Leaderboard

Popular Content

Showing content with the highest reputation on 06/28/23 in all areas

-

3 points

-

I picked this Black dial 1967 manual waterproof Caravelle up in a lot for $13.20. It sat in my drawer for a few months not working and one of the other watches in the lot had my attention. Found it last night and took off the balance and fiddled with it a bit. Put it back together added a $2.75 new acrylic and a $4 forest green nato strap. Not bad for $19.95 US. Needs a crown and a general servicing, but the dial is sweet. Is a 7 jewel Japan movement that is a bit erratic on the timegrapher, but is only about 1 minute fast after setting and 10 hours wind.3 points

-

3 points

-

2 points

-

2 points

-

I'm all for trying new ideas, but it has to be an idea of substance, just not a money making gimmick that has nothing to teach please.2 points

-

I agree, especially the 17 jewel version of the 11DP. I recommend that movement for people just starting out as it's an inexpensive solid movement, easy to service, with readily available parts. Just a couple of hours ago I was deciding on which watch to work on next and it was either a Caravelle or a Roamer. I started work on the Roamer but it needs a part so will probably start on the Caravelle tomorrow.1 point

-

I have to say, I know these Caravelles were the lower-end line, but I have one and love it. I wear it all the time.1 point

-

Another shot with a slightly less worn crown. This one is signed and I can gain better purchase for winding. Hard to see but I like the wet dial look, at the base of the hour numbers you can see it a bit. Also got a shot of the movement while swapping out the replacement crown/stem (yes I had another non runner with the same movement and case size apparently).1 point

-

I would try to be careful with that one I continuously screw up my sleep And I can tell you it's a not a good thing.1 point

-

The other thing when doing a test like this is the same as timing machine tests more than one position. I love her style up and down should be identical and turn it sideways obviously that will be less but it's necessary because as worth thinking here one pivot might be a little short so in one direction it looks great to another it doesn't. Oh and yes sometimes if you leave the watch on the bench long enough maybe I'll just go away. One of the items on my bench because we couldn't get parts customer finally just gave it to us. Which isn't particularly helpful because we still need to get the parts which will probably have to be custom-made. Another item on my bench went away to the other watchmaker he volunteered he wanted a challenge. So occasionally stuff will disappear if you ignore it long enough otherwise it's the nightmare that never goes away we all have those. At least until some that gets done and goes away but I sometimes wonder if some projects may never go away.1 point

-

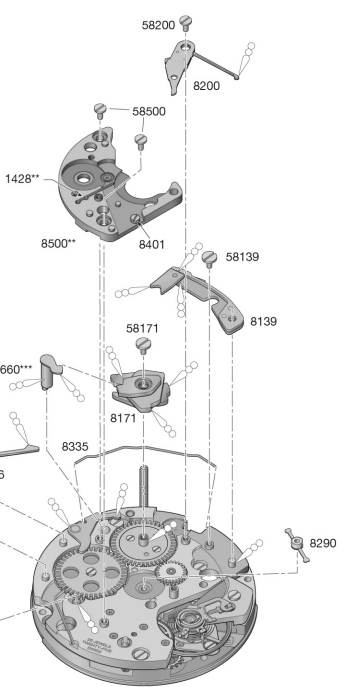

Yes, one tech guide (older) shows it as #8200, a more recent ETA parts list shows it as "33 Var" , "lock, assembled" . Jules Borel lists it as blocking lever, #08200.7750.0. There are two versions, older ones are usually plastic, newer ones seems like they are always metal. Either will work fine.1 point

-

I admire you for being able to make a staff. I'd love to try. If only I had room for a lathe (You have all the room there in Texas @LittleWatchShop - about 3x the land area of Britain and 40% of the population. Could you send some spare room over please )1 point

-

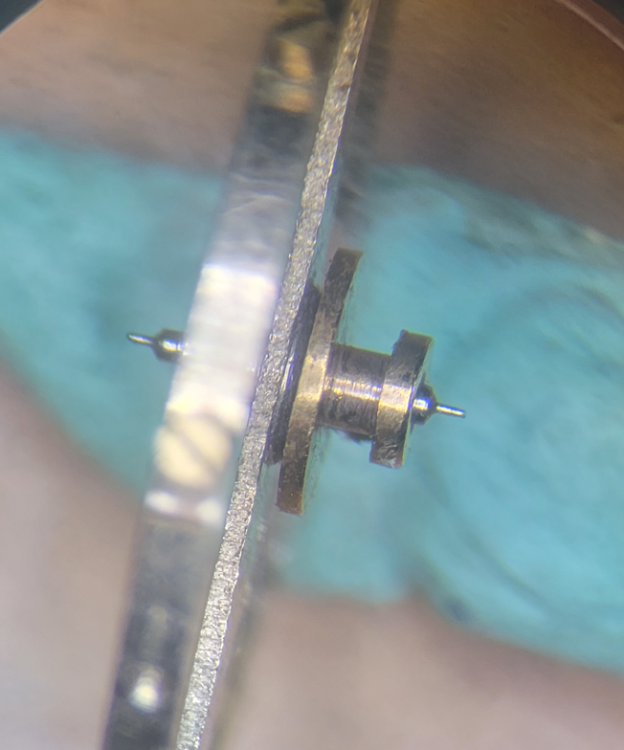

The top of the roller looks very close to the pivot, and it may be the pic, but is the top of the roller flat? Could it be touching the jewel setting?1 point

