Leaderboard

Popular Content

Showing content with the highest reputation on 06/20/23 in all areas

-

My friend asked my to look at her beautiful (quartz) Cartier Tank. Not running, gold plating didn't look good. I changed the battery. Ok, running again. But I assumed that the gold plating had started to come of and it would need restoration (or, my preference: acceptance of a cool vintage look). But I decided to give the crystal a good rub with Polywatch. Then... as I was polishing, the diry/oxidation of the case started to come off... so I continued and the case ended up as good as new. She was elated when she saw it. But seriously, what's up with that Côte de Genève décoration !?!? Can't keep a straight line across TWO parts @Cartier??4 points

-

4 points

-

What sold west end watch in my neck of the woods was that importers provided spare parts, even today balance complete for fifty year old fhf70 can be bought. You get a standard grade automatic ETA and spare parts to it, so its still a daily wearer specially in rural areas. Spare parts to bulova, Elgine, waltham are not available here, mainly due to it being considered an American brand despite the Swiss movement in such American brands. Same Swiss movement in Swiss watch sells fast. Whoever though of watch market bearing the brunt of potitics.3 points

-

Eyup watch peeps, so is there anything more difficult than hairspring repairing and adjusting. I'm on my final leg of completing an AHS movement that involves pining the hairspring at the stud. This stud is part of the fixed stud arm so involves fitting the stud pin direct to the cock. I decided to do this while the cock is installed, seemed the best approach to work with something stable and solid fastened in a movement holder. The brass pin is super small and round, from books I've read a flat should filed onto the pin. This flat side then fits towards the hairspring allowing staightening of the hairspring before the pin is pushed fully home. After messing around for a few minutes and pinging the pin across the bench ( this is something you dont want to lose sight of, no magnet is going to help you find it ) . Pushing the pin into soft timber and stroking across with a 600 grit ceramic file, perfect. All that remains is to fit it . What a ridiculously small piece to work with. BTW, these files are the dog's nads, cousins price, whoa !!! Chinese seller negotiation price Thats not a single handed operation by any means, a glass of orange juice to steady a slight shake ( very noticable when doing this ) but no couldn't wait. Just a finger from the left hand to steady one of your tweezer fingers makes a huge difference, eliminates any shake completely.3 points

-

2 points

-

Hi. Pictures of the movement would help members to locate the release point for you . As with any questions pictures please.2 points

-

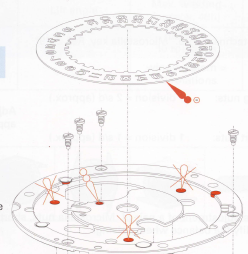

That's very cool looking watch. Love the blue tones and the yellow contrast. Oh man, what a bummer. Sorry to hear. Of course you'll have to face it and open the watch But there's one super-random thing that comes to my mind for your to check. I was working on an Omega cal 244 and the intermediate wheel of the keyless works (see pic below) was flat on one side and a bit rounded on the other side. As you see in the picture, the flat side goes on top. When I was re-assembling, however, I hadn't checked this picture and assumed the opposite. When I was winding, there was some strain and thankfully I discovered that I had to turn that wheel around. Most likely, this isn't your issue, but I thought it's worth posting for the 1% chance that it helps. Thanks! If only every restoration would be so easy!!! Well, it'll also not be fun. I agree that it looks better now. And well, it's still the original plating. The thing with the Geneva stripes and the "intentional" misalignment is very interesting. But also absurd. So even when Cartier repairs/replaces this part with an original Cartier spare part, they intentionally make the movement uglier?? They could just engrave/mark the part.. I also have no reason to doubt the always-instructive "watchmaker from the Netherlands", but it seems quite ridiculous to me. I've also looked at dozens of Cartier 690 calibres on eBay and they ALL have this mis-alignment. Well, either way --- non-intentional misalignment or intentional misalignment of spare-parts --- I think Cartier should to better (at that price-point).2 points

-

When I run out of supplies, I use slightly above body temperature distilled water and Dawn (dish detergent) followed by two alcohol rinses and drying. The alcohol is displacing the water and is no risk of rust. This method was used since the beginning of watchmaking (other detergents probably not Dawn) without any problems. Since the used of modern lubricants the manufacturers are promoting special solutions for more money. As long as you do not immerse the pallets and other parts that have shellac in alcohol and the transition time from water based washing cycle to the first alcohol bath is very short, you shouldn't have a problem. I have used it many times and Dawn does an incredible cleaning job, on the other hand, it does not have any brightening agents and the metal is not as shiny as with the specialized cleaning solution. I also use the water based bath when I have just one or two repair jobs followed by a longer period of time when I'm busy with other things or I'm travelling. I never had any problem with using the water based procedure when the movement was pegged and pre-cleaned as it should be.2 points

