Leaderboard

Popular Content

Showing content with the highest reputation on 07/03/23 in all areas

-

4 points

-

I would leave the stains. Most methods of removing them (completely) will remove metal as well, and that's not a good thing. If you want to try to get them a little better without hurting them, around here we have stuff called Metarex, which is cotton soaked in some kind of metal cleaner. I think Never Dull is similar. Metarex is really good at getting off light rust, and I think you'd have to spend a month rubbing it full time to remove any measurable amount of metal. It must have some sort of slight abrasive, but it's so mild it is harmless.3 points

-

One more Caravelle. This one had a scare when I went out to an antiques fair this morning and it was 95 f by 0900. Came home to AC and started getting condensation under the crystal. Opened it up and used a hand blower to clear it up! I liked this chunky rubber band with a Caravelle clasp. It was on a modern watch but fits perfectly on this vintage diver from 1972. Now i need another crown as this one is worn and not sure it is original as it us not signed.3 points

-

2 points

-

typically when people think about this you really haven't thought it through as much is your thinking. Not just in watch repair I've seen it for other examples of a hobby that moves into a business all the business things they should pay for but they didn't even think about it at the time. So the cost of something that's relatively cheap all of a sudden becomes expensive when you add in all the expenses it should be there. Oh and then there is the other little thing you're doing retail work what if word got out and people want to send you wholesale work would you have a wholesale price? Typically jewelry stores will double whatever you charge them. I have seen an example of somebody who suggested the retail prices is this and I'm going to bill you this but there's no guarantee that that's what's actually going to happen. then sometimes you lose business from the wholesale accounts because the customer couldn't pay the price because occasionally jewelry stores not just doubling up occasionally built triple prices. Then whose fault is the price being so high it's your fault not the jewelry store for tripling by the way. in real life what you are doing is a specialty item. If watch repair was like any other field a specialty item would get a higher price are you charging a higher price for specialty item? Then students in school are not taught how to work on vintage then definitely not cylinder watches. This means typically 99.9% of the watchmakers out there have no idea what they would do with the cylinder watch other than it would not be in their best interest to take it in and service. Contrary to popular belief not every single watch can be serviced successfully and we're trying to please a paying customer that's something you should keep in mind. Even if they want to throw money at you if you can't actually successfully service their watch it's not your interest to take the money.2 points

-

Yeah but Doc sez with a cheap chinese dremel you want the wheel to run fast and everything that way it doesn't take very long ( to fook it up ) . So that has to be a bonus right ?, that way you're not spending a lot of time fooking it up Haha OH , your tact is immeasurable How about just fixing it all onto a board, 3/4 mdf, ply, bit of old kitchen worktop.2 points

