Leaderboard

Popular Content

Showing content with the highest reputation on 06/13/23 in all areas

-

Do you want just a movement or a whole watch? It would be really hard to beat one of the 30s- 60s Omega 30mm movements, here's a read. Anything from Longines up to the late 60s is amazing, for precision go for the larger calibers like the 30L. Peseux movements are pretty fantastic across the board, and there is a "current" one available from ETA, the 7001 (at least I think it's still in production). There are others, depends on what you can spend. An IWC with a caliber 89 movement is fantastic, but will cost a lot more than something with a Peseux movement. For pocket watch, the 992B John mentioned is probably one of the best movements ever made, with Hamilton's own Hamilton Elinvar Extra hairspring and stainless/ Invar ovalizing balance, it completely solved the residual middle temperature error.2 points

-

Hi. You would need a hook attachment to hold the other punched end springs, just drill the bracket near the outer end or remove the post if that’s possible and attach a strong hook though the hole/slot. The spring would fit onto the arbour the hook in the spring end then keeping control of the spring ( gloved hand) wind up as normal and clamp or wire up, or if you have them retainer shells/rings.2 points

-

2 points

-

you already have a vintage Timex, so no need for anything else!2 points

-

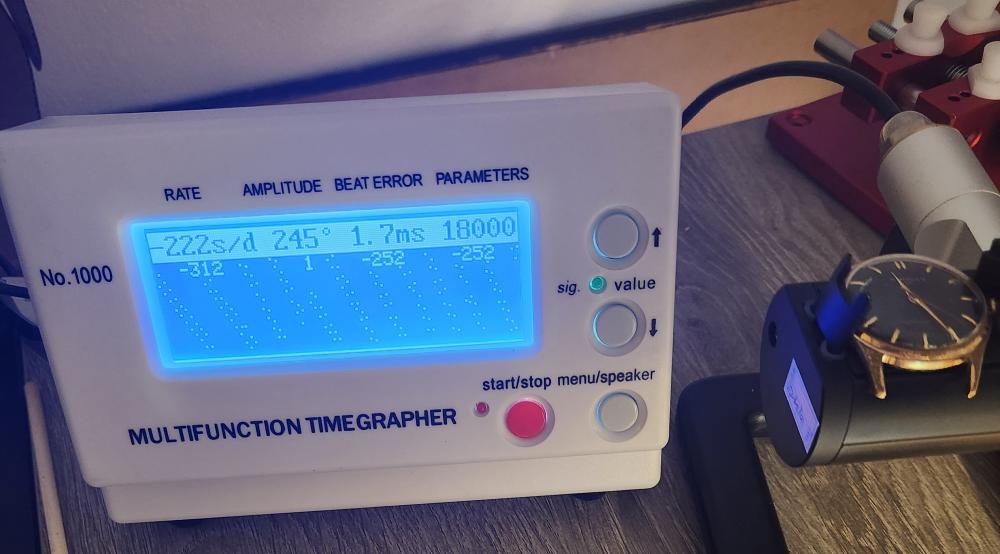

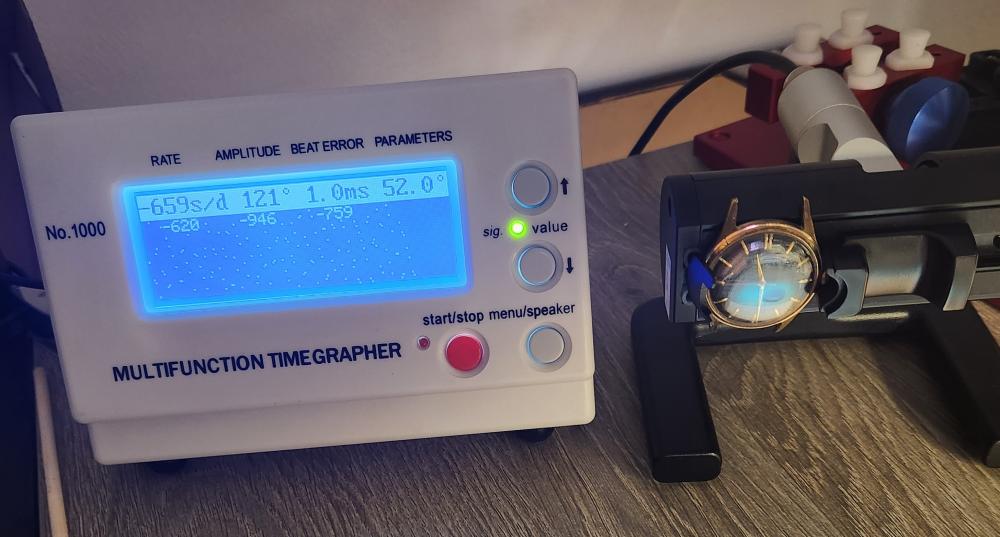

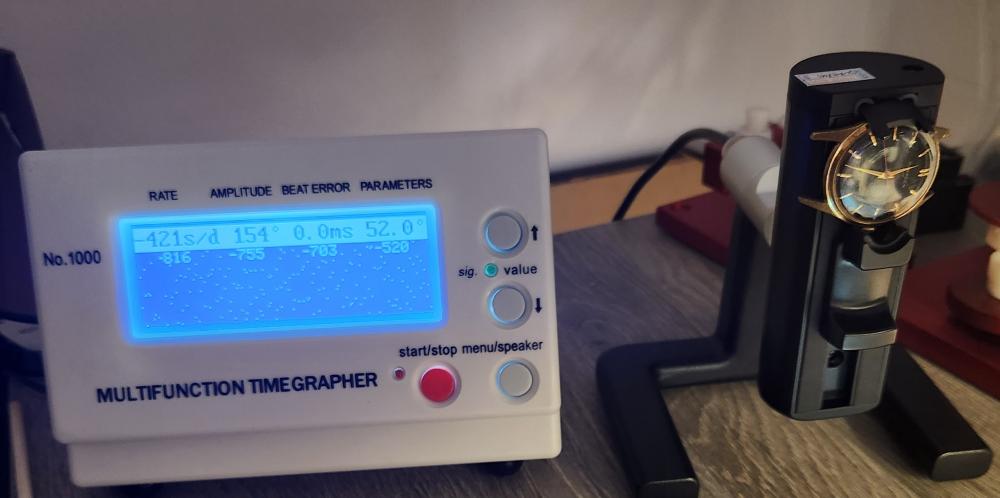

This one has been waiting patiently in the tray for several months but I'm calling it done this evening. A FleaBay Waltham A-17 that was a non-runner I've been pecking away at. It was seized up tight. A photo of the flabby before to follow… If you're familiar with Waltham military you'll recognize it's the predecessor A-11 dial. Some intelligence gathering suggests some of the early A-17s went out with A-11 dials or Corporal Endshake may have dropped an old A-11 in there to get it back out in the field. Of course it could be all the back and forth on EBay. Forever a mystery.... I'm passing it off to a friend who resides in Waltham