Leaderboard

Popular Content

Showing content with the highest reputation on 06/21/23 in all areas

-

4 points

-

Enjoyed bringing this one back to life for a (female) friend. Not my personal style, but it has a pretty mother-of-pearl dial. Very hard to photograph the shimmers. It was her early adulthood watch and it had stopped working decades ago. If fact, it was actually still running, but the crown was completely stuck due to water damage and rust. So it wasn't usable / couldn't set the time. Fortunately, the rust was only in the keyless works and relatively easy to clean off (after struggling for quite a while to get the crown/stem out ). The Cupillard cal 233 is running really well now. Now: Before:3 points

-

The problem is do people grasped what they need to learn to avoid the problem? What makes you think going to a professional school would help with this? When I went to my second watch repair school everybody there was supposed to have completed an accredited school. But my amusement was that all the schools were teaching watch repair differently everybody had differing knowledge and skills because there wasn't any kind of a standard for which they were teaching to. Then even with standards there's still missing a lot of knowledge that's needed to repair watches. Sometimes the best people at repairing watches are not the professional watchmakers. That's because you don't have customers screaming because they want their watch yesterday. You can take your time you can look at the problem and if you're capable of learning by researching and figuring out what the problem is conceivably you can be better than the professionals. It's amazing all the silly mistakes I've seen professionals make that they shouldn't be. Yes all of us need to do that. The positive of when the watch runs whenever that may be if that ever happens. Yes I have a bad attitude I work on vintage watches and their a pain in the ass and they don't always run. I can't give anyone a timeframe of when they're going to be finished. I can't guarantee that they're going to run ever. They may be worn out which is unacceptable to customers who don't understand that. So yes we need to embrace the positive wherever it may be lurking. Just unfortunately not necessarily in the watch were trying to work on.2 points

-

we have one of those at work it works nice except as stated above not everything is magnetic unfortunately. Microphone off here's a website that lists the parts for your watch what makes it interesting is you can click on the part and see which other watches are using the same part. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ELG_996 then you can go to their home page and take the part number and enter it in and see if they have it available sometimes they do like you mentioned your click spring I think that's available. then this is their home page http://www.julesborel.com/ then how did I find that page you will hear http://cgi.julesborel.com/ if you look at your own image it looks like the part of suffered a lot of damage. As I believe someone else said there's a lot of stress on that part and viewers failed. The best would be to just replace it as I don't think you're going to build attached it back to factory new strength which didn't work very well in the first place it just be best to get a replacement2 points

-

I have come across ratchet wheel screws which are reverse threaded, like the crown wheel screws. It's worth trying to turn the screws a fraction in the opposite direction you are trying to go, as it might break the stiction - and you might discover they are reverse threaded.2 points

-

That's a proper sweeper !! However, not all watch part are magnetic, so best it to improve your "containment" skills. As I thought, it's a reduction wheel and the little sprocket will see a lot of force. I had a quick look on the European eBay and a donor movement doesn't seem expensive. With a bit of luck you can find a movement which has all the parts for repairing both of your movements....... Suc62 points

-

Hello Murks, try as follows. Go slowly. Complete one step, then go on to the next. 1. Close the micrometer by turning the ratchet knob, that's the small knob at the end. You should feel and hear the ratchet clicking when the jaws are closed. The knob will still turn. Always use this knob when taking measurements. 2. Press the button on the left with the label on/off - set. The display will come on and you will see a number. Write it down, please. If the number is 0.000mm, then everything is OK and you can start measuring. If the number is not 0.000mm, do step 3. 3. Press the on/off - reset button and hold it down until 0.000mm appears on the display. Now take your finger off the button. You are ready to start measuring. Please let me know if this helps.2 points

-

Not having the tech-info of the movement, but If that broken part is from the automatic winding works, gearing down to the ratchet wheel, there will be a lot of force on that little sprocket. Chances are high that self-repair is going to be futile. You may have to find that part, or a (running / non-running) donor movement for spares, and get your movement properly repaired. Plus, if you buy a donor movement, it will give you some additional springs to improve your searching skills, or better, a chance to learn how to contain the springs2 points

-

Hello Gary, can you post some photos of the movement and the case I'll be able to advise you.1 point

