Leaderboard

Popular Content

Showing content with the highest reputation on 07/04/23 in all areas

-

Always funny to hear folks' idea of what stuff should cost.3 points

-

would that be because you have the silly notion that watchmakers should be able to make a living? outstanding congratulations for volunteering. Yes from your description it sounds simple and easy this should be repaired in no time. Let's look at the message board rules specifically were not supposed to profit off of the website. In the case of his Facebook group the definition of profiting would include posting links to your YouTube video's. I really hate when people on this group say look at my video as opposed to just answering the question for instance. But here were not supposed to directly sell parts and make money off of the website. Because realistically if you did you should be giving a big cut to mark who pays for the website and we don't want to go there because he'll tell us how expensive it is so were happy he has a website. now you can profit off the website by gaining knowledge and sharing knowledge. Like I'm looking forward to where the bezels come from inexpensively. But it does mean you can list where all the parts could be had and found. Just as long as you're not the person selling them. So the number one thing is we're still missing something? were still missing a key component but based on the above evaluations shouldn't be an issue at all but it really would be nice to have a picture of the watch movement or in the absence of that the serial number. no no no that's a very bad attitude we can't have that on this discussion. We've already determined that $800 is by somebody who's extremely greedy and it can be done for considerably less. haven't you been paying attention? so we seem to have discrepancy here and we're going to carry this discussion through to its finality. In other words this is an excellent learning opportunity. One of the places where I get very annoyed is whining about the high cost of watch repair. The last person who did it on this discussion group I happily blacklisted that person never to see anything from that person ever again. fortunately while there is some whining about the greedy watchmaker we are having a discussion about what things cost this is an excellent learning opportunity. Which is different than somebody whining about the cost of watch repair with zero comprehension of what their whining about. Of course we still have a problem we need the serial number the movement. then you're right it could be a key a wound watch. Yes I've seen that it's hard to find key wind cases sometimes they will use a stem wound case and yes that is a reason it might have rotated. Which is why we still need a serial number or a picture of the movement. So yes of its key wind things become much more simple. We need better pictures of the case even though I've seen a case like that before I do not conveniently remember who made it so we need pictures of the inside makers marks etc. Then where exactly do bezels come from to be replaced and that question is not for @nickelsilver to answer because I know what he would suggest so for right now are the skip over that answer. So were going to go with the off-the-shelf solution and just purchased a new bezel shouldn't be that hard to do based on this discussion.2 points

-

I think the Jeweler has moved on, he's given the owner a difficult task of sourcing the parts himself. The 800 dollars is starting to sound like just a labour price. If more damage is to discovered inside that might mean more parts and more labour. This is where finding a good retired amateur that is doing repairing for the love of his hobby and not for a living is a good solution.2 points