-

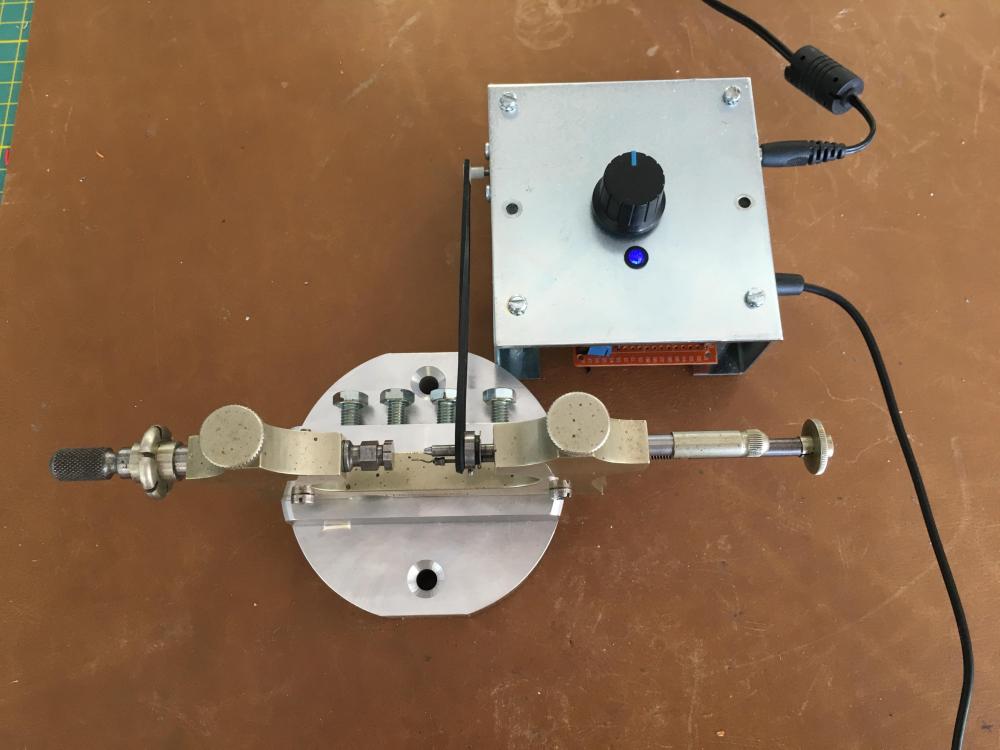

Nearly done. Speed adjustment is seamless, foot-switch works perfect and everything runs smooth & silence. Currently the "driving-unit" is a "stand-alone", which seems to work. If not, I may have to get a small piece of angle-iron and fix the unit to the Jacot-tool stand. Next, clean my desk and learn to burnish. Plenty of test-wheels2 points

-

Not easy to find this information out even less easy to understand. Tetrachloroethylene ( a chlorocarbon ) did replace trichloroethylene ( a halocarbon ) was also used in making pesticides and refrigerants . Apparently the trichloroethylene had a stronger cleaning ability but higher health risk. Cheaper than hexane this litre was 22 quid.1 point

-

I best get digging in my garden then as it arrived today, but as I'm very much a dog lover i will need a substitute for the other ingredient. Bull's pizzle ? They're readily available.1 point

-

The amount i will be using will be very small and exposure very short. About 30ml in a small sealed bottle with the time taken to remove the top place parts onto a mesh washer close the lid, repeat to remove parts. 20 seconds tops. I could wear a mask but probably won't. Its still used in the dy cleaning industry, heavy prolonged exposure in terms of years is suspected of causing cancers. I actually think I'm too old to worry about my low usage. I did concern over the environment but I'm sure getting in my van and driving to work in one day has a far greater impact than my lifetimes use of this stuff. I am very keen to see how well it cleans, i only have lighter fluid and elma pro to compare it against. Hexane was a close contender but i was thinking about its flammable nature, whereas this stuff is a chlorocarbon and not a hydrocarbon.1 point

-

After a long wait for parts and tools, I'm back to work on this guy. Decided to try reaming out the barrel pivot hole in the main plate for a jewel. Never done this before, so I tried it out on the plate that I'm not planning to use. Ended up getting a reamer holder for my K&D staking set. I bought it and reamers from 1.09 up to the 1.59 that I need from Dave's Watch Parts. So I took my time and went through each 0.10mm step, then deburred it with a 3/32" Dremel engraving tool in a pin vise. Worked an absolute treat. I may have gotten a little overzealous with the chamfer, but this is why I tried it here first. You can see in the first photo just how oval this hole was when I started.1 point

-

looking at your picture you're missing your hands and that's because you don't have a crystal. You don't have a crystal because it looks like you don't have the bezel to hold the crystal in that is a major problem. then there's the other peculiar problem it looks like the movement is rotating around inside the case? This would normally be impossible if the crown was engaged with the movement and yes it would normally be impossible. That might indicate somebody broke the stem off that's a casing issue like the bezel that's a problem. Then based on the amount of damage the cases suffered the movement is probably not in a good condition. did you give you a clue of what sort of price they would charge?1 point

-

Most of my machines have rust stains on them somewhere. Not rust, just the dark steel left once the rust is removed. Definitely better like that than "all cleaned up!" and no longer precise, haha. The Metarex is great, curious how Never Dull is, but it looks pretty much the same.1 point

-

Yes, I'm left handed and it's running in one direction; the top of the pivot towards me.1 point