-

That is how it should be sorted. If you tried to reduce the pipe that the stem screws into you might split the pipe or it just might bulge. Sorry for my other comment I thought it was the out side of the button you needed to reduce.1 point

-

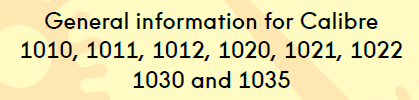

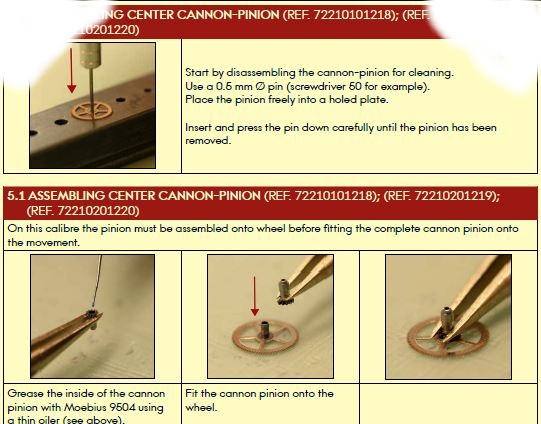

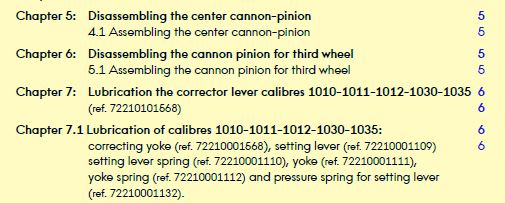

One of the problems are dealing with is missing information. What is missing information it is Swatch group revising documentation and not giving it to the world. Swatch group is very paranoid over there documentation every single page on the corner is watermarked with where it came from. You think they would get unhappy if you distributed internal documents to the whole darn world? They took the time to watermark every single page let's see if I can find an example We can see the name of the person when cousins used to build a get some documentation this would've come out of one of their working instructions as far as I can tell cousins never had some of the other stuff like your watch has another document that covers a whole bunch of key critical thing is which is why also referred you to the other discussions where maybe some of those key critical things have shown up. It would be nice if you could narrow down exactly what your question is otherwise you're going to get an answer that's probably not possibly what you want because I have to interpret. For instance you're missing a document that has this title Conveniently the picture you need is covered by a watermark with a different name and information than what I have below so that is a problem. Did you disassemble it before you cleaned it? Oh and which one are you thinking about as there's sort of two of them. There is the center and the third wheel cannon pinion They have to each be handled differently. One of the reasons I wanted you to do a search the group is does maybe have already answered the question especially if I do a search in my pictures and I find this picture which says yes it's already been covered which is why I asked you to do the search and look at the other discussions Okay that's the reassembly of one but you do have to disassemble and yes there is a procedure let's see if I have that picture and little notice the corner is missing I wonder why could that be the watermark that I don't want you to see. I'm really do the pictures out of order because it's the order in which I'm finding them as I said these would've appeared in some other discussion on this group had you've done the search Looks like this image is related table of contents I guess.. Oh one of the struggles you have is missing documentation where of I heard that before? This means if you find other YouTube video is other people servicing the watch they don't have the missing information. Which then becomes extremely unhelpful for you because they have no idea what they're doing. Okay it looks like you just need the two pictures that covers both of them.1 point

-

1 point

-

Bit dramatic rehajm lol , its frustrating but try to think of it as just another watch to repair and learn from. We as newbies, beginnners and amateurs beat ourselves up too much with this, we are not professional watchmakers, we didnt attend some years at watchmaking school or have decades of experience under our belts. It is what it is, we make mistakes plenty of them. Disassemble, find the fault, fix the fault ,clean, assemble and lubricate it. Second time around the pride of repairing it yet again will outweigh and disappointment felt. There is a positive for every negative, we tend to overlook that and concentrate on the minor setback.1 point

-

1 point

-

I just checked on a 984 in my parts bin. The ratchet wheel/arbor screw IS reverse or left hand threaded, so clockwise to undo.1 point