-

Apart from the condition of the case and the dial, which are a challenge, the movement (as far I can read) is a 2836-2, which is a 2824-2 but with additional day-complication. The movement isn't hard to work on. Most springs are in "one-piece". Be aware of the flimsy ratchet-wheel, easily and often damaged. If it is a 2836-2 (?), attached the tech-info. CT_2836-2_FDE_481924_17.pdf2 points

-

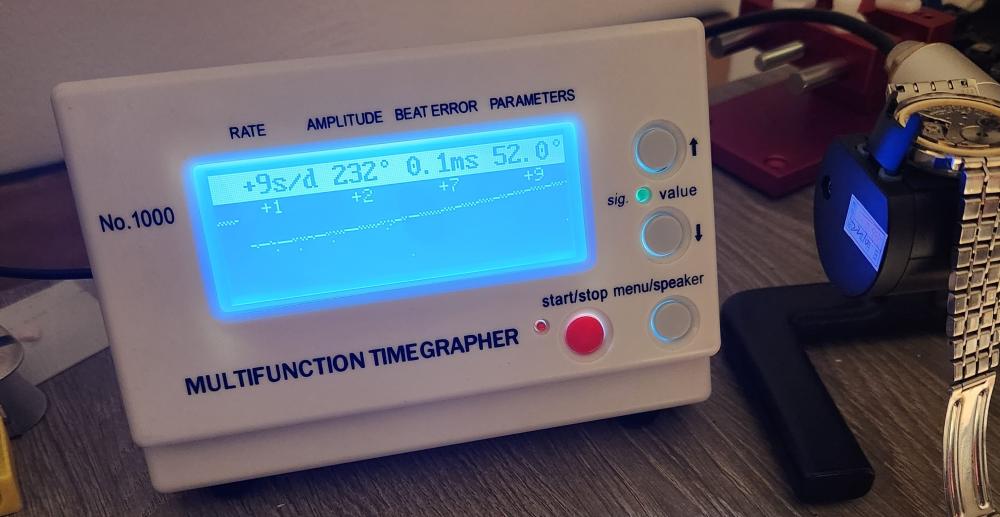

Unfortunately the Laco watch I serviced earlier stopped on the bench and it took me a very very long time to sort it out. The issue with the Laco was that the bearing of the center wheel was worn out and I have not realized that because I did not know this movement and I am not experienced enough. It was actually a bit suspicions when I put it together, but I was a bit tricked as I thought that the movement was a working one and indeed it was working until your luck ran out. The center wheel had too much side shake so depending the position of the watch and what sort of forces had an effect on it when it was moved on your wrist or otherwise it was ticking or not as my tests proved it. Because I thought it was a perfectly working movement when I received it and it was actually running I took it apart again and again thinking that I made a mistake somewhere. Better to say I took it apart completely two times and cleaned and lubricated two times and then when I realized that there is a problem with the power transmission I replaced the mainspring first, but did not help, then I took apart the train wheel a countless time... as I thought... thing is that the center wheel has its own bridge... can be taken out only if you remove the rest of the train wheels and also the barrel bridge, but it is still part of the train of wheel... so when I say I took apart the train of wheels it is only half true... the center wheel was not taken out... Then I asked the Hungarian watchmaker community for help at the same time I fired up my eTimer which is a beautiful piece of timing software came with an outstanding very sensitive microphone. The long term test showed an hourly fluctuation in performance... and what turns once every hour? Yes, the center wheel.... Luckily cousinsuk had brand new center wheel bridge. With the help of the community and eTimer the problem is sorted. I am very very happy about it, it was not just because this watch belongs to my best customer... it was a question over my head asking me constantly... why are you doing this if you cant even fix a simple watch? Before: After: Center wheel side shake: Phew...2 points

-

I sometimes do this, i would love to say a calculated risk on my part but there is very little calculation involved, its nearly all risk. Sometimes pays off sometimes doesn't. What it does do is push most buyers away leaving it open for low bidding. I did this recently with some tools and it paid off, i also did it on Saturday with 6 watches at just under a tenner each. 2 Sekondas, a Smiths Astal National ( this alone is around 200 restored ) not sure about the other 3. Some folk just have a crap camera phone, dont know how to photograph or understand presentation, cant get the back off or simply cant be bothered, dont know what they are selling or just dont care. If its cheap anyway then that softens the blow if the risk turns bad. Its only money after all, you cant take it with you so why not enjoy it because you dont know when you're leaving.2 points

