted fully by modifying the inside to accommodate the pivot or arbor of the wheel. But I've noticed a bend has to over corrected to allow for its resistance to return to original shape.1 point

-

Usually when I'm looking for an American pocket watch balance staff I will look in the following Swartchild's American Balance Staffs It's a very handy publication to have because getting American pocket watch staffs is usually not a straightforward thing even if they are available. This means that while you can look up the actual staff you need is still have to measure the staff in the watch and verify that it actually is the staff you're going to order. Then when you get your new staff you have to measure that the make sure it actually is what you think it is. Then the problem with US watch company is I think they made more than one watch you didn't specify which one. Not that it really matters US watch company is listed at one time staffs may have been available but notice the reference to special order and made to sample. Which basically tells us getting a balance staff would've been difficult Well yes parts are hard to find and it's not just for vintage it's for everything. Parts Are typically only available if the company supplied parts not all companies supplied parts. If they're really popular parts conceivably they're all gone. Then yes there were some parts made by companies other than a factory but only if they were really popular. No point in making obscure parts that you're never going to sell. Which unfortunately affects all parts nobody wants to make modern parts to fit vintage watches if there is no market for those parts or not enough market to justify making those parts.1 point

-

I think the wheel straightener is an old tool from the past but would work just as well to day as long if done with great care. Stroking them back also works as I have done it before, takes time so don’t rush it. Don’t forget to check if the wheel is true between center, fit into watch without thr fork and spin the train and watch the wheel edge.1 point

