Leaderboard

Popular Content

Showing content with the highest reputation on 07/02/23 in all areas

-

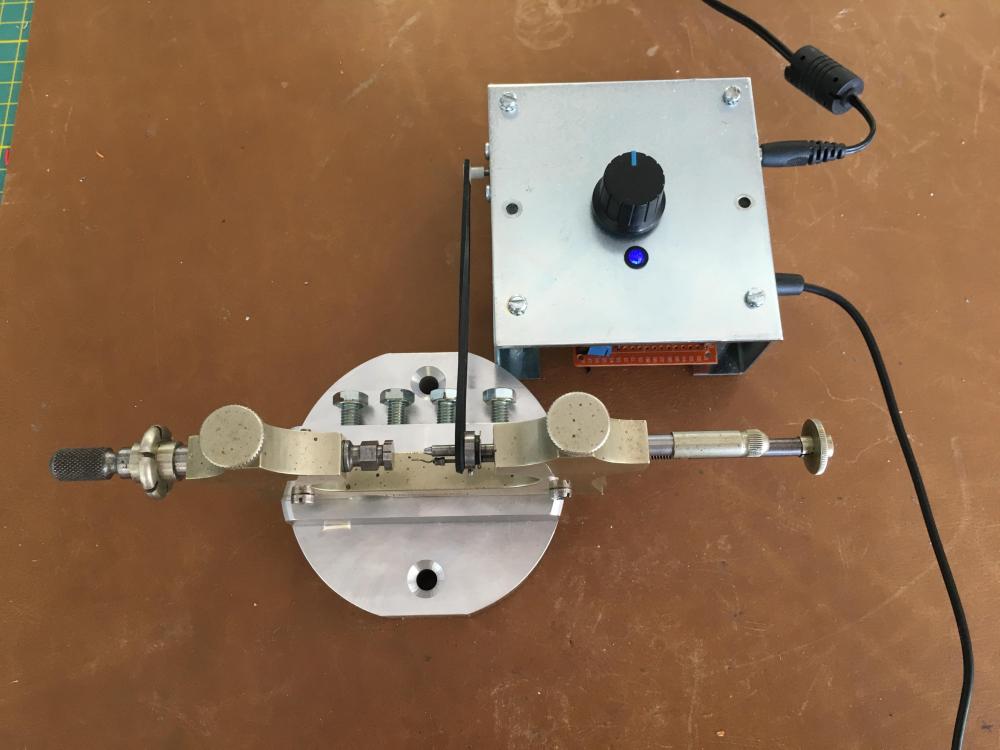

Nearly done. Speed adjustment is seamless, foot-switch works perfect and everything runs smooth & silence. Currently the "driving-unit" is a "stand-alone", which seems to work. If not, I may have to get a small piece of angle-iron and fix the unit to the Jacot-tool stand. Next, clean my desk and learn to burnish. Plenty of test-wheels4 points

-

4 points

-

Here is the watch I want to show, a Zodiac Incasecurit Hermetic which I think is from the late 40s. I chose it because it is the first watch in my collection, the one that lit my watch fire. It's my only Zodiac. I haven't had to do much to it except clean and buff. It was filthy and so scratched I could not see the dial when I got it. I kept the "Hong Kong" fabric band it came with, only when I got it it appeared to be a light gray. I had to run even that throught the ultrasonic. Not sure what it came with originally. I love it for a few reasons: It runs and keeps good time. The almost-gone rust spot on the back amused me because it is right where the thing claims to be rustproof! I love the color of the dial and just don't think it started out that color. I like the rendering of the numerals, the restrained application of luminesence, and it inexplicably reminds me of the beach.I like it just the way it is.3 points

-

Eyup fella. Are you saying you want help with repairing this yourself ? Or advice on where to take it to be repaired. This is based heavily on how much repair it entails and how much money you are prepared to throw at it. It sounds like you have little to no knowledge regarding repairing, so really that idea is out of the window for the time being, unless something very simple is wrong with it, even then a very risky venture with no experience. If you are lucky it might just need to have the inside workings cleaned and lubricated. And that by no means does it mean dunking in petrol, drying and spraying with wd40. To learn how to take apart a watch clean and lubricate it and reassemble to an average standard and not damage anything in the process can take months of practise. I'm not trying to discourage you by all means if you intend to take this up as a thing its a very rewarding hobby. You do need to have a logical mechanical mind and patience oh and spare money. Oh dear I'm not doing a very good job of sugar-coating it . That not me , i wont mislead anyone into thinking its easy. So depending on the type of person you are i hope you might work out from this if you are up to the job of repairing, just not this watch just yet.2 points

-

Is that just since we've all been arguing about it Because we are all different, i can theoretically see the advantage of using two hands to keep the burnisher in position. To keep it steady and in the correct position, but if its a balance staff thats such a small piece to work on, the extra weight of more than one hand on the burnisher may be too much. I always try different things to other people, in my head they seem to make sense and should be better alternatives. When put into practice thay aren't always a better idea, there is sometimes an aspect that isn't apparent until you actually try it. Always worth a try a though, no experiment is a waste of time, if you dont try then you wont know. Looking forward to seeing how it goes matey and definitely a better idea than the galaxy pivot polisher.2 points

