Leaderboard

Popular Content

Showing content with the highest reputation on 06/11/23 in all areas

-

2 points

-

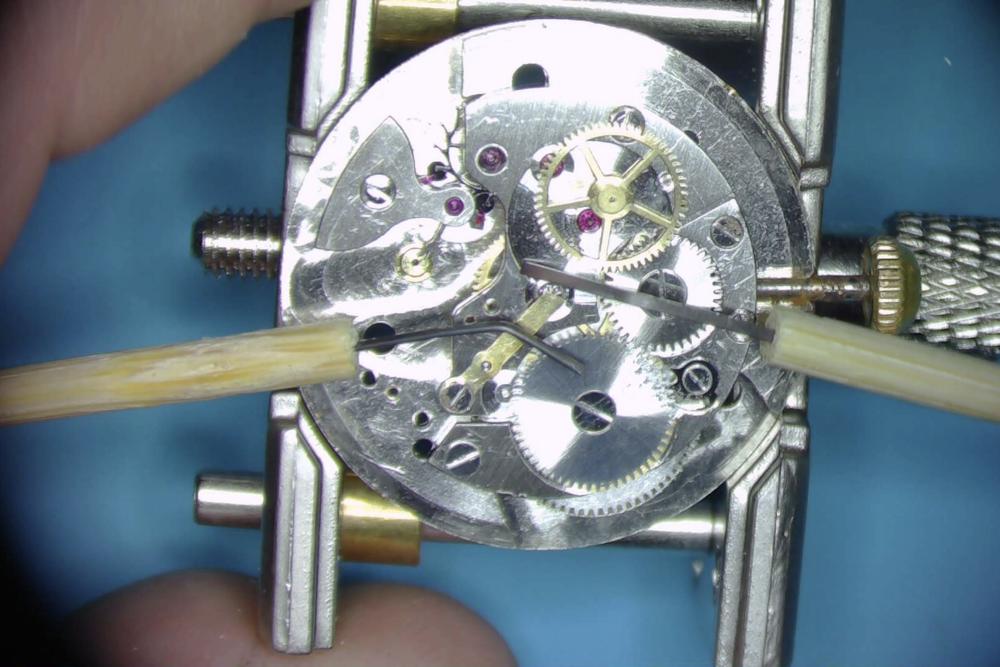

My newest aquisition and project. Was a non-runner picked up fairly cheap as a BIN with just 2 photos of the front and back. Very worn case and broken acrylic. Has an Otero 71 in it. Got it open with the superglue nut trick. The gasket was pinched and worn and I think the Combo of the over tight case with the broken crystal was causing a bind on the seconds hand. Once removed form case and loose debris tapped out and inspected under the scope, looks pretty good. Very nice black linen dial in great shape. The case did its job protecting the movement. Look like it was plated gold over brass.1 point

