Leaderboard

Popular Content

Showing content with the highest reputation on 06/09/23 in all areas

-

That is truly awful, especially the plastic bit that looks like a modified cable retainer from a mains plug.2 points

-

2 points

-

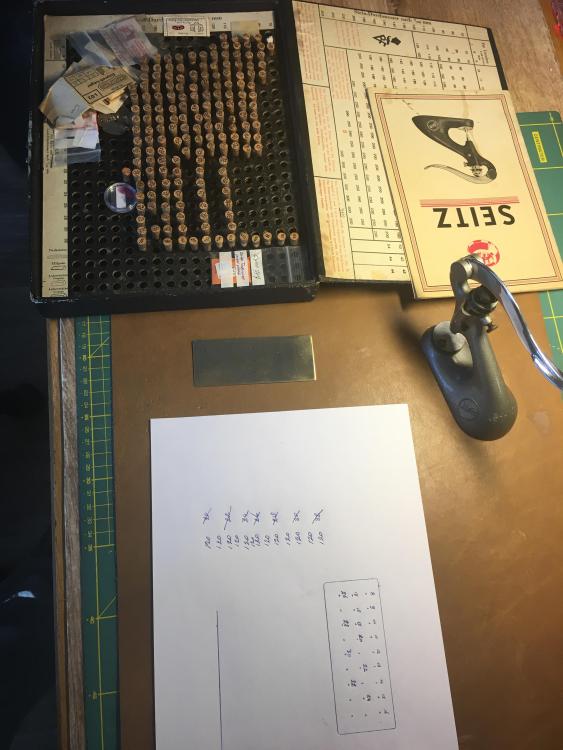

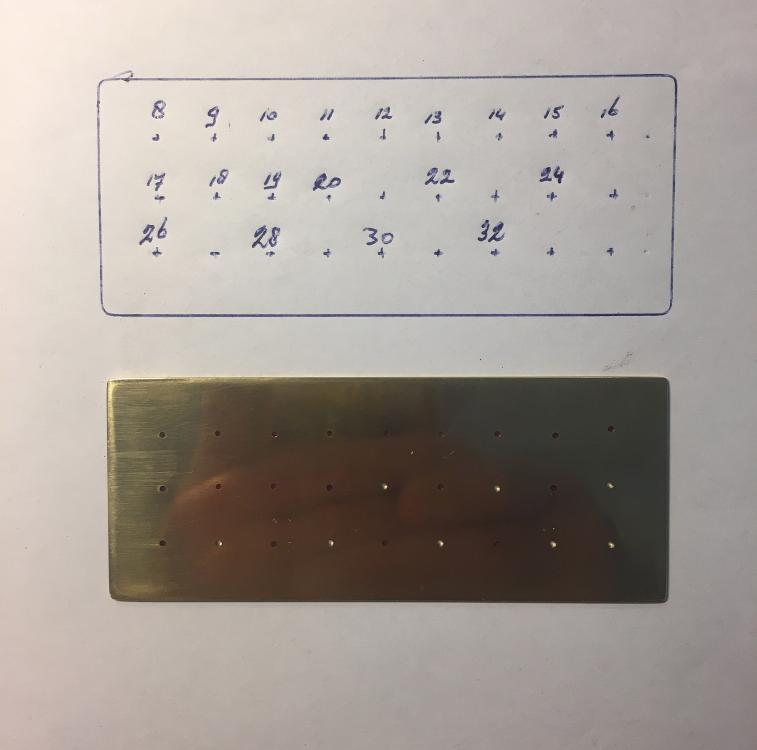

In order to start learning my Jacot tool and select the right size bed, I wished for a Seitz jeweled pivot gauge. Sadly, the prices asked for these gauges are astronomical. Currently on eBay from €350 and way upwards to over €500 !! Wild West prices In my Seitz jewel-box I had a "complete" range of jewels 8,9,10,11,12,13,14,15,16,17,18 & 19 in the OD size of 110 and 20,22,24,26,28, 30 & 32 in the OD size of 120. Marked 27x spots (1x1cm distance) on 10cmx10cm, 1mm thick copper-sheet and drilled them out with a 1mm drill. The holes for the jewel sizes 8-19 were reamed to 109 and the other holes reamed to 119. Cut the "to be jewel-gauge" at the size of 10x4cm, polished it and inserted the jewels; Left the holes open for the "missing" jewels; 21, 23, 25, 27, 29 & 31 and there are two more slots empty for 33 & 34; Whether I'll ever need these bigger sizes? They weren't in the Seitz jewel-box, perhaps for a reason? If I ever stumble over these sizes, I can insert them, the holes are already there. Those "missing" bigger sizes are also easy & safely to measure with a micrometer or gauge-caliper. For now, I have a jeweled pivot-gauge with a full range from 8/100 to 20/100 and from 22/100 to 32/100 in steps of 2/100, I think enough for making a start on my Jacot-tool Next, to finish this project off, is to find some small metal-stamps to number the jewel sizes.......2 points

-

I found one dip to be utterly useless. I soon when back to Ronsonol lighter fluid.2 points

-

Neither made from gold, nor baked bean cans, it showed up today and is a very attractive, high quality, very well made, Peseux 320 based stainless steel cased little watch. As the "least expensive Catorex on the web", it was certainly worth the gamble. I would guess it is from the sixties or early seventies, as it has a fixed stud, rather than the later moveable one. I'll post pictured once I have it cleaned and serviced. Here are a couple of teasers just in case I forget to post the finished result.2 points

-

I did something better yet, I updated my report and included a link to this thread!1 point

-

Tradera doesn't swich pics to show the movement, I guess its a ST96. Made in India.1 point

-

Haha, i used to do that when i spotted fake rolexes partly hidden in the corners of joblot watches. I guess the seller would hope some poor soul would think he had discovered a hidden gem and bid up. I suggested i was part of rolex's elite fraud squad and would be visiting the address listed by the end of the day, the listing promptly disappeared1 point

-

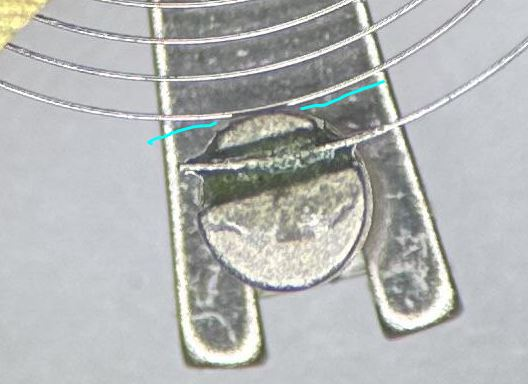

As nice as your picture isn't it does show something that's a problem it would be nice to have a picture of the balance wheel in the watch looking straight down so we can see if they hairspring looks like it's centered. Because right now it does not look like it's centered but that could be because the balance wheel is leaning as it's out of the watch. In a case here is an image from your image and notice a problem it looks like they hairspring is touching the stud? So when you put it back in the watch look carefully is the hairspring actually touching or not and when the watches running even if it's not touching when it stopped it may be close enough that when the hairspring opens up it will touch the stud. Then this is where it's nice to have pictures of your watch so we can give you helpful suggestions fortunately I found another picture online. I notice your stud has a screw on top I assume when you loosen the screw the stud will rotate? With no power on the watch providing they hairspring actually is touching the backside of the stud you can loosen the stud and see if you bump they hairspring back into being centered in other words you have to move the hairspring away from the backside of the stud like in the picture where you notice the outer terminal curve is much greater than what you have as a guess caused by your stud not being quite in the right place I suspect when you loosen the screw up with no power of probably just align itself where it's supposed to be. Then yes the words to describe this totally sucks versus if you could just see somebody do it. That's why I'm giving an image that's more of what you should see versus what we see with yours as soon as you get us a picture in the watch of the balance wheel then the definition a centered is if you look at your image you look at the coil spacing near the stud and look at the coil spacing on the other side of notice on the other side they are much closer together. I think once all the spacing is even you should be away from the stud the watch should be fine.1 point

-

1 point

-

Whenever you're telling somebody that you think their watches a fake you should list out the reasons why. Like the movement in this watch is total crap Although I probably change the wording of it's not of the same quality normally found in one of these watches. Or the 17 rubies On the dial looks like it's missing a letter. So you just tell somebody the reasons you think it's fake. Then this gets much harder for things like a Rolex watch because sometimes just swapping a dial could make a huge difference etiquette still be a real Rolex watch and still be a counterfeit. This is considerably different it just doesn't look for a nice. Then typically if anyone asks whether their watches fake typically it is fake this happens where I work people find watches get watches are paid with watches and want to know if they're legit and so far they've always been not legitimate watch us I'm sure someday someone will come in with a is this real and maybe it's going to be real but it hasn't happened yet1 point

-

Just so were all on the same page here are watch really has two ways a regulating sort of. There is the micro adjustment with the screw. You put that in the center position then the arm that actually does the regulating can be manually moved. Then when you really close at then you can play with the micro adjustment otherwise as you found it has very limited range if the other arm is not where it's supposed to be. Then which I believe I set up above floating stud can be moved independent in all three are layered together so to a certain degree all three will move each other.1 point

-

Thats awful Watchie, everything about it is screaming Mumbai to me, besides the dial the hands look very standard from india. Even if the seller isn't listed as being from India then someone has bought it from india and wants to offload it. Haha i stopped at the first picture then decided to go back for another laugh, there is plastic inside the movement.1 point

-

1 point

-

1 point

-

https://www.instructables.com/Mechanical-Apple-Watch-From-Real-E-Waste-Apple-Wat/ You might enjoy this.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. I wouldn't advise anyone to start on a Longines watch. You need considerable experience first.1 point

-

Always nice to have pictures of the item you're talking about just So that we are all on the same page here. Then nice watch is this going to be the first watch you service And is this the one you'd like to remove the back? Then welcome to the group you've come to the right place You forgot the mention the availability of parts will be a bit challenging for this one. But it depends upon how a person learns some people need painful lessons I wasn't going to bring that up I thought I would be encouraging and helpful and ignore the fact that this is an extremely expensive watch not the best for learning on unless somebody likes painful lessons.1 point

-

Please begin your journey on a different less expensive watch.1 point

-

Sounds exactly like mine. Most likely due to the clock falling off the wall hook. I managed to reshape the teeth of the contrate wheel with the blade of a screwdriver that was reshaped to fit the space between the teeth. But you can get a replacement wheel from the same seller in Ukraine.1 point

-

An attractive movement. The graining on plates gives it a retro modern look consistent with the case and dial…1 point

-

Broken balance staff pivot, downwards tilted pallet fork jewel failing to lock the escape-wheel, broken pivot on bottom escape wheel pinion and some damage to the tops of the contrite-wheel teeth (which are hopefully repairable). For the rest; perfect and very nice ! No real wear and I'm the first one in since the clock left the factory1 point

-

…copied in quantity they could be plates for the buttons in very small elevators?1 point