-

Meanwhile, Mr nickelsilver has done 400 pivots with a bow and burnisher . Or some orders of magnitude less, but with no issues, and could do them during a blackout (this actually happened at the Swiss school I attended- blackout, but the 1st year kids were doing turning using a hand crank, so, go on!)2 points

-

Something like this to start. As you get further into clock making you might want different types. https://www.cousinsuk.com/sku/details/vices-bench-vice-jaws/v96921 point

-

Post pictures of the movement when you get it back, we might be able to give you some information.1 point

-

Now you are paying the price and learning the hard way. Perhaps in future you will leave them alone unless you know what you are doing. The person who taught me always said if you don't know what you are doing leave it alone and yes he was talking about watch banking pins.1 point

-

I think you'll find the PDF attached will answer that question and several more that you didn't ask. X-D-DVH-Di-Im-N_EN witchy calculation of numbers timing.pdf1 point

-

1 point

-

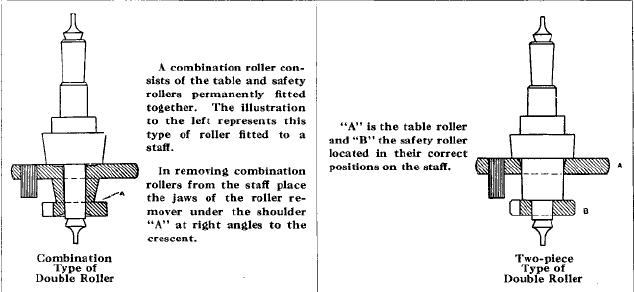

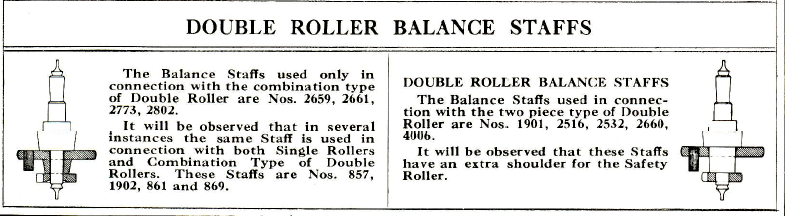

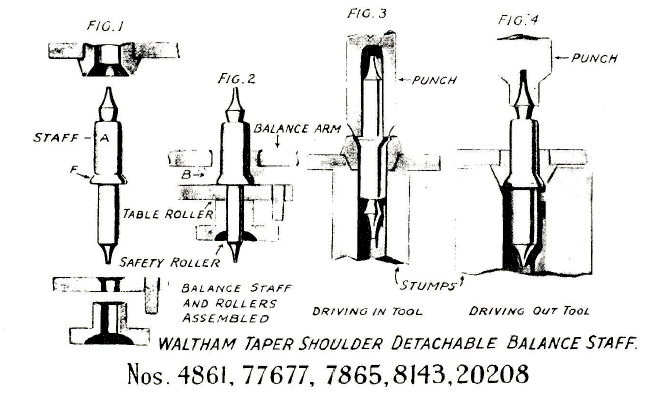

I just ran into this tonight while doing a balance staff replacement on an Elgin 478. It surprised me for sure, and I initially thought I had broken something. On closer inspection it didn't appear that I had, and thankfully I found this thread afterwards. Thanks to all. My blood pressure is coming back down now!1 point

-

Eyup peep. Looks handy for pushing ( friction fitted ) studs out of stud holder , with. Rgds1 point

-

I'm very happy for you that you have the skills to do so ! I don't seem to have those skills and try it differently. It may or may not work, but than at least I tried something which could work for me To me it's not a competition "Bow" vs "Belt-driven". If the bow works for you; by all means and perfect! I do hope, at least for me, that there are more ways to skin a cat. That's correct, both hands will be free to concentrate on the burnisher and what has the be burnished, since the switch is a foot-switch1 point

-

Great info. Thanks. Unfortunately, New England, not England. I will look for some repair places within a reasonable distance and see if I can find someone who can work on it and how much they charge.1 point

-

Yes that's the classic problem of lack of understanding. The other classic problem is standing in somebody else's shoes. For instance the watchmaker who taught me how to use the tool claimed you need the practice every day to be good. My experience with the tool was I didn't like it so at some point in time in my life when I needed money I sold it. If I'm going to polish a pivot I use a balloon Chuck. Works fine for me. But then somebody else very likely you came along and said the tool is really easy to use but that's the problem easy for you not necessarily easy for me. We both have differing experiences and differing points of view does not make either one of us right or wrong. The motor drive looks interesting to gets rid of the bow it would allow you to get everything set up everything in place including the burnishing tool in place before you even start spinning. They should be enough friction in the belt itself that if there's a problem and you release the switch to the motor it should stop instantly. Sounds like a nice concept. On the other hand the people that understand how to use the bow that sounds nice to just wasn't working for me at all.1 point

-

1 point

-

When you start playing around with the balance and the pallets which includes the impulse face which is governed by the banking pins you will find yourself in a mine field, which can and will be difficult to get out. I wish you luck.1 point

-

Why did you adjust the banking pins, that is one thing that should be left alone.1 point