so I went for authenticity and will send along the old dial JIC. There's new lume that won't upset the geiger, new escape wheel, bridge screw and some balance poising. Unfortunately I borked the collet when I got greedy for better than naught-point-six on the TG beat error, but now sorted it runs strong and flat on the TG any way you hold it. I've heard 30 seconds/day is great for these but so far this one is a bit better than that... Edited 40 minutes ago by rehajm2 points

-

I've seen a Vostok 2409 (no complications and costing about $30 new) with an average accuracy of about 3 seconds per month. A bit of luck, of course, but still. A change in the way I was using it and it wouldn't have been as accurate (wearing it for about 16h a day, always wound in the morning, not subjected to any extreme gravitational forces or magnetism, and resting dial-up during the night). Basically, most watch movements can be averagely accurate as long as they are in good health. However, only a few really high-end movements can be precise. The ones listed by @nickelsilverlikely belong in that category. So yes, there's a difference between accuracy and precision. Imagine a rife shooting on a target where the lowest score is 1 and the highest 10. If all rounds hit, for example, a score of 1, it is precise, but not accurate. If all rounds are spread around the target, it is not precise but it can be accurate provided the average is in or near the middle of the target. My Vostok belongs in that category. In general and before quartz, if mechanical movements had not been able to be averagely accurate, timepieces would not have been affordable to the masses. Luckily, the Swiss lever escapement is a very robust construction. Without it, the world would likely have looked very different as an efficient society can't function as well without people being able to tell reasonably accurate time (+/- a few minutes). Here's a very interesting video about accuracy and precision from where I got the analogy between a rifle and a watch movement. A special thanks to @nickelsilver for the suggestions. My next watch purchase will have one of the movements you listed for sure!1 point

