Leaderboard

Popular Content

Showing content with the highest reputation on 06/18/23 in all areas

-

I purchased a digital microscope with a 7" screen for £35 (reduced from £125 down to £65 then to £35. Don't ask me why?) When extended as high as possible, the head was too low to view the whole of the watch. I removed it from the base. Made a wooden block to higher the post and glued it on. It now views the whole of the watch. I have the post angled slightly back so that I can work without anything in the way. See the photographs. I work in a box to limit 'pings'. Post is supported by the box, so no recording wobble. As can bee seen, all I have is the desktop area for everything. When using the computer I place the box on top of the printer. I am starting to record, but using the microscope base is new to me, therefore practice is the name of the game, again. Has been really useful for inspection. This is the cheapest way I can record. Can't afford high end camera's or phones (My goodness do I envy Guy Montag). I use VCL media player and will use Shotcut for editing. I do not intend to post YouTube.5 points

-

I always advise you should start with pocket watches (not fusee pocket watch’s they are very different) Pocket watches are just the same as an ordinary watch but much bigger. Practise taking them apart putting them back together. This will give you good practise using your tweezers, screwdrivers and your eye glass. You will learn how the movement works. You will get to know the pieces. It doesn’t matter if the movement doesn’t work. I have said many times on this forum no matter how many books you read there is nothing better than to get your hands dirty. You might find this helpful. 704789946_TZIllustratedGlossary(2).pdf4 points

-

3 points

-

This post made me recall some of the (IMO) most useful videos on the Chronoglide Watchmakers channel.3 points

