Leaderboard

Popular Content

Showing content with the highest reputation on 07/01/23 in all areas

-

3 points

-

Meanwhile, Mr nickelsilver has done 400 pivots with a bow and burnisher . Or some orders of magnitude less, but with no issues, and could do them during a blackout (this actually happened at the Swiss school I attended- blackout, but the 1st year kids were doing turning using a hand crank, so, go on!)2 points

-

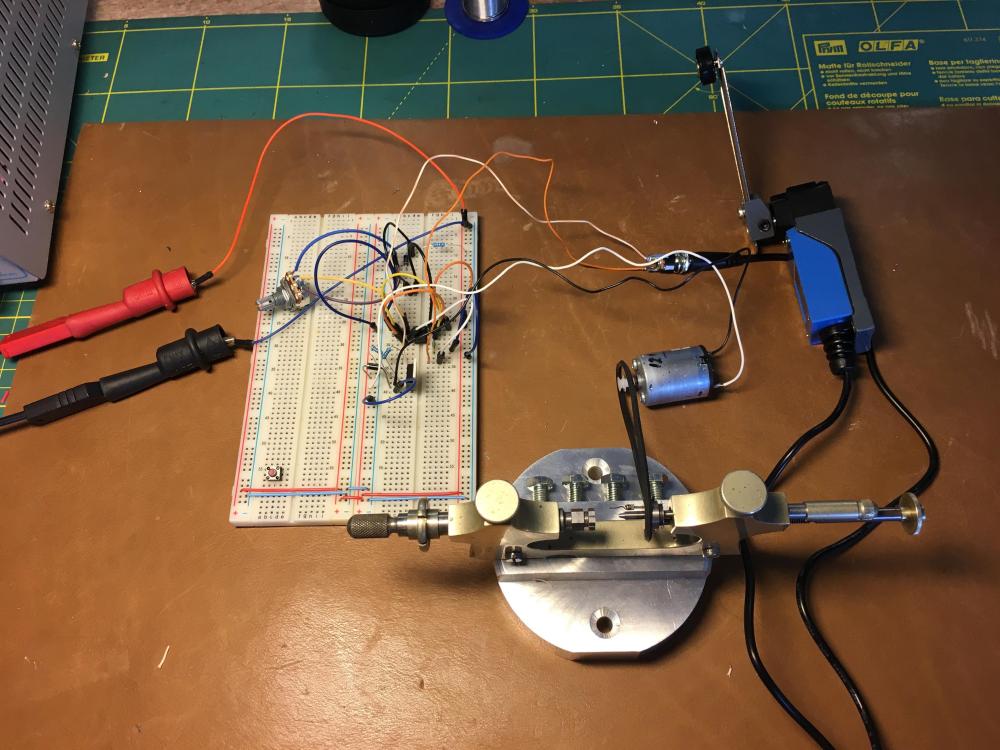

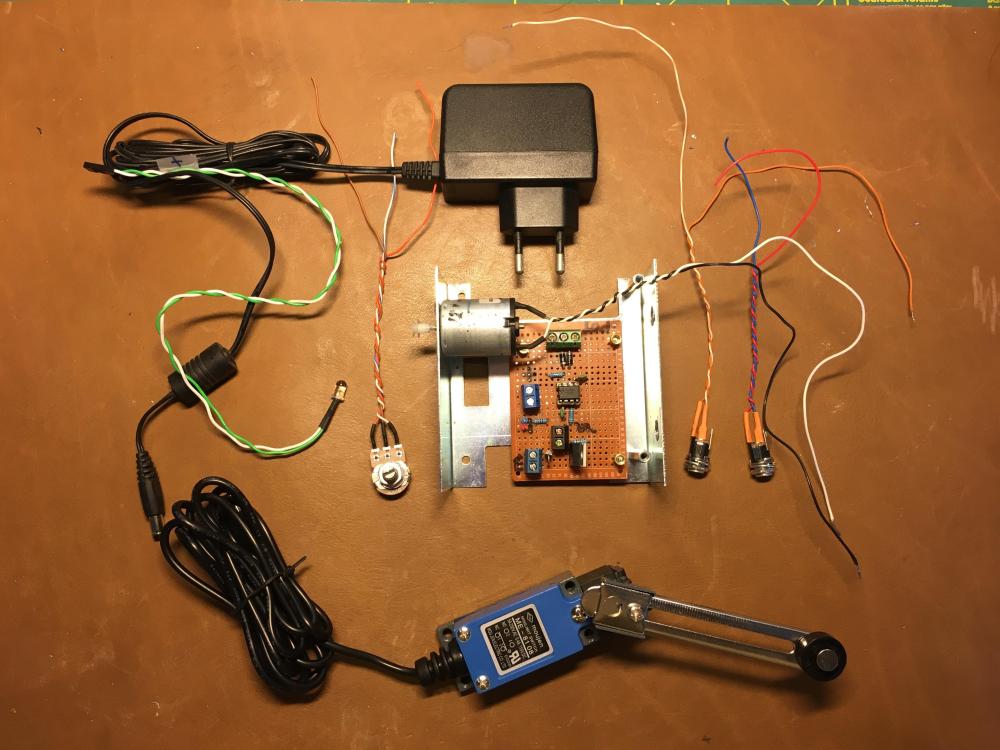

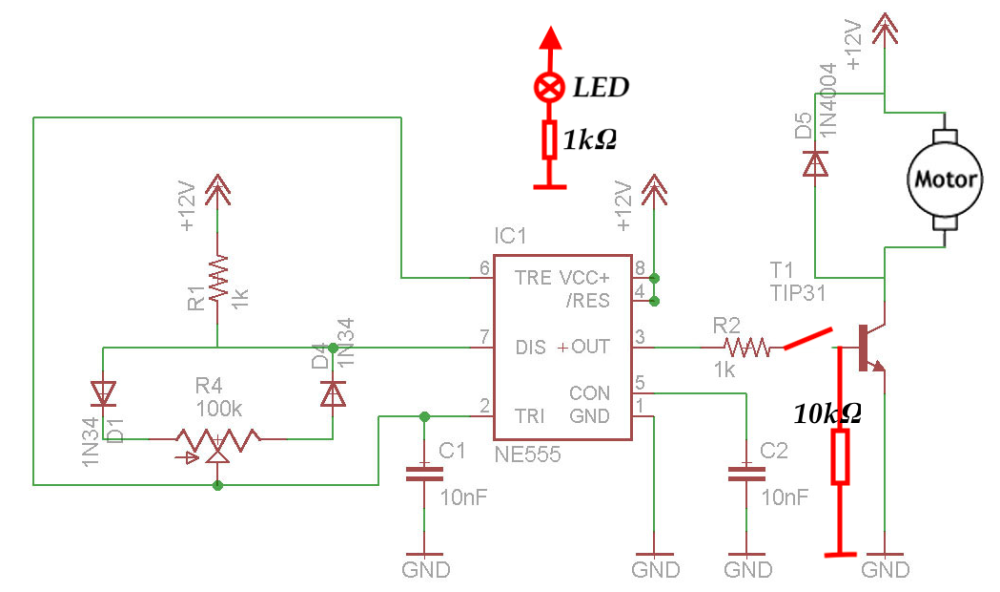

PWM with a 555 and a foot switch (RH, blue, momentary switch) has already been incorporated Here the breadboard trial, which works very well and I'm now in the final stages of the construction. More pictures to follow. An "intermediate-stage" picture below: Top: 240AC / 12V DC Adapter with 5.5mm plug, Bottom: foot-switch with 5.5mm plug, from left to right: LED, Pot-meter, metal box c/w motor & PCB, socket 5.5mm for foot-switch & socket 5.5mm for 12VDC power supply. Updated schematic; added foot-switch controlling the TIP31 gate, pull-down resistor so the gate doesn't float and a LED for 12V power indication.2 points

-

JohnR725 brought up an interesting point. Some of us have the luxury of *sufficient time* and *sufficient resources*. If I were working on watches as my primary source of income, I would need to dramatically increase the volume of my work and the output to match. I would not have as much time to spend on difficult and lengthy repairs. As a result, I'd have to make judgement calls on what a watch's needs were. I'd have to decline certain jobs if I thought they'd take up too much precious work time. But I don't need to do that. I have a day job. That's one reason I learned how to also work on cylinder escapements and why I bought the punches for them. They keep showing up here in Indianapolis, and needing work done. I don't know if it's due to word-of-mouth, but somehow these "friends of friends" sometimes hear that I know how to work on cylinder escapements and, wouldn't you know, this person will pull out their grandmother's little silver pin-set watch, or grandpa's old cylinder Galonne, and tell me how every other watchmaker took one look inside...and turned them down. Wouldn't touch it. Many of the watchmakers around here work for major jewelers, and so they specialize in what the jeweler sells (which makes sense). If a jeweler sells mostly modern Tag Heuers, the watch repair tech works on those all day, and will barely know what to do with a Timex, or an antique Galonne, or anything other than a Swiss lever. And he may not even have tools adequate to the task. Same with repair techs who are certified for Rolex, or Omega. There are a few independant watchmakers nearby who might take on varied work, but when they encounter something other than a Swiss lever, they seem to do what JohnR725 describes: either refuse the job and send the person away, or name a ludicrous price and hope the person is discouraged enough to leave on their own. More work for me, I suppose.2 points