-

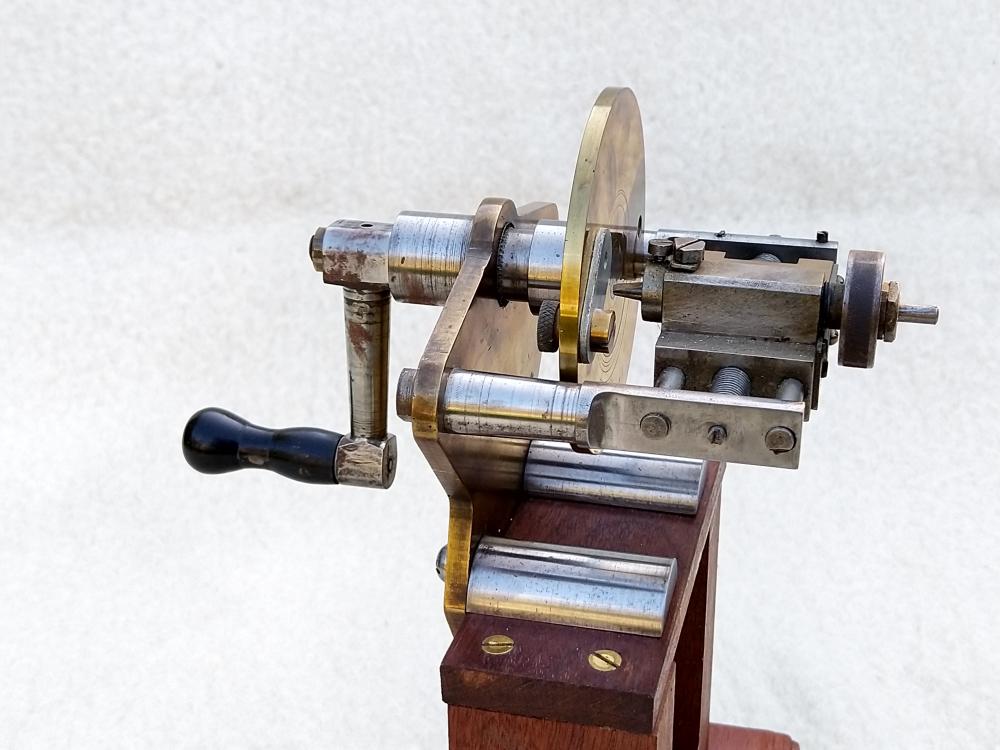

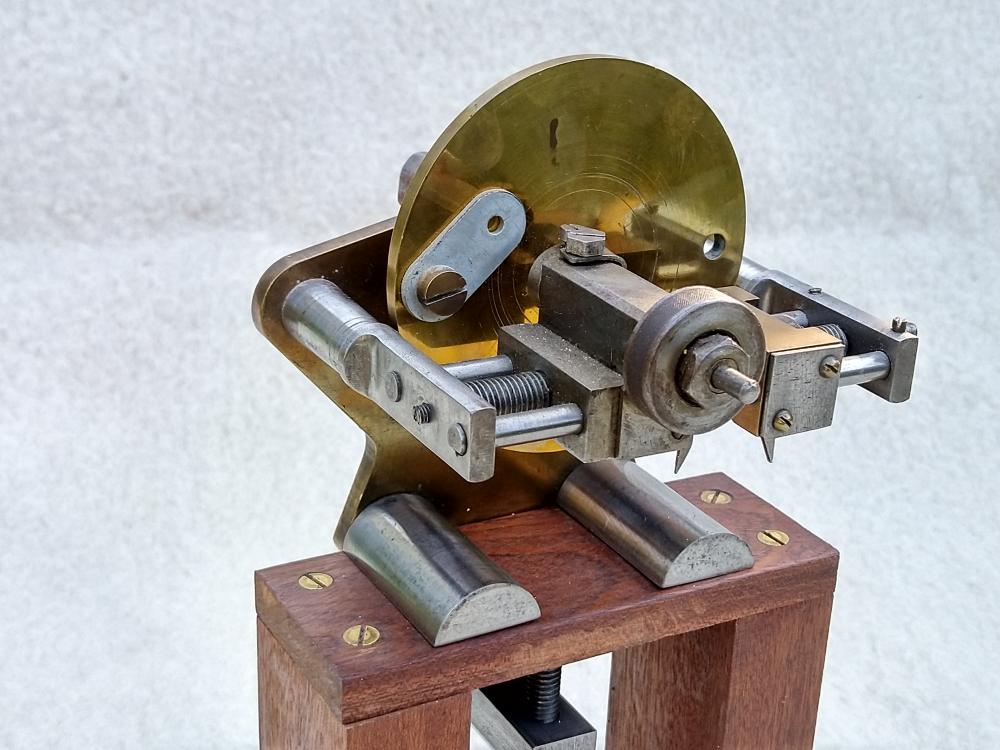

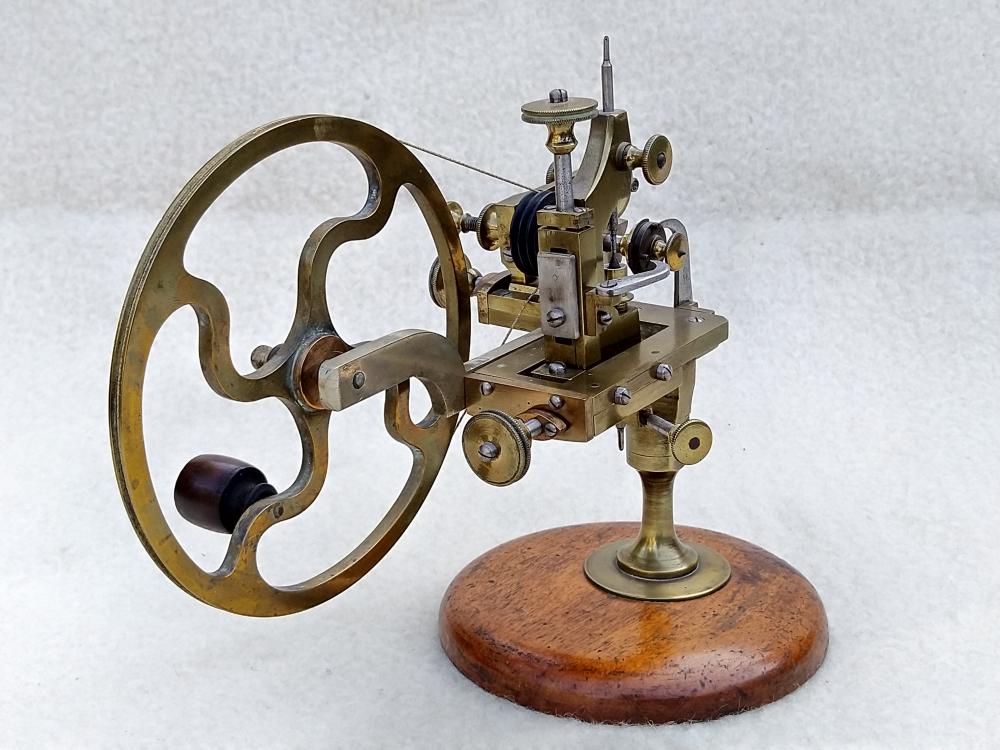

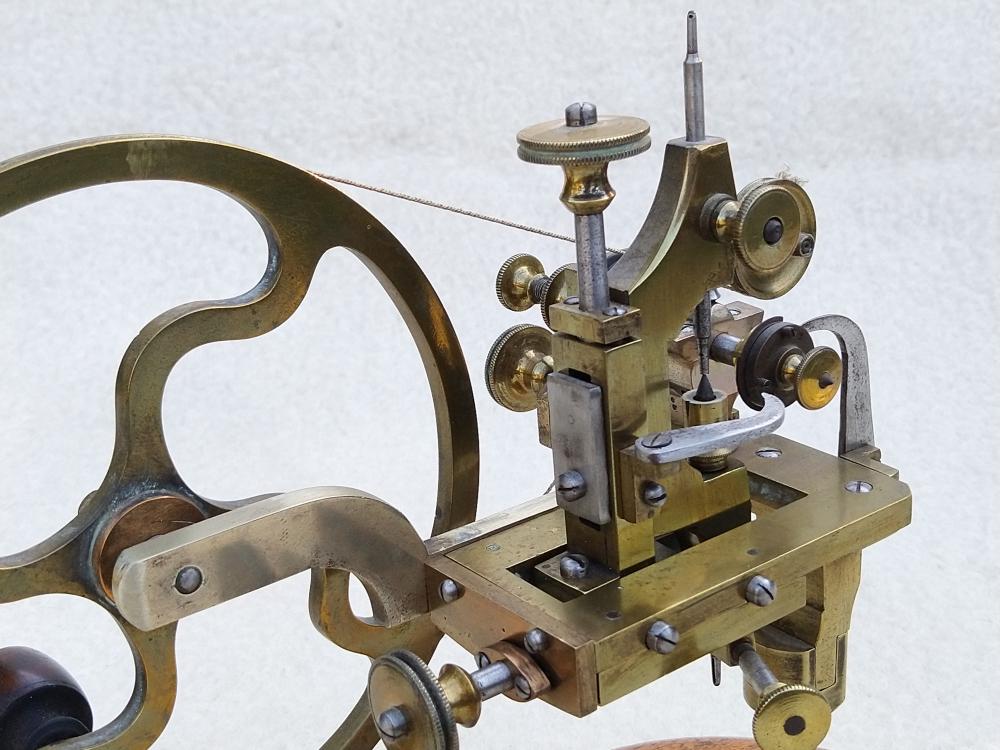

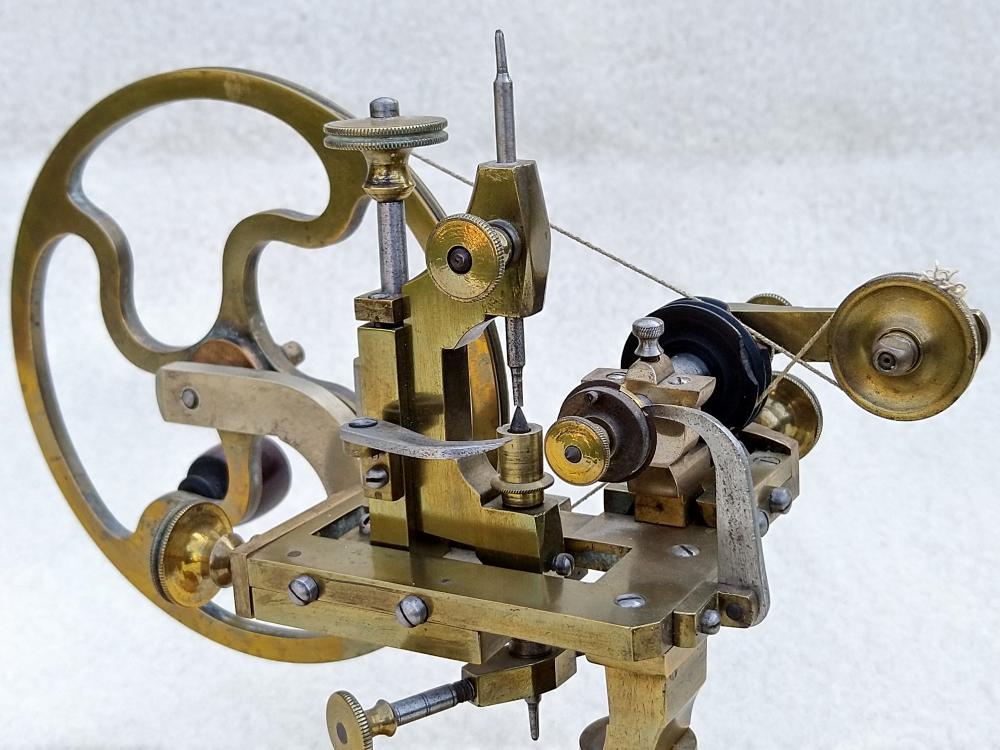

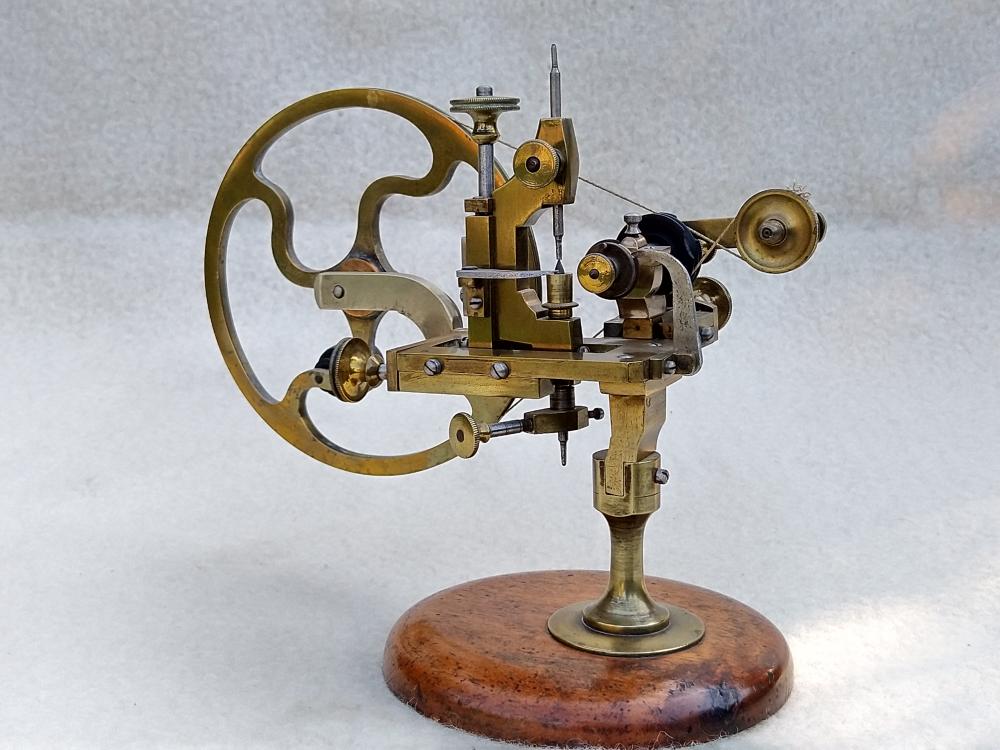

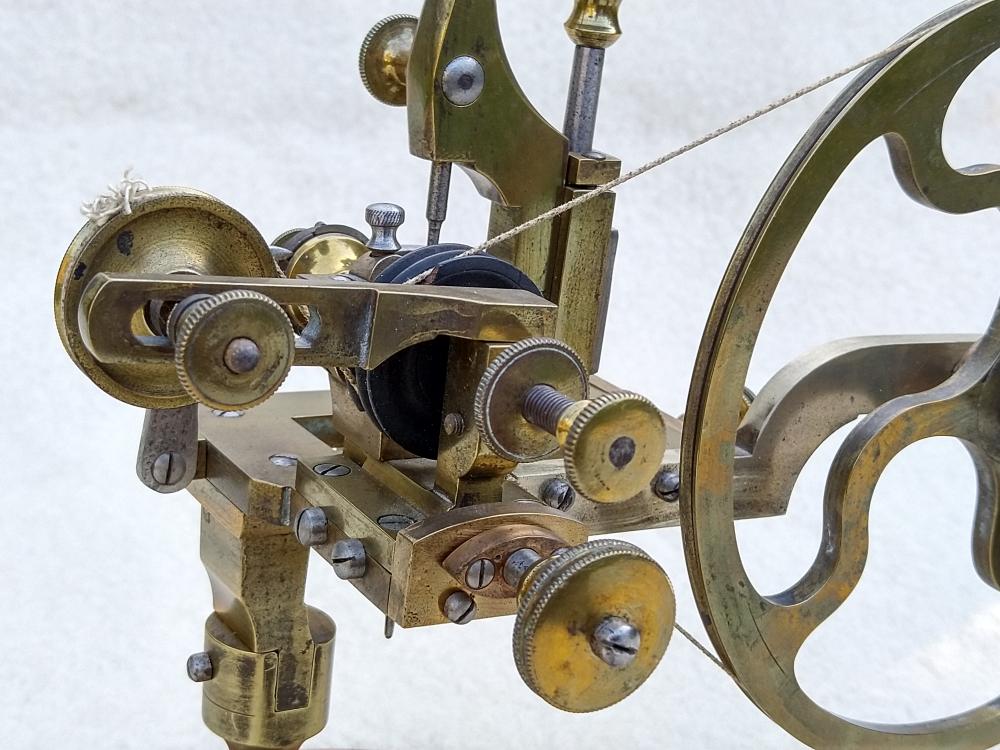

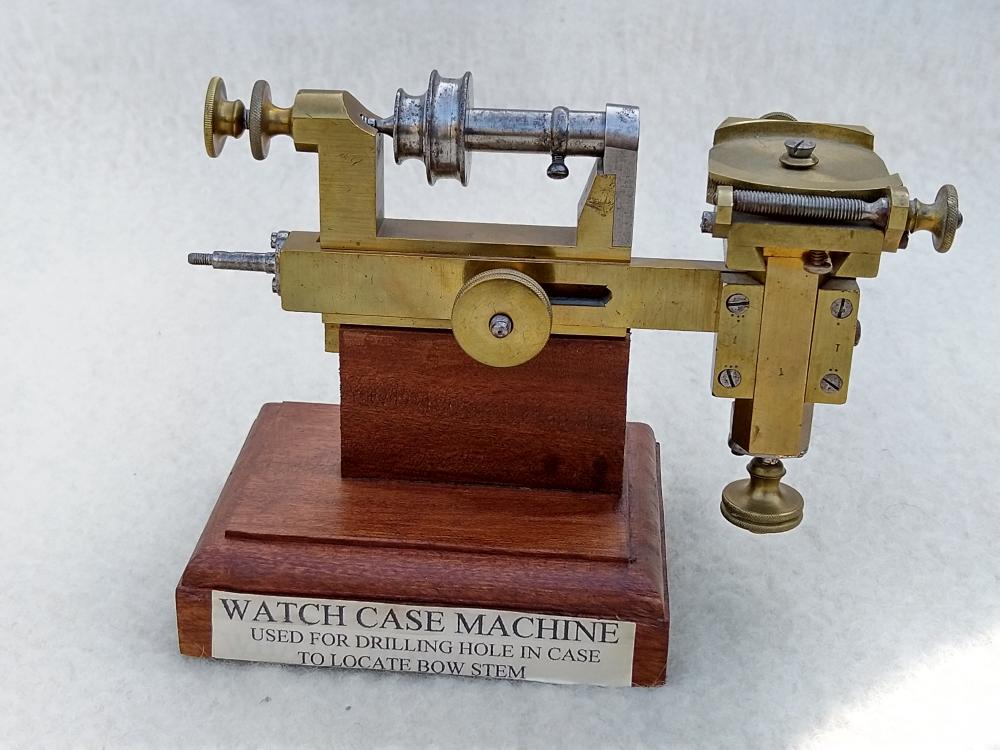

