Leaderboard

Popular Content

Showing content with the highest reputation on 06/14/23 in all areas

-

If using a round punch on the barrel side, you have to be really careful not to make a dome larger than the shoulder of the pivot. The shoulder will go into the dome, increasing endshake and massively increasing friction. I won't say I never close holes with punches, but I've found it's quite hard to do it and have a really good result. The hole will close, but not be cylindrical anymore. So you broach it a bit, which still isn't cylindrical but an improvement, but now maybe the hole is as big as it was to begin with, and back and forth you go. If you close it just enough that the slop is taken up, the fact that it's small in a small portion of the hole length means it will wear quickly back to where it was. I have the view it's kind of like putting sawdust or bananas in a noisy car transmission, helps for a while, but not very good long term (I know I just dated myself there).3 points

-

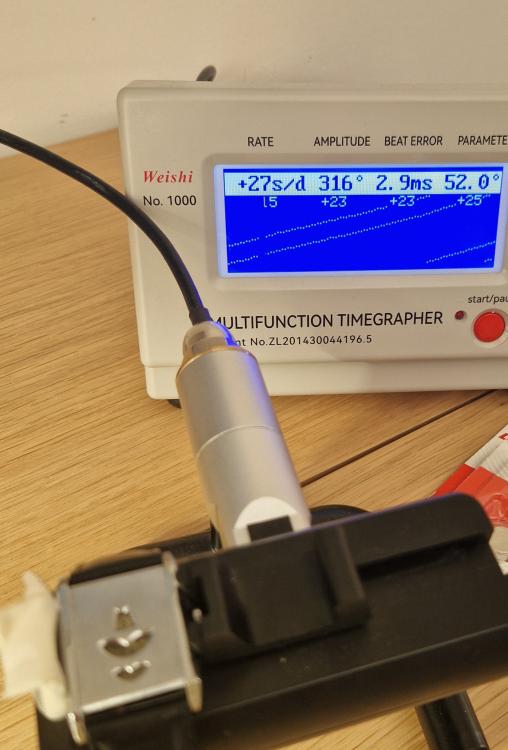

Hello everyone! This 1930s non-branded jump hour watch has been my project for a month or so. The balance spring was broken and the balance wheel wasn't staying in place. One of the old-school cap jewels was broken. And DIRTYYYY! During cleaning, the plating on the movement parts came off... I then had to clean it again several times to the get it off completely. Another non-running donor AS 574 movement helped with the broken cap jewel, but the hairspring also wasn't doing so well... I managed to get another balance replacement from the UK -- which arrived today. So this afternoon was the big moment to finally put the last elements together! And it runs well! To be honest, the timegrapher screen looks better than it really is. It fluctuates quite a bit over the course of a few minutes. The amplitude goes up and down between 280 and 315 (dial up, fully wound) and rate between +40 and -30. Must be a bent pivot (where the second and minute discs are directly attached). But I think it averages out. I'll wear it a few days and see. Not sure if I'll tackle the beat error. Since I have manipulate the collet of the balance spring, it feels too risky. I doubt that I'll find another replacement if I slip... It's a funny mechanism, I must say. The seconds disc is directly stuck onto a prolonged seconds wheel pinion. The minute disc is directly stuck on the canon pinion. And the hours disc is just screwed on without any connection to the movement --- it is moved by a tiny "thorn" on the minutes wheel and stopped from spinning by a special spring. When the "thorn" of the minute disc engages with the hour disc, the movement clearly struggles a bit with the resistance -- for about 1min, the rate goes down to -300sec/day and the amplitude drops by 50°. But as soon as the hour "jumps", the movement recovers quickly. Next will be an effort to restore the minute disc. Original state of the movement with broken balance spring (etc) and its original colour/plating3 points