-

OH...lol...forgot to post the fact that I found a donor in my box-o-watches. Calendar works are functioning properly now!!1 point

-

I just had a brainwave... https://www.livescience.com/physics-mathematics/dark-energy/the-expansion-of-the-universe-could-be-a-mirage-new-theoretical-study-suggests This was published this morning. The content isn't all that important (though interesting), but it got me thinking. There's this theory called VSL (Variable Speed of Light) which holds that the big bang was caused by a sudden decrease in C (the speed of light). All that energy that was tied up in that higher speed precipitated out into matter. What if red shift is illusory, and actually C gradually increasing? Leading yet again to another... Big Precipitation? I haven't run through all the various aspects and outcomes that would arise from this, but this is about the only place I know of where such discussion wouldn't result in glazed eyes.1 point

-

1 point

-

I do - I have a lathe. It hadn't occurred to me before (not that I had a lathe!)1 point

-

I bought the Bergeon 30070 tool but unfortunately, the quality was so poor (Chinese copy!? Got it cheap on Amazon) I can't get the roller into the slots (extremely poorly made). However, the two punches are well made so I use them with my Platax. They don't have the same diameter as the original punches for the Platax tool, but as the diameter is slightly smaller it still works well to remove rollers. However, when removing the staff I use the original (also clogged) punches, but I file down the pivots first so that they will rest on the staff cones.1 point

-

In 2020 a small property went for sale in my small town. It was nothing more than an agricultural warehouse without even a firm floor, made of piled up blocks and with an uncertain roof. But the price was right, and during that time having a project or a reason to leave home was an attractive perspective, so I bought it. The ugliness was demolished, foundation and construction quickly started. By Christmas '21 most work was completed, minus doors and windows, the exterior, electrical, plumbing and what not. I took my time to refine it the way I wanted, and last summer I was using it already for what you see, an hobbyist machinist and general repair and 'making' work. The building is actually designed and intended to be a small home, by regulations is resistant to earthquakes and highly energy efficient. I plan to add solar panels and an accumulator as soon is convenient. Heating/cooling will be with a split Inverter A/C, with floor units in each room. I haven't installed yet because in our climate and the efficient insulation one does well even without it. I've arranged the unit for the purpose of doing stuff for my own interest and business, as well to service the local trade which may need turning, milling, sharpening, and the like. There is virtually nobody else doing that for quite a distance around. Above is the garage room, the leftmost in the first picture. Everything is on castors, so beside re-arranging as I want, I can also store a medium car in there. Currently I'm about to restart a vintage universal milling machine (the dark grey one), which has suffered a road 'accident'. Also a largish vintage lathe is supposed to be coming and be restored to working order. The other room with the entrance door is predisposed to be a kitchen and living room. This space is better suited for light mechanical or electrical work, studying and designing. In the middle on the left is an half bath with mezzanine storage above it, and on the back is a large bedroom and a spacious full bath. These are still unfurnished, so no pictures. After much fighting, I managed to get basic ADSL Internet, so I can also watch Youtube videos, buy more stuff, or conducing other online business. Still there are so many details that I want to add or improve, but all in all I feel well rewarded for the time and money spent. Time goes fast and for as much work one does, there is always more. I have few machining projects lined up, and hope to get more also. Because of all that I had to place watchmaking on the back burner for now, but have no intention of quitting it. I want to thank the forum friends that had asked about me, and send friendly regards to everyone.1 point

-

Maybe an added shot of ammonia solution will give you the missed gloss.1 point

-

Why do you need to change the jewels ? I'll give you this Murks , you certainly have ambition for a beginner.1 point

-

I have seen a few videos on Chronoglide where the presenter (Kalle Slaap) states that these Geneva stripes are there so you can spot if a part has been replaced. If this is the case (and I have no reason to doubt him) the slight misalignment of the stripes would indicate that the watch has had a replacement part installed at some point in its' life. So the stripes are doing their job, nice example . Great work on the restoration by the way, as someone who isn't necessarily a big fan of the vintage look (sacrilege!!), I think the watch turned out great. So I'm gutted.... after about a week of working well, I noticed that it was becoming more difficult to wind, to such an extent that I thought it better to stop before I damaged it and I left it to wind down. I am so grumpy about it I can't bring myself to open it up and look inside and I'm going on vacation tomorrow so didn't want to start anything I couldn't finish. The watch before I tried to fix it had broken teeth on the ratchet wheel.. so my fear is that I missed something and it is the old issue re-surfacing? Or maybe the horseshoe type click spring I made is not working correctly and fowling the spring barrel or ratchet wheel??? Any ideas?1 point

