Leaderboard

Popular Content

Showing content with the highest reputation on 06/22/23 in all areas

-

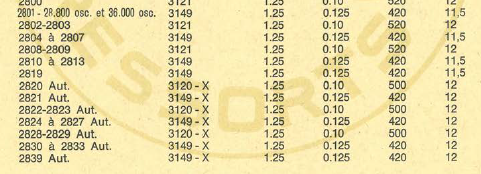

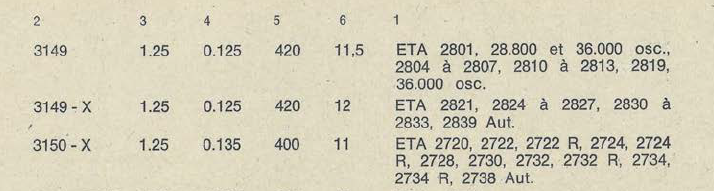

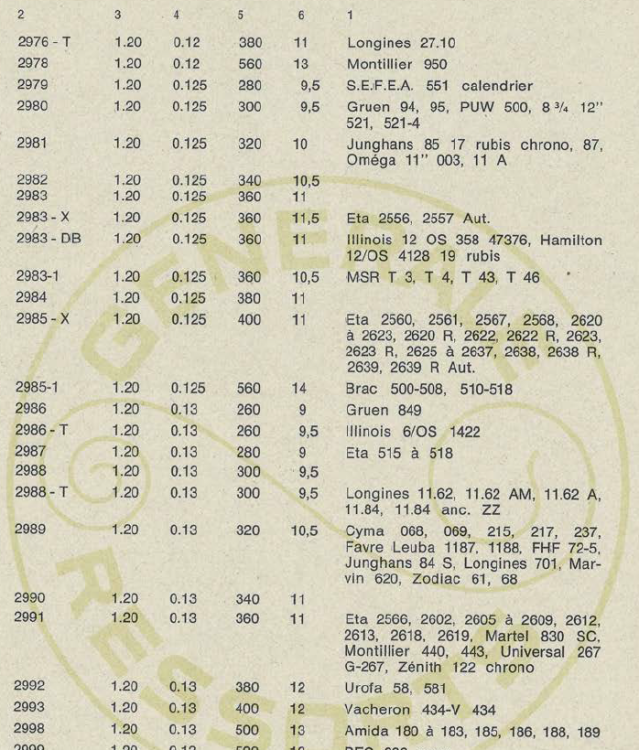

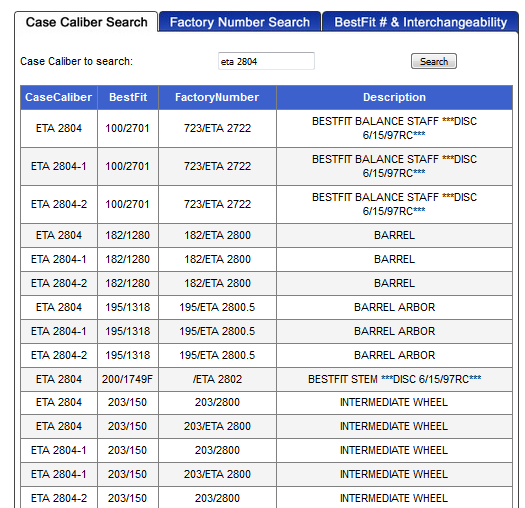

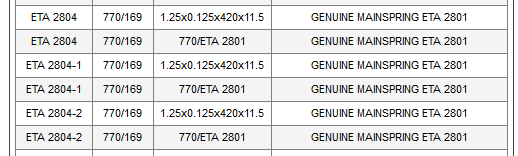

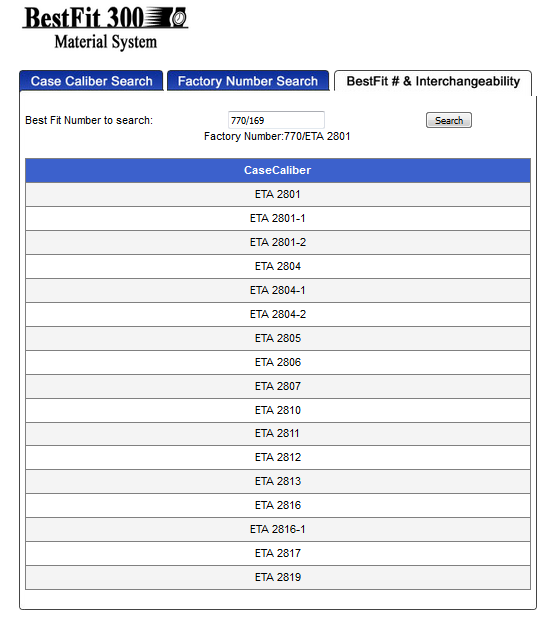

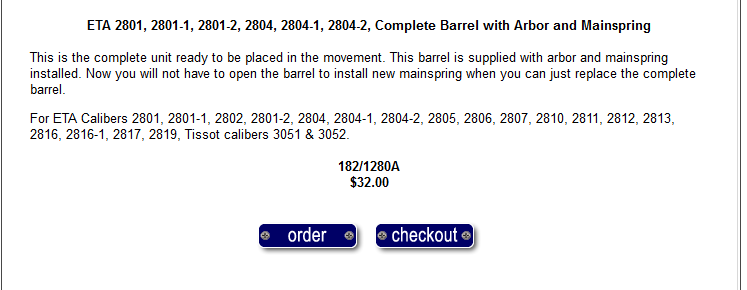

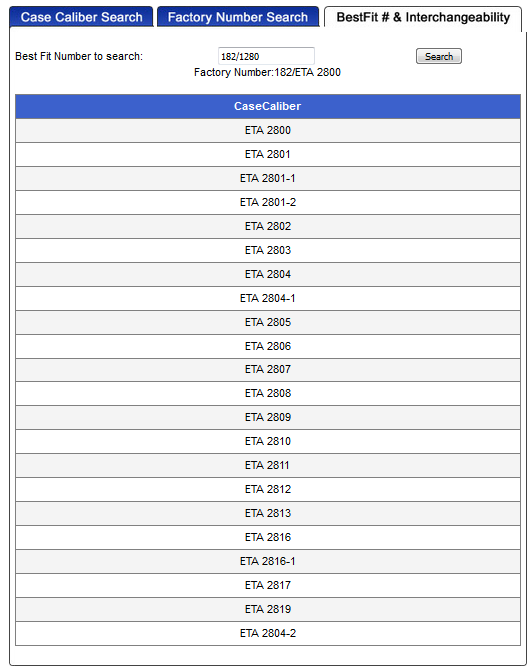

The problem would be that's not a specified size in the mainspring catalogs. I run into this occasionally with pocket watch mainsprings where they are more of a generic spring and the not taking into account the inner size. Where most of the time with a lot of annoyance and fiddling around I can get the arbor in most of the time. The worst problem is as when there to being then they have to be carefully closed without breaking them. But I think really what's going on is there more of a generic spring and because there is no specification that's where the problem becomes. Out of the mainspring catalogs their recommendations The problem with the catalog itself is its vintage and we don't have the -2 calibers and does that change anything? Wondering if there was a difference went to the bestfit online and it looks like at least for the barrel no difference at all Not going to the whole list but looks like basically everything is identical although apparently could have purchased a chronometer grade balance wheel have to wonder if that was ever available? Then just because I'm here let's get some cross reference numbers Okay I decided to reread the entire discussion because we all seem be ending up with the exact same place. Always the problem with the modification as we don't know what they modify If you had a blued steel spring then the other part is not hardened But these modern white spring as they are hardened which is of course why they break. It's also why the mainspring winders themselves have a different kind of hook for the white Springs versus the