-

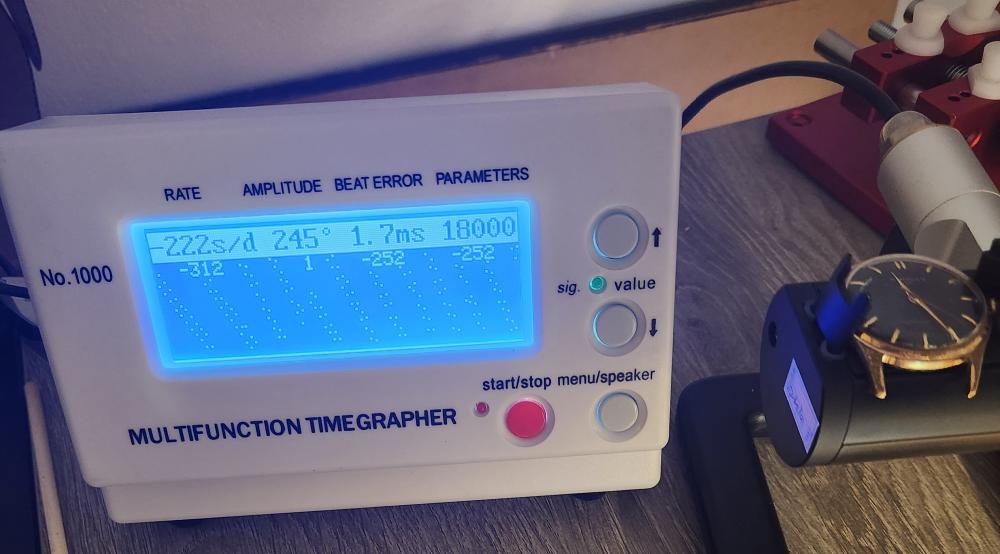

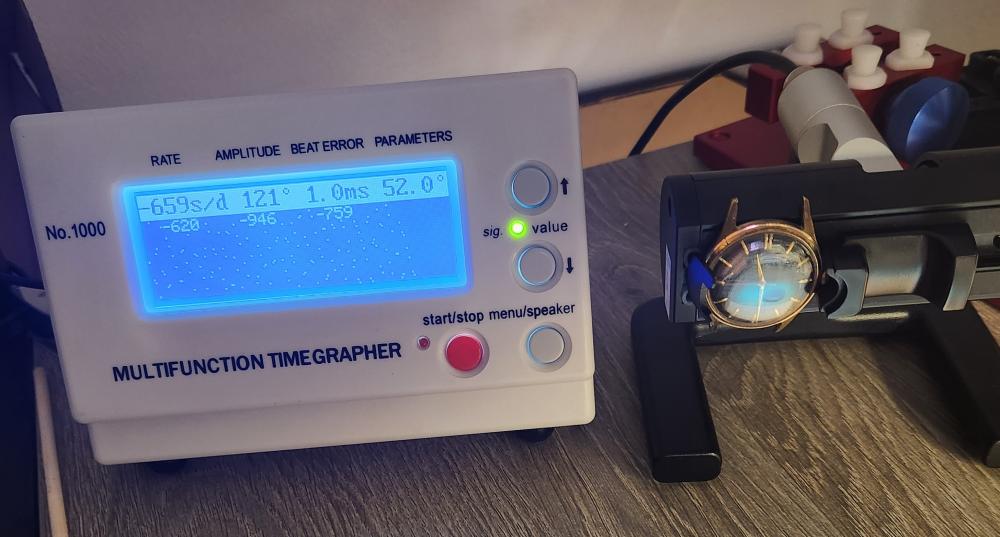

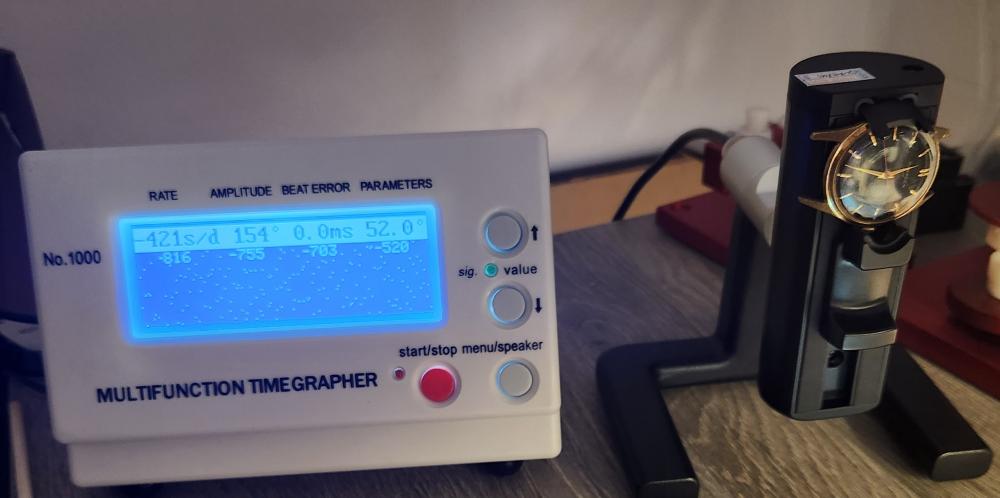

This is to be my project. May take a while as I want to get it right. DOXA by Synchron. Movement is Cal 41 (ETA 2750) Winds OK and runs OK. However, I will do a service and replace the crystal and any parts. I have not yet opened the watch. Looking at videos first to familiarise myself. Placed on Timegrapher. Result can be seen in photograph.1 point