-

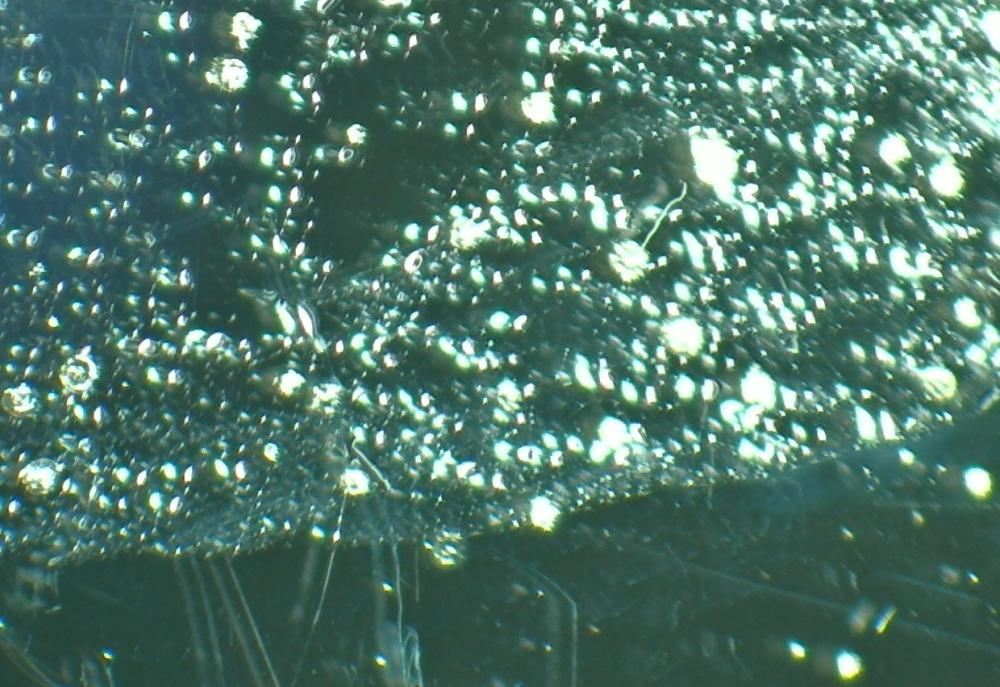

I just did an experiment (I love an experiment ) @HectorLooi to test your theory about fluid remaining in the jewel holes. I put the mainplate back in to the rinse for a minute, blow dry with a puffer, then 30s IPA. Result = small deposits around the jewel holes. I then repeated, but after the 1 min rinse, I made sure I blew the solution from the jewel holes. Result = almost clean jewels. So slight contamination in the rinse, and IPA ? So I used fresh IPA for another 30s = clean shiny jewels. I wouldn't expect fresh Elma Suprol Pro rinse to leave a residue, so I just put a large puddle on a mirror and evaporated it off. Result - I can't see any residue. I then repeated with Elma WF Pro cleaner - as you can see, it leaves an oily residue which beads-up like the deposits on the jewels. Conclusion. The deposits are not due to pure rinse solution. Maybe the cleaner solution, or a rinse (contaminated with cleaner) is remaining in the holes and only gets cleaned out in the IPA. It's only the small jewel holes where I see the problem. The larger jewels where the solution is unlikely to remain don't show the problem. So from now on, I'll make sure the jewel holes are blown clear after each step, and change my IPA more frequently3 points