blue because they are so tightly made there supposed to go on very specific arbors. This is also why is this specific mainspring winders sets for exact Springs. Thinking of mainspring winders I'm attaching a PDF that someone else in the group had previously given us. Which Winder in other words which exact Winder one of the one specified for a eta watch or one of the generic ones? It looks like for the PDF the barrel diameter is 10.9 at least that's with the tool is using so that should drop in. Don't know about the handle parts another thing to try when you're closing of the center part is to put something inside so a new trying to squeeze with your pliers you can't squeeze beyond a certain point I find that's where things break like what I'm doing a pocket watch spring I put a piece of piglet in and then what I squeeze that keeps me from squeezing too much and if you're really patient you can actually squeeze without tempering. Although I usually let my boss do that can be seems be really good at doing it without breaking it. But something in the middle does keep you from squeezing to budge otherwise tempering would be the way to go. It appears to be that everything takes us right back to the exact same place where you started from. A mainspring company in Switzerland making a generic replacement spring that doesn't actually fall exacting specifications like they should. It's all goes back to if we could get original mainsprings somewhere in the universe something that did not come from this one particular company. I was looking at a different mainspring list I think the problem is the half sizes in both the width and the thickness. Which is why some of the sites dropped the half-size and just go a little smaller and thinner. Then looking for mainspring I stumble across barrel complete top right-hand side of the page. You get a part number 182/1280A I wonder if anyone else has this that would solve the problem? https://www.ofrei.com/page1439.html#35376 HJ-Mainspring-Winders.pdf2 points