-

1 point

-

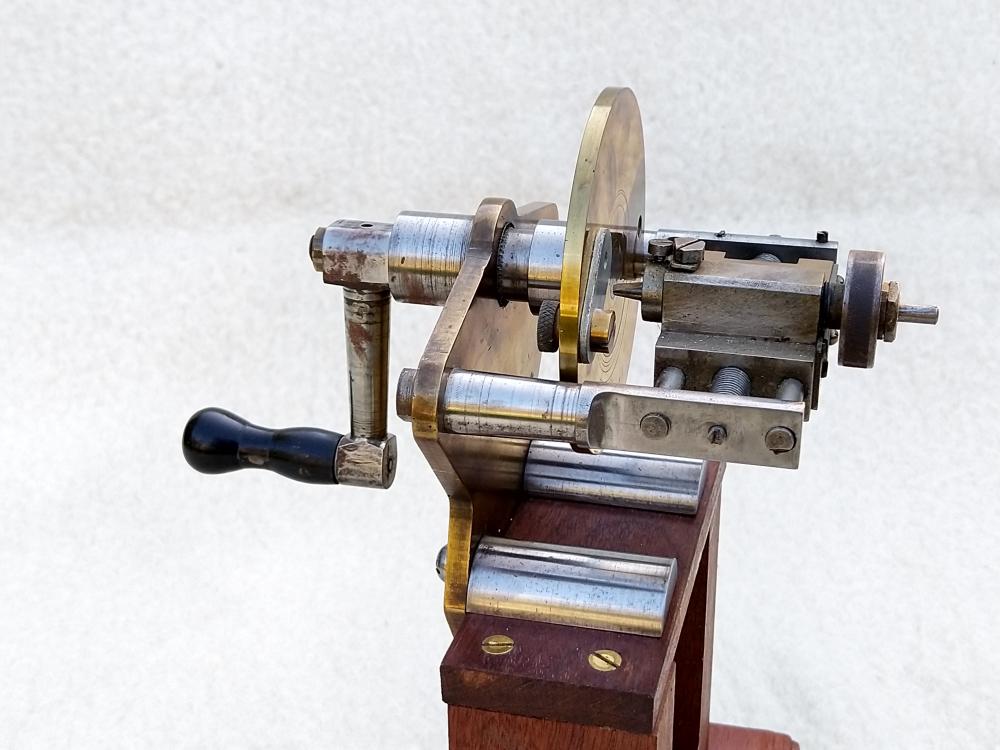

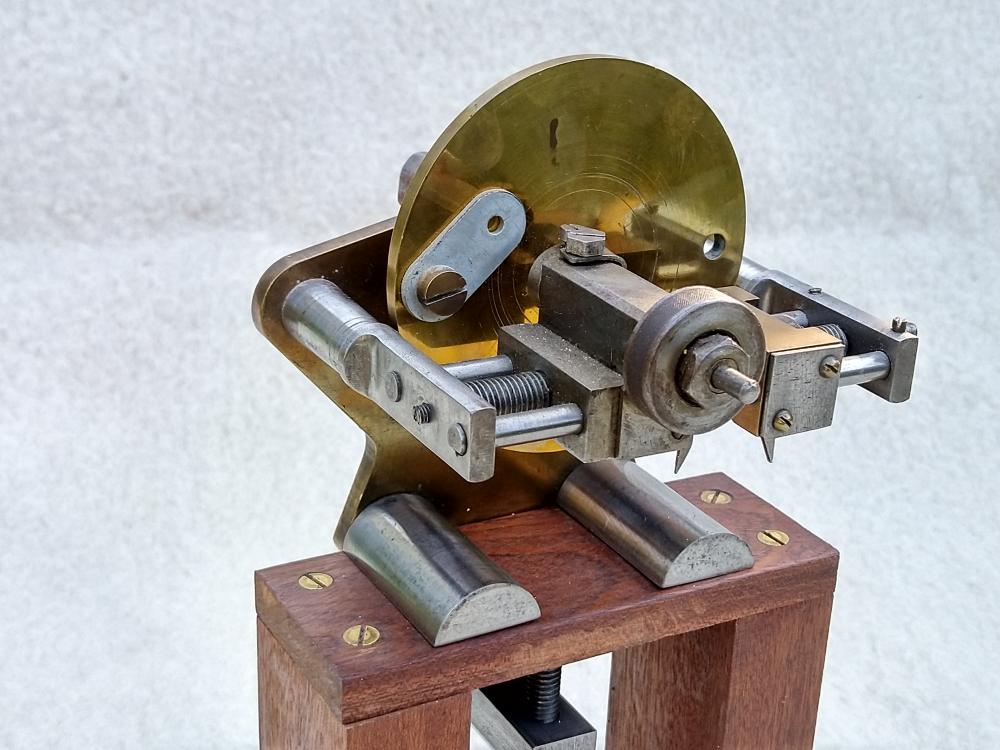

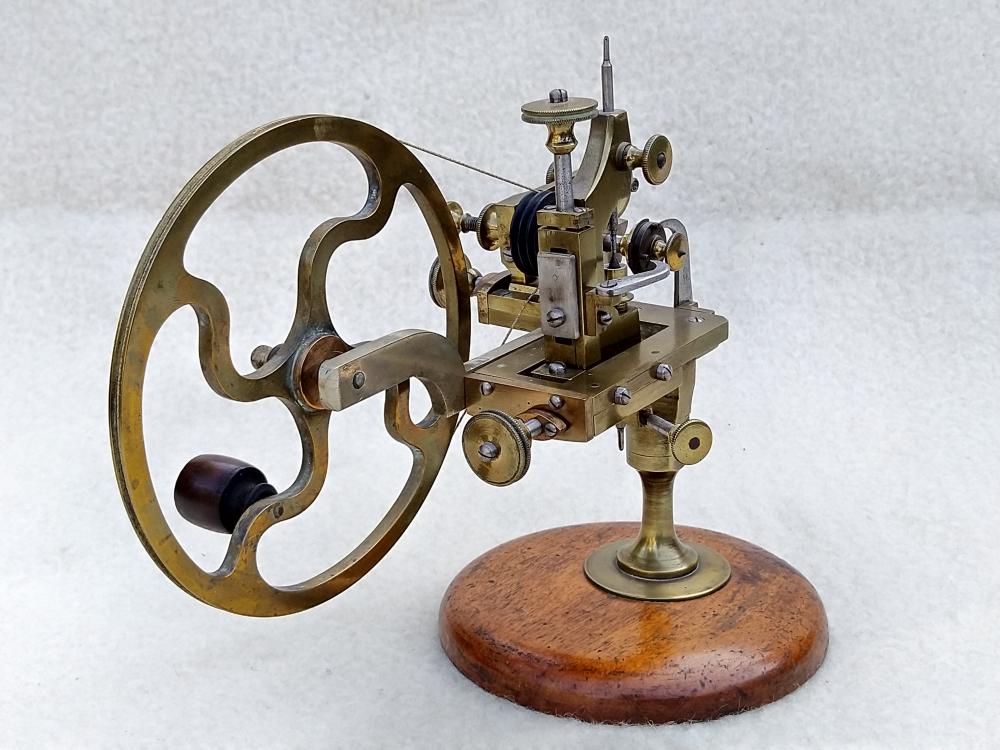

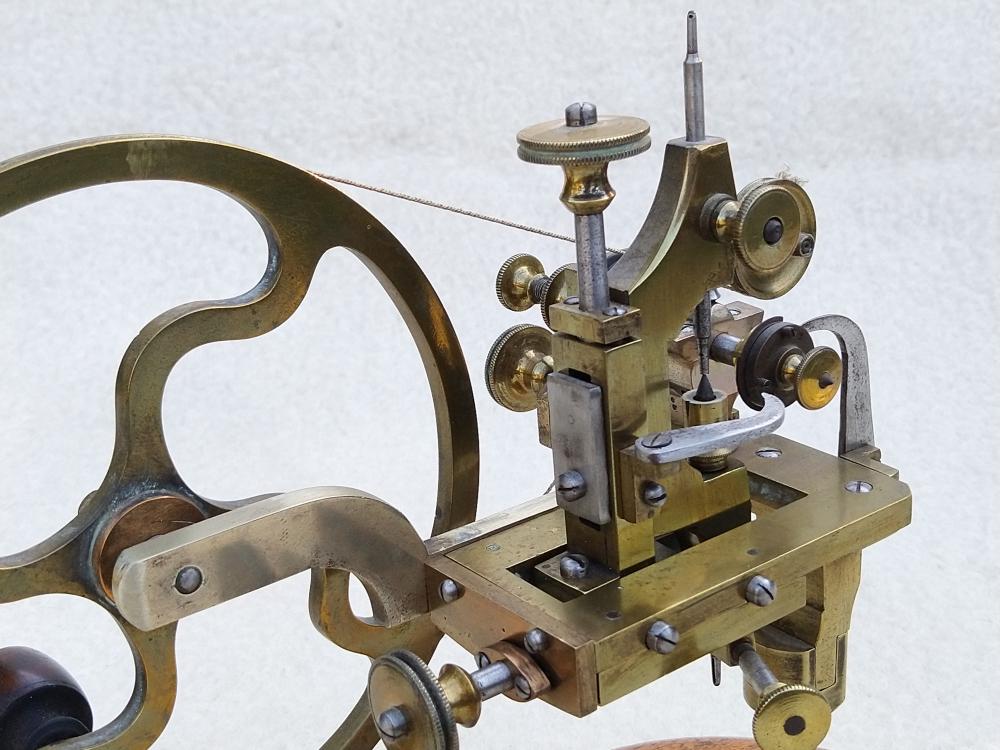

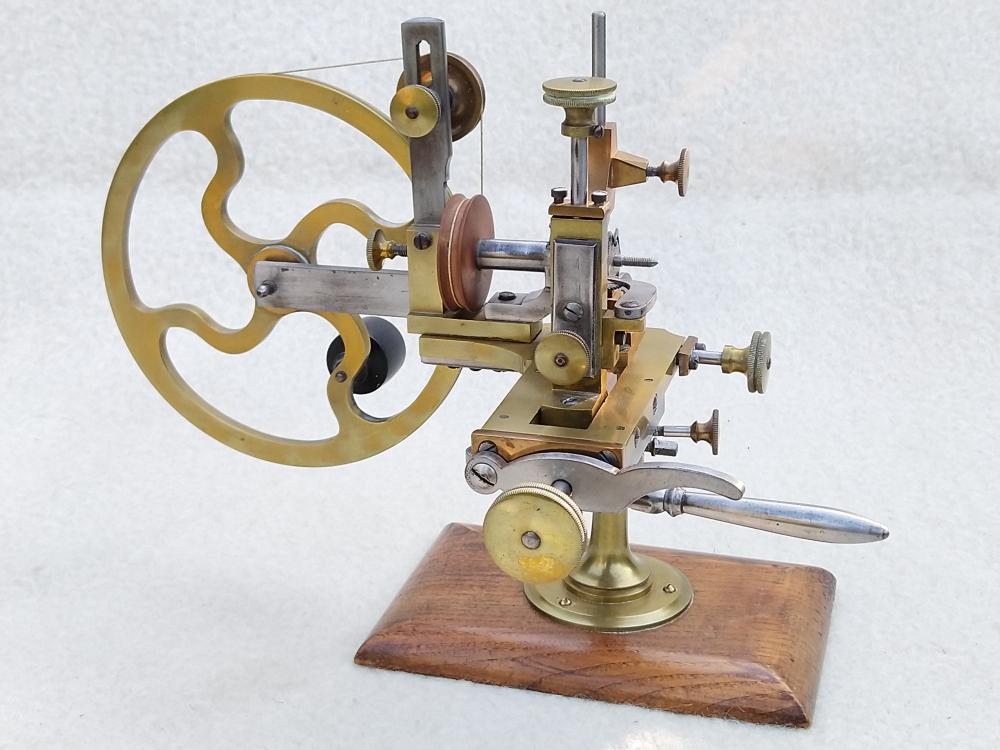

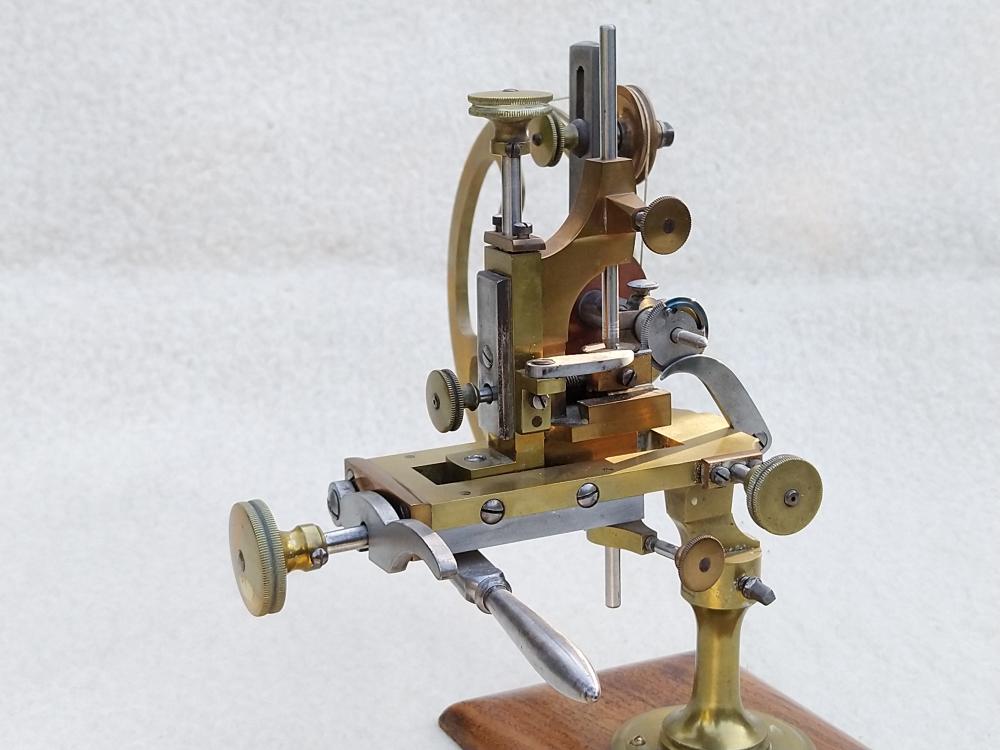

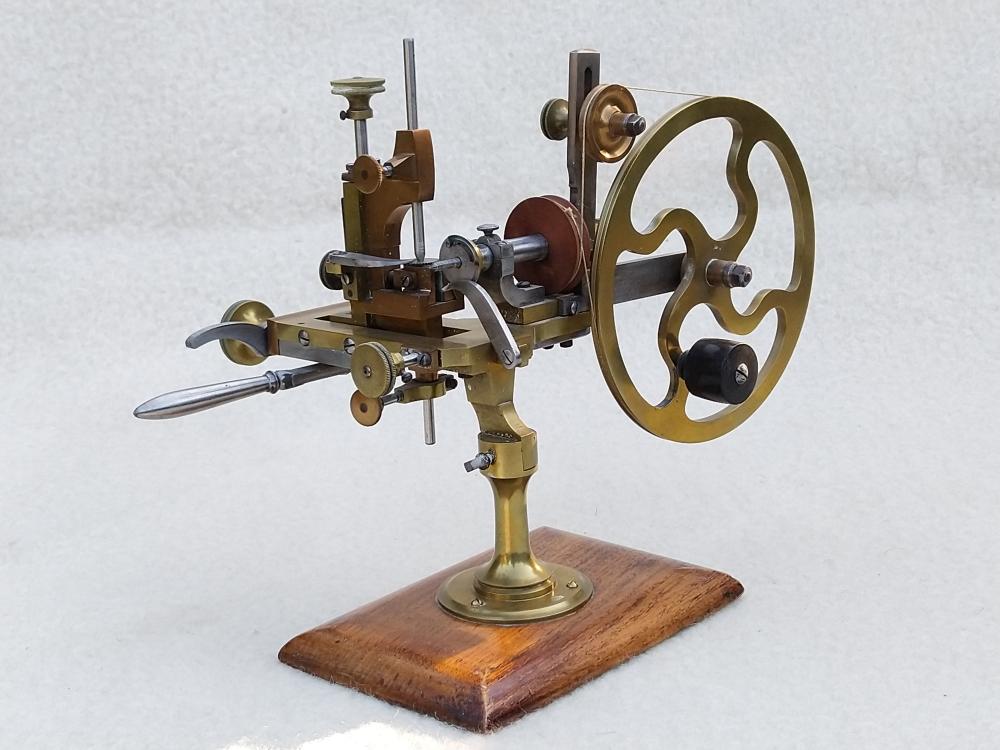

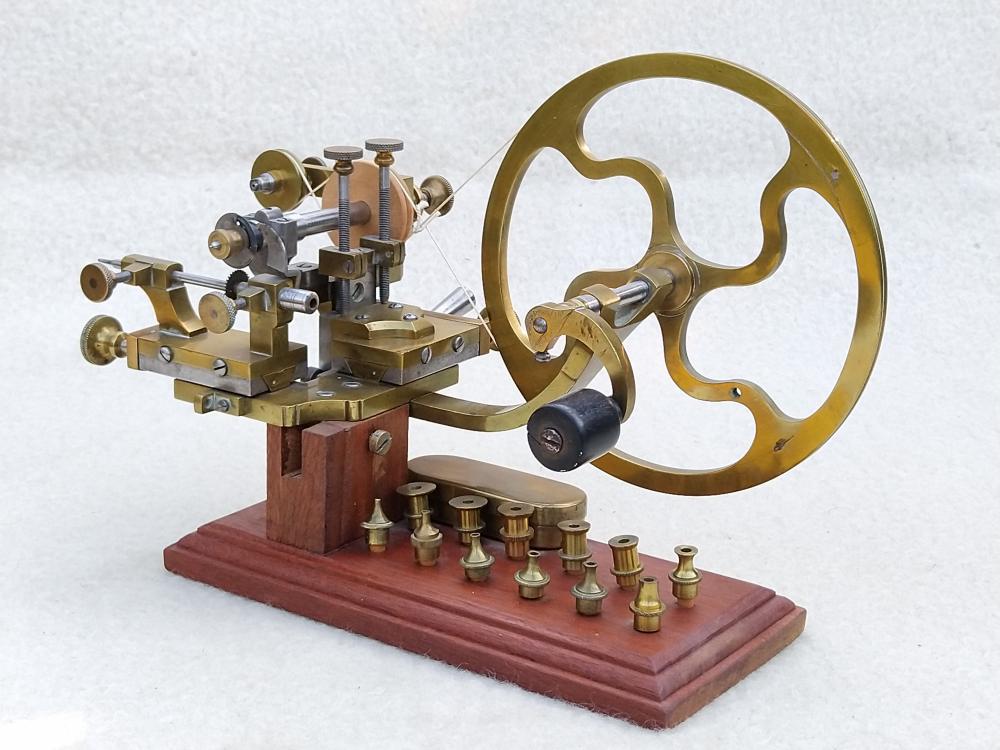

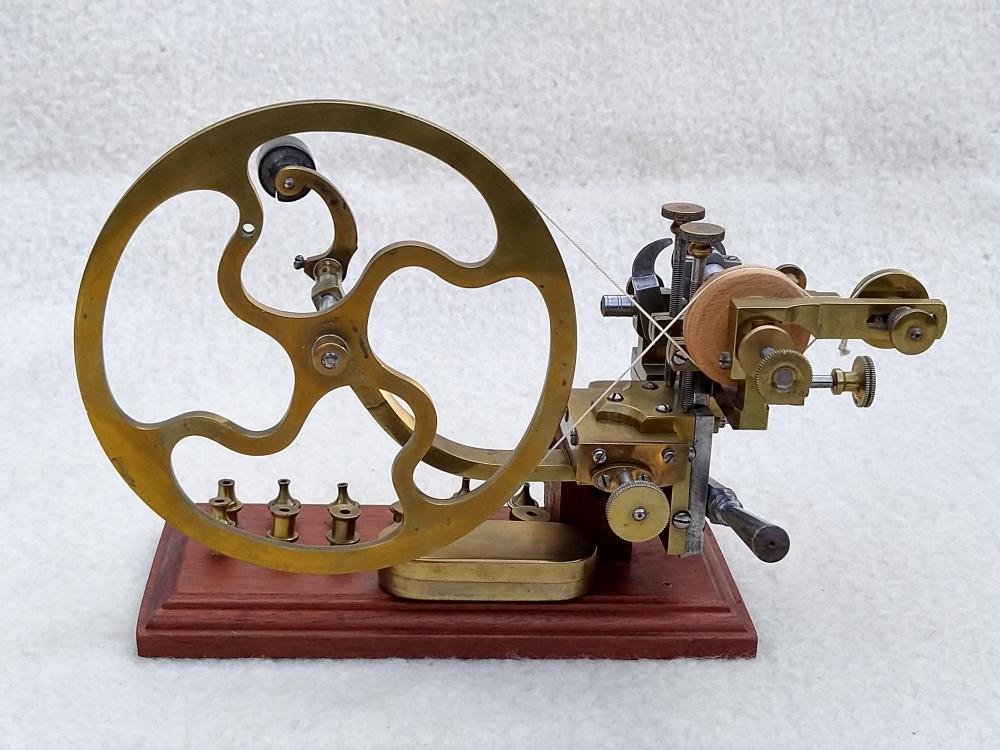

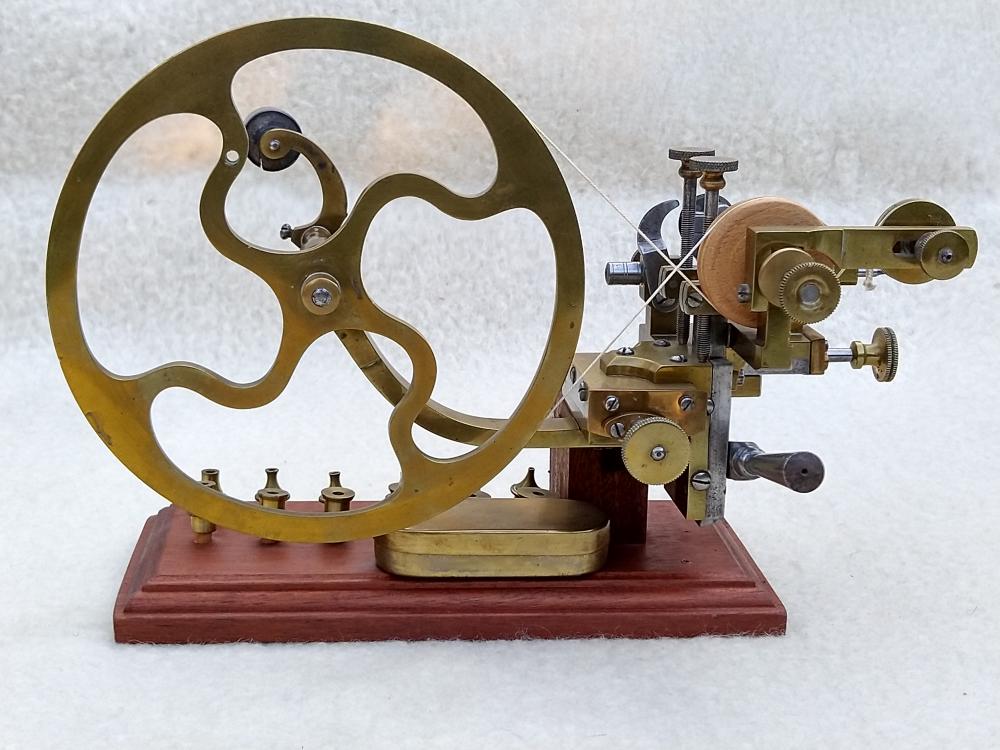

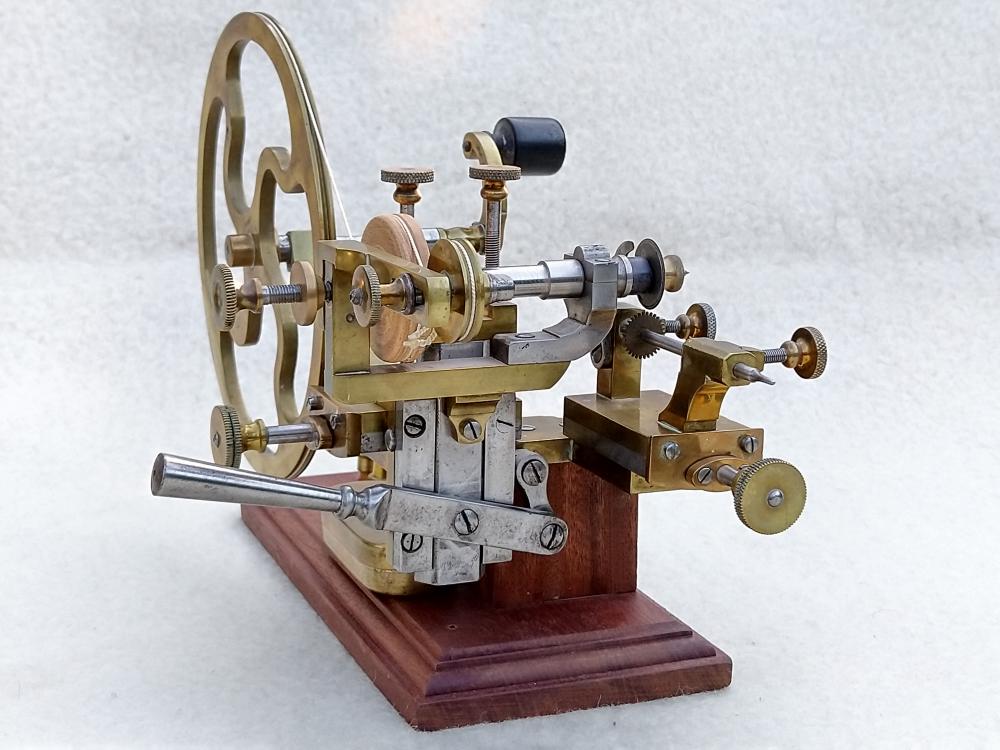

To conclude this thread, here the end result. Not as neat & slick as I had in mind and not as neat & slick as the "real-$$$-deal", but it