-

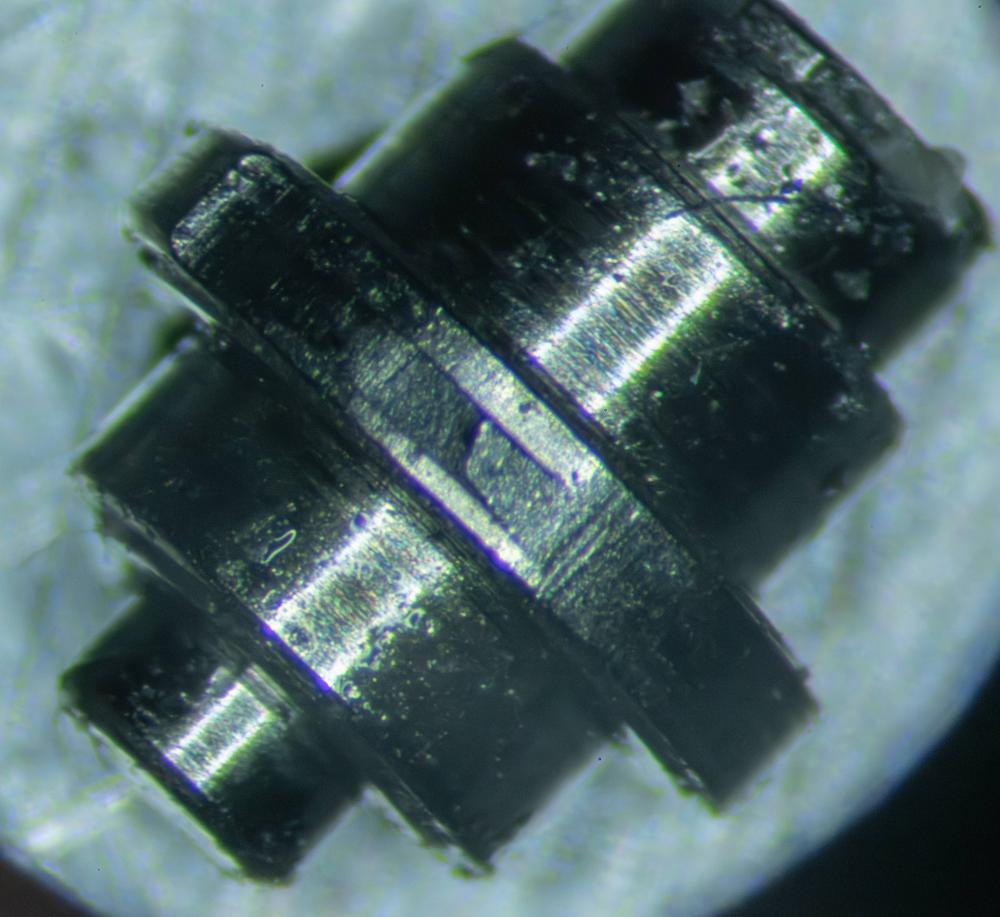

Thanks Joe. It was the bottom endpiece of the balance taken from a spare part of god know what. It was tight to move the jewel not like a plate bearing,but it did move , i thought i heard my jewelling tool groan. All sorted and endshake is good now, i think I'm about there with fixing problems. A trial run to see if it will take then it will get cleaned and lubed up. not as much give as a mainplate jewel the endpieces are only a thin plate. But still enough to adjust for a couple of hundredths either way. The offending endpiece shown here, not actually offending as the spare part got me out of a fix.2 points

-

2 points

-

When I got into watchmaking, I checked out every book my library had on it. I already had serviced several cameras (thanks to a book). I got a set of screwdrivers and some Dumont #3 tweezers, and went to town on every cheap watch I could find. Carpeted work area, no idea you could buy parts, learned how to find cap jewels in shag carpet. 2 and some years later a graduate from watchmaking school, couple years after that working in Switzerland, been here 20+ years. Be careful what you wish for! But the old books, DeCarle, Fried, Gazeley*, good stuff. YT also, but a lot of bad practices. If you want to pay your rent off watches, go to school. Want to do it as a hobby, stick with YT and this forum. There are a bunch of very clever folks in these parts. *Gazeley has so much info in his book it's nuts. I swear Daniels copped 30% of his writing from him. Deep watchmaking.2 points

-

Hello, everyone. I did work on Seiko 6106 movements in the past and they had 17 and 23 jewels. Currently I am working on 6106 with 25 jewels and the use of jewels is very different comparing to the 17j and 21j movements. First, there are no diafix blocks anymore and this is my first question - why? But the second question relates to 6 jewels, located on the main plate (4) and on the calendar cover plate (2). They have no holes, just look like small round windows and I have no clue what is their function. The picture of one of them on the main plate is attached. Please explain. Thank you!1 point

-

Can you remove the pallet fork, clean it nicely and post high magnification photos of both pallet stones. I think the entry stone might be damaged.1 point

-

1 point

-

And after burning off the fingerprint from my right index finger, creating an art deco mainspring shaped pattern on my sycamore self built desktop and an acrid stench to rival that in my bathroom after curry night, I decided to look at my barrel arbour carefully. Perhaps I should have looked before I beeped.1 point

-

There were a number of pieces in that auction that went way over estimate. Very cool for Roger, that piece deserves recognition.1 point

-

My tuppence on this, always learn the basic principles, first by reading/watching then going practical. Once you start doing the practical you will start to learn what you need to know. You then go back to the written and you then understand more, the loop continues. tom1 point

-

Or in this day and age no matter how many YouTube videos You watch In watch repair. So many people watch the YouTube videos where everything looks so simple versus how small a watch really is.1 point

-

Eyup N.E.W s. that is a pain on bench. I am not sure if the setting in cock side is moveable, lower one seems to have some leeway, if adjusting the setting suffices ! thats best approach for sure, otherwise you probably have no choice but to shorten the lower pivot. Rgds1 point

-

It’s a good question as I find myself in the same boat. Started reading a bit of de Carle but then life took over. I think I’ll go for a mix. Just enough reading to be dangerous and then tear apart one or two of the junk movements I have. Then maybe get the online class and move onto a real practice movement. This just reminded me of an approach to learning I read about. A brief hands on introduction before getting much in the way of instruction can be very beneficial. Even though you have no idea what you’re doing, when instruction starts you’ll have some context so it hopefully makes sense instead of just going right over your head.1 point

-

Thanks for the reply Rich. Happy doing it with plate bearings and jewels , wasnt too sure about an endpiece. But i expected it to move just the same and it has.1 point