-

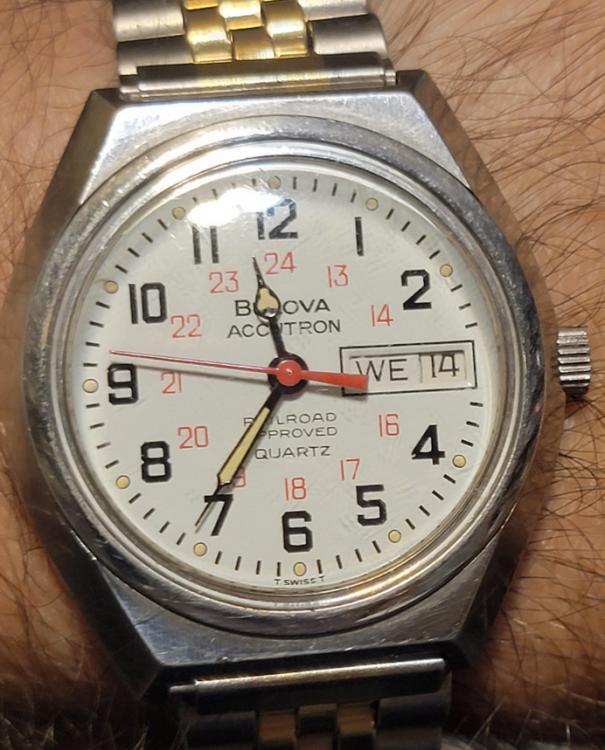

Looks like it's to adjust if you have drift in the seconds hand. From the Accutron 242 service manual found over at Watchguy:2 points

-

I would interpret it to mean: a plywood constructed with (at minimum) a layer of hardwood on the outside face. I believe most plywood is sheets of fir laminates. Some plywood is laminated with all hardwood sheets while some may have a particularly figured sheet of decorative hardwood on the outside face.2 points

-

I haven’t done loads of that kind of work, ideally close from both sides but if you're not comfortable with closing the outside it should still work. Tbh i would say only a temporary solution even more temporary if the watch is worn daily. The thickness of the bearing material is going to be much less than it was when it left the factory so its going to wear quicker that it did originally.2 points

-

2 points

-

Always stick with the barrel diameter ok, you could drop a little on the height to compensate for the additional strength of the new spring, just incase yours is 0.4 mm strength. But I would be happy ordering the cousins one as a replacement. Is the old spring shot? if its still 2 1/2 times the width of the barrel diameter when relaxed and not coned then its still good to use.2 points

-

i would be much obliged if you are able to come up with something. thank you. i bought a one inch socket today at the local hardware store. i got to show off my ww2 watch to a couple of young sales associates; they seemed quite interested in the old watch. then, without adding the glue i thought i'd try laying down some of that non-skid rubber padding on top of the bezel, under the socket. voila, it came right off. Thanks for the ideas. Arron.2 points

-

Is anything in watchmaking ever easy? So, I need to add metallurgy to metrology, stereotactic brain surgery and an ability to cuss fluently in half a dozen languages. I'm truly doomed.1 point

-

I'm always wary of anything which refers to a "Joy" machine. The last time I bought one, it really wasn't what I was expecting. The wife still keeps it in her underwear drawer, I guess for sentimental reasons1 point

-

I work in oak primarily and had some offcuts of this https://www.howarth-timber.co.uk/plywood-white-oak-veneered-single-side-2440-x-1220mm/. Sanded off at the edges and only needs to be 10cm by 10cm for my purposes. I had 6 ply, but for this, 3 ply would do. Ive found that for me, by supporting the last cut, subsequent ones are more accurate and less likely to result in tip snappage.1 point

-

Done it numerous times. There's a limit how much you can take off, and the sides become sharp rather than rounded and that has to be addressed. You can't take a 2.00mm spring down to 1mm for example, there won't be a hole anymore. I've only done it when there was simply no other option, typically ultra thin pieces. You really have to glue (I use black Loctite super glue) it to a flat support, and have a bit of a method to keep it uniform. If you don't glue it down, inevitably the center coil becomes thinner than the rest. Of course you have to grind a bit, then unglue and reglue the other side and do the same. It's a hassle, but can save the day.1 point

-

A glass spindle shaper. Soldering gun for soldering the lead joints. When i began work as a joiner some 40 years ago, i spent years replacing windows, the top lights of pre war house windows were often stained lead lights as we called them. We had buyers for them that shipped them off to America who probably made 10x what we were paid. Bloody shame, if i knew then what i know now i would have kept them here were they were made.1 point

-

1 point

-

I picked up a couple of these as part of a parts/tools/watch lot. The dial reads well, so I like that aspect. It is quartz, so it keeps accurate time. There is a feature on this watch that I do not understand: ACCUSET. I have found descriptions and instructions but they make no sense. Probably does not matter, it is running as accurate as I need.1 point

-

This was also my thought, especially on a high-pressure pivot like the barrel. Thing is, I don't have a Seitz style jeweling press, nor reamers. I've been searching for reamers that would fit my staking set, but no luck. I have been wanting a lathe, though...1 point