-

An update. Carefully looking at the pivot on the roller side, it seemed that the shoulder should be recessed a little more. The picture I show may make you think otherwise...no analytics here...just a hunch. So I chucked it up on the lathe and took a little bit off the shoulder as well as polished it some. The result was dramatic. My free-wheeling test lasted well more than a minute. When I assembled the escapement, I got about 50 degrees more amplitude. I am guessing that the shoulder was rubbing (ever so slightly) on the base of the jewel.1 point

-

I watched the video again and I think I know what happened. The bridle is so long that it made a complete round in the winder barrel, then the end came out through the opening from the opposite side.1 point

-

True dat. Despite copious notes the lead time for parts is a killer for me as well... In my humble limited experience opinion: just looking at the behavior of the oscillation I think you may be on the right track. Assuming the wheel is flat and reasonably poised...do I see a wobble what looks like rotational center is moving around excessively? Pivots too short or too narrow? I'm working on an A-11 what looks like that- a good looking Breguet and good energy from the train but...anemic. I'm waiting for life to stop getting in the way to replace the staff (of course with Waltham I'm just guessing at the appropriate staff size)...1 point

-

Websites websites like this are very helpful http://cgi.julesborel.com/ Eventually will get to this link and I have a suspicion that will be a hard balance complete to find http://cgi.julesborel.com/cgi-bin/matcgi2?ref=[^[DXMXJ Then you go to the main page enter in the part number and a good bad news scenario occurs the good news is I was available at one time which means that might be one out there somewhere in the universe unfortunately it's out of stock that means it will never come back in the stock ever again more than likely http://www.julesborel.com/s.nl/it.A/id.79240/.f Then the Internet to search for the watch see what comes up may be might find one on eBay like this one it's another place to search https://www.ebay.com/itm/1341401984521 point

-

Was it necessary to polish all of the pivots? Yes the fun of trying to figure out why someone in the past did the bizarre things they did and what problem Did they perceive there were trying to solve. Then of course what problems of the introduced by changing and modifying things that perhaps you are looking at because no one ever changes or modifies those things typically. I always like to see a timing machine result? Then what exactly do you perceive the problem to be? What is the definition of a performance issue?1 point

-

I test the balance by giving it a strong blow from a puffer - my criteria is that it is still oscillating well after 30s. Your test is more repeatable as you are starting from the same point. But it stops after about 25s - that's not good. How much end shake is there? Are the coils evenly spaced when looking from above?1 point

-

Thank you. ManSkirtBrew, my English is not so good (because I rarely speak it), but if you need information about Italian language, here I'm.1 point

-

Glue a steel hex nut to the back, then open it with a wrench. You can remove the glued-on nut with acetone later.1 point

-

1 point

-

As far as I am concerned Rich this is not a precise science, we all have a different way to achieve the same thing and strive for excellence as best we can. Stuff like this only encourages people to take shortcuts when they don’t know better, it is sad. Personally I am disappointed in this being promoted by who I think are good folks and leading others astray. Tom1 point

-

Are you thinking like the Longines 990/ Lemania 8810? That's a fairly unique movement. There are two barrels, of different size, geared together (the barrel teeth gear into each other). Both barrels also have hollow barrel arbors, with keyways, and there are wheels with arbors that traverse the barrel arbors and key in. So, when you wind, you are winding one of these keyed wheels (or the automatic works wind it). It winds the barrel arbor, which makes the barrel want to turn, and it does, and winds the other barrel up. The smaller of the barrels has a fixed mainspring, the larger has a slipping mainspring, so when the first barrel is fully wound, it continues to wind the second- and when that one is fully wound, the spring slips along the barrel wall like any other automatic watch. The wheel keyed into the second barrel is what drives the gear train of the watch. It's a very clever design, and provides a very even power output for the duration of the running. The keyed in wheels make the barrels effectively motor barrels, as opposed to going barrels, which some feel has certain advantages. Of note, a motor barrel can be made to be a little more "stable" than a going barrel, like Hamilton's motor barrel design. In the case of the Longines/Lemania movement, the part that drives the gear train is the keyed in wheel, which rotates on its pivots like any normal wheel; this is more stable than the short bearing span of a barrel riding on its barrel arbor (going barrel), and probably does contribute to the longevity and stability of the watch. In most iterations this wheel rides in beryllium copper bushings, but in some cases (like Vianney Halter's use of this caliber) it's jewels. Either way the bearing surfaces are easily renewed in case of wear, unlike in a going barrel. Aside from that caliber, most double barrel watches I can think of just have two barrels that are wound simultaneously and also simultaneously drive the center pinion.1 point