-

1 point

-

From what I can see where you have pinned the hairspring it has a lot that is passed the pin. What you need to do is unpin it, remove the complete balance, mark the wheel so you know on the wheel where the hairspring was pinned, then judge where it needs to be pinned nearer to the end of the hairspring, this will make the balance out of beat so remove the hairspring and re position to the mark. Because you have let the hairspring out it will gain less time in fact it should lose. if it is keeping better time you should be able to use the proper regulator to adjust time. This is a trial and error practice it might take a few goes.1 point

-

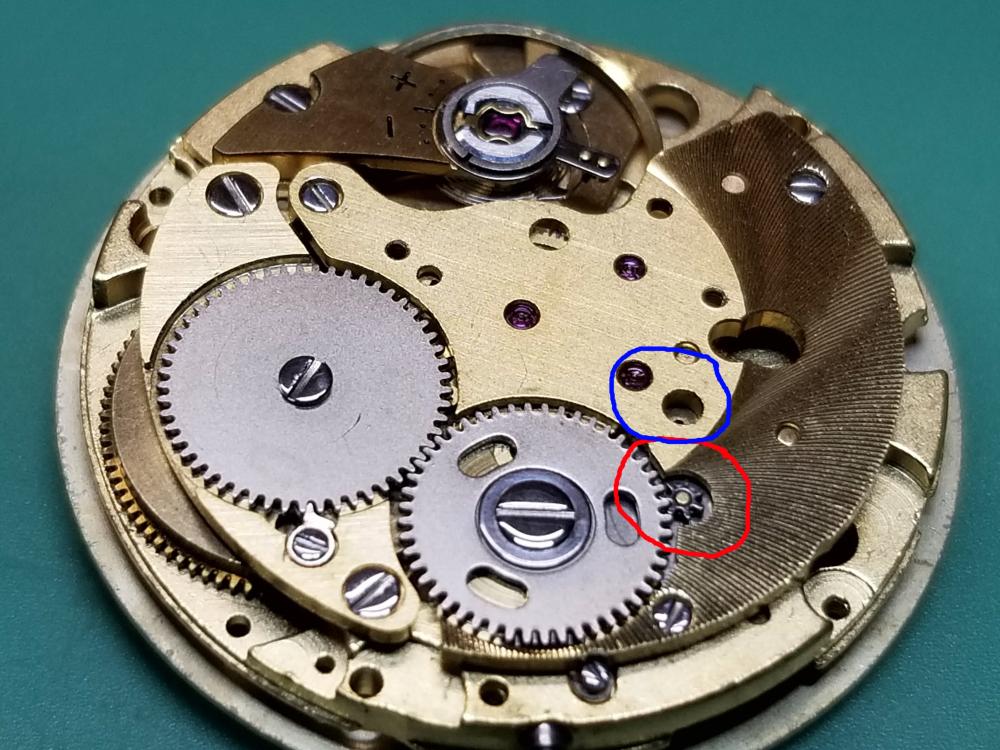

I happen to have another Elgin 996 movement, which is missing the automatic works. That sprocket is shown in red. It interfaces with the ratchet wheel. The other part of the wheel interfaces with the auto works via the hole in blue. I was originally hoping that between the two movements, I would end up with one good. But they are such nice movements, I wouldn't mind having two working ones. I did manage to improve my future searching probability significantly today, lol. As I was at the hardware store, I found a magnetic sweeper with 12" wide head. It's meant to pick up nuts, bolts, nails, and it would now seem, watch parts.1 point

-

This is a great question, compared to a slug a chimpanzee is very intelligent, but a chimpanzee no matter how hard it tried, or however many generations* of learning could ever master calculus, or even rewire a toaster. So this begs the question... is man smart enough to ever understand how the universe works... are we the metaphorical chimpanzee poking a stick at the universal toaster wondering how it makes toast? It would be the height of hubris to assume that we are smart enough, but this doesn't prove we aren't either. *I know someone will pick up on this and state that the chimp could evolve to learn... but then it wouldn't be a chimpanzee it would be whatever a toaster fixing chimpanzee evolves into, similarly, do we have to wait for mankind to evolve into the next type of human to be smart enough to understand the universe?1 point

