Leaderboard

Popular Content

Showing content with the highest reputation on 06/12/23 in all areas

-

Update: The oiling and the amplitude: I oiled the exit pallet only, on the pallet fork. Added a drop then 4-5 clicks and added some more .. around 3 times I repeated the procedure. After that I checked that all the tooth's of the escapement wheel are evenly oiled. And left it too run... Well I was expecting that the amplitude would rise, a bit, say 10-20deg... but from 220 to 290-295 (what??!!!) ... I guess you guys know a thing or two. Regarding oils that I use: Mobius 8000 "light viscosity" - train wheels Microgliss D-5 "med viscosity" - main spring barrel, the date and wheels, or where there is "as I imagine" more friction Molykote DX Paste (DX30) "heavy viscosity" - keyless works, basically metal on metal (steel) Moebius Natural Grease 8217 - mainspring barrel walls Epilame: After listening to you guys and watching this dude in the video. (also after seeing the latest results I got), Epilame was removed from my wish list in the Bergoen's website https://www.youtube.com/watch?v=eHk-qRWiOJ8&ab_channel=WatchRepairTutorials So, what I see not on the machine is -10s/d, Amp 280-295, error 0.1ms ... will adjust the rate a bit later, will let it run for a day or two.3 points

-

By the construction of it it is used for loop end springs which slide the loop on the plain shaft and the spring on the arbour then wind, once under the tension. a C clamp is used to keep it to gether whilst fitting to the clock alternatively a stout wire is wrapped round it and cut off when fitted. I built my own got use with the ansonia open springs somewhat lighter in construction. That one could wind a tank in. Nicely made too all the same. Yes clock springs have to treated with great respect with regards to the power factor could sever a finger if not avery nasty cut. Glad to say for all the years I have worked on clocks all my own fingers are still attached.2 points

-

2 points

-

2 points

-

Eyup watch peeps, i hope we are all well and have enjoyed our weekend. I'd like to show off my new jewelling tool if i may and pose a question or two to add to our previous discussion last week regarding reaming holes with the Seitz. My lovely post lady delivered this Marshall jewelling tool and set this morning. Its not extensive but it is complete inc. reamers and in great condition barring a little touching up. This is my first play at enlarging jewel holes so re-reading last weeks discussion and applying the information make a big difference to my understanding now. Now ive toyed ive realised that there is 2 cutting surfaces and both are usable. I dont think that the use of both sides of the reamer was mentioned last week. So my first question would be what the effect on the hole would be if the reamer is used to cut both clockwise and anticlockwise during the same hole enlargement. Or is the best approach to cut entirely clockwise or entirely anti clockwise ( I'm thinking this is better ) . And if that could minimise or increase the asymmetric wobble produced while cutting, which tbh I'm not really noticing ( i assume Endeavor noticed it more because of the large plate being cut ). So having the two cutting surfaces gives us twice the life extent of the reamer. This brings me to my next question of how to sharpen the reamers in a non professional workshop. I appreciate any replies and hopefully this helps other new to jewelling members.1 point

-

This one has been waiting patiently in the tray for several months but I'm calling it done this evening. A FleaBay Waltham A-17 that was a non-runner I've been pecking away at. It was seized up tight. A photo of the flabby before to follow… If you're familiar with Waltham military you'll recognize it's the predecessor A-11 dial. Some intelligence gathering suggests some of the early A-17s went out with A-11 dials or Corporal Endshake may have dropped an old A-11 in there to get it back out in the field. Of course it could be all the back and forth on EBay. Forever a mystery.... I'm passing it off to a friend who resides in Waltham so I went for authenticity and will send along the old dial JIC. There's new lume that won't upset the geiger, new escape wheel, bridge screw and some balance poising. Unfortunately I borked the collet when I got greedy for better than naught-point-six on the TG beat error, but now sorted it runs strong and flat on the TG any way you hold it. I've heard 30 seconds/day is great for these but so far this one is a bit better than that... Edited 40 minutes ago by rehajm1 point