-

I'm thinking that it would be safer not to use a motor at all. What would happen if the pivot jumps out of the pivot bed on the runner or the burnisher slips up on the arbor while the motor keeps spinning? In the latter case one would quickly have to remove the burnisher from the pivot bed on the runner - which would make the pivot jump out of the pivot bed - or quickly try to get the burnisher back into position - which could take long enough to damage the arbor. I could be wrong, but I wonder if the drawbacks outweigh the benefits I would think that for a majority of people, it would only take a few hours to (worst case scenario) a day or two to really get the hang of using a bow or a yoyo keyring to spin the pulley back and forth in a controlled manner.2 points

-

Any specialised work should always command a higher price. Restorers of vintage cars compared to your basic mechanic. My hourly rate repairing old houses or fitting bespoke staircases kitchens and bathrooms, overcoming issues is higher than my standard joinery work. Skill and knowledge beyond the norm developed from years of experience deserves more payment.1 point

-

1 point

-

1 point

-

Anything could happen, I suppose. But, on my setup, the spindle turns at about the speed a bow would turn it. And the motor runs only as the button switch is pushed. If something goes off track, just release the button. Reaction time would be similar to a bow...I am guessing.1 point

-

I have gotten several pies, numerous bottles of wine...wagyu beef, and a few dinners!!1 point

-

Perhaps a more realistic approach if you were working in the trade would be to do a Assessment is this going to be a problem? Anything that's going to be a problem You just don't do. Although typically what shops would do is charge what they perceive be a high price and then their surprise that the customer says yes and then they still get stuck doing it making a little more money but thinking they should Have picked a much much higher price.1 point

-

1 point

-

I really wonder why there is enough time for several posts but no time to perform the (more than once) requested vertical test? Frank1 point

-

I'm not sure if John suggested it but using a pin vice with sharp jaws can work. It might be possible to put an edge on the jaws. I'm about to try on a cheap sliding collar pin vise.1 point

-

Are the regulator pins gapped correctly? I understand you closed them more, but they should be almost pinching the hairspring. Also, check the balance for timing washers. If there are pairs (opposite sides), try removing them. But also, check in 2 horizontal and 4 vertical positions, as the poise may be thrown out if they weren't matched pairs. You would want to check in 6 positions anyway on a watch of this grade, and it should keep very good time.1 point

-

I use the Bergeon (the one on the left) when on the bench and need a basic measurement. I use the JKA (center) when measuring a staff (or wheel pivots, etc.) and willing to go to the extra effort of fetching it and opening it up. It consumes bench space, so I use it only when its features are necessary. I use the caliper on the right when working on my lathe. I used a Mutitoyo digital caliper (not shown) for crystals, stems, crowns, etc. BTW, I picked the Bergeon for $47 plus shipping and tax on ebay. It was a steal.1 point

-

The regulator pins should have a gap just large enough to allow the regulator to move without binding on the hairspring. Are you sure you have 250 amplitude? What lift angle are you using? It would be in the low 40s or high 30s on this piece. 500s a day would be a lot even if the gap it too large, unless it's really large and also if the amplitude is lower than thought. It could be that the hairspring isn't even touching them when running. Solution is to close the pins. Is it stable at -500 in several positions, 2 horizontal and 4 vertical?1 point

-

Yes, one tech guide (older) shows it as #8200, a more recent ETA parts list shows it as "33 Var" , "lock, assembled" . Jules Borel lists it as blocking lever, #08200.7750.0. There are two versions, older ones are usually plastic, newer ones seems like they are always metal. Either will work fine.1 point

-

I use Mitutoyo digital calipers for large stuff, where I don't mind being off +- a hundredth of a mm. When I need to split hundredths, it's a micrometer. I prefer non-digital ones as they are lighter and more compact, I find digitals cumbersome. Then there's an array of bench mics, with various shaped spindles and anvils, horizontal and vertical, and some indicating bench mics that will reliably measure to microns. Large mics for diameters up to 75mm, internal mics, I think there's at least a couple dozen around the shop haha. But a good caliper and regular 0-25mm mic covers most everything. Digital or vernier is a matter of choice. Mitutoyo for digital calipers are by far the best on the market, mine are over 20 years old and run at least a couple years on a battery (I never turn them off), and check out spot-on on gage blocks like when they were new.1 point

-

1 point

-

1 point