-

The brass section is the arbor/lid combined. I have tried winding it onto that but the tension is too much to hold by hand, especially when attempting to insert into the barrel. There is a hook on the wall of the barrel as well which is a better option but still tricky and did mis-shape the bridle end of the spring and i'm super-cautious of not damaging it given I don't have a spare. That sounds feasible. I could actually machine up something of the correct diameter - and slightly thicker than a washer which will help. I'll give that a go.1 point

-

I use a similar digital microscope head for recording and taking single and timed photos. It doesn't have the screen but connects to my laptop for viewing. The magnifcation is not bad at all , I'm able to see very good detail on a balance staff. There is a little time lag when bumping up the resolution but then my laptop is around 15 years old. You could just run a recording from your phone or a dictaphone alongside and in sync with your video .1 point

-

You can find all sorts of calibers in west end watches nearly all are of low to mid quality, there are few exceptions however Longine movement powered some SECUNDUS ( a sub brand of west end ) for the Indian elite. The most famous class is the SOWAR, a Persian word meaning rider ie; one who rides, in farsi if you ride a bicylce, a horse, motor cycle even a aeroplane you have sowar ed the vehicle. Sowar was initially made for the British Indian cavalry. Not many matchless were made but no rare west end watch as fifteen million pieces were sold world wide, and nothing is obsolete in India. Wear your west end watches in good health pal.1 point

-

They are genuine with the exception that neither are remotely "railroad" anything. These are almost bottom of the barrel quality, just a hair above Roskopf. Many cheap watches from the early 20th century incorporated railroad themes to promote a view of quality; a dead giveaway is usually the mention of railroad and/or images of trains. I doubt either is late 1800s, both look 1st 2 decades-ish of 20th century (maybe up to 30s or so). These are worth very little. But might be fun to fix up and carry around.1 point

-

I usually keep the washers that already wound brand new mainspring come in. If you can find a washer with ID equal to or a bit smaller than ID of the barrel, we then are in business. Hand wind the used mainspring inside the washer, like new ones are, next rinse the mess, spread a bit of oil on top of the coil, grease bareel wall. You now have your mainspring wound as a new one, ready to be pushed into the barrel. Hope this helps and good luck.1 point

-

Hi Which bit does the inner coil attac to ? The coil is to big for the fixed arbour but looks as though it fits on the brass wheel which then fits on to the fixed arbour. In which case try winding it onto that or making an arbour fitting into a pin. Vice and doing it that way.. a Single spring winder is around 50£ and you may only use it once.. a close up of both arbours attaching points ? Would be helpful1 point

-

Normally we don't get enough detail now we have too much could you back out a little bit so we can see where the jewel is. Then often times when you go beyond a practical jewel count they start to get creative. Bonus jewels here and there that may or may not serve any real purpose at all. But they do bumped the count up so they can have a much higher number printed on the dial and probably bump the price up. My favorite is the ring of jewels they go under the automatic weight just in case for some unknown reason should touch the plate which of course it's not supposed to do. Rolex does something similar You can add three more jewels to your total number of jewels1 point

-

Interesting interpretation of the instructions of? Your interpretation of the quoted instruction above was to remove the individual stone and clean it which is not what the instruction was. Instruction was to clean the fork with the stones in place so we can evaluate the situation. Now that the stone is out everything is changed. Really hard to tell when it's out of the Fork but seeing as how fast it came out does make you wonder if other pallet stones are involved in this? Thinking about above quoted section that would refer to the link below https://www.watchrepairtalk.com/topic/26766-pallet-fork/#comment-222622 I think it would be helpful if you answered the questions from your previous discussion where you conveniently ignored the questions In a classroom situation you're looking at at least a week of eight hour days to learn how to adjust the stones and of course you learned how to check the entire escapement because you need that to adjust the stones anyway. Then in the classroom situation that doesn't fall of having the proper tools which most of us don't have because they're just too darned expensive. Then typically most people don't play with the pallet fork as it leads to nothing but misery. I believe currently there's another discussion on this group where someone is having issues with The pallet fork not running watch and misery. Oh and as a reminder both stones are physically different. See do have to put the right one in the right place and they both have the face in the proper direction and of course they have to be the right depth. Then The shellac is also supposed to be on the bottom not on the top of the fork.1 point