-

You really need a microscope to do this properly - I don't think you have enough magnification with a loupe. I need to take the 0.5X Barlow lens off to give me 45X mag to be able to see the oil under the teeth clearly. Too much oil can kill amplitude (as I recently found on a small ladies Omega).1 point

-

Getting the right amount and type of lubrication between the surfaces of the escape wheel teeth and the pallet stones can have a pretty dramatic effect on the amplitude. And, treating these surfaces with Fixodrop (or some other brand of epilam), makes it so much easier to get it just right.1 point

-

Glad it worked out. The hot glue works on that principle- grip and surface area. When you’re finished it peels right off. The Horotec Maxipress case back opener has a set of dies with a rubber-like grip surface, too. Same idea…1 point

-

There are two reasons why wouldn't use this for cleaning a watch case. First you really should be using a water-based cleaner this soap and water and toothbrush will do quite well. Second the definition of soak how long are you thinking of soaking it? The watch cleaning fluid has ammonia which is really nice for making things bright and shiny. But typically when cleaning watches you would want to go more than five minutes I typically go four minutes. Because the ammonia that makes things bright and shiny if left too long to start the etch brass your solution will turn green and brass things will be frosty. Goldplated watch cases typically have brass that they're made out of underneath and you don't want it to look frosted. Then the word soak in this definition is bad because the longer you're in the worse is going to get then is another type of cleaner we've discussed it before they cleave even discussed DIY somewhere in the group and that would be a ionic cleaner. It really does a beautiful thing of making tarnished cases look bright and shiny without polishing I have a Link to a video that explains how it works.1 point

-

I didn't like to show my newbie ignorance, but there are some parallels I have seen with my other (woodworking) hobby. Most commercially produced blades have rough edges that can be improved by a few passes on a leather strop +/- a honing compound eg Autosol. But, for me, it's the technique of sharpening the peg wood that makes the biggest difference. I use a piece of hardwood faced ply as a cutting surface and after the initial cut, support the cut surface for subsequent cuts. Seems to keep the finest tips more consistently, but sadly it doesn't make them last any longer in use! I use Swan Morton scalpels with disposable blades (and yes, even these are improved when you get your strop on).1 point

-

You can still peen the arbor hole from the inside where the barrel sits. The outside seems like a deep oil sink or has been previously peened because of wear. Find a round nose stake to match what is already there.1 point

-

Yes thanks WW, i noticed it has at the bottom the typical solid block with a ledge for clamping to vice.1 point

-

This came as a 'NOS" watch, which the case is. On the other hand, the ETA 2789-1 on the inside was anything but. The movement looked like it had been sitting in pieces in a drawer banging about for a few decades before being reassembled. It runs fine, just a lot of wear and tear on the parts. This is the "youngest" watch I've serviced (1980's?) and the first watch I serviced that had both a quickset day and date, which sure is a joy to use. The instant change day/date is pretty cool too. I do love the look!1 point

-

I used to get this problem too. It happens when not using a watch cleaning machine which spin dries after each solution. I think a small amount of cleaning solution with dissolved lubricants remains in the jewel holes at the end of the 2nd rinse and when it dries, it creeps out of the hole and leaves a ring of oil. Now when I use the ultrasonic, I put the basket in a specially designed bottle with a bolt coming out of the lid, chuck it in my cordless drill and spin dry. I find that I don't get this problem anymore.1 point

-

The AS 1802 was produced around 1965: a_schild-1802 As you can read in the following thread Waltham has used AS calibers:1 point

-

1 point

-

There used to be somebody out there that didn't do this but I think he got overloaded and work and doesn't do it anymore. Then when you're making a machine for winding coils about a machine to make index wheel's. Then I figured out where I put the information on phasing for silver cells. I'm attaching a PDF on that. 1996-08-web horological times Accutron silver cells phasing.pdf1 point