-

Thanks Guy, let me check for the case number when I get back to my bench in a bit. I agree, hard to find the all SS case and a 17J movement. This one has some wear on the back near the crown and where the case edges touch the skin, and sweat, contact and time really can get the plating worn away. Looks like aAS/ST 1951 aka Bulova 11 UACD movement 17J. Case number W 830 is what is inside the back cover.1 point

-

Nice! Caravelle really had some great watches. I especially like those that intersect a stainless steel case with a 17 jewel movement. I haven't seen a lot of those, I think maybe 2 of the 20+ Caravelle's I have hit both of those metrics and I started working on one of them today. I have some NOS Caravelle crowns. Do you know which crown you need? If you have the case number on the inside of the case back I can check.1 point

-

I had this problem too. Even broke a few crystals before I learnt how to do it. If you look at the edge of the crystal, there is a beveled edge and a square, less beveled edge. Intuitively, one would think the beveled edge is there to facilitate easier insertion and should go towards the watch case. But that is wrong. The square edge goes towards the case. And you will need a good crystal press that puts even pressure all round. Make sure you place the crystal carefully so that it doesn't pinch the gasket and damage it. Sometimes the generic gaskets do not fit the case as well as the original one, so be very careful. The beveled edge is for cosmetic purposes and probably to prevent chipping during daily use. Hope this solves your problem.1 point

-

1 point

-

Eyup fella. Are you saying you want help with repairing this yourself ? Or advice on where to take it to be repaired. This is based heavily on how much repair it entails and how much money you are prepared to throw at it. It sounds like you have little to no knowledge regarding repairing, so really that idea is out of the window for the time being, unless something very simple is wrong with it, even then a very risky venture with no experience. If you are lucky it might just need to have the inside workings cleaned and lubricated. And that by no means does it mean dunking in petrol, drying and spraying with wd40. To learn how to take apart a watch clean and lubricate it and reassemble to an average standard and not damage anything in the process can take months of practise. I'm not trying to discourage you by all means if you intend to take this up as a thing its a very rewarding hobby. You do need to have a logical mechanical mind and patience oh and spare money. Oh dear I'm not doing a very good job of sugar-coating it . That not me , i wont mislead anyone into thinking its easy. So depending on the type of person you are i hope you might work out from this if you are up to the job of repairing, just not this watch just yet.1 point

-

1 point

-

1 point

-

Here is the watch I want to show, a Zodiac Incasecurit Hermetic which I think is from the late 40s. I chose it because it is the first watch in my collection, the one that lit my watch fire. It's my only Zodiac. I haven't had to do much to it except clean and buff. It was filthy and so scratched I could not see the dial when I got it. I kept the "Hong Kong" fabric band it came with, only when I got it it appeared to be a light gray. I had to run even that throught the ultrasonic. Not sure what it came with originally. I love it for a few reasons: It runs and keeps good time. The almost-gone rust spot on the back amused me because it is right where the thing claims to be rustproof! I love the color of the dial and just don't think it started out that color. I like the rendering of the numerals, the restrained application of luminesence, and it inexplicably reminds me of the beach.I like it just the way it is.1 point

-

Meanwhile, Mr nickelsilver has done 400 pivots with a bow and burnisher . Or some orders of magnitude less, but with no issues, and could do them during a blackout (this actually happened at the Swiss school I attended- blackout, but the 1st year kids were doing turning using a hand crank, so, go on!)1 point

-

Actually, I love Kalle's laid back relaxed demeanor. Typical Dutch I believe, so different from how people behave in the UK. I love watching how much delight he takes from working with watches and sharing his knowledge in such a relaxed way. The pace of life can be too fast these days and watching Kalle is a way for me to unwind and learn along the way.1 point

.thumb.jpg.d03c27cff25aa867e99c2e296d9cf119.jpg)

.jpg.d2efd492d8d34cd9dfe14d50c50192e9.jpg)

.thumb.jpg.ec1aab5dbcf50f2df54f0b8055746872.jpg)

.thumb.jpg.1acb6e84618b3dcb2085398c2be2559b.jpg)

.thumb.jpg.1d577fee7b5de4cf78a90cafe12a171a.jpg)