-

1 point

-

Tidy old watch cleaned up case polished and new crystal. It will .look great. Like the dial. Different.1 point

-

1 point

-

Ultrasonic will also damage SOME balance pivots. Damage seems to be due to vibrations , not the cleaning solution. A research a member with good microscpoe can do is; to put bunch of damaged balances ( the kind on which staffs are not replacable) in ultrasonic and show us image of pivots before and after ultrasonic bath.1 point

-

Phopheric acid in Coca-Cola breaks molecules in oil/ fat , (thats how it helps digest food). Coke gains access to molecules embeded deep as it breaks the ones in the front. Give it 48hrs to complete its job, a few minutes in untrasonic wouldn't do the same.1 point

-

Ordinary hand levers will be too large and the presto tool is specifically designed to fit inbetween the five spokes. You really need to manufacture something for the removal. The pivot is easily bent and distortion of the drive wheel also. You've been warned1 point

-

1 point

-

1 point

-

If you do a search on here we have a thread about mainspring winders with loads of advice.1 point

-

I had no idea we had a watchmaking school. I am just south of Everett. I've taken apart and reassembled a few movements already. The Bulova is the first automatic movement I tried. It just happened to one that I couldn't find any good videos of. I have a microscope and camera so I'll be able to get it back together. There's just one plate that has a wheel on each side and they seem connected? And I wasn't sure if I should try to pull them apart. They might just be pressed together, idk. I'll take a picture. I think some of the parts I have would be worth selling. There are some Rolex parts including two dials for 1665 'sea dweller'. And a bezel for the same watch. I assume all the Rolex parts are worth something. And i have no interest in Rolex watches. The quartz stuff I have no idea about. I'll go through it more thoroughly. Also all the pocket watch stuff. Most of the watches I've picked up are like Bulova, Elgin, Waltham.. stuff like that. I guess I'll just hoard everything for now. That's the nice thing about watches. They are so tiny. You can hoard so much stuff.1 point

-

Check Cask-Ker and Otto Frei. Their prices are usually less (sometimes a lot) than Esslinger. I bought size 5, 6, and 7 (both left and right) from Otto Frei.1 point

-

Gott in Himmel! And I thought the cheap Chinese movements were bad. It looks like it's made of stamped aluminum foil. Is that white plastic in there? Does that thing actually run?1 point

-

It's a brazed carbide turning tool ground to bore very small holes. I think that one will do less than 0.80mm bores. In the hole is a plug gage showing the hole size. I use diamond grinding wheels. In my early days (like slightly pre-2000s) used a roughing wheel in a crappy WW lathe, then honed on a copper disc with 3 micron diamond paste. More recently, a proper grinding machine, with diamond wheels, rough and finish. All freehand, and for tiny things like this, finish the functional faces on another (lathe object) with a really fine, D7, diamond wheel.1 point

-

This is something i always check seperately before assembly, i also do the same with the lever. I Install the lever with nothing else, check the end and side shake and a final check to see if the lever will fall from side to side under gravity while tilting the movement. That feels like a good indication of free movement with no restriction and no interference from anything else. It is so much easier doing this first without the barrel and train installed, especially if a problem is found. The train restricts visibilty and you also have the ease of removing and installing the balance and pallet without working around the train.1 point

-

1 point

-

Wow that's a shocker It's not an ST96 @Nucejoe (I got caught out with one of those) - it looks even worse ! You can find plenty of similar items on ebay. That's why I never buy unless I can see the movement.1 point

-

You can look for case parts on Cousins, but they don't list any for your movement. Neither do the Jules Borel database. Cousins have a page for Seiko gaskets, but you need to know the Seiko part number https://www.cousinsuk.com/category/seiko-gaskets-list For the case back gaskets, I measure and buy generic. Here is a link to some very useful Seiko case info : https://www.watchrepairtalk.com/topic/13897-seiko-casing-parts-guide/1 point