-

I have never seen this model before but agree with watchweasol it is for open loop springs so it has a limited use. Both my hands and all my fingers are still with me.1 point

-

Just had the classic corroded in screw in a 1946 Bumper Omega - Very dried up but otherwise good. Tried Lubeta since it’s basically thin solvent with a small amount of oil. The trick is patience. It takes a day or two for any liquid to get between the screw and the thead. Have a look on youtube for experiments using all the popular potions. Even overnight on large nuts the penetration is minimal. If you have room make a little moat with Rodico so the screw sits under your tiny paddling pool. Please get rid of the dial before you start. Practice servicing a couple of old indian hmt’s -the ones that say “fully serviced” they will get your skills well up to expert1 point

-

Haha, stick around Joe i will teach you everything i know. Wouldn't you know it I'm even a poet Oy tricky Dicky, I resemble that remark1 point

-

I have a Spring drive , relaxing to watch the sweep hand glide but the piece itself is a heavy son of a gun you feel like you carrying an army rifle, later models are somewhat less heavy, but all are made of high quality material. Service expenses are high as you ought send them in to Seiko authorized service centers where owner is charged an arm and four legs. Don't get me wrong please, thats how I fee like ! four legged , everytime the bill is too high dollars. King Seiko normally cost you less and some are officially certified chronometer which truely comply to COSC standards.1 point

-

Well...this post caught me off guard "Grand Seiko?" Sorry I am stuck in a Wittnauer C11KAS...lol. So, I went off to discover what is a Grand Seiko. Interesting...Spring Drive...fine finishing...big $$$$ Well, I must have been sleeping or playing with Mickey Mouse watches. Didn't notice. LOL. Rolex, Omega, Grand Seiko, Seiko Presage...they would look nice on my arm, but my JD Tractor does not care. I showed up late to this party I guess. Cool watches for sure...don't get me wrong1 point

-

Good timing for your question I was looking for something related to grand Seiko is and the website below those looking at is really good. When you had the word grand to Seiko you're supposed to have a very nice looking watch. I'm not looking at the band itself I'm looking at the watch and the dial doesn't really looked as grand as I would like to have a look. But there's also a really big giveaway here which model is this exactly and where's the case back number who would sell a Seiko without showing you the case back? https://www.theseikoguy.com/grand-seiko-vintage/ You never know with Seiko where somebody might not grasp what the word grand means and your Seiko might be cheap perhaps unfortunately the price of Seiko's have gone up. It seems he a lot of people that want to collect those. Then if you achieve there are alternatives perhaps. Lots of other Seiko watches that may be art grand but still are quite interesting like at the link below. Which probably explains why a recently acquired one of these. http://www.beyondthedial.com/post/collector-guide-the-seiko-crown-special-an-alternative-to-vintage-grand-seiko/1 point

-

Welcome Thomas, as you may be starting to realise watch collecting can be expensive. As you may not realise watch repairing can be even more expensive. Tbf if you are an avid collector being able to repair and service what you have and cheap bought non working to fix and add to your collection, the cost for tools etc can be offset against that benefit. Who am i kidding?1 point

-

I've no idea either but the strap does look poor. Searched plenty of images and I can't find one where the dial look like a badly cut putting green. Hehe.1 point

-

hey, thanks for the response! I am just starting to delve into the world of horology, and I seem to have bug. I have a growing collection of modestly priced timepieces; nothing fancy, but all personally interesting for different reasons e.g. an original timex marlin, a modern seiko sacm171 with high accuracy quartz, a handful of microbrands etc. I am not sure that I will progress to my own repairs, but I find the theory part fascinating. I've consumed a couple of books - wrist watches explained by michael fraser was my most recent find. in particular, I am interested in caliber design and the intersection between the science and the art. fwiw, I am based in the uk.1 point

-

You can stone the flat a little bit, but really they need to be ground along the length. The flat is at the centerline of the tool, but generally they are made just a hair above, like 0.02mm. If ground below, they can start behaving strangely, even cutting oversize.1 point