-

I've seen some of them. I think it's for the date ring to ride on.1 point

-

1972 Tissot Seastar 2511 I picked this up off the bay for my 60th bday coming up next month. I went out on a bit of a limb as the lot had no pictures of the movement. It did however show an original case, bracelet, signed crown, and awesome dial. It is a non runner, but I am hopeful that it is not to difficult to diagnose. It winds almost too easy and is a bit sticky on the setting though the calendar works is fine and the push quick date set is also fine. I hope it is a loose screw on the ratchet wheel or something that is not allowing a wind into the mainspring as the balance spins quite easily with a blower. As no pix of the movement in the lot description I was hoping for a 784-2, but very surprised and happy with the 2511, which is the same as the Omega 1481! 20 microns gold plate in great shape, case with sharp lines and drilled lugs. You can tell I am quite smitten at the moment. No scratches on the movement or screws, the rotor doesn't seem to have play. I will take my time on this one and ease my way into this as a practice run for my eventual foray into my grandfather's Omega Constellation pie pan with a 561.1 point

-

Is anything in watchmaking ever easy? So, I need to add metallurgy to metrology, stereotactic brain surgery and an ability to cuss fluently in half a dozen languages. I'm truly doomed.1 point

-

1 point

-

1 point

-

The "for leather" sewing machine needles arrived today, so I dug out one of the machines and tried a test pieces, or to be more precise, two off 18mm wide x 2mm x random length leather test pieces sewn together with contrasting thin gauge polyester thread. The topmost, and more squint row of stitching was stitched by hand cranking the machine very slowly, just to see if the needle was going to explode. For the bottom row, I plucked up the courage to use the motor, and nothing broke, so to answer my own question, yes, you can cut and sew fairly precise leather pieces at home. If and when I take this any further, I'll need to set up a work piece feed guide jig, to keep the distance between the edge of the workpiece and the stitching to a more elegant and more consistent 3mm or 1/8th inch, and probably knock the stitch length down from 4mm to say 2.5mm as sewing by hand-feeding at the standard 1/4 inch edge gap that the machine is usually used at, looks a little rough and ready, and a standard 1.5mm stitch is probably a little short. I guess I should take some measurements of stitch length, edge gap etc. from some of the better made watch bands I have, and use those as a guide. I also probably need to use thicker thread (to make the results more robust) in a matching, or more interesting colour, rather than white. I also probably need to move this topic into its own thread, as it currently has wandered quite a bit from the custom watch dials topic. One advantage of white thread is that you can colour it fairly easily with alcohol based inks. So I brought out the coloured felt tip pens to see what would work best. Bear in mind also that you can load up the top spool of the sewing machine with one colour of thread and the bottom with another, and so long as the tension is correct on the sewing machine, you will end up with one colour on the top of the stitches and another on the other side. Dashed clever these sewing machines.1 point

-

I love this forum. I love @JohnR725 because he puts an edge on every blade. I have three vehicles not counting the John Deere Tractor. Two of them are beyond 100K miles. I do the oil changes myself. Sometimes I make a mistake and get the wrong oil, like 5W-30 vs 5W-20. I dont throw the mistake away, No. I took chemistry. Remember very little, but I do know how to do mixtures. I just mix up some 5W-23 and get the job done. Sometimes it is 5W-24. I really don't care. My truck doesn't care either. I have even skipped changing the filter when I forget to order one on Amazon! At the end of the day, the guys selling this stuff are trying to make a profit, so you have to take that into account when looking at the recommended intervals. Go look at the expiration date on that acetaminophen. Yeah, you need to toss it in the can. Nope. That sh!it will last forever. I saw a government study about efficacy of meds over time and the reality is that those expiration dates mean almost nothing. But...none of what I just said is horological. So, lets get back on track. Cleaning solutions are a mystery to me, so I just buy L&R because I worked my @ss off for so many years designing circuits, I have lots of money so I can send Ofrei a few bucks to get the bona fide stuff. I have thought about mixing my own brew but I have also thought about DIY cardiac ablation to calm down my PVCs, but there are some things you should just not try. I will end with a reference to one of my other posts. I don't buy into the five or six different oils from Moebius. I use one oil, maybe two. That is it. Good enough for my Dad, good enough for me. For anyone who reads this 30 years from now...I AM AN AMATEUR WATCHMAKER. ANY ADVICE FROM ME IS TAKEN AT YOUR OWN RISK. I leave you with this1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)