-

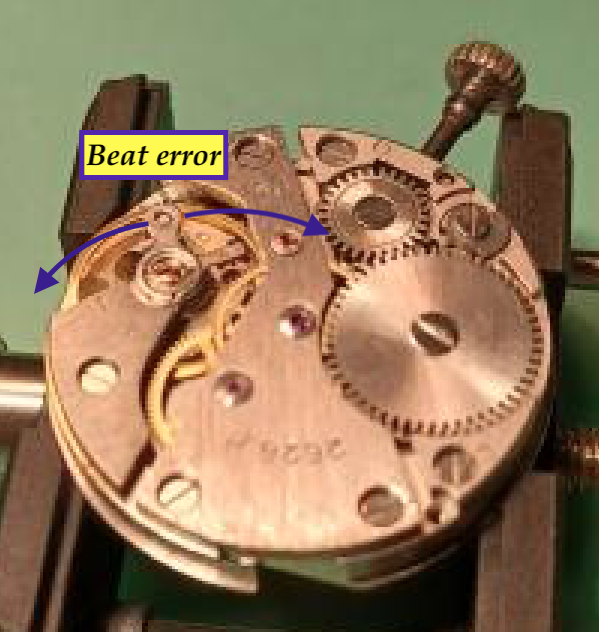

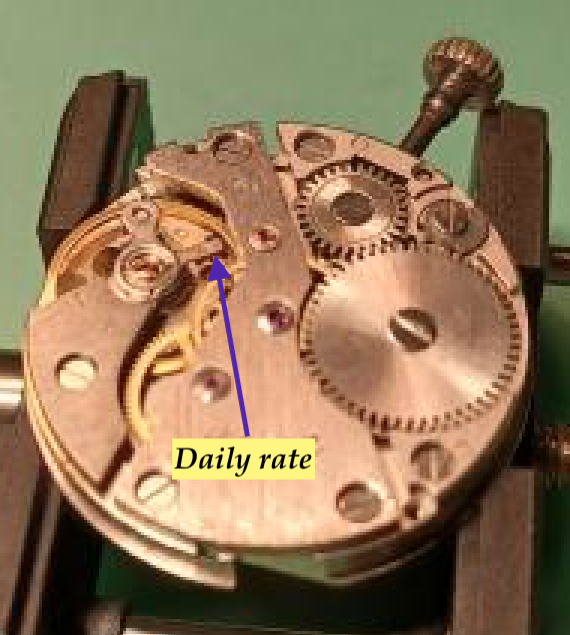

We need to work on your Timing machine diagnostic skills. The beat error is unacceptable then the amplitude is extremely unacceptable. In other words this watch has a serious problem beyond stopping. Then ideally you should do at least two positions dial down and maybe crown down for wristwatch so we can see the difference. You want to try an experiment? Wind the watch up put it on the timing machine change to crown down position take a picture forest as I really do like to see the picture. Wait give it some time look at it every half hour so until it comes to a stop. This group has a amplitude obsession. Somebody is probably having a heart attack right now over that amplitude you have. Usually for this group to minimum acceptable at the end of 24 hours would be 200° it will vary for the watches though some Omega's Can go down to 160° but that's a really nice watch. Then on this group the obsession is aiming for 300 which is silly but 170 for a fully wound up watch you have a serious problem. If you were to allow the watch to run in its current condition you'll notice the amplitude should be dropping off really really fast and the reason your stopping is you're running out of power so there is some serious problems here. In other words it's probably not the mainspring barrel that there's something else going on.1 point