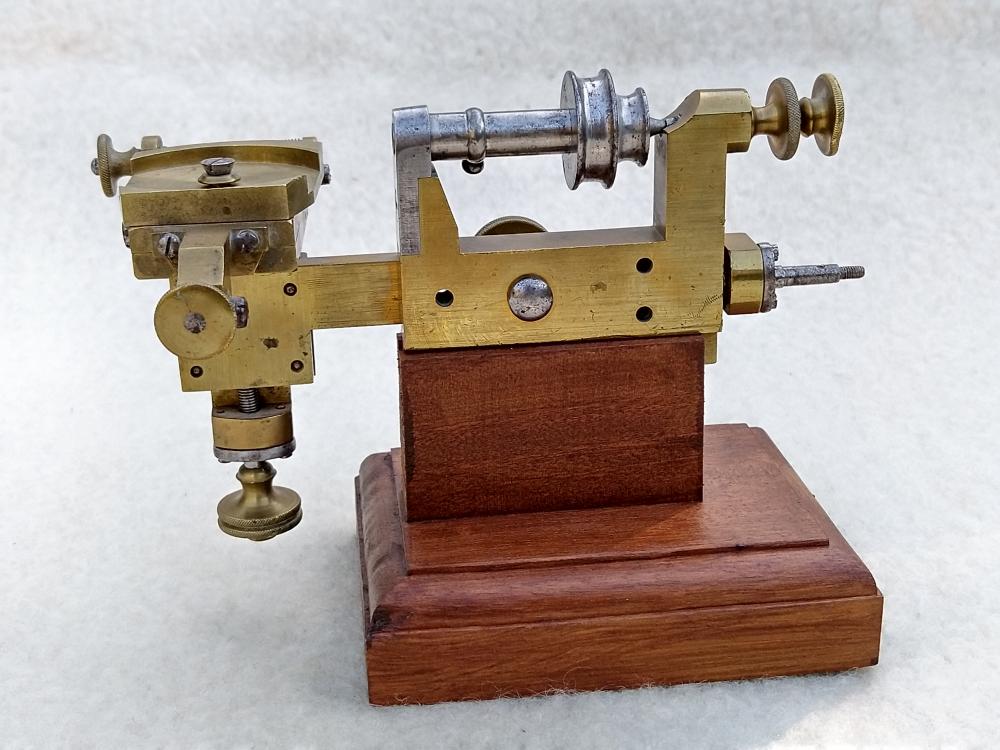

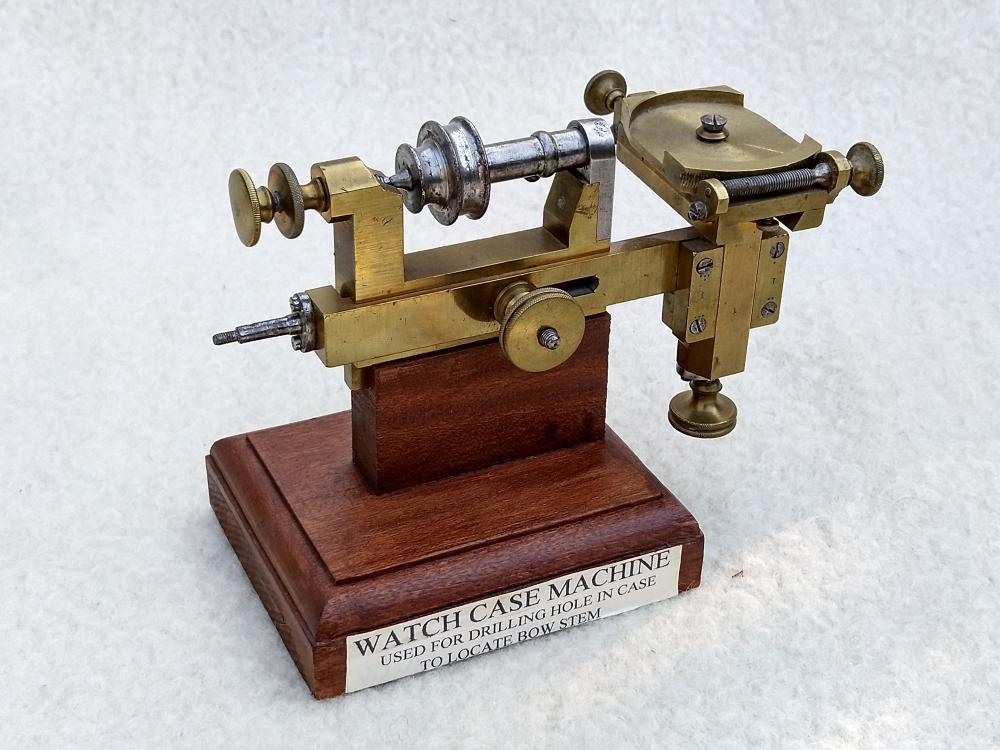

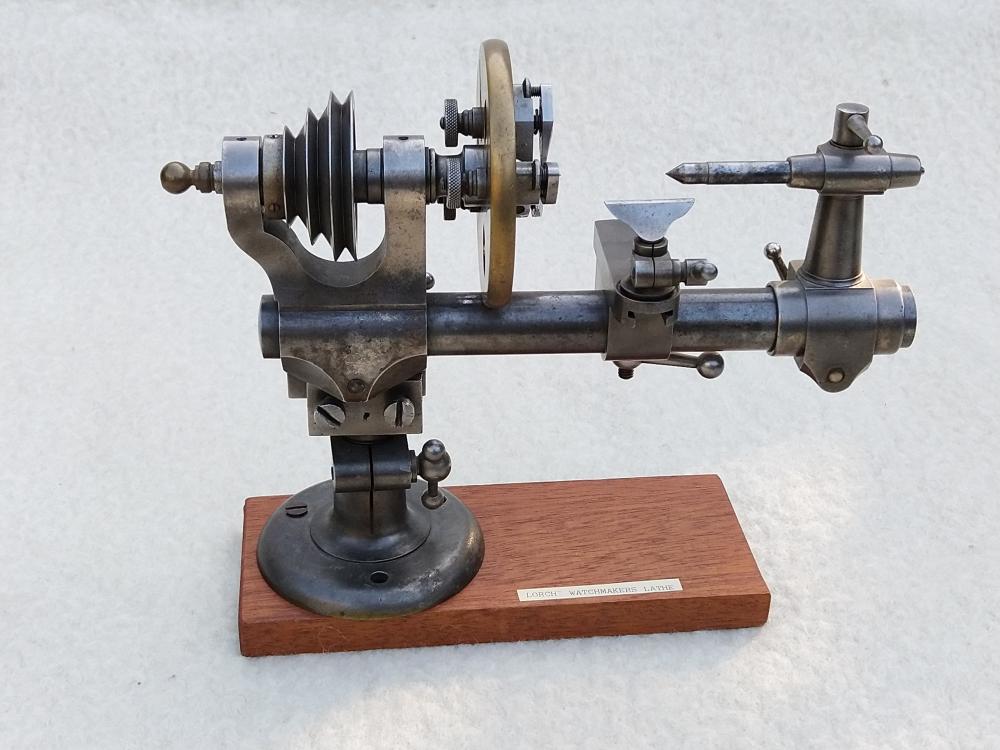

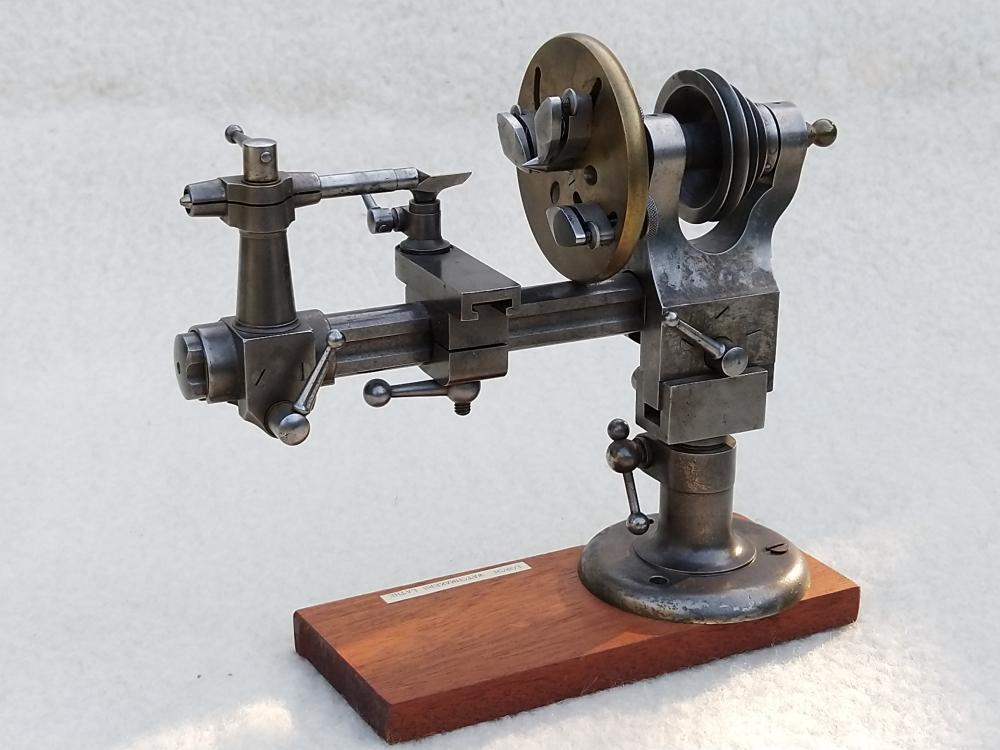

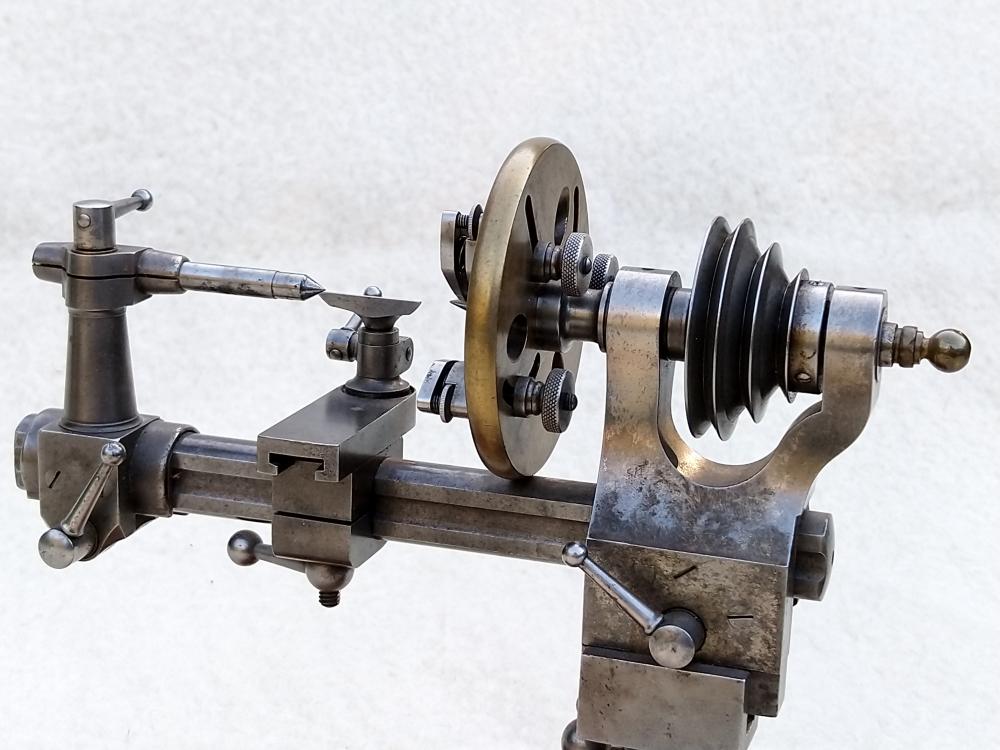

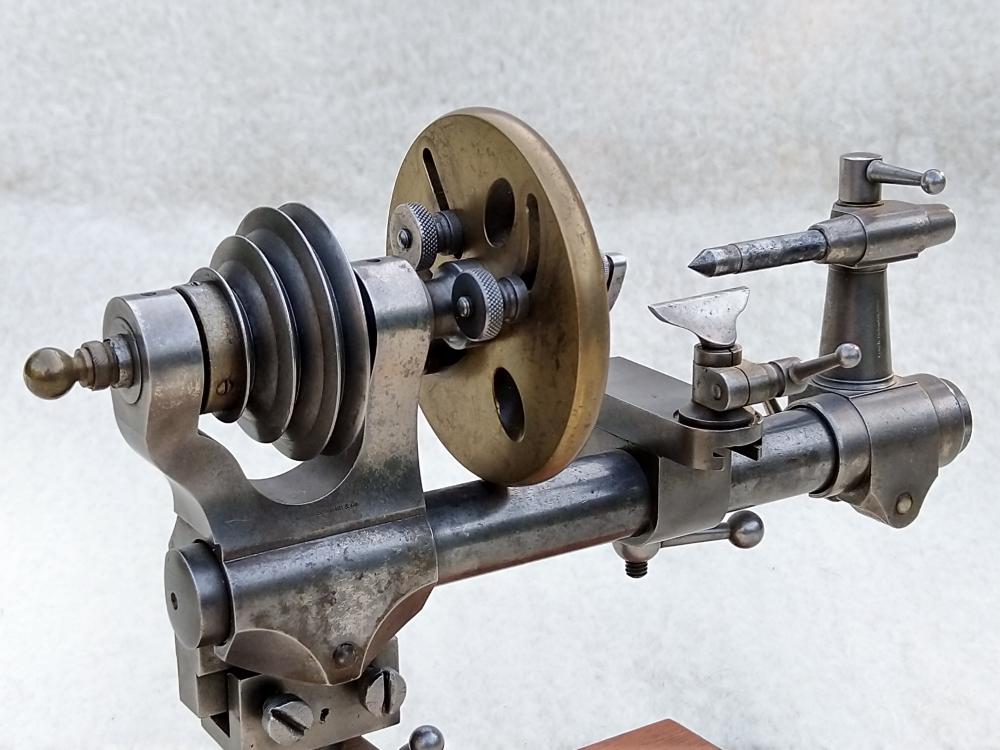

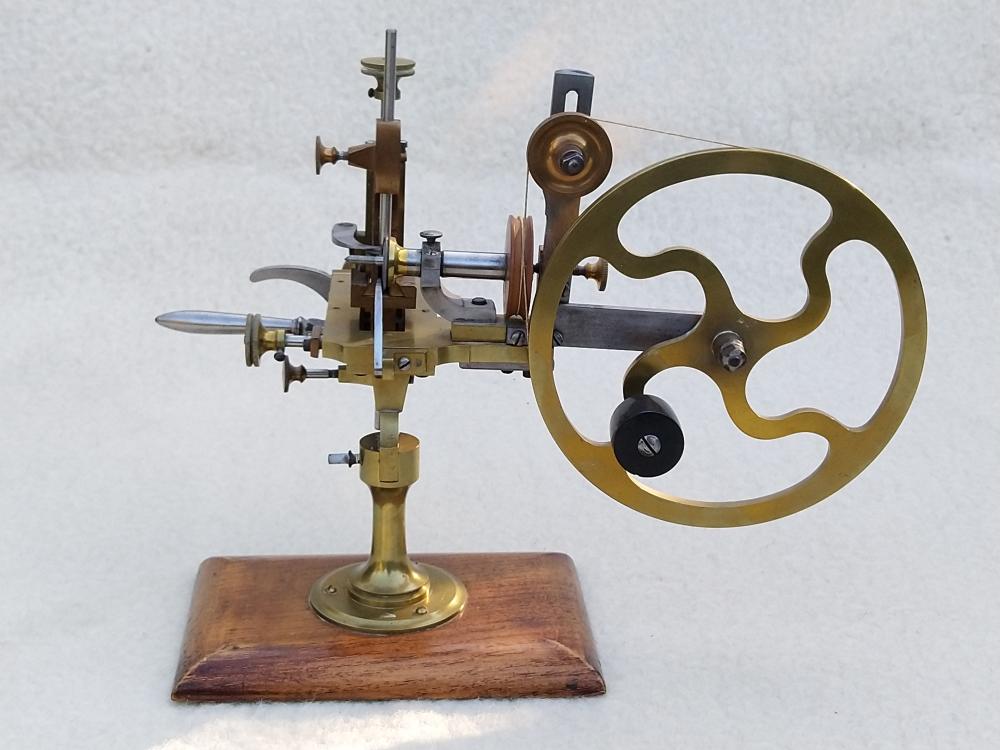

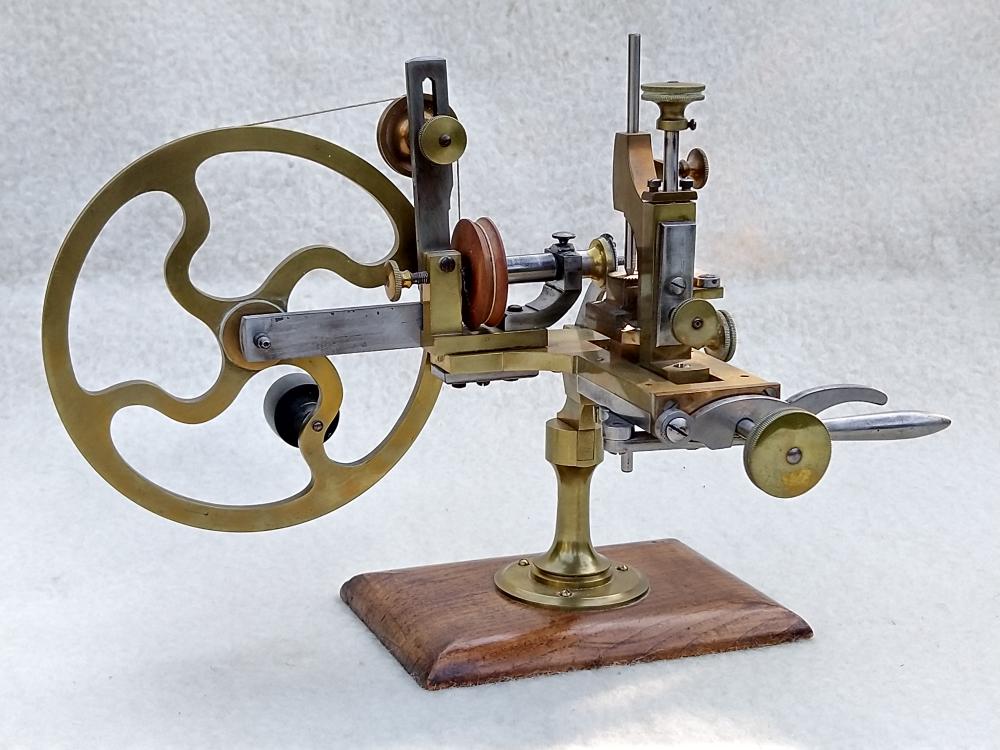

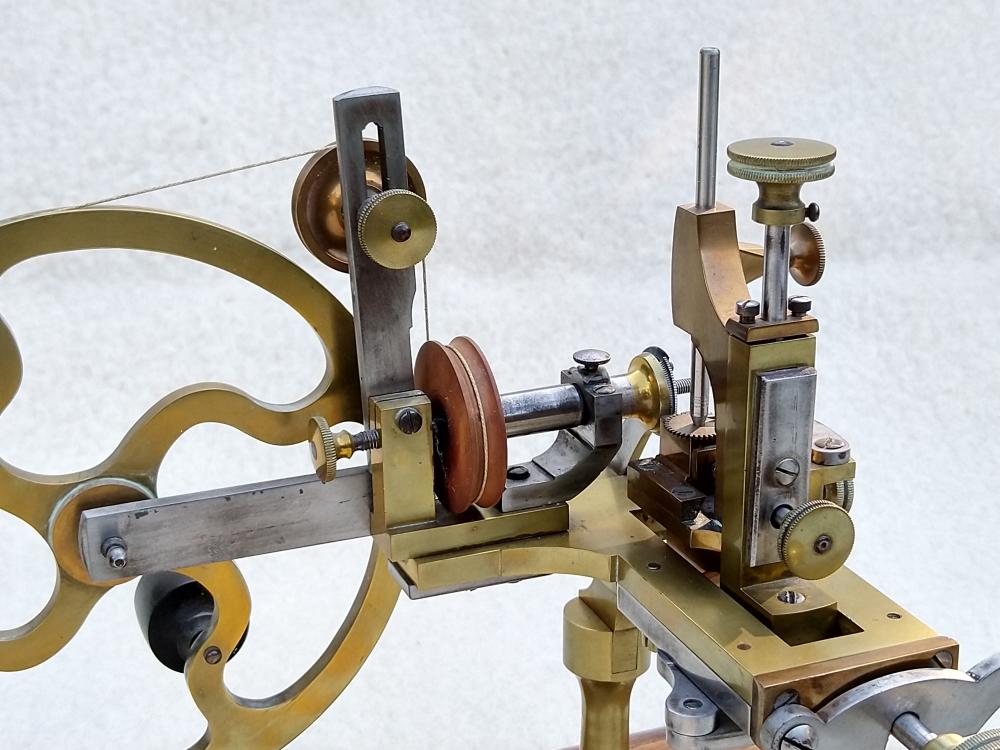