-

Is that a 218 movement? 218s are a good starting point to learn Accutron repair. They are infinitely simpler than 214s. The uA are an indication of the amount of current drawn. It should be within the current range for the movement. An abnormally high current could indicate a faulty circuit, a dirty gear train or a high amount of pressure of the pawl/index fingers on the index wheel. A high current draw will result in short battery life. The adjustments to the index finger that we are talking about here are incredibly small. My 218 just died on me after two years. I found that it's due to an open cell coil. Looks like it's time to build a jig to do coil rewinding as working coils are getting really hard to find.1 point

-

I have to admit that when i read your reply i was skeptical, to say the least, that a piece of putty could remove what two machines and harsh chemicals could not. But, alas, it did work. I went ahead and tried a pink pencil eraser and that worked too. Go figure. It's not bright and shiny but it did remove the tarnish. Thanks for that great idea.1 point

-

Good day everyone, I just completed a watch for my wife's uncle as a gift, its a Seiko 6309 which was in pretty poor condition and a non runner for obvious reasons. I had to replace the crystal and the ratchet wheel which was completely corroded (see pictures below) I also had to replace a screw and the cannon pinion. A quick lume on the hands and polish the case and it was good to go. Let me know what you think: Before Front: Before Movement: Corrosion damage to ratchet wheel and screw(s) Here is the finished watch along with the time graph after 24 hours:1 point