-

Hi New. On its own it’s an interesting tool another variation of getting the job done, by the way it should be clamped in a vies to use efficiently. But i guess you realised that.1 point

-

Didn't really care about whether you using a jar for a beaker. When I was curious about the answer the question was in between did you do anything to remove fluid which you're doing I still find it interesting. It be interesting to take a plate and just run it to the cleaning and then don't run it through the rents and see if you have the residue.1 point

-

Just be careful choosing the right ones. A 6mm collet isn't just 6mm collet it also has a thread pitch which can vary. Keep your eyes peeled for genuine wolf jahn I know the 8mm version matches up with Bergeon and one other but not sure about the 6mm. I have a book somewhere with a table of the different sizes , i can dig it out later if that helps.1 point

-

This came as a 'NOS" watch, which the case is. On the other hand, the ETA 2789-1 on the inside was anything but. The movement looked like it had been sitting in pieces in a drawer banging about for a few decades before being reassembled. It runs fine, just a lot of wear and tear on the parts. This is the "youngest" watch I've serviced (1980's?) and the first watch I serviced that had both a quickset day and date, which sure is a joy to use. The instant change day/date is pretty cool too. I do love the look!1 point

-

I used to get this problem too. It happens when not using a watch cleaning machine which spin dries after each solution. I think a small amount of cleaning solution with dissolved lubricants remains in the jewel holes at the end of the 2nd rinse and when it dries, it creeps out of the hole and leaves a ring of oil. Now when I use the ultrasonic, I put the basket in a specially designed bottle with a bolt coming out of the lid, chuck it in my cordless drill and spin dry. I find that I don't get this problem anymore.1 point

-

Eyup watch peeps, i hope we are all well and have enjoyed our weekend. I'd like to show off my new jewelling tool if i may and pose a question or two to add to our previous discussion last week regarding reaming holes with the Seitz. My lovely post lady delivered this Marshall jewelling tool and set this morning. Its not extensive but it is complete inc. reamers and in great condition barring a little touching up. This is my first play at enlarging jewel holes so re-reading last weeks discussion and applying the information make a big difference to my understanding now. Now ive toyed ive realised that there is 2 cutting surfaces and both are usable. I dont think that the use of both sides of the reamer was mentioned last week. So my first question would be what the effect on the hole would be if the reamer is used to cut both clockwise and anticlockwise during the same hole enlargement. Or is the best approach to cut entirely clockwise or entirely anti clockwise ( I'm thinking this is better ) . And if that could minimise or increase the asymmetric wobble produced while cutting, which tbh I'm not really noticing ( i assume Endeavor noticed it more because of the large plate being cut ). So having the two cutting surfaces gives us twice the life extent of the reamer. This brings me to my next question of how to sharpen the reamers in a non professional workshop. I appreciate any replies and hopefully this helps other new to jewelling members.1 point

-

Interesting questions @Neverenoughwatches! I never thought about this, so I quickly looked at my Seitz jewelling tool reamers and they all have the "relief ground in on one side" as @nickelsilverdescribes and shows (thanks!). I thought this might be interesting knowledge for anyone looking to buy a jewelling tool. Seems like we should stay away from trying to sharpen the reamers, huh? If really needed and I already have a Seitz jewelling tool, I'd just order a new Seitz reamer instead. Cousins have them for £9 each.1 point

-

1 point

-

Thank you chaps, i was a bit unsure if it was of any use as it was almost a freebie, and i half expected you to say its rubbish chuck it in the bin. After your help I'm now sure its worth hanging on to.1 point