-

Ah i saw the Seitz last night as well, it went pretty cheap. Nobody bid on the one i have and the starting price was quite low so pretty pleased with the purchase. These are always a bit of a gamble with the condition of the pushers etc, worth paying a bit more for something thats been looked after by a good pro.1 point

-

Think I nearly bid on this one but didn't remember until after it had finished. Did the same with a Seitz one last night.1 point

-

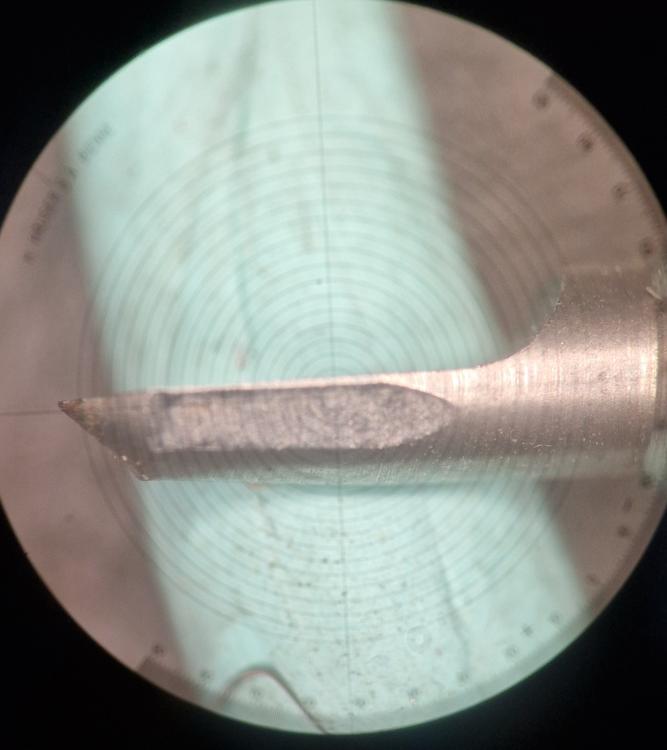

The reamers I have (Chatons SA watch size, Bergeon in clock size) have relief ground in on one side, which is to be the cutting side. I would be surprised if there is no relief on yours... but- they can cut without it, just not very freely. If you look at the pic, the relief is ground almost to the flat face; the little "land" there keeps it from digging in, and the relief lets it take a free cut. I think you'll find they do cut better going the right way. I have yet to need to sharpen one, but you would have to grind the entire taper in a uniform manner or it won't cut at all. Tricky work. These are called D-bit reamers in the machining world if you want to Google it, lots of info out there.1 point

-

1 point

-

The reamer is the same size both sides so it makes no difference which way you cut. They must have had a hell of a lot of use or the metal must be quite soft if you need to sharpen them, when I sharpen graver's I use an Arkansas stone with a little oil, that should do the trick, you can buy very small stones.1 point

-

1 point

-

This is to be my project. May take a while as I want to get it right. DOXA by Synchron. Movement is Cal 41 (ETA 2750) Winds OK and runs OK. However, I will do a service and replace the crystal and any parts. I have not yet opened the watch. Looking at videos first to familiarise myself. Placed on Timegrapher. Result can be seen in photograph.1 point

-

Some more positional readings will might show you where to look for issues Ross. Nice watch btw.1 point

-

The 2750 is a nice movement to work on. Aged enough to make you feel like you are working on an older watch, but new enough that the shock protection is modern and parts/spares are plentiful. It's one of those ETA movements where you don't need to pull the cannon pinion – it just slides on with no "snap" so it comes off easily as well. It has dial hooks rather than screws, and a push-button stem release instead of a screw head. Oscillation is a bit faster than its 18,000 predecessors (2370 and 2390) but not as fast as the 28XX generations. Most non-military 2750s don't have the balance stop lever installed, but the plate will be milled to accept one so it's easy to drop in if you can find one and you want a hacking movement.1 point