-

I watched a video where the jewel was repositioned, I think this is the correct route. Someone with more experience will tell you soon.1 point

-

I have an early version of one of these. Never was happy about the quality. Newer ones should be better1 point

-

I have a similar approach to anything I'm learning. I want to know the far end of a fart but cant sit back and procrastinate. I love to jump in and get down to business and when I'm not doing that i read anything i can get my hands on. Theory is great but putting that theory into practise helps to understand that theory and formulate your own ideas. And without the knowledge building of theory your doings are blind attempts at repairing with lots and lots of mistakes.1 point

-

Have a good look to make sure there is no damage to the spring, a kink that might be stopping it from pressing into place. The rim that it presses onto has bevel to allow the spring to expand over then click into the groove behind. Check this is undamaged then a light smear of silcone or silcone spray might help the spring slip over the chamfer.1 point

-

It would be helpful if you could give some background history of the watch. What caliber is the movement? What condition was it in? Was it running? I can see that something is not right with your pallet fork. The shellac is visible on top. Shellac is usually applied to the underside. Has someone attenpted to repair this watch before? I would strongly advise beginners to work on a working watch. It would take experience to diagnose and correct faults. That's level 2 watch repairing.1 point

-

In my setup I have the camera facing the same way I do. I see a lot of top down camera setups that, because it's more convenient, have the camera mount clamped to the rear of the desk, which usually means the camera is facing opposite to the watchmaker. So everything in the video is reversed to what the watchmaker is seeing. The other thing I do with my camera is to not have it facing exactly straight down, it's angled slightly so that when I lean forward a little, it doesn't block the camera. Also, my hands are not always in the way with a little tilt to the camera. I also have that back camera so if I am leaning forward AND my hands are in the way, the back camera has a clear view to fill in for that particular moment.1 point

-

One of the problems that I've noticed when people do teaching for instance. Teaching without cameras the students come up and stand in front of the bench and try to look at whatever you're doing. Doesn't work for me because everything is backwards and you really can't see. Photographing the problem becomes how are you looking at the watch I'm using a loop others as we can see in the group are using a microscope. For instance typically with a microscope you're looking straight down. Which has minor concerns for other reasons but when you looking straight down have you noticed how your hands get in the way. When using a loop you looking at an angle and your hands are less of a problem. I've actually seen this with people filming where I can't see what they're doing because their hands are in the way. When I was teaching at the school when I did for my PowerPoint presentation was I used a Canon SD 1000 digital camera in macro mode. It's a small camera is why like Debs and I would hold the camera where my eyeball should've been and photographed the watch. So when the students were doing whatever they were doing they would more or less see what I would've seen and what they should be seeing. But if you doing that with anything resembling a professional camera it becomes hard to look through what ever to see what you're doing. This is where a lot of times people filming videos basically give up them seeing the work and instead they filmed the work for us.1 point

-

1 point

-

I have two cameras filming when I disassemble. The boom arm coming off the tripod works but I'm not crazy about how much space it takes up on the floor. Also, the camera wants to bounce for a few seconds anytime I have to touch the camera. I used to use one of these Glide Gear setups but it sits on the table top and just touching the table top transmitted vibrations to the camera. Also, sitting on the table top it was always in the way. Ideally I'd like to build a larger version of that so that the legs are on either side of the table. Unfortunately, I think that project is outside of my abilities.1 point

-

Maybe we missing something here but i think WW's theory is very plausible. It has a patent on its design, so it was designed for a reason so what or where else could it actually be used if not here. So another company designed this part to overcome an issue, the two companies may also be connected in some way. It also may have been designed for a 19 jewel version of the movement which could explain the addition of the two jewel count. Cars gets recalls and revisions.1 point

-

1 point

-

1 point

.thumb.jpg.b7c39bfd24e50ce1b860993185be6f3b.jpg)

.thumb.jpg.edba2ef8bf23d6923426e34a69073e21.jpg)

.thumb.jpg.1036995e3ae3bc0649fc5796db674011.jpg)