Leaderboard

Popular Content

Showing content with the highest reputation on 06/30/23 in all areas

-

4 points

-

I tried to write up a concise method of checking the escapement here. Using that method, which is actually the "right" way (how good schools explain it), you could take the banking pins out completely and do 90% of the escapement checks. The banking pins are the last thing you need to look at- but the first thing most folks mess with, especially on American stuff with eccentric adjustable pins.2 points

-

This is why I think learning the escapement inside out is so important. Instead of adjusting willy nilly hoping something corrects itself. John and Nicklesilver have posted some great information on setting up the escapement. Its a good idea to read it and practice it over and over till it sinks in. Just a random thought and maybe not completely related to this thread. We all know what the actual measurement of amplitude is but indirectly is it worth thinking of it as a measurement of friction as well. If it was possible to add up all the points of energy reducing friction in a watch from barrel to balance, i wonder if it would be in proportion with the swing of the balance taking into consideration the amount of stored energy.2 points

-

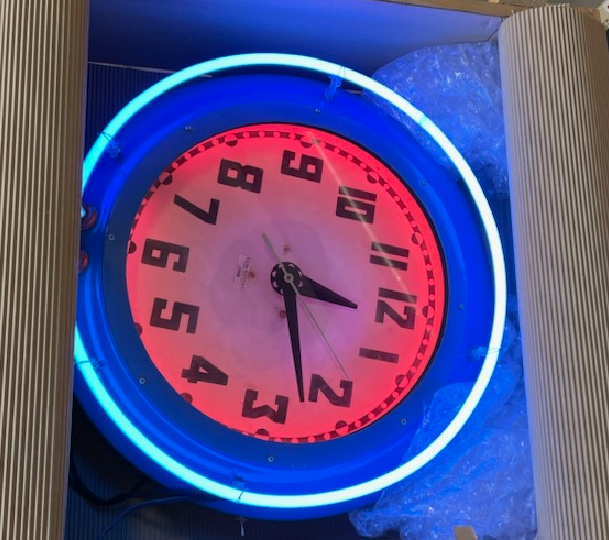

My garage door busted and it is so damn hot here in Texas, I decided to pay someone to fix it. I know I could fix it myself, but at 100F...nope. Anyway, the company I called is a family business (brothers). The estimator came out this morning. He had a prosthetic leg and missing an arm. (guessing combat) He looked at the door and said it was simple...he would fix it at no charge. As he was fixing it he ran into a problem that needed another brother and the service would be $139. Meanwhile, I was trying to find one of the rollers that "plinged" away. I told him, that it was like looking for a "plinged" watch part on the floor. Then I told him I was an amateur horologist. His eyes brightened up! He showed me a picture of a clock on his phone and asked if I could fix it. YES. So he said the service would be free if I fixed his clock. That was a no-brainer. I'll trade working in the heat for working in the cool!! Yeah...I can dig that. The brothers arrived an hour later and the garage door is fixed. He will bring the clock next week. He said that it is slow...like real slow. I figure there is a stripped gear in the movement. It most likely runs off a synchronous motor (Telechron, Sangamo, or one of the others). It will be an interesting repair. The guy absolutely loves this thing. I said I would come get it today but he said that he is having a party this weekend and the clock must be in place for the party. OK...whatever.1 point

-

One of my buddies paid for his watch repairs with another watch. I decided to go for it. I cleaned his Bulova and Benrus, and he gave me a vintage 21-jewel Timex. It was in good shape, and he was a friend so I did the deal. I've also accepted Pizza, tailoring, and a shoebox full of watch parts and tools. I'm flexible.1 point

-

1 point

-

Perhaps a more realistic approach if you were working in the trade would be to do a Assessment is this going to be a problem? Anything that's going to be a problem You just don't do. Although typically what shops would do is charge what they perceive be a high price and then their surprise that the customer says yes and then they still get stuck doing it making a little more money but thinking they should Have picked a much much higher price.1 point