-

Use the hot glue and jelly jar lid trick but find a deep well socket that fits just right. In the USA there are hardware stores what sell economical quality single sockets…1 point

-

I would just like to add to what watchweasol has just said. You could drill and tap the hole and screw in a screw.1 point

-

The Seiko crystal code for your watches is 315W02AN0, and the Sternkreuz equivalent is XS317.407. Very nice watches BTW.1 point

-

Yes, I watched. The stickies were…maybe the responsible fix given his skills? Is cold epoxy or low temp solder a better solution? I’ll defer to the experts… It showcased the positive aspect of this vintage revival, I thought. So many amazing things would still be sitting in the sock drawer…1 point

-

I had a stubborn screw on the back of a Fossil watch. One of four on the back, they were crosshead. It was solid and someone had tried before and almost made the cross head round. I tried with heavy pressure, but not heavy rotation, to move the screw. It was solid. I sort advice from the members. I placed WD40 on a cotton bud and placed it over the screw to soak. Did this a number of times. I used a flat edged screwdriver to allow purchase on the edges of the crosshead, then I applied rotational pressure. Only a few tries. It did not move. I did this system every day for nearly 1 month. WD40 followed by heavy pressure but not heavy rotation. Did not want to damage the crosshead anymore than it was. Nearly 1 moth later the screw moved! It was like it had never been tight. 10 minutes later I had changed the battery and the Fossil watch is like new. Good advice from the members. If you have to use heavy force, then you force a break.1 point

-

I think you're asking for the impossible because you don't actually understand what you're looking for. Accuracy is not determined by its simplistically it's determined by other things this will present a challenge for you to find something that does this. Okay simple that means no automatic no complications at all. How about a SW210-1 b? It's manual winding and it has a technical sheet so I can explain things. I'm attaching the PDF below. You'll notice if you read carefully at the movement comes in three different grades Elaboré, Top And Chronomètre. They're all sort of identical except the two upper grades If you go to PDF page 4 you can see the various grades and what the differences are. First thing we see is the balance wheel nickel balance wheel on ordinary watch much much nicer balance wheel for the two top grades. Basically a balance wheel that doesn't change because of temperature chronometer grade watches are supposed to run and keep time regardless of temperatures. Looks like they're shortchanging on specifications normally they hairspring is different for the two top grades I was the balance wheel and hairspring are decided not to respond to temperature changes. Then we get the PDF page 5 we get timing specifications you notice I don't actually publish the chronometer grade because you need the chronometer grade specifications which is published by another company. Also the top grade watches identical to the chronometer grade except somebody has to tweak it to the chronometer grade. Yes I know this because I know somebody who purchased movements from them originally there were supposed to get the chronometer grade but then they wouldn't sell them slanted top grade adjust them and submit them for chronometer certification. So yes the top grade will keep chronometer timekeeping somebody has to do the manual labor save your money and extremely accurate watch all have to look for one that says it's a chronometer grade watch which is different than the suggestion down below of what a chronometer Is. https://sellita.ch/index.php/en/movements Yes a Marine chronometer definitely would not fit on someone's wrist. But do we really need a Marine chronometer anymore?To understand what a Marine chronometer is I have a link basically I think of it as a clock with a detailed escapement. But it's not your regular clock and yes it keeps phenomenal time.. But one little mishap and it's an expensive thing to fix. The detailed escapement is very unforgiving to things happening to it. https://en.wikipedia.org/wiki/Marine_chronometer So classically at least until modern times chronometer would refer to a clock with a detent escapement that keeps phenomenal time. You can have pocket watches with detent escapement's but I would really recommend not having one of those. Today of course chronometer just means timepiece that keeps really good time Here's a link to the Swiss people who certify whether your watch keeps good time are not. Unfortunately the Swiss will not look at other watches that are not Swiss because then they would feel embarrassed as Seiko has watches that will keep chronometer time keeping and so do other people so they only certify Swiss watches this means if you want to your watch chronometer certified jewel have to go to one of the other certification agencies https://www.cosc.swiss/en/certification/chronometer Now back to do we really need a Marine chronometer in the answer is no. When Hamilton was doing a Marine chronometer they worked out a better way to make a balance wheel a bimetallic without having a bimetallic. Traditional chronometer making with the bimetallic balance wheel from what I had once read was once your chronometer balance wheel and hairspring or in the clock it needs to stabilize for one whole year before you can regulate it that's because there's a lot of stress on the metals to put this thing together Hamilton figured out a better way. So the same balance wheel bus used in their chronometer at least the concept is found in a Hamilton deck watches. When I was reading was if the deck watch had come out first the chronometer would've never of come out. So if you want something really nice for timekeeping that does not quite fit in your pocket get a Hamilton deck watch or? But the same design of hairspring and balance wheel found in those is found in the Hamilton 992B they could just buy one of those. But if you're not going to do your own work you're not going be super happy because more likely somebody's played with it and it will require adjusting to put it back to keeping really good time plus they in general need to be serviced anyway Then I'm attaching the specifications for Hamilton 992B just you can see what timekeeping they can keep the problem becomes if you don't want to do your own work you basically should just go by Rolex or a grand Seiko or anything that says it's chronometer rated. Or something vintage just buy a good railroad grade pocket watch but they may require some work to get them back into keeping really good time. DocTec_SW210-1.pdf Hamilton 992b 950 timing.pdf1 point