will work. Two more jewels to be added (23 & 25), which are on their way, kindly donated by our valued WTR member @praezis It's fun and educative making this usable tool. I hadn't done jeweling before and this has given me quite some practice. I also learned more about the Seitz jeweling tool and the reamers (https://www.watchrepairtalk.com/topic/26672-hole-shape-when-using-a-seitz-jewel-setting-tool-reamer/) Sadly for the few, it won't be taken into production. Inspirational only Oh yes, I managed to screw up the stamping of the numbers, but which other number better to pick than number "13" ?1 point

-

1 point

-

You mean you haven't found/ bought a stem for your watch as of yet. Helps to know the caliber, who knows I might have one to send you.1 point

-

Escape wheel is a percision wheel which is to distribute five timely and equally strong impulses into the rest of the escapement. Lucky a new one is on its way, once installed your watch will be running happy again. Home made wooden tool and a bent escape wheel . Good luck pal.1 point

-

1 point

-

Its just a random modern quartz movement for size comparison. I think its a Ronda, as I have a pile of various new old stock Ronda movements I bought in a job lot. Whatever it is, its similar in size to the one in my Sekonda, but the Sekonda is actually slightly larger (but considerably thinner) than the "Verity". As I say, its only purpose is to show the relative size difference between the 1970s ESAQuartz 1501 - (ESA 9183 quartz movement) and a 2020s quartz movement. I put the "Verity" to one side as I wanted to take a look at the Peseux 320 in the little Catorex pocket watch, and who can blame me. It seems it rather relished the attention as it is now ticking away nicely, and looking almost brand new. I'll let it run for 24hrs and then set it as close to 0 