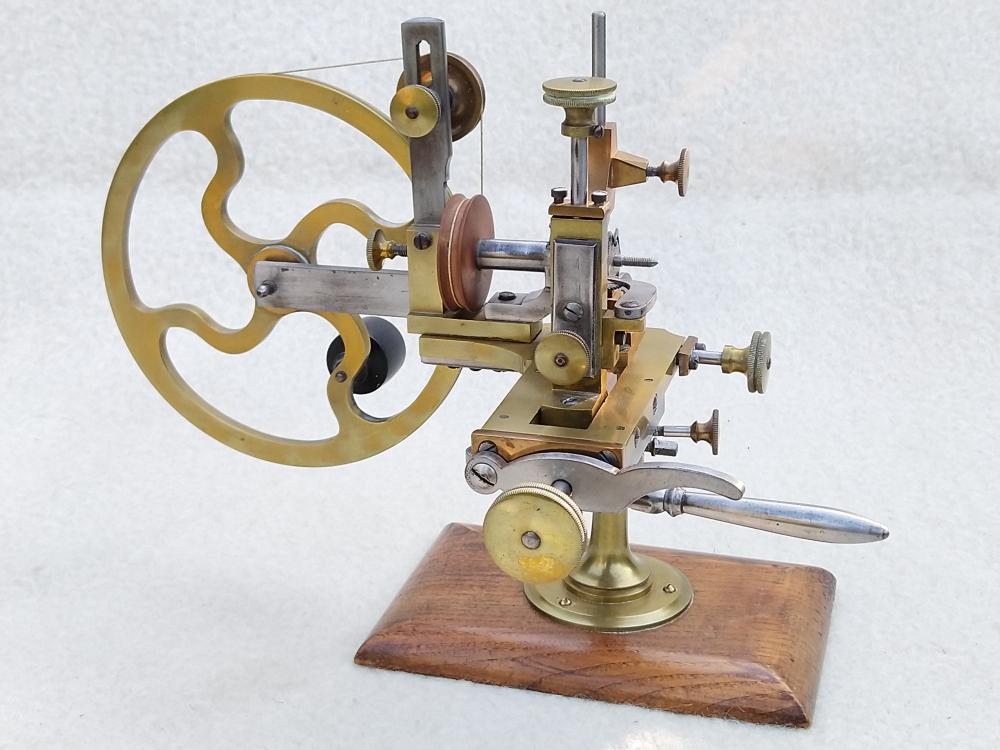

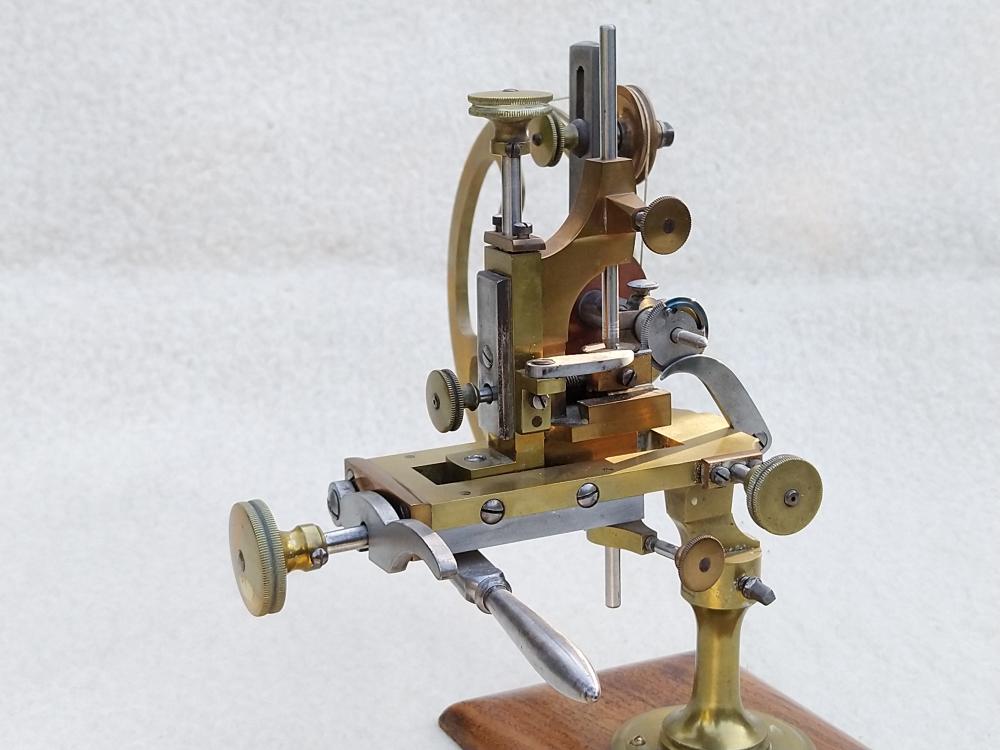

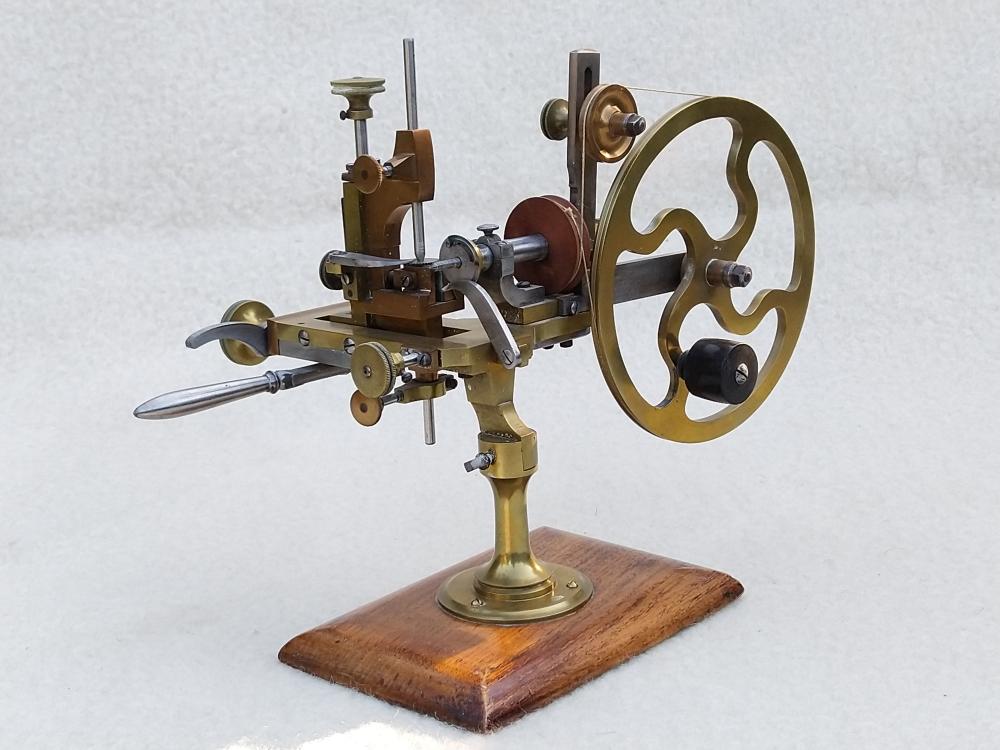

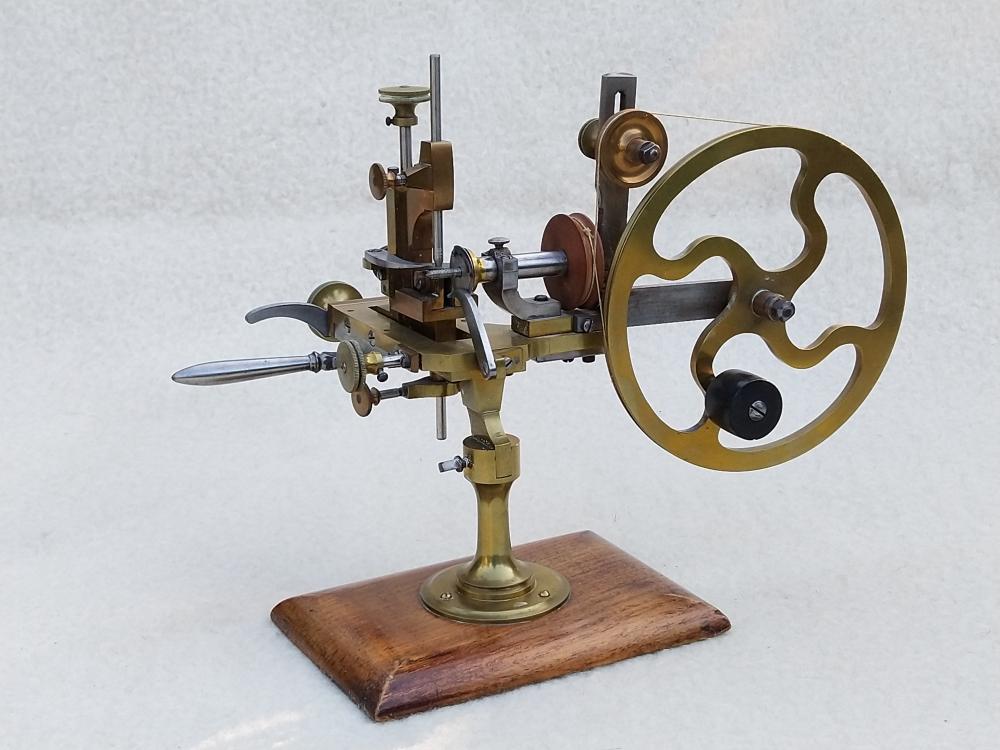

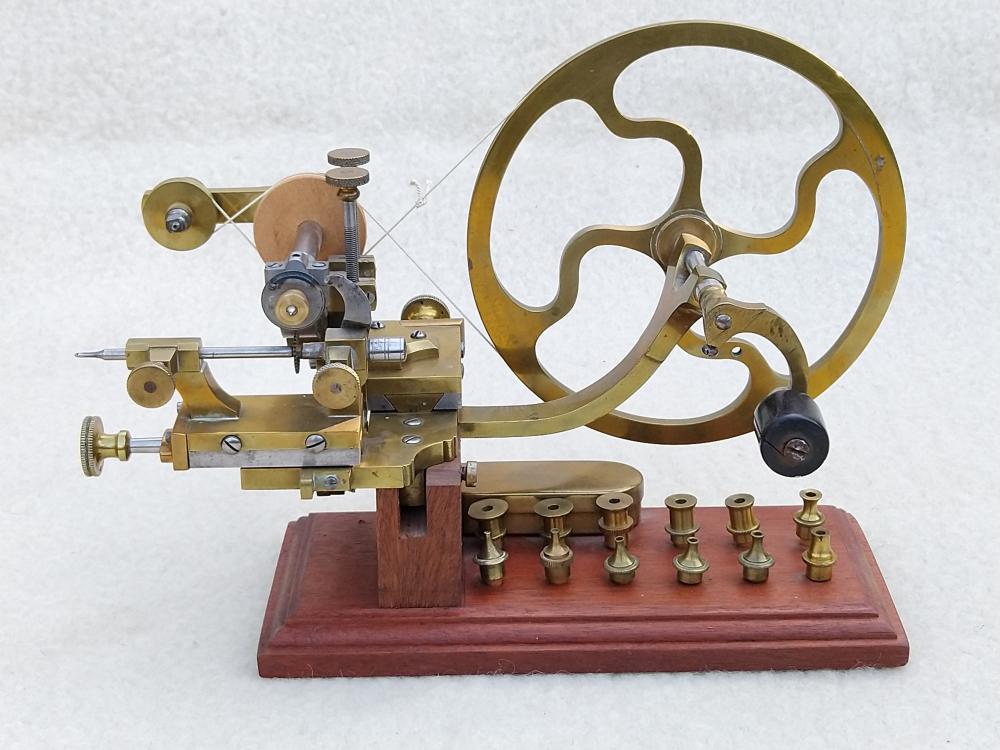

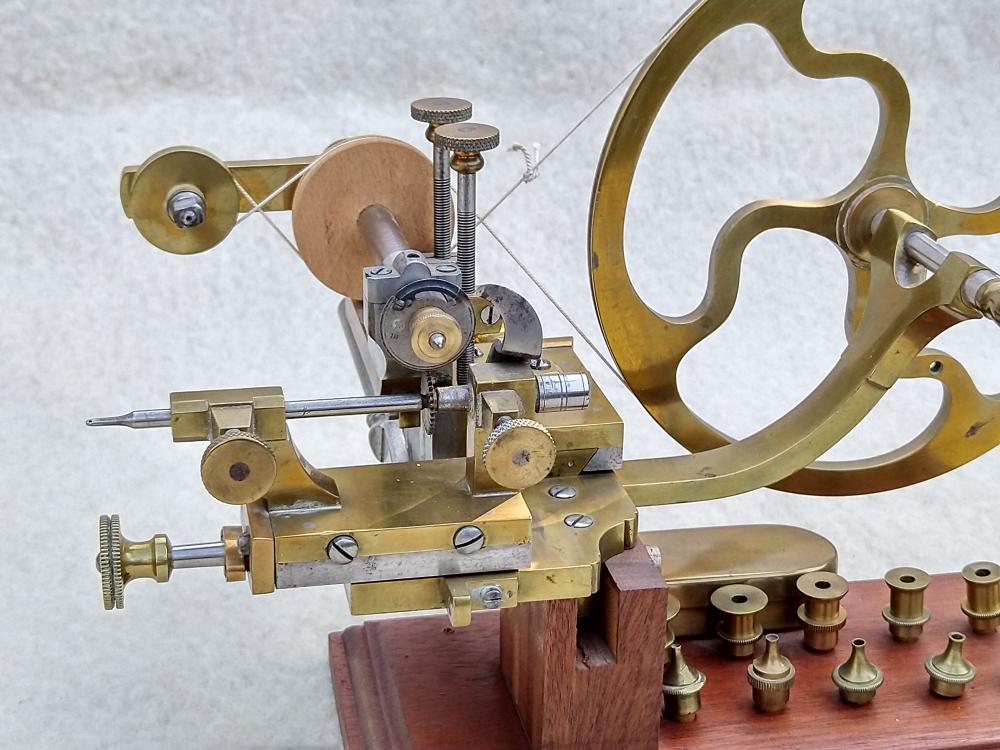

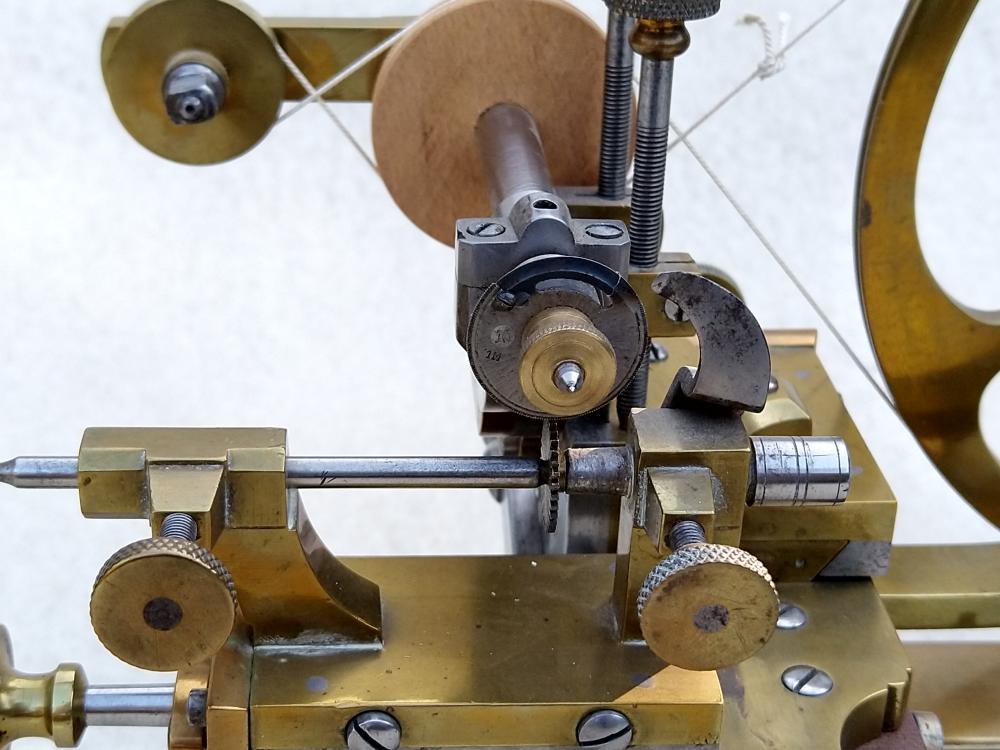

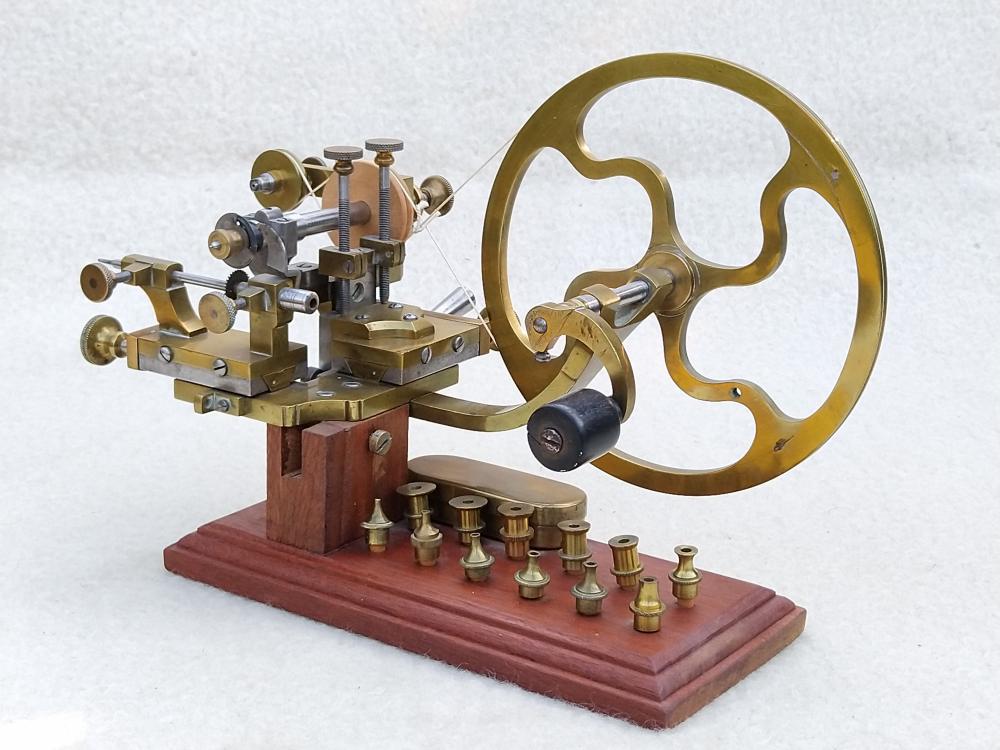