-

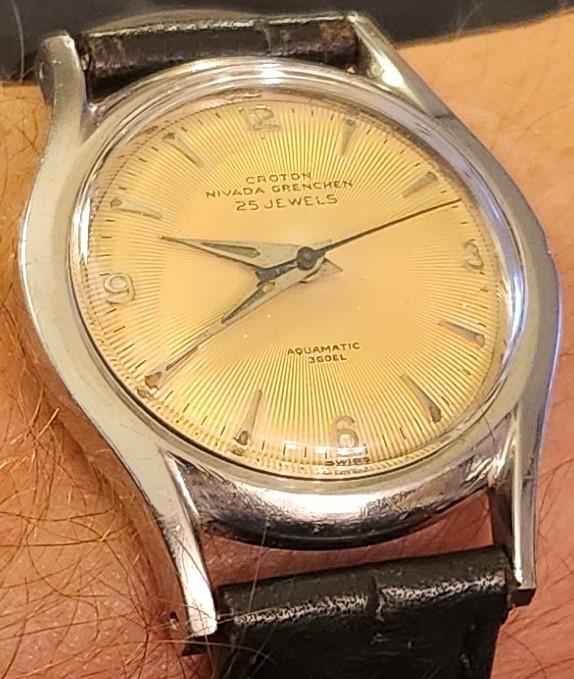

Really handsome watch. I'd love to get my hands on one. I'm such a sucker for the 70s aesthetic.1 point

-

1 point

-

I really wonder why there is enough time for several posts but no time to perform the (more than once) requested vertical test? Frank1 point

-

Hi thanks for your help with this. It gave me a clue. It turns out the crown was loose from the stem. When I tightened it to the stem so it did not come loose moving the crown I could move the dials clockwise when I turned the crown counter clockwise (which is probably what I was doing before the issue). This was a case of a little common sense so thanks.1 point

-

Hi. I love these clocks and have several in my collection. ( need full plate). The anniversary. / 400 day clocks were popular,in the early 1900s, 1949 saw a resurgence in the import of theses clocks to America/ Europe after the war. The minimum requirement would be a service ( clean & oil) new suspension and regulations, some can take days to get right on beat. To me. Worth doing but not many will do them because of the time involvement and economics. The pendulum support cup .was introduced in 1933 which places yours post that date as the cup is installed.1 point

-

1 point

-

As far as I have learned the flammability of celluloid increases over time.1 point

-

I'm not sure if John suggested it but using a pin vice with sharp jaws can work. It might be possible to put an edge on the jaws. I'm about to try on a cheap sliding collar pin vise.1 point

-

Are you saying this happens regardless of which direction you turn the crown in time set position?1 point

-

When you start playing around with the balance and the pallets which includes the impulse face which is governed by the banking pins you will find yourself in a mine field, which can and will be difficult to get out. I wish you luck.1 point

-

That seems to be the same basket I have. My stirrer has an 8mm motor shaft and the hole in the Elma lid is 8mm. So there's a 8/8 shaft coupler and an 8mm shaft that I cut from a beaker holder that came with the stirrer. Those jars are just some kitchenware but the lids are metal and there's a rubber seal. Not the tightest one around so you can smell the 566 if you sniff the jar close. The shaft goes through a lid that slides up and down and acts as a splash guard while spinning the basket. It also keeps most of the flammable fumes and odours inside, which is nice. The jars are not very uniform, there's a little deviation in diameter and roundness so one jar fits the base better than the other but I just stick a piece of cardboard in if there's too much space. What or who is Mr. Kilner? First I was about to buy an Indian basket but I read and saw some bad things about the randomness in quality so I went with Elma. The machining is precise so the basket doesn't wobble in the shaft. The wobble I experienced is due to high RPM, jar not supported properly, long shaft and the shaft going through a tight hole. But no problem if I support the jar with hand. I have no idea about RPM, still experimenting myself. The Elma wavebreakers seem to work fine so I can go a little higher speed. I went with 10 min wash and 5 min rinse, and finally 30 sec rinse in IPA. I guess you can do a longer wash cycle when not using ammoniated cleaner? The results are very satisfying. I haven't tried using ultrasonic with L&R 566 but before I had hard time getting all the gunk off pinion leaves. Now they come up all clean and shiny with no precleaning.1 point