sec/day as I can. The chain I put it on is a somewhat utilitarian, so I'll need to keep an eye out for something a little more refined. Its mainly there to lessen the chance of me accidentally launching the watch across the room while I'm carrying it about for testing purposes.1 point

-

Neither made from gold, nor baked bean cans, it showed up today and is a very attractive, high quality, very well made, Peseux 320 based stainless steel cased little watch. As the "least expensive Catorex on the web", it was certainly worth the gamble. I would guess it is from the sixties or early seventies, as it has a fixed stud, rather than the later moveable one. I'll post pictured once I have it cleaned and serviced. Here are a couple of teasers just in case I forget to post the finished result.1 point

-

Think it's this one: https://www.aliexpress.com/item/1005001670367765.html?spm=a2g0o.productlist.main.3.2dc850b67RQSnK&algo_pvid=2f946012-60ff-49c9-b4a7-76e0eb3d45a7&algo_exp_id=2f946012-60ff-49c9-b4a7-76e0eb3d45a7-1&pdp_npi=3%40dis!GBP!39.89!30.32!!!!!%40211bf3f816853405030362238d07dd!12000029482496908!sea!UK!4321097666&curPageLogUid=n7ynCOcv20QC1 point

-

I revisited this as the crown action wasn't right (too stiff to select the time setting position). Basically the lever was pushing too hard against the balance rim. I suspect that in time some damage could easily be caused to the balance pivots. I shortened the lever as shown filing away the wider bit at the end and then rounding it smooth (like a lolly stick). Lever is shown in the crown pushed in position. So much better now and the crown action is back to how it was. I can only conclude that ETA 2789 balance diameter is a bit larger than that of the ETA 2824-2. I don't have one to check but it sounds feasible due to the higher beat rate of ETA 2824-2. Steve.1 point