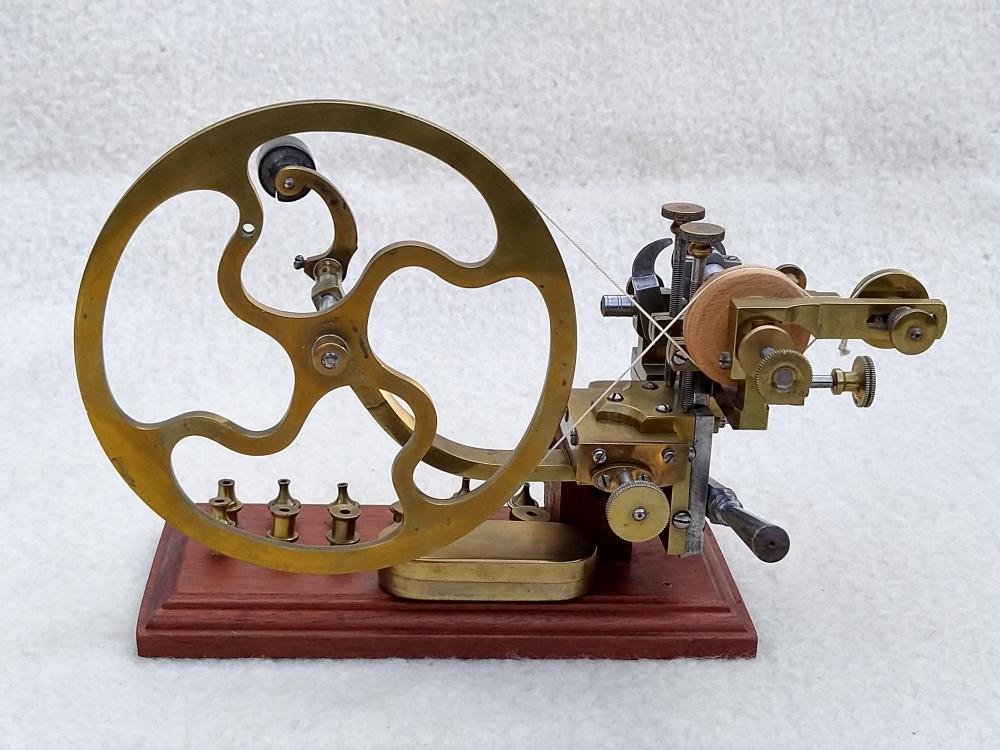

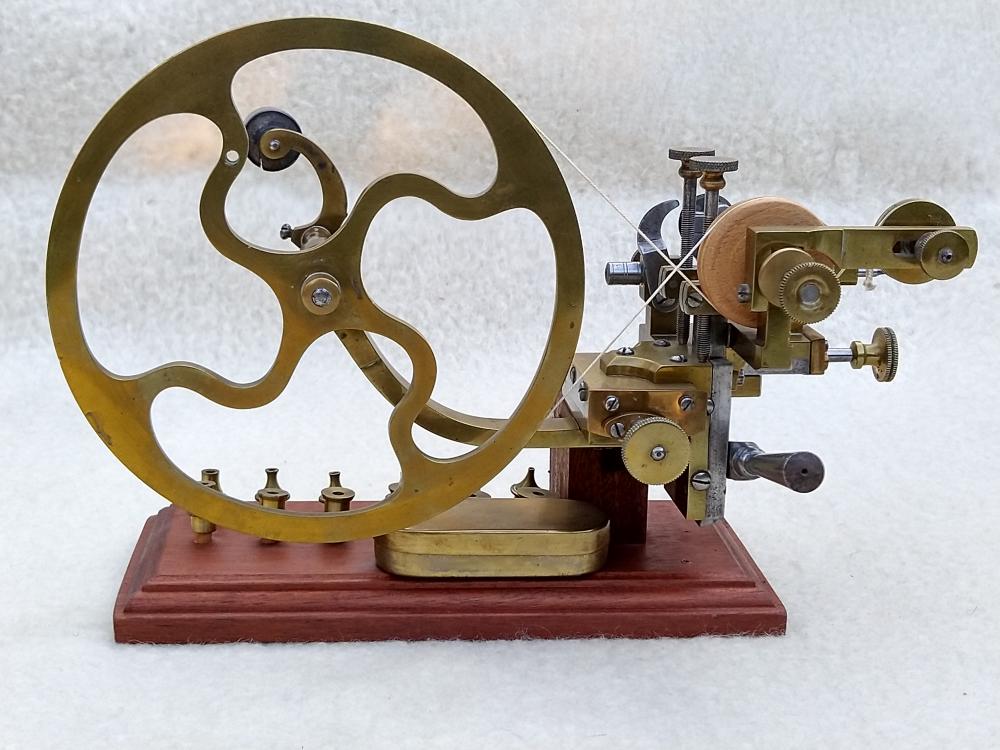

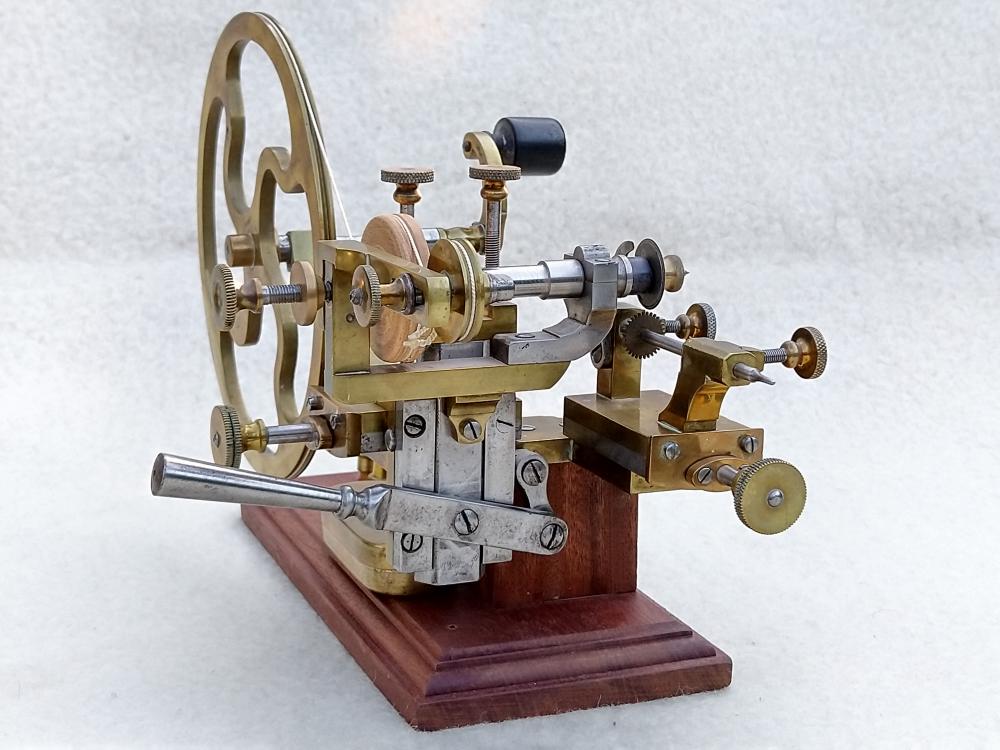

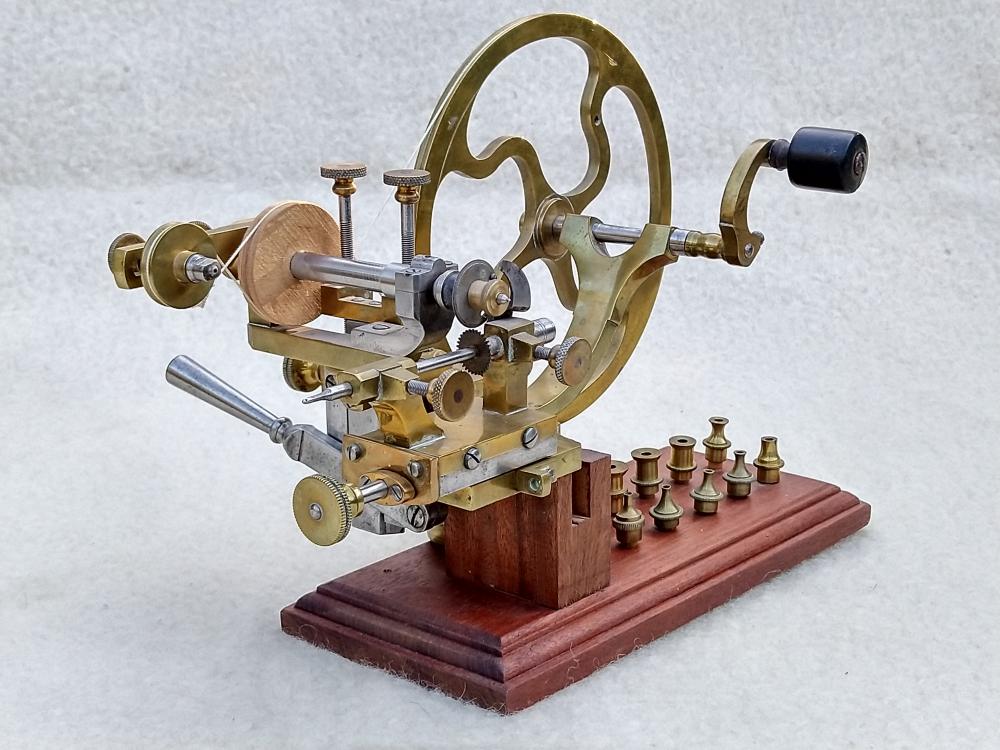

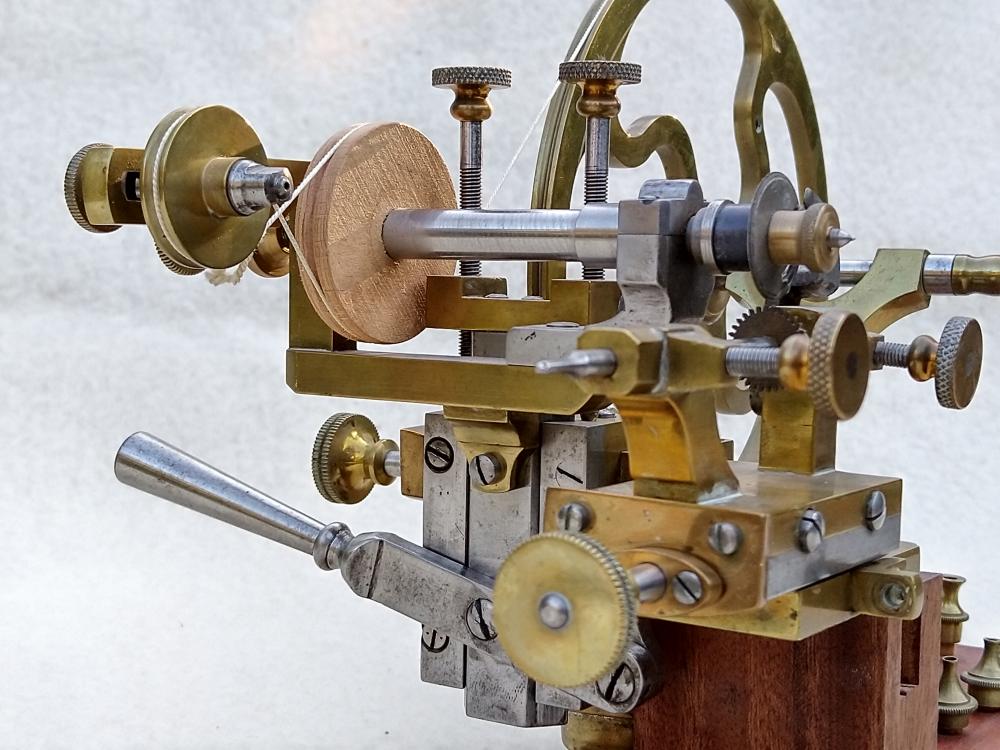

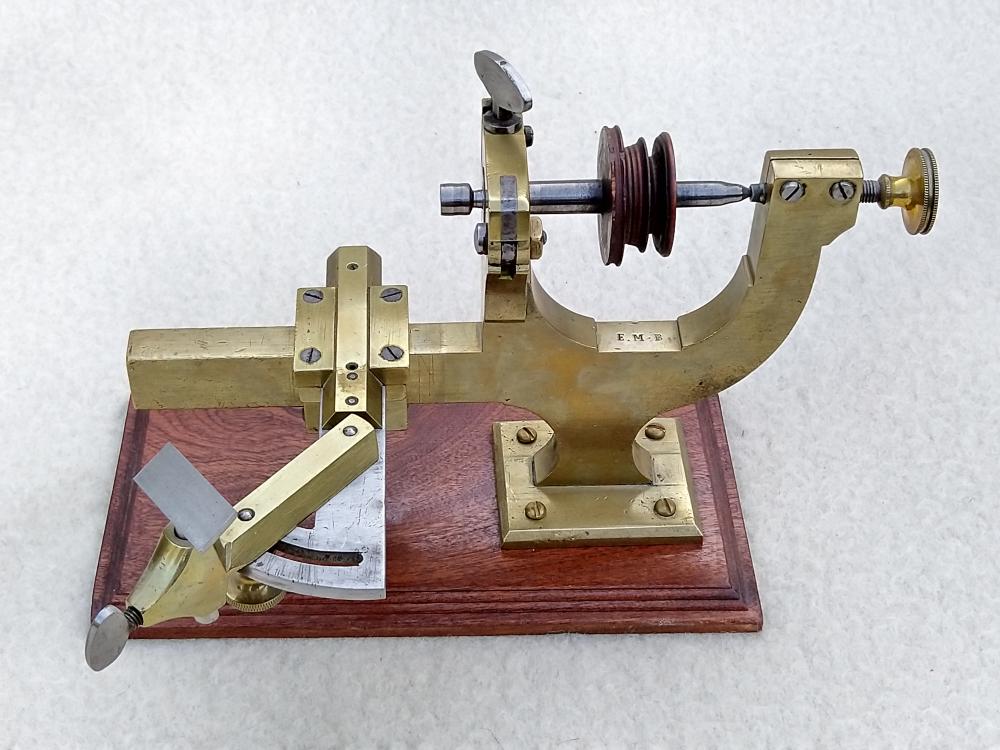

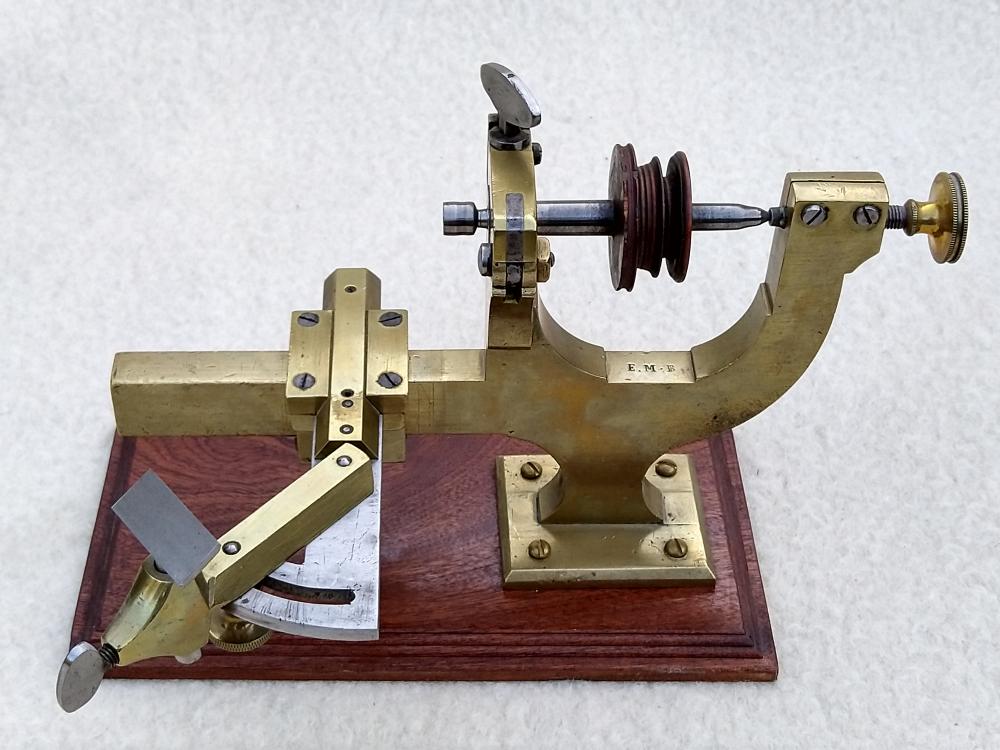

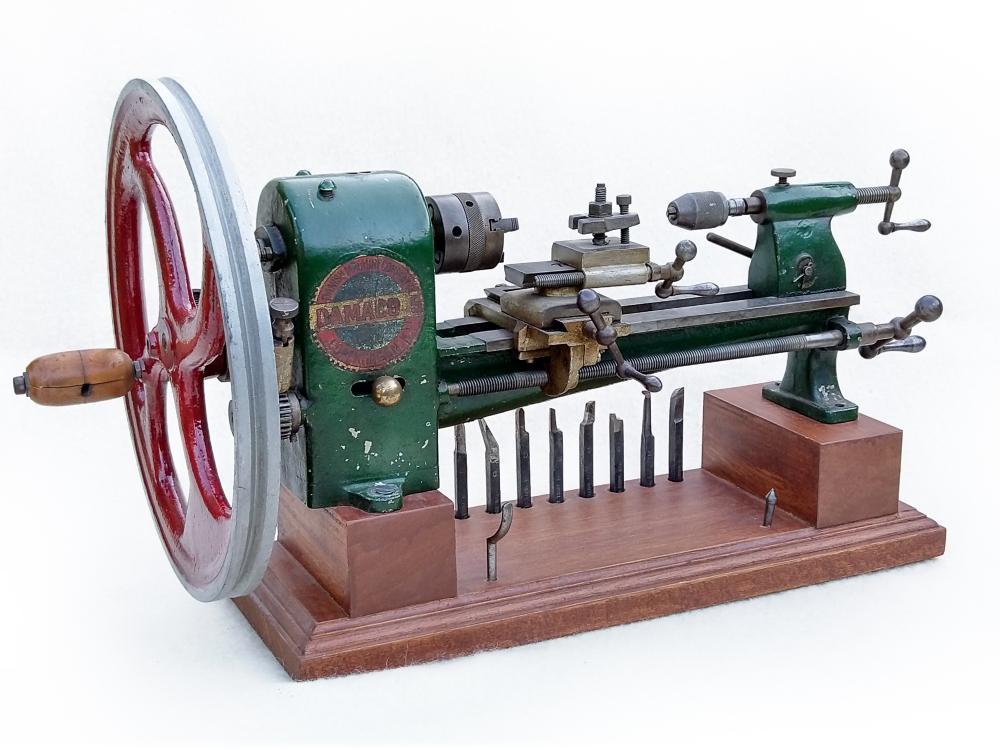

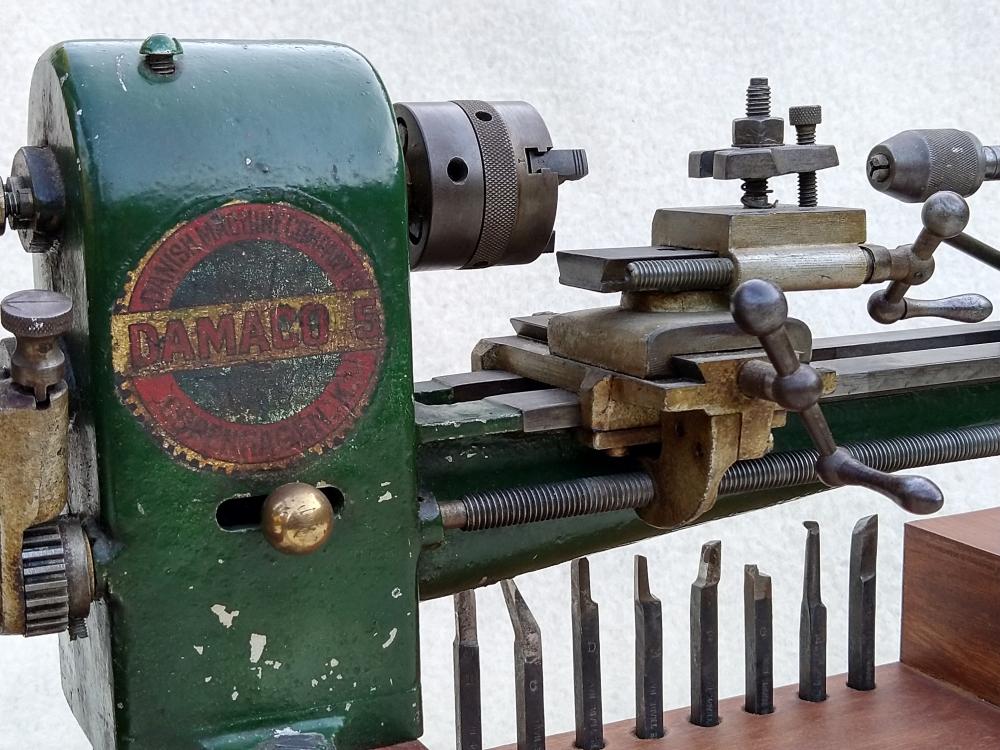