-

I agree I have a few and they are solid movements. I prefer the 17j versions as well. I have a couple of automatics made in West Germany that are nice. Great to work on and parts are easy to come by as needed. Here is a 1960 (M0) with a nice white dial. The underside of the case is pitted likely from sweat. AS 1430 17j. Runs better, but still needs a service. Time to try my new short set (3) of mainspring winders and try to get more amplitude.1 point

-

Another shot with a slightly less worn crown. This one is signed and I can gain better purchase for winding. Hard to see but I like the wet dial look, at the base of the hour numbers you can see it a bit. Also got a shot of the movement while swapping out the replacement crown/stem (yes I had another non runner with the same movement and case size apparently).1 point

-

1 point

-

1 point

-

1 point

-

I'll check both, but putting the cap-jewel upside down in the Chaton THAT would be something......... but you never know ! EDIT: cap-jewel fine. One could argue that the rim is a bit rough. Knowing in great lines the history of this watch since 1975, the rim (like with the entry-jewel) must have been like this since the watch left the Omega factory. Not to say that this is as it supposed to be, but I've to be very sure what I'm doing before I make any changes to what passed the 1975 Omega quality control.1 point

-

Not sure if it's an optical illusion but does your guard pin look a little off center?1 point

-

The entry lock does look quite strong. From the pic the exit stone looks a little light too, but could be just fine. The thing is with the escapement you have to check everything- total lock is just one aspect. Briefly, to check (mind you in school some weeks are spent on this): All checks done with balance in, some power on train rotate balance slowly and observe drop lock, it should be minimal and equal on both sides at the moment of drop, manipulate the fork to check for freedom, this is "corner clearance". There should be freedom, and the escapement shouldn't unlock move the balance further a few degrees, check the fork freedom again, this is horn clearance to roller jewel face, should be small enough the escapement doesn't unlock continue moving the balance, now you will be checking guard pin clearance. Should be smaller than the horn clearance, and if so it will also be safe The above checks are checking the function of the pallet jewels relative to the roller jewel and safety roller. Observe how much lock is left with the fork horn against roller jewel- this is an indicator of how much adjustment you have as far as moving the stones in. The lock must remain safe with horn in contact with the roller jewel. All checks done on both stones of course, and in theory over the course of a whole escape wheel revolution. Next, moving balance slowly, at the moment of drop lock, observe the travel of the fork to its banking (looking at the escape tooth/pallet stone, not the banking). This is the "run to the banking". It is essential, but can be very small, bearing in mind that there are sideshakes that can eat up some of the clearance between fork and roller table in vertical positions. Run to the banking plus drop lock = total lock. So to boil it down as simply as possible for practical use, you can check the fork horn clearance, observe the lock remaining, and that amount "minus a little" is about the max you can move the stone in. *** If the total lock is large, and there is a lot of run to the banking, you can also close the banking. Easier said than done on many movements, as this might entail forging the banking with a punch in numerous cases. ***One very important thing to keep in mind with drop lock: moving one stone affects the drop lock for both itself and the other stone. If you move the entry stone into the fork, you reduce drop lock on the entry stone, but the escape tooth will also be released sooner on that stone, reducing the drop lock on the exit stone as well. And vice versa. After moving a stone, you must recheck for safe drop lock and safe fork horn clearance. Moving a stone affects drop lock similarly on both stones, and total lock on that stone. Moving a banking affects total lock for that stone, and run to the banking for that stone. No effect on the other stone. Can't really see much regarding the barrel holes in the bridges, but that could be some wear there in the upper one.1 point