-

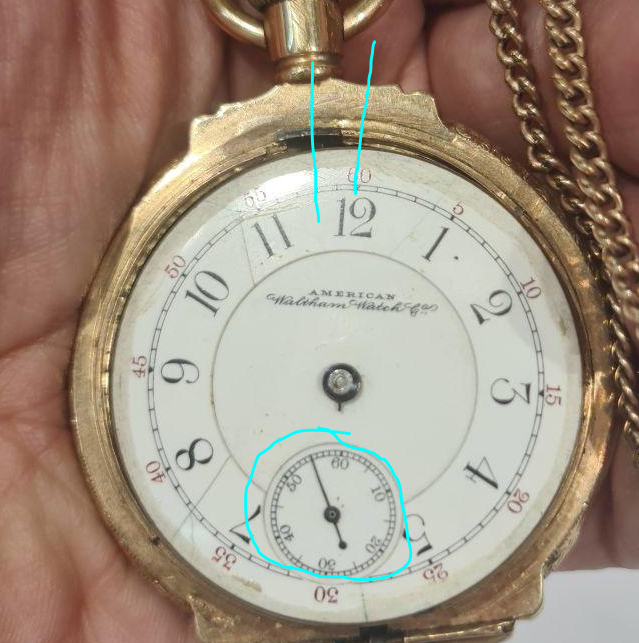

we still need to see the picture of the movement. It's hard to know what the problem is if we don't see that. then I need a clarification just so I'm sure about something so the price they quoted of $800 is that with you supplying the parts or with them supplying the parts? $800 that would be US dollars so I can assume that the jeweler is in the US? Because the people on this group could be just about anywhere on the planet and some locations would have a much harder time grasping how to fix an American pocket watch. Then jeweler that's a problem. Typically you do take your watches to the local jewelry store to get it repaired but they don't always have watchmakers on-site some do some don't. sometimes they might claim the watchmakers in the back room but the definition the back room could be someplace else on the planet as they send the work out. so if the jewelry store has an actual watchmaker on premise doing all the repair work pricing would be different possibly than if they send the work out where of course they would probably typically double the price. This is where it's always best if you can find the actual watch repair person and bypass the jeweler. now let's look at the price is $800 a good price or a bad price. To understand the price we have to look at things more seriously and we have way too many unanswered questions like $800 with the customer supplying the parts or the repair with the jeweler doing the parts. okay let's pretend we're going to do the repair as I pointed out up above crystals missing that's why the hands are missing and the crystals missing because there's no bezel to hold the crystal in. That's means were going to have to replace the bezel which I think there's people out there that might do a custom bezel I bet you it's expensive. then let's look at the other problem for that let me steal an image from up above and draw some lines on it. So notice the alignment of the crown with 12 o'clock position it's off a little bit? That normally should be impossible there's a stem that goes into the movement and it can't really go anyplace else and yet it's moved. Common lay when dials rotate like this it's because her dial feeder broken off but notice in the picture the secondhand? Secondhand is currently or at least appears to be where it's supposed to be in other words on the fourth wheel post so this indicates the entire movement must've somehow rotated? now notice in this image what do we see about the crown in relationship to the dial? The secondhand is still there indicating of that the dial is where it's supposed to be in relationship to the movement but the entire movement has rotated which as I said is impossible because the crown is still in place well sort of it would indicate that the stem is broken off and I don't think I've ever seen it before at least this I've never seen this exact problem before with one of the's I did see a stem broken the other day but that's a different style a case. oh and of course notice in the picture above the invisible bezel. so this means we need bezel, crystal, hands, stem and case work, complete overhaul the movements and we don't know the damage plus possibly a new staff based on the bizarreness I'm seeing so what you think $25 cover it? So basically you're looking at finding another case. I've seen this style of case before so they're not impossible to find but ill take a while looking at eBay one will show up sooner or later and I'm assuming the cases gold filled but it does have interesting decorations on the outside of the case looks like a couple of different shades of gold.. Yes I know the color gold isn't quite as colorful as it could be but there's a couple of different colors there is not your usual case but it's not impossible to get either. So used case probably off of eBay take a while to find one but one will show up sooner or later. Whatever problems the movement has in the jeweler should a given you a list of everything wrong with the watch especially if you're supposed to be finding the parts how can you find stuff if you don't know what you're supposed to finding2 points

-

2 points

-

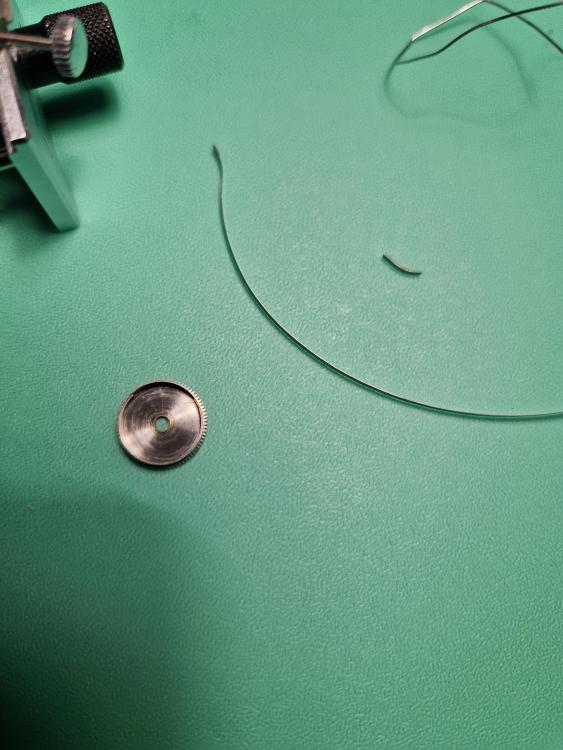

I'm always impressed just looking at these, and lucky enough to own a chronometer grade one, now finally had the chance to work on a repair, and all the positive opinions got confirmed. The owner lamented water ingress and the watch stopping all the time. Seeing no major damage on a first inspection I undertook the work with good hopes. Starting with the dial side the overall feeling of quality and maniacal height saving design becomes evident. The dial fits so precisely that a dial washer was not present or needed. This being a time only version I can't do any praising to the calendar works. As soon I lifted the hour wheel the watch started running strong in all positions with good amplitude, then I pulled the cannon pinion which was quite tight. Note to myself, MUST get a cannon pinion remover. The black oxidation on the contact section was the root cause of the fault, but after 50 years it was time for a complete service, and I have the distinct impression that mine was the first one. One incredible fact is that Omega still updates their technical documents about this long discontinued caliber, I can only think of the aeronautic industry doing something similar for certain "never old" airplanes and engines. The way I did it may be called not fully professional, as I didn't do surface treatment, and used only 9010, HP-1300, and 9415 without an automatic oiler. However I'm happy with the results, and I hope that the owner will be too. That being said I plan to upgrade on the above points in the immediate future. One tool detail that I really recommend is to use soft metal tweezers whenever possible, I have got cheap brass Indian ones which I then dressed to eliminate any sharp edge. These are OK to handle most of the screws and all the bridges and plates. Keyless and motion works are rational, and easy to work with. Some dirt and micro-spots corrosion, but nothing worrying. The stem was the rustiest part, and the crumbles are all what was left of the crown gasket. It is defintely possible with some patience to open these and fit an o-ring, which luckily I had from an assortment box. Even the stem came out very decent after the due care. Just give a tap or two to the washer to make it seat nicely again. I've even refitted the steel ring which matches well the O-ring profile. Two screws hold the automatic bridge