-

Does it have to be a wristwatch? Large balances are good for accuracy, so a marine chronometer? I am surprised at how accurate some of my old pocket watches are - again nice large balances. Are you planning to tweak it for accuracy, or do you just want to buy an accurate movement?1 point

-

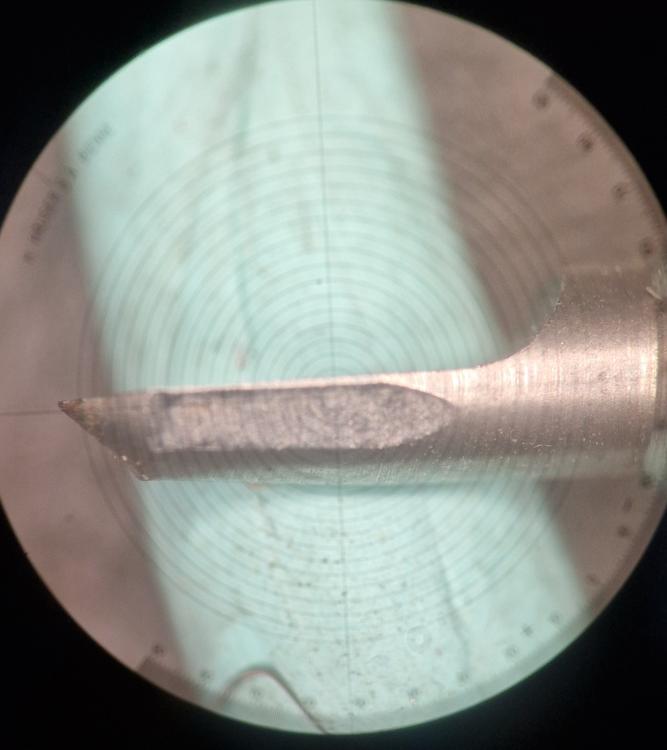

You can stone the flat a little bit, but really they need to be ground along the length. The flat is at the centerline of the tool, but generally they are made just a hair above, like 0.02mm. If ground below, they can start behaving strangely, even cutting oversize.1 point

-

The reamers I have (Chatons SA watch size, Bergeon in clock size) have relief ground in on one side, which is to be the cutting side. I would be surprised if there is no relief on yours... but- they can cut without it, just not very freely. If you look at the pic, the relief is ground almost to the flat face; the little "land" there keeps it from digging in, and the relief lets it take a free cut. I think you'll find they do cut better going the right way. I have yet to need to sharpen one, but you would have to grind the entire taper in a uniform manner or it won't cut at all. Tricky work. These are called D-bit reamers in the machining world if you want to Google it, lots of info out there.1 point

-

Hi there is a putty like waggy said I have some. Got from the hobby shop, Iam sure that Kirsten on repair shop used some for a dial repair for Steve Fletcher and another women did the numbering very goo at it .. Google. Enamel watch dial repair putty should find it The stuff is millionth availablein various colours. Dis regard the predictive rubbish …. Product is Milliput available in several colurs. Try again.1 point