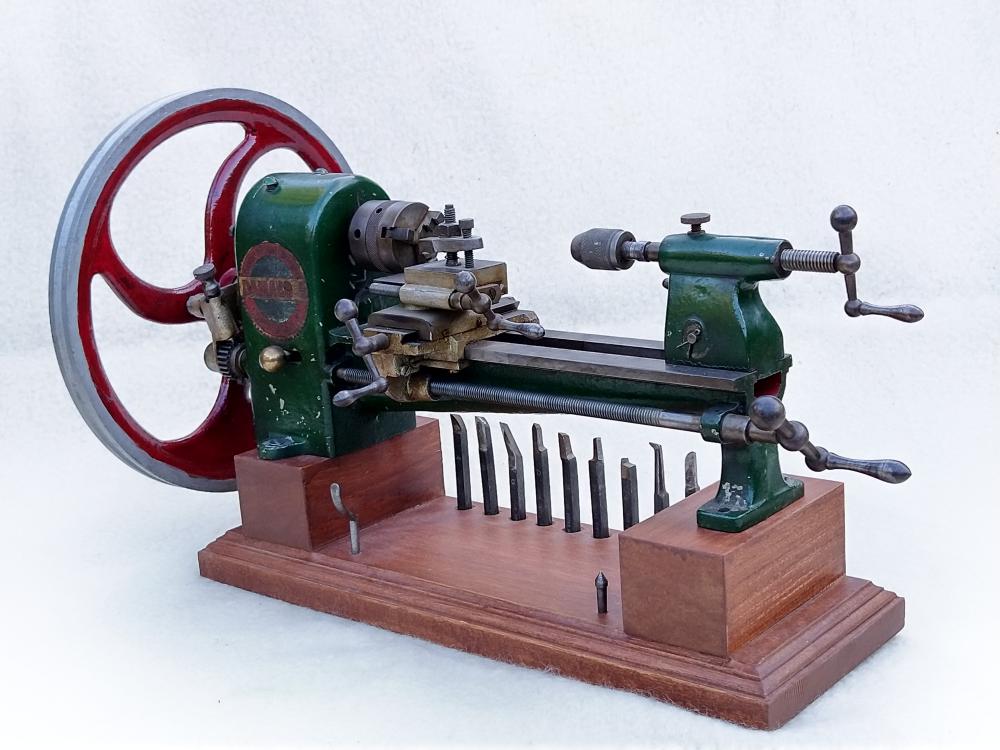

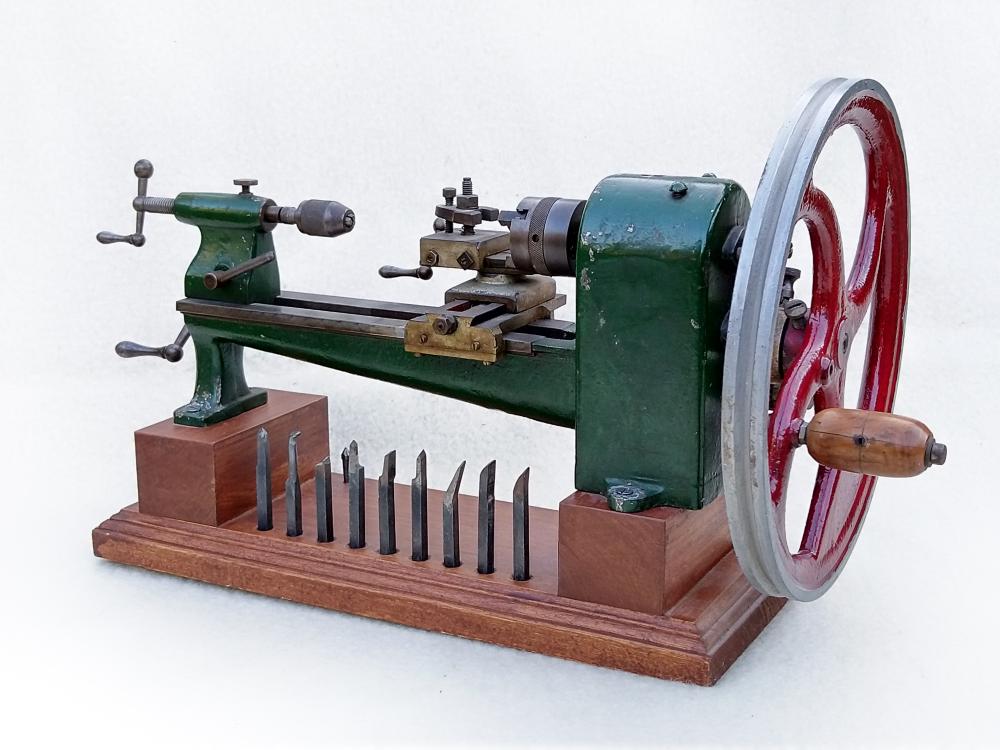

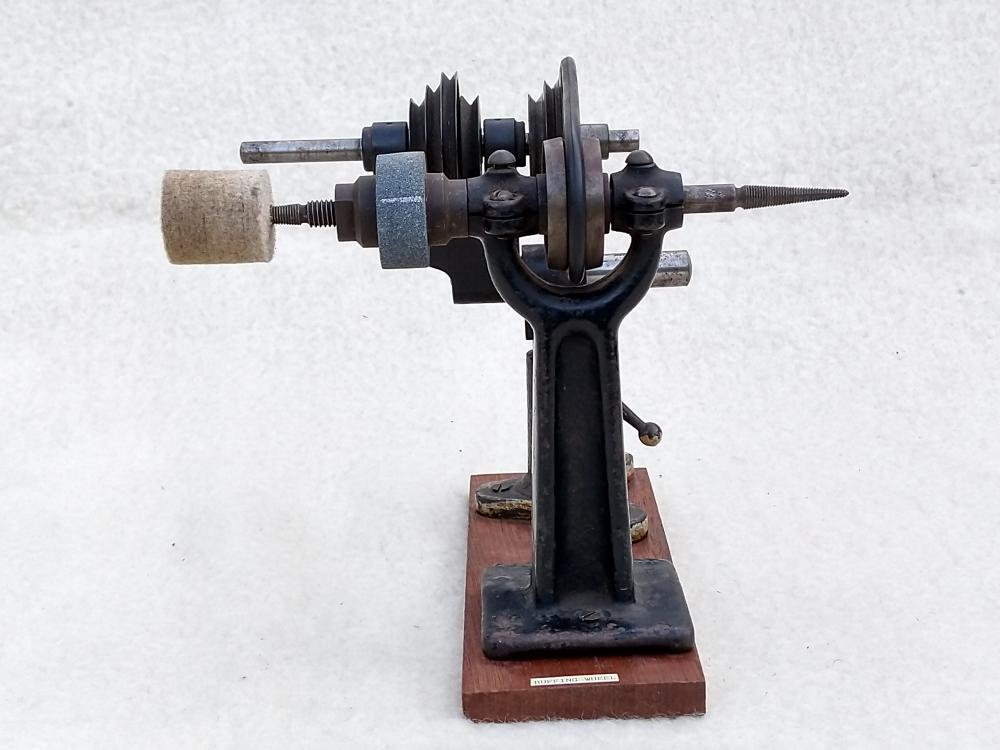

No, not really. I received them recently and even though I am no expert of them they all seem to be incomplete or need adjusting before any practical use. They are display pieces more or less at the moment.1 point