-

2 points

-

2 points

-

You mean this tool? https://pivotpolisher.com/ Is there a standard that things should be clean to? What's going on here did you look at the website did you look at where the company is from Texas and then you're asking what's going on here? A product by the clever people of Texas maybe you should pay them a visit it would be worth a laugh. Oh I see on their website gets undergoing revisions for three weeks of deer I wonder what that means? To me it looks like an accident waiting to happen tool but what do I know I see that they're getting a thumbs-up from a famous YouTube personality somewhere towards the bottom of the page. So fortunately for you the tool is not available. But there's a reference to what they're using for polishing which they call EveFlex soft silicon polishing pin, 3mm diameter, extra-fine grit. Somewhere on this discussion group I've seen references to people using something either this exact product or something just like this but no idea where I saw it on the group just as someone was using an abrasive rubber type compound to clean the pivots which is basically what this Is.1 point

-

At the link below top right-hand side we see the image that I've snipped out That looks like your barrel complete. https://www.ofrei.com/page1439.html#35376 Here's a link that talks about it but I don't see a parts cross reference listing https://calibercorner.com/eta-caliber-2804-2/ Then cross reference part number comes up with the image below but notice they don't have a letter a on the end of the numbers so no idea what that means or how it changes things. This is where because the Watch has been made for a while you need to reach out to physical material houses and ask if they have the barrel complete. Like a lot of the website say not everything is listed.1 point

-

Eyup watchie. This is where Sellita put together movements for ETA for something like 50 years. Then began to make their own copies for out of patent registered ETAs. I wouldn't know if they were interchangeable but i have read that they initially had problems with different calibres to the one you mentioned. Personally i would be weary , you do right to ask ,hopefully someone with more than a couple of experiences of a swap of parts will give you an answer. Aquiring new parts is becoming more and more difficult for us mere mortal repairers. The switch to repairing clocks is looking more alluring.1 point

-

1 point

-

"polishing your pivot," "sharpening your pegwood..." Where are we going here?? Back to the GalaxyPro. I looked it up. Interesting. I would be concerned by the registration of the "claw" that holds the wheel. Perhaps the pivot polishing tube holds things in place. The "motor" is a tool that I have but under a different name. I use it all the time at my lathe bench. It is a quick way to do coarse cutoff or coarse grinding. Better than a Dremel for that purpose. However, it does vibrate, so having it on the pivot polisher could be problematic. --------- I went back to the website and watched the video. The claw is on the stationary side. I am not so worried about registration. I think it could work. I did see some vibration in the motor, so that is a minor concern. Here is the rotary tool on ebay. I highly recommend.1 point

-

1 point

-

1 point

-

Thanks! Fortunately (or unfortunately), I'm used to servicing ladies watches for my (very few) paying clients. The Cupillard 233 with 23mm diameter was therefore rather easy going compared to my recent Omega 244 experience (oval/rectangular 13.5x17.5mm).1 point

-

Yes that is correct it is not as difficult as it seams. the bush should be able to just fit in the hole and with a few taps of a small hammer it should fit tight in the hole, you might need a flat end punch to make sure it is flush with the plate, using a punch will make sure you do not bruise the plate. Reamers broaches and bushes are all slightly tapered.1 point

-

I am certain the pride will outweigh the disappointment the first time the repair happens the second time around … Well done with such a small movement- not a lot of lignes to work with. - and a very interesting watch and movement. That detail is like fish scales- very unique…1 point

-

Enjoyed bringing this one back to life for a (female) friend. Not my personal style, but it has a pretty mother-of-pearl dial. Very hard to photograph the shimmers. It was her early adulthood watch and it had stopped working decades ago. If fact, it was actually still running, but the crown was completely stuck due to water damage and rust. So it wasn't usable / couldn't set the time. Fortunately, the rust was only in the keyless works and relatively easy to clean off (after struggling for quite a while to get the crown/stem out ). The Cupillard cal 233 is running really well now. Now: Before:1 point

-

Hello Gary, can you post some photos of the movement and the case I'll be able to advise you.1 point

-

1 point

-

Sooner or later I might be called Mr Coca- Cola here, for having prescribed Coca-Cola as penetrating solution for loosening screws all along. Give the ratchet screw a 48hr soak in Coca-Cola، try loosening before the coke dries. Rgds1 point