-

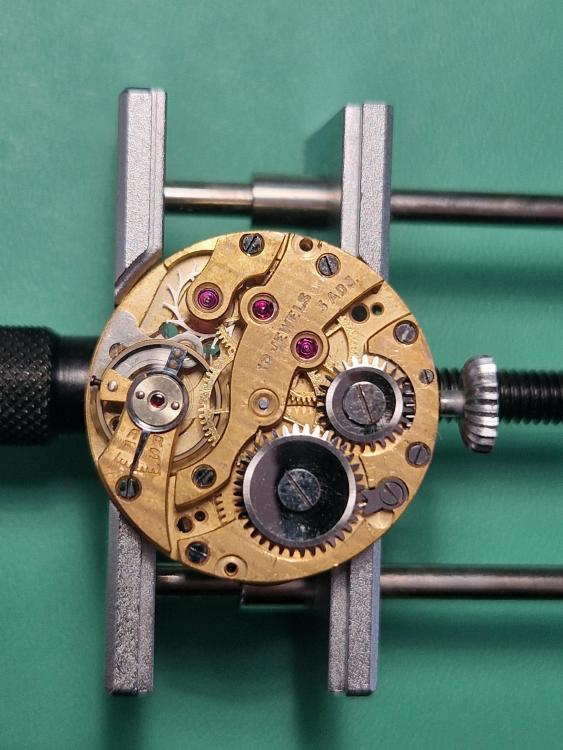

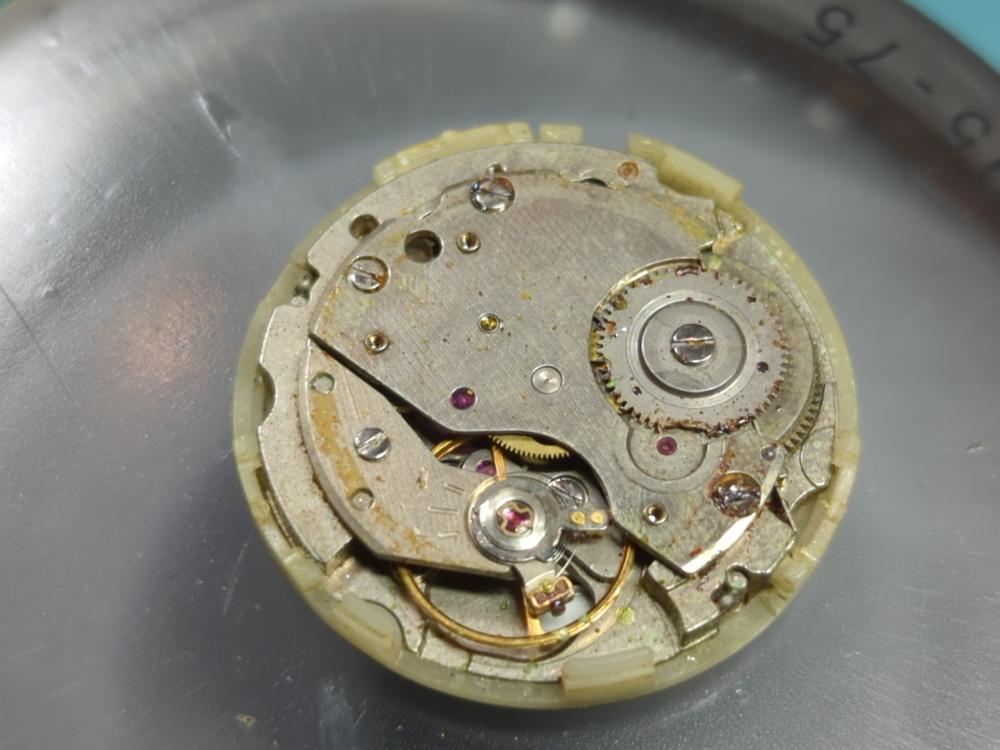

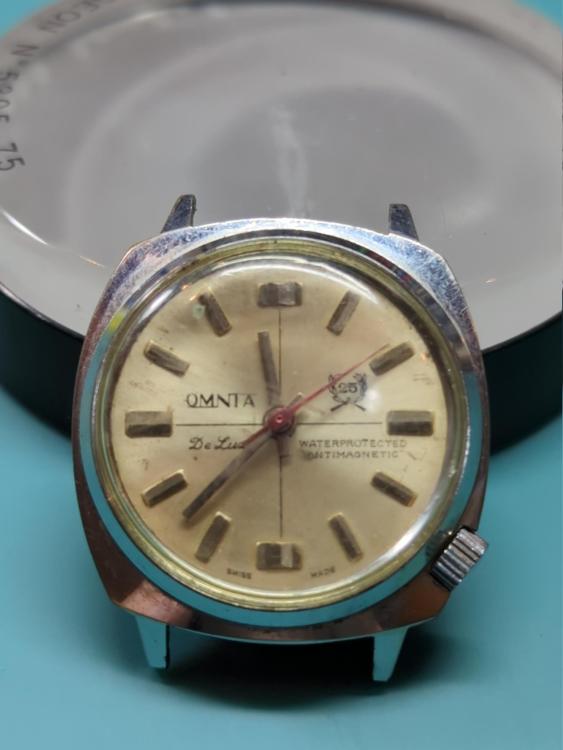

Good day, I have a new OMNTA watch to add to my collection, this watch was one of 16 purchased for £32.00 from eBay, which works out at an average cost of £2.00, so also qualifies for the 404 club The watch was a non-runner and it looks like this resulted from a broken pinion on the second wheel, also, I had to use my staking set to reduce the arbour hole on the barrel bridge as there was way too much play. Finally, the bridal was broken on the mainspring - so after replacing the wheel and mainspring (fortunately there was another watch with the same movement in the lot of 16 which I used as a donor - lucky!!) and the bridge repair here are the before and after pictures: Watch front view (before:) Here is a picture of the movement - I just noticed that you can see the orange smudge of corrosion in the top hole to the right of the ratchet wheel and just under where the click screw is, this is where the wheel pinion was broken and had to be replaced, it looked like corrosion on the pinion, but there was little other evidence of corrosion in the watch: And here is the dial out of the case, this needed a little work, and was better in the final restoration but still not 100% and I didn't want to push my luck and make it worse: And here is the finished watch:1 point

-

1 point

-

Hi have a look at this little box. I actually built one and its very good. http://www.pocketwatchrepair.com/catt/catt_pwr-supply_03a.pdf goes up to 3v has display etc worth the effort.1 point

-

Come on now that's a bad attitude it's all set up it's almost perfect other than the price. Then in the early days of electric watches the watch companies came up with all kinds it interesting things. I was trying to find a picture of a movement holder that Bulova made instead I found the patent. Doing it idea it allowed you to run the watch with a battery or his clip your leads to their test wires and run the watch that way. That I find the hook type micro grabbers work really well on quartz watches Bulova US3848484.pdf1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)