-

Yes. That makes sense. It's a size 18 and I guess there just aren't that many of them around so when one gets dropped/broken it will be impossible to repair. I'm find with it the way it is for now. It is still nice to look at and maybe someday I'll have the extra doh to have someone put it back into working order until someone drops it again.1 point

-

I'm guessing completely and imagine so would most other folk about this. A strong possibility that unused old parts will run out before the appearances of vintage watches does. Supply of watches to repair i think comes from two main sources. 1. Ones that have been around and around the block on ebay and various other sites that have had numerous hobbyists etc inc. muppets that are just after making a few quid on the side that gave up on them along with attempts at repairing watches altogether because it was too much effort. Lets face it you have to be a certain type of person to stick with this for many years, patient, persistent, diligent,determined, delinquent , passionate, have more than a couple of brain cells to rub together and then have money to burn as well. I seem to fit this description fairly well ( the delinquent part anyway ). So theres one source that have been battered around and have used up thousands upon thousands of parts that could have been used in a much more professional manner. And source 2 that i can think of is the new onto ebay watches, the ones that are on their first time around that have been pulled from passed relatives draws during clearances. Generally the younger generation are much less sentimental than us oldies and bang em on ebay for a few quid ( I'm certainly not having a poke at our younger members here I'm sure they are passionate enough to care,but theres no denying it is a fact and does happen) hopefully these would be ones will fall into the right hands that take care of them,but many will not and the circle of damage and using up of parts will continue as new folk jump into the hobby, have a go then disappear. Apologies about the rant , the bloody unfolding destruction inside my current project is peeing me right off.1 point

-

Usually when I'm looking for an American pocket watch balance staff I will look in the following Swartchild's American Balance Staffs It's a very handy publication to have because getting American pocket watch staffs is usually not a straightforward thing even if they are available. This means that while you can look up the actual staff you need is still have to measure the staff in the watch and verify that it actually is the staff you're going to order. Then when you get your new staff you have to measure that the make sure it actually is what you think it is. Then the problem with US watch company is I think they made more than one watch you didn't specify which one. Not that it really matters US watch company is listed at one time staffs may have been available but notice the reference to special order and made to sample. Which basically tells us getting a balance staff would've been difficult Well yes parts are hard to find and it's not just for vintage it's for everything. Parts Are typically only available if the company supplied parts not all companies supplied parts. If they're really popular parts conceivably they're all gone. Then yes there were some parts made by companies other than a factory but only if they were really popular. No point in making obscure parts that you're never going to sell. Which unfortunately affects all parts nobody wants to make modern parts to fit vintage watches if there is no market for those parts or not enough market to justify making those parts.1 point