-

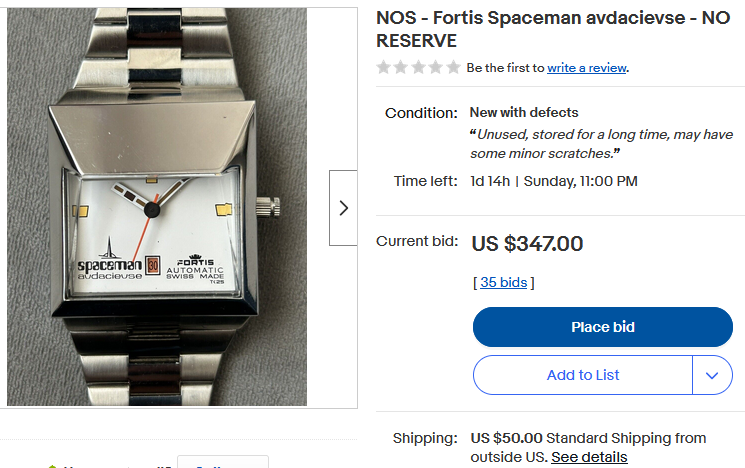

Because some of us don't think it's ugly at all and chose to spend money on it? Just guessing here. Sure is. Turns out I already had one in my closet. I still see a lot of them around, especially out of Brooklyn, NY. They're mostly the brown dial and strap and not as much fun as this one. This was the one I originally (and still) wanted, but almost all of them come out of Pakistan and look like exactly the same photos, so I'm hesitant to test my luck there. Edit: also quite a bit more expensive in general. E.g.1 point

-

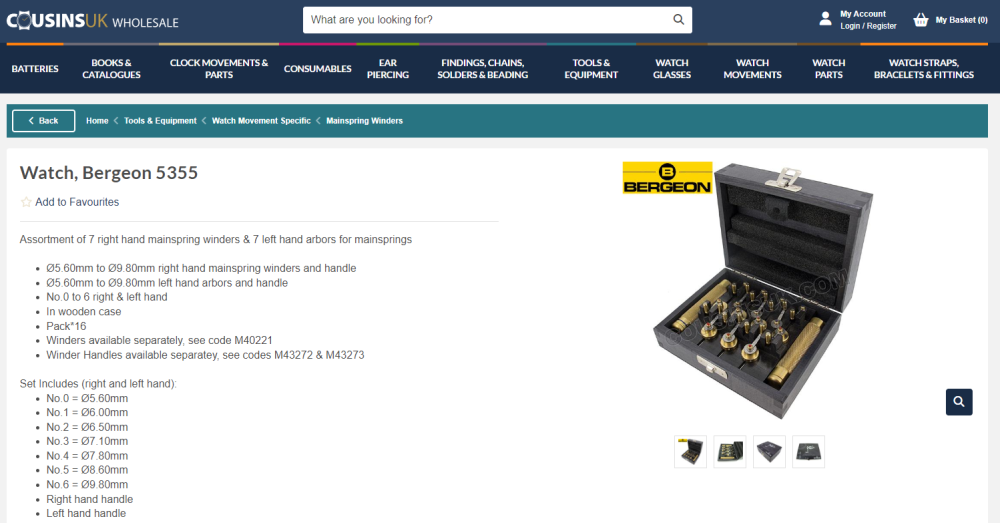

If you do a search on here we have a thread about mainspring winders with loads of advice.1 point

-

Thank you for your kind words @RickTock and glad my Vostok cal. 2409 walkthrough could be of help! I somewhat recently serviced a Vostok 2431 and it uses the exact same type of calendar complication as the Vostok cal. 2414. You'll find my service walkthrough of it here. Anyway, I'll include the assembly pictures for the calendar works in this post for your and any future Watch Repair Talker's convenience. The only difference is that the cal. 2414 doesn't have what I call the "1st intermediate date indicator wheel" so you can simply ignore that part. I include the picture where the "1st intermediate date indicator wheel" is assembled anyway since it shows lubricating the upper section of the cannon pinion. Unfortunately, it has become increasingly difficult to source parts for Russian movements as Russian sellers have been banned on eBay. Good luck with your reassembly!1 point

-

Bergeon used to sell a cheaper set, the BG2729. I placed an order for it in Feb. 2022 with Jules Borel but after a couple of months of it being on back order they told me that Bergeon no longer offered it:0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)