-

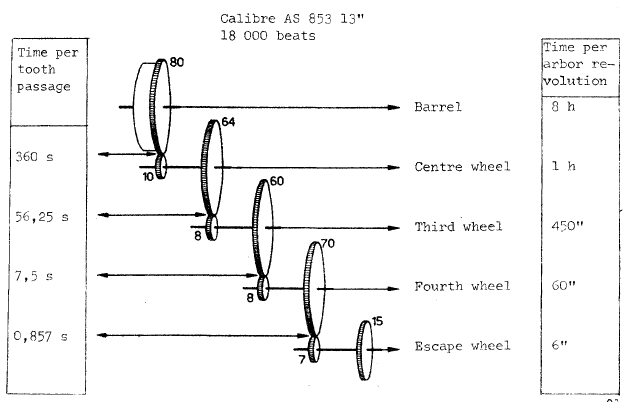

Do you have a timing machine? I kinda hate trouble shooting in the dark a timing machine will reveal a lot of things. Without a timing machine we have to guess. For instance when the watch stops does it come to a slow stop or does it suddenly stop?. Like of the hands touching If the hands are on. Then is it the correct mainspring or was there a substitution made. Then each watch discussion is unique which watch you were talking about and anything about the background history we should know? In other words was running when you got it it's not running now can a helps to figure out where the problem is whether it came from before and after it worked on So back to guessing image attached below. Gear train ratios they'll vary a little bit obviously the center wheel will always go around once per hour. If the hands are hitting stuff on the dial side. This is where if you're having a problem we remove the hands and move the stuff of the dial side to narrow the problem down. Then runs more than an hour and you did change the mainspring in see that the revolution of the mainspring barrel is around eight hours if there's a problem with one of the teeth on the mainspring barrel or the lids not down tight. I've had that happen with pocket watches occasionally. Or some mainsprings have T ends and that sticks up and that Can catch on something. If the barrel arbor is extremely warns the barrel doesn't sit flat another issue. But usually we have to rule out the simple things first a lot of times people start looking for the really obscure things that it's usually something pretty simple just not entirely visible if you're not sure what you're looking for. Or as I like the comment it's the elephants in the room which is too big to be noticed and then you start looking for the dust in the corner of the room's. But timing machine is really a interesting device for troubleshooting either the Chinese 1000's of the 1900 preferred still nice for troubleshooting and relatively inexpensive.1 point

-

Get yourself some acupuncture needles less than a tenner for a box of a hundred. The diameter ranges from 0.3mm down to 0.18mm the points are extremely small and thin. They fit very easily into the workings of the movement and small enough to seperate the coils of a hairspring. Their uses are endless.1 point

-

The reversers on these must be treated with epilame, like Fixodrop, to function correctly. Super clean, epilame, then oil only the bearing points, not the ratchet parts of the reverser.1 point

-

Don't sleep on buying a printer. I started printing a set after I read your post. Should cost me about 10 bucks once I get dowel pins. Another day or two before I'll finish a full set. https://github.com/vishnu350/rs-mainspring-winder full link with the instructions and full sets from the ebay one you posted.1 point

-

As for jumpy springs; Has happened to us all in the beginning. Experience and better techniques will reduce the frequency. As a starter, if you suspect a jumpy spring you can put the movement inside a transparent plastic bag. If or when it jumps, it should be inside the bag, but check your hands and sleeves when you pull them out! For me, best is to hold them down with a chisel-shaped pegwood and be "light" on the tweezers when handling. But there are many other ways to prevent them from flying ..... nonetheless, still some will do the escape-trick. I guess, in the beginning I spent more time underneath my desk, searching, than above When a spring jumps, and you don't hear it landing, don't move and check your hair, eyebrows, hands, sleeves, your lap, desk, chair, trousers, socks, shoes etc. When you get up and move, check your shoe soles, the chair again, etc. Try to find it before you move too much around or leave the scene. Magnet is a good idea, in the night a very strong narrow beam flash-light scanning close over the floor (looking for a reflection) or an empty bag in your vacuum cleaner may also help. Clean the floor before you start, good for your hobby and your wife will be happy too These should be in every watch-repairers kit: Suc61 point

-

Hi attached is a lot of files apertaining to the seiko casing guide information. 03. Casing Guide seiko.pdf Seiko Casing Parts List (1977) IV. Cal. 3302 to 5245-6010.pdf Seiko Casing Parts List (1977) V. Cal. 5245-7000 to 5740-8010.pdf Seiko Casing Parts List (1977) VI. Cal. 6100-8000 to 6245-9001.pdf Seiko Casing Parts List (1977) VII. Cal. 6306-5000 to 8346-9020.pdf Seiko Casing Parts List (1977) I. Notes & Index.pdf Seiko Casing Parts List (1977) II. Watches Japan Market Only (1).pdf Seiko Casing Parts List (1977) III. Cal. 0702-0723.pdf1 point