-

1 point

-

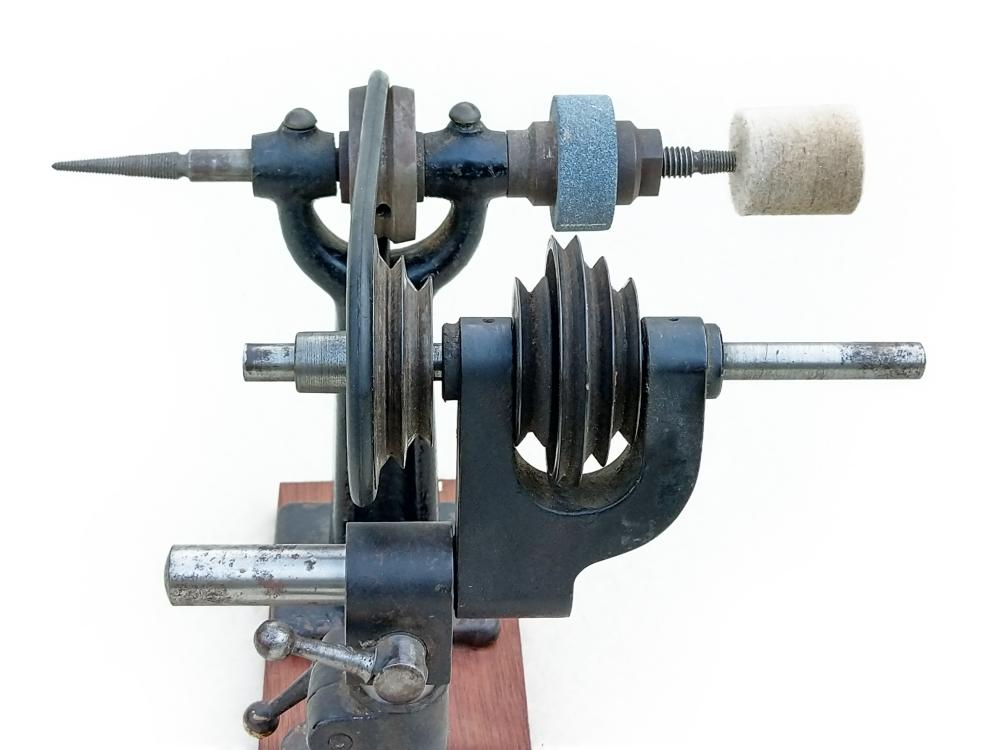

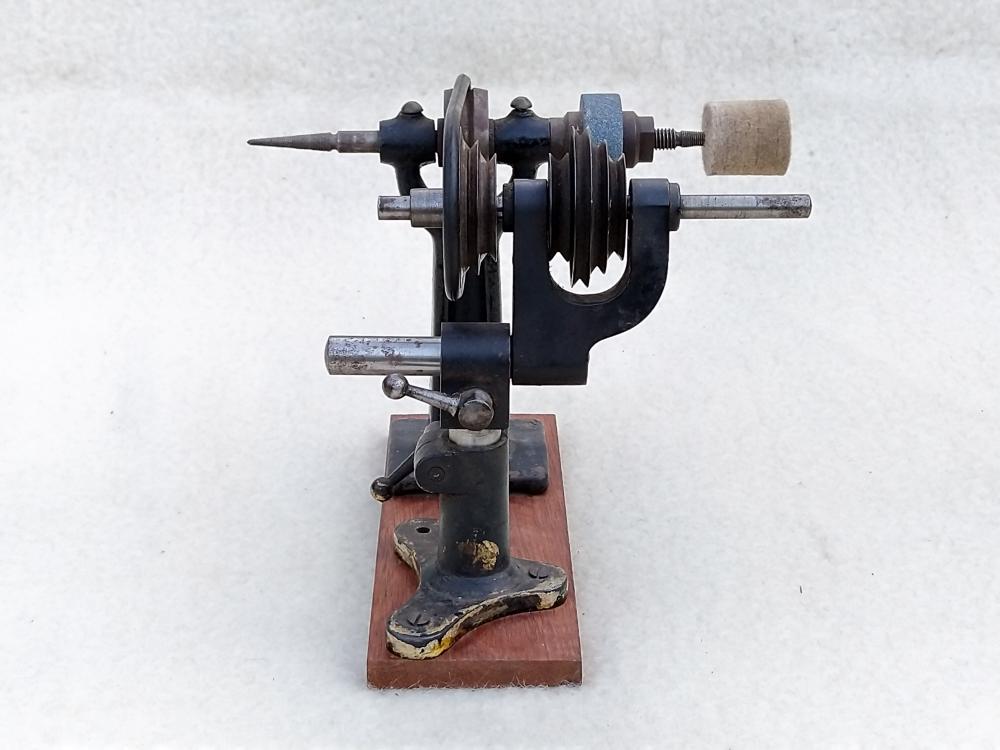

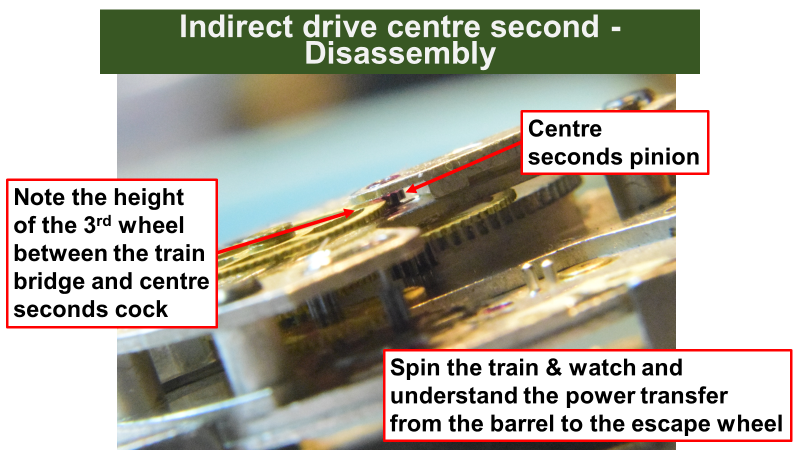

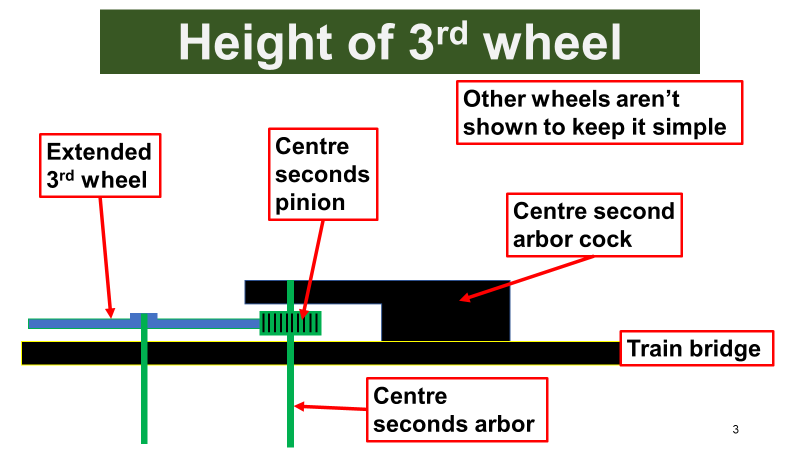

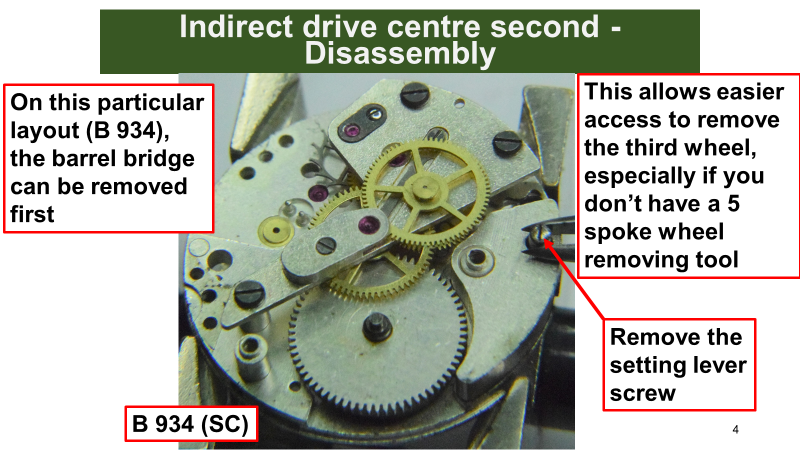

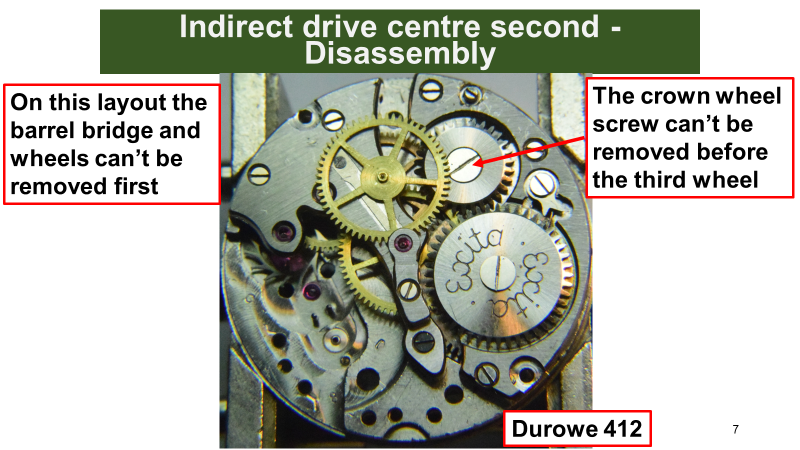

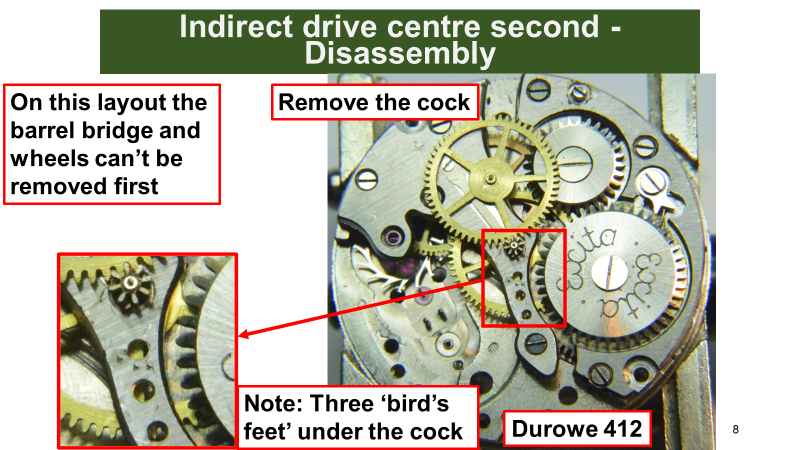

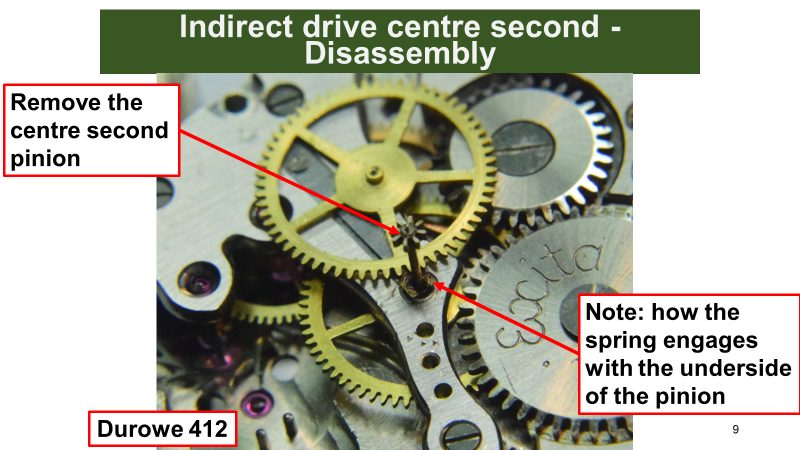

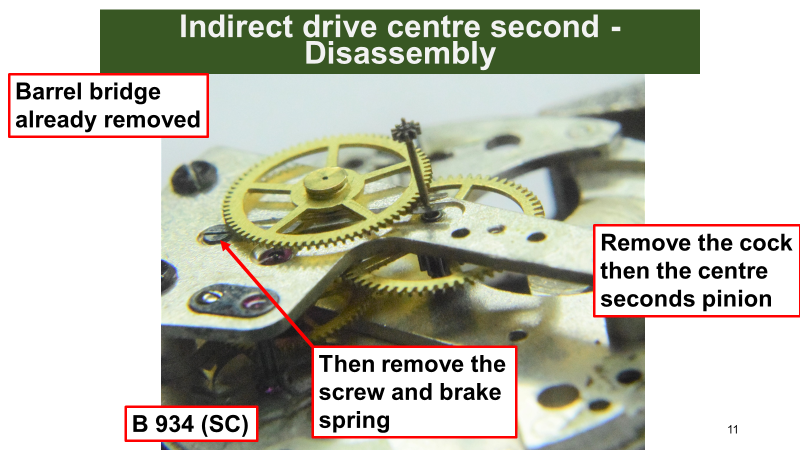

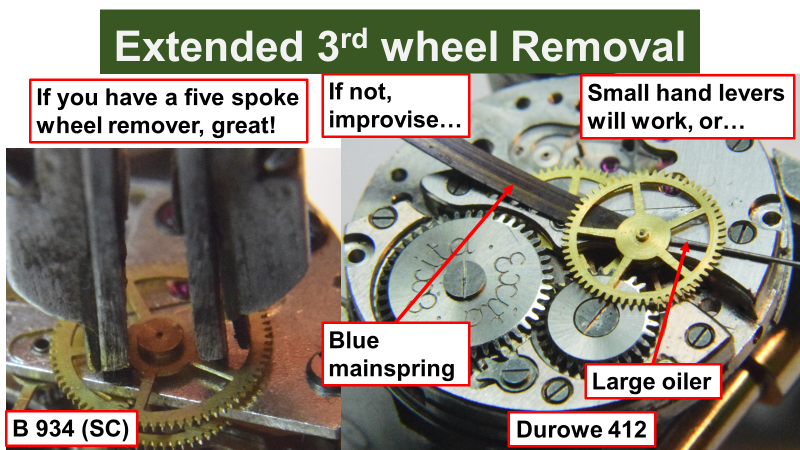

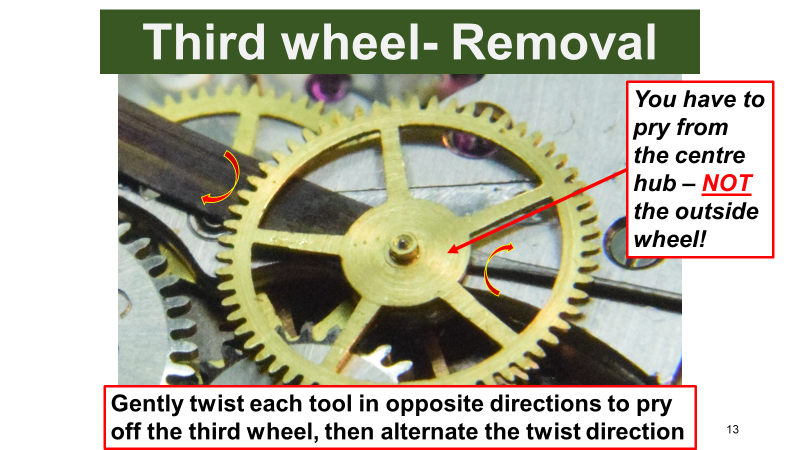

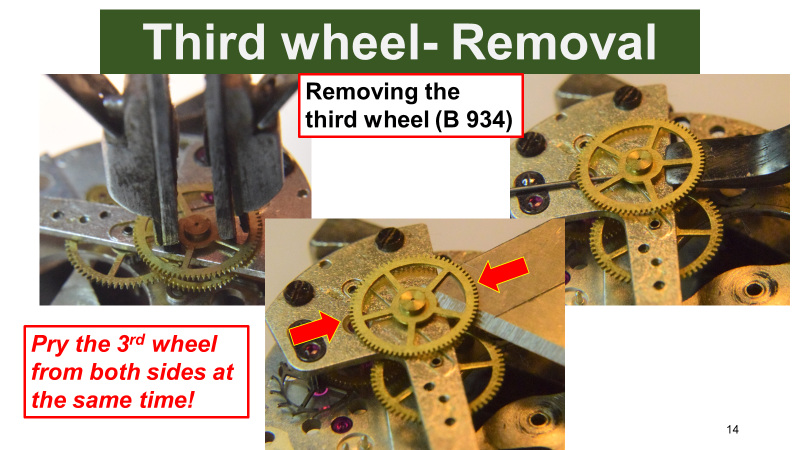

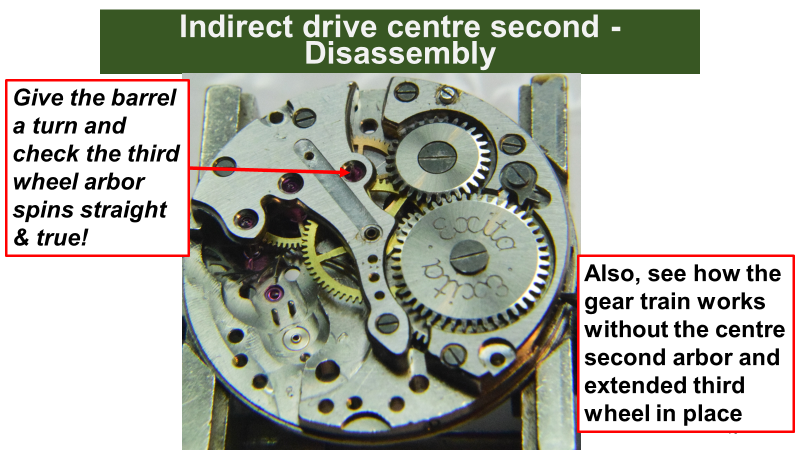

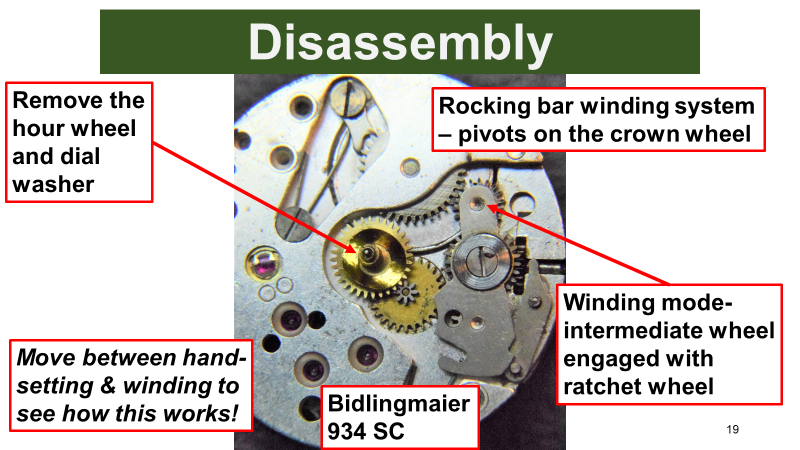

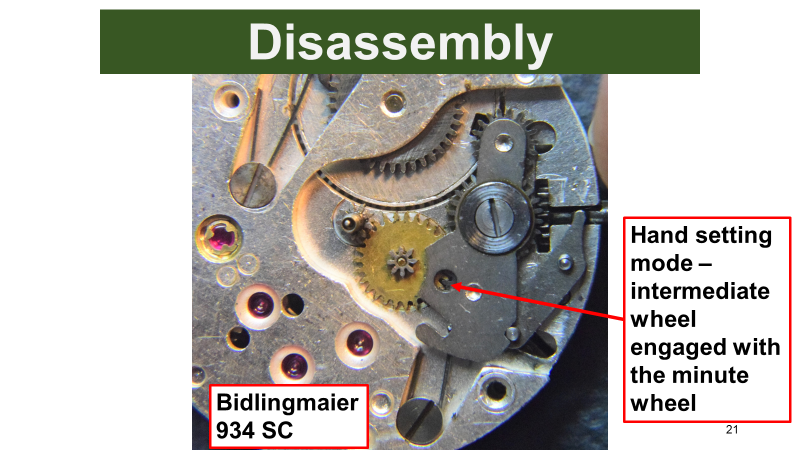

I posted some of these slides from a lesson I take on an indirectly driven sweep second movement. I hope it help anyone. I really should post the set of lessons on a sweep seconds movement sometime soon. The Bifora (Bidlingmaier) 934 has a great rocking bar winding system, which isn't usual to see, as seen in the last two slides1 point

-

Well that was an interesting little game. I set the wheel up in a horia type jewelling tool using a stump that nicely fitted the hub of one side and a jewel pusher that fitted the rivet on the opposite side of the drive wheel. This gave a nice even free wheeling wheel as tight or as loose as i wanted . I needed an index to work to as the bend was actually only slight ( which now leads me back to a possible bent pivot as well ) i decided a physical sacrifice was called for, so a very small nick in the nail of my forefinger and pressed up against the stump served rather well. Held up at eye level with plenty of light and a x10 loupe, just pushing past horizonal to straighen. Did it work ? Bloody right it did, not perfect but much better than it was.Nicklesilver you're a diamond great tip. Now to check for a bent pivot. I see these all the time on ebay, now i have an excuse to buy one And i thought i was the king of commas1 point

-

For something with big pivots, not holes like the sweep wheel, I have truing calipers that will take them (dozen or so different, some with replaceable nibs so they can be made as needed), but for instances where those are too small like center wheels on a pocket watch, I use a depthing tool, or put the wheel up between centers in a dead center lathe. Depthing tools in watch sizes are plentiful and cheap, don't count on them for depthing, but for truing a wheel they're great! Clock size depthing tools on the other hand... expensive! My 8th grade English teacher would literally kill me for the first paragraph.1 point

-

1 point

-

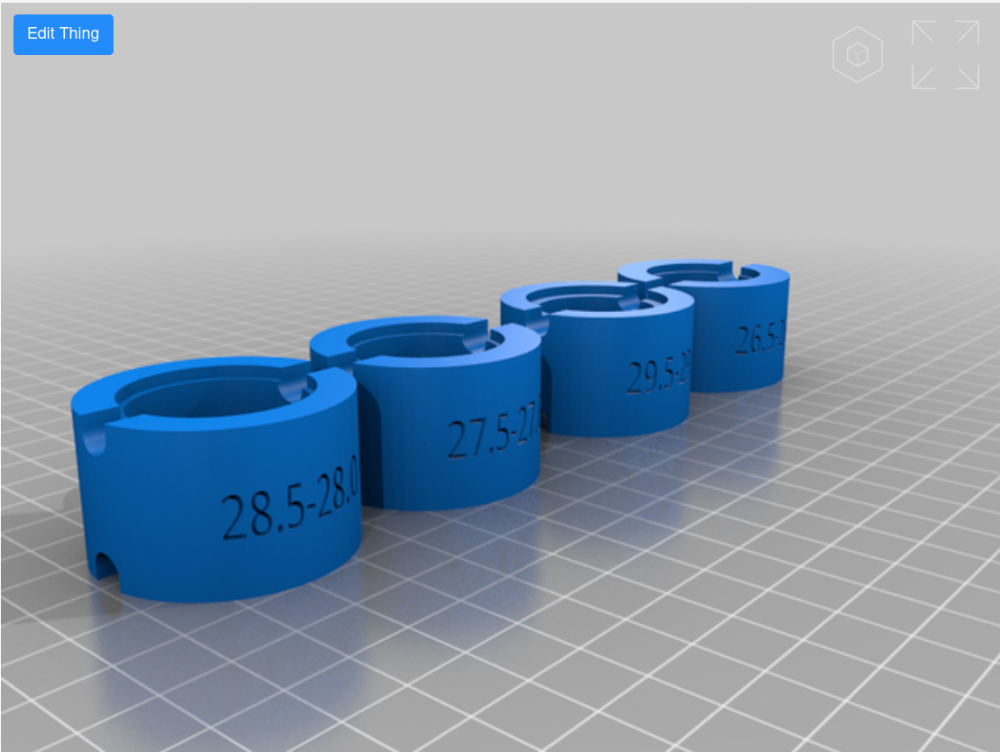

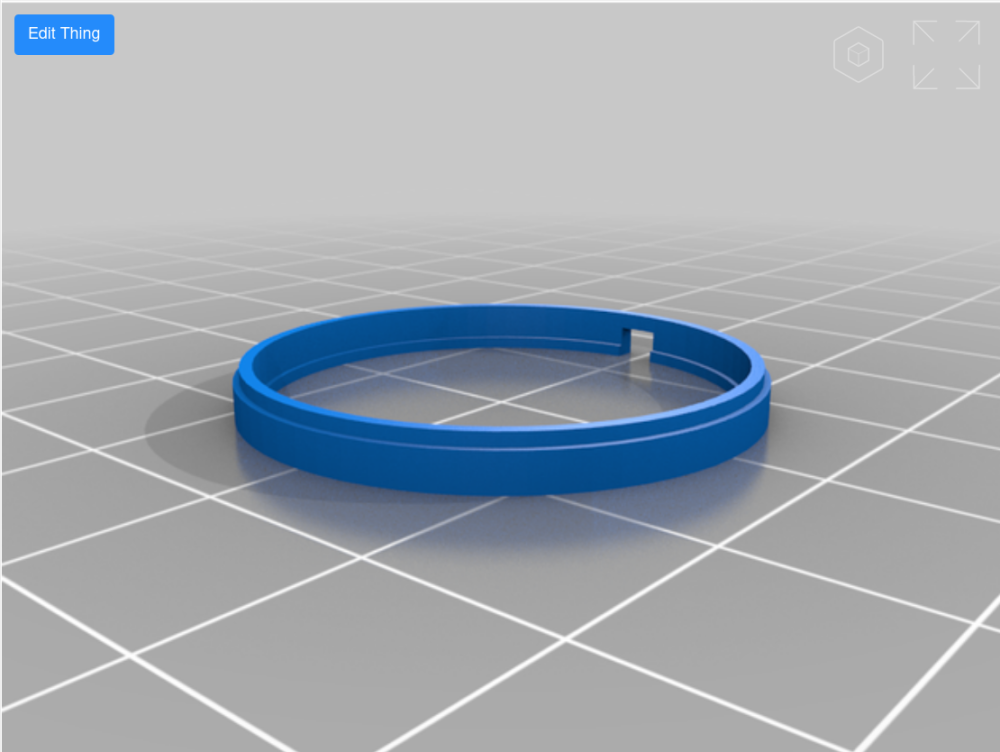

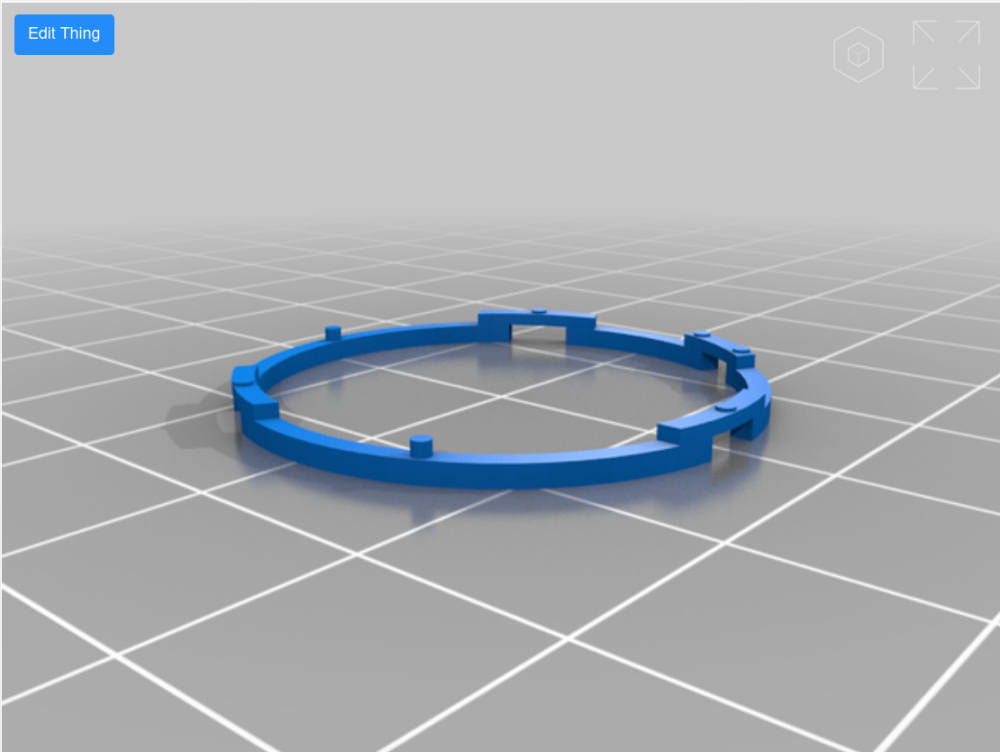

I just uploaded these movement holders to thingyverse as well as two types of movement rings for Seikos, all free to use, modify and distribute. Just doing my bit to help fellow enthusiasts.: https://www.thingiverse.com/thing:5866401 https://www.thingiverse.com/thing:5866398 https://www.thingiverse.com/thing:58663881 point

-

Forum policy will not be discussed publicly on the board. If you have suggestions or concerns then kindly contact a member of the volunteer Moderators or Myself via PM. To those who have strong opinions on how Moderators (all of whom volunteer their free time to help support this project), then I would say - you are welcome to put your hat in the ring and volunteer yourself, I have on several occasions in the past invited people to apply and rarely does anybody step up. None of us are getting paid to do this, the website barely breaks even financially (despite people complaining to me about ads) and so its disheartening when people complain. So back to the subject of this post - Suggestions on policy are very welcome, but not publicly as I don't want arguments or divisiveness. Policy suggestions from members will be discussed by the team and decided upon. Thank you.1 point