-

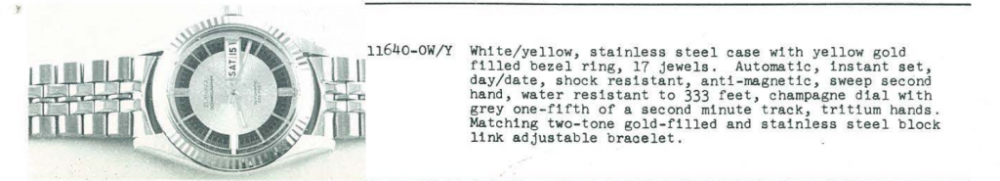

Bulova had Oceanographers rated for 333 feet and 666 feet. The 333 feet rated watches tended to have a little more "flash" to them compared to their 666 rated watches. I recently serviced this Oceanographer and am putting a not very water friendly leather rally strap on it BTW, yours looks to be the model 11640-OW/Y.1 point

-

1 point

-

1 point

-

You might want to have a look at this article to make sure that you correctly identify what you have got. The original EPSA Compressor and Compressor II cases were snap on backs, while the Super Compressor was mostly screw on, with a few bayonet fit backs. The lack of any notches in the back strongly suggests that you have a Compressor or Compressor II which is a snap back. The fact that it rotates suggests that the rubber gaskets are actually missing or have been replaced with gaskets that are too small.1 point

-

1 point

-

I sometimes do this, i would love to say a calculated risk on my part but there is very little calculation involved, its nearly all risk. Sometimes pays off sometimes doesn't. What it does do is push most buyers away leaving it open for low bidding. I did this recently with some tools and it paid off, i also did it on Saturday with 6 watches at just under a tenner each. 2 Sekondas, a Smiths Astal National ( this alone is around 200 restored ) not sure about the other 3. Some folk just have a crap camera phone, dont know how to photograph or understand presentation, cant get the back off or simply cant be bothered, dont know what they are selling or just dont care. If its cheap anyway then that softens the blow if the risk turns bad. Its only money after all, you cant take it with you so why not enjoy it because you dont know when you're leaving.1 point

-

Thanks. You are correct, I was lucky. But I will say I was prepared and took a calculated risk. There were a number of things that I took into account when bidding on this item. I knew several things including that the seller probably did not know what they had. Although they have over 8k items sold, at the moment they only had a dozen items for sale but only 2 other watch lots. Asking for pictures of the movement might have tipped the seller off, which then could have added to the bidding pressure. I was content if it was the 784-2. Also described was that it was a presentation watch with a inscription for 25 years service in 1976. In the middle of the quartz crisis I don't think the corporation would have given a piece of junk to their employee just a hunch but things added up...there were about 40 bids on this item and I got in early and waited. 2 other bidders put it up fairly quickly, but I did not snipe it either. I put my Max bid in about an hour before the end and it came in just a bit under. Finally, during this time period Tissot's were a poor man's Omega, similar to Tudor to Rolex. So I got lucky that no one else took a bigger risk or had contacted the seller yes, but I thought it was a very value added bet to make!1 point

-

I purchased a digital microscope with a 7" screen for £35 (reduced from £125 down to £65 then to £35. Don't ask me why?) When extended as high as possible, the head was too low to view the whole of the watch. I removed it from the base. Made a wooden block to higher the post and glued it on. It now views the whole of the watch. I have the post angled slightly back so that I can work without anything in the way. See the photographs. I work in a box to limit 'pings'. Post is supported by the box, so no recording wobble. As can bee seen, all I have is the desktop area for everything. When using the computer I place the box on top of the printer. I am starting to record, but using the microscope base is new to me, therefore practice is the name of the game, again. Has been really useful for inspection. This is the cheapest way I can record. Can't afford high end camera's or phones (My goodness do I envy Guy Montag). I use VCL media player and will use Shotcut for editing. I do not intend to post YouTube.1 point

-

Have you used this before? MainspringCalculator.xlsx1 point

-

I never figured it out. Cost me 3 springs in the end with breakages. You could try any of the above, but the critical thing I found was the inner coil size. I don't know why they made it so small - I mention above 2.3mm. All you can do is get your round nose pliers ready, anneal the inner coil, and hope it doesn't break.0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.b7c39bfd24e50ce1b860993185be6f3b.jpg)

.thumb.jpg.edba2ef8bf23d6923426e34a69073e21.jpg)

.thumb.jpg.1036995e3ae3bc0649fc5796db674011.jpg)