-

Maybe just the chrono hands , do they have a ripid flyback that could loosen them over time ? Incidentally i do have a couple of old quartz chronographs that have flung their chrono hands off.1 point

-

Me too, thats if he actually did, but when money is involved good ethics can take a back seat unfortunately. I part watch a video by the horology biology guy talking about some new idea for polishing pivots. I must look for it , it may have been the same idea as the Galaxy pivot polisher.I really dont think the design was very well thought out. Found the video. Apparently the tool is under revision. At the end of the video some issue occurs with mounting the wheel followed by some swearing haha.1 point

-

1 point

-

1 point

-

1 point

-

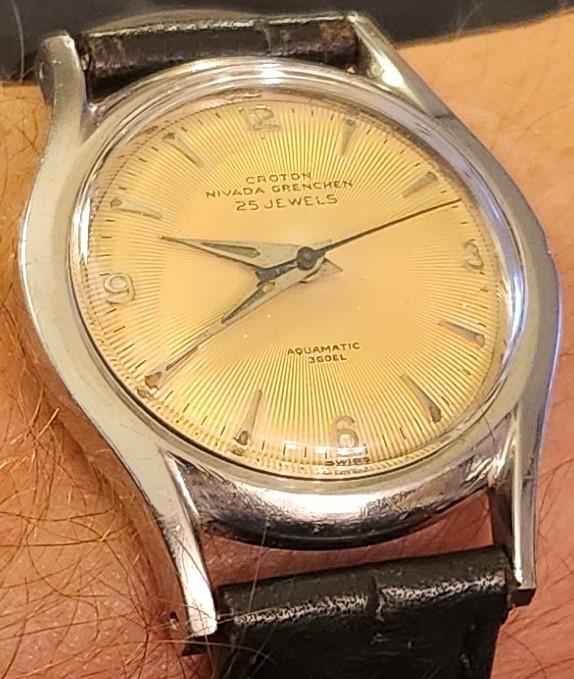

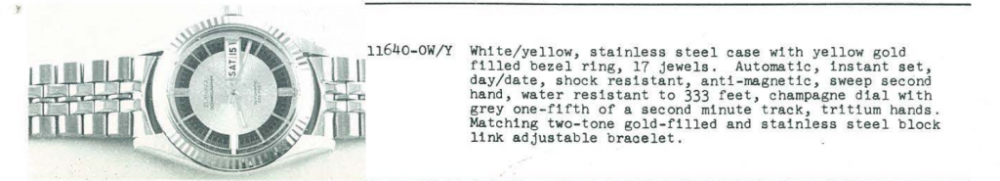

Bulova had Oceanographers rated for 333 feet and 666 feet. The 333 feet rated watches tended to have a little more "flash" to them compared to their 666 rated watches. I recently serviced this Oceanographer and am putting a not very water friendly leather rally strap on it BTW, yours looks to be the model 11640-OW/Y.1 point

-

A smiths mantel 8 day timepiece is a good place to start that is if you can find one. Other then that a Smiths pendulum strike. You can pick up a strike from ebay for around £25 You will need a clock mainspring winder. A good set of screwdrivers you can pick up a set in most hardware shops. A bottle of windles clock oil. Peg wood Clock cleaning fluid. I always used Horolene Concentrated Clock Cleaner. Tubs to put the parts in. If you are new and working on a strike you need two tubs one for the strike and one for the going. A large tub with a lid for the cleaner big enough so all parts can be submerged, parts that are just part covered will have a line across them. A few washout brushes, you can get them from a good materiel suppler. Drying parts you can use a hair dryer or you can do it the old fashion way I used sawdust. Some old rags for the cleaning the mainsprings. At some point you will need a clock makers lathe for pivot work and burnishing. I have two Unimat 3 one with milling attachment. If you have a watchmakers lathe you can do the pivot work on that. A set of clock clock makers broaches and plenty of clock makers bushings. Emery sticks assorted grit Burnishing file. A bench vice A mainspring let down tool with different keys That should get you well and truly up and running.1 point

-

1 point

-

Thanks noirrac I have not tried the cling film trick but tried about everything else. Unfortunately only had two replacement springs and after 4 hours of trying to fit they both got bent. The problem I have, & I don,t know if this is unique to Rolex but at the securing lug there is also a pointed section that also secures the spring & for the life of me I cannot get it to fit over this lug without it flying. I have attached a poor drawing to explain better. My next move I was going to try before the last one bent was to try and set up my Seize jeweling tool to see if I can secure it that way.1 point