-

1 point

-

That’s an astonishing presentation. Clear, concise and complete. I doubt I shall ever be in you league, but I’m only 3 months into the hobby!1 point

-

yes these vintage documents nice where they explained things versus today where there is slightly less explaining. It also brings up a problem. The biggest problem is exists and how do we know it exists because I scanned it to a PDF you can see it exists but otherwise how would you know this exists? It's the annoyance I have with the watch companies where there's so much bonus as I will call it documentation that never sees the light of day just because it doesn't. Basically all the procedural stuff of how to do things. Then today it's even worse because they don't want to share with anybody even including people that have accounts with them then epilam? Is it really needed in your shop maybe maybe not. its purpose is to keep the lubrication wherever it's been placed hopefully for the time in between servicing. Always bad for a variety of reasons if your lubrication is no longer doing its thing because it's typically spread away from wherever you placed it with the unfortunate problem of synthetic oils not getting sticky conceivably on a timing machine we may or may not see a problem with the lubrication. At least not until it's really bad and then it will be extremely bad then do you really needed in your shop? If you look at the scanned document what are they using on the keyless and yes I know I should a photograph that page where I get all the lines to line up with their bottles. If I knew where I put the physical thing I'd rescan at least that part. But they're using something really thin on the keyless. Oh don't worry I had looked and they're using something heavier in a few years and now are all the way up to heavy oil? So basically with the oils that are using epilam will allow them to stay where there supposed to be. But what about if you used grease instead? Especially if you using some of the horological grease. for instance if you look at some of the horological greases we will see that it has thixotropic properties. In other words is a grease and stays were you wanted but on friction becomes more fluid. Wouldn't this be better for keyless works it will stay where it's needed then would you still need epilam for a grease perhaps? then in the case of @LittleWatchShop I believe he is currently hoarding the world supply of Elgin oil. A oil that has a very interesting property and what I can tell much much better than the Swiss oils of it stays wherever you place it. So conceivably you don't need epilam because it's better at staying wherever you put it. so basically it isn't going to hurt anything isn't going to improve the quality of lubrication but it should hopefully guarantee that the lubrication stays wherever it's been placed in between servicing. As opposed to mysteriously disappearing like lubrication's sometimes do.1 point

-

Hey, Ok, no more inhibitions! Here are a few links: https://www.ebay.fr/itm/285282262920?mkcid=16&mkevt=1&mkrid=709-127639-2357-0&ssspo=57nfUKW_Txy&sssrc=2349624&ssuid=-tqzh2byt-e&var=&widget_ver=artemis&media=COPY https://www.ebay.fr/itm/275705044040?mkcid=16&mkevt=1&mkrid=709-127639-2357-0&ssspo=57nfUKW_Txy&sssrc=2349624&ssuid=-tqzh2byt-e&var=&widget_ver=artemis&media=COPY https://www.ebay.fr/itm/394635018656?mkcid=16&mkevt=1&mkrid=709-127639-2357-0&ssspo=pdtyoikkrmk&sssrc=2349624&ssuid=-tqzh2byt-e&var=&widget_ver=artemis&media=COPY1 point

-

I thought I could share my journey servicing an ETA 205.111A Autoquartz. Yes sometimes I just get an urge for something different and now it is a bunch of quartz movements in my scope. Today I have taken it apart and made a small PDF describing the process, might be one or two interesting shots in it. When I received the new capacitor part two will be released. AutoQuartz_Disassemble.pdf1 point

-

Now the capacitor has arrived and the assembly of the movement is finalized. After Reading Andys post about a glove box I too realized how important it is with a Clean enviroment when working on watches so i invested in this glovebox. Now i can have a Watch repair meeting with up to 8 participants working in an extremely Clean enviroment . The progress is as usual documented in a pdf file called Autoquartz_Assemble. AutoQuartz_Assemble.pdf1 point

-

1 point

.thumb.jpg.5bd474e8169c40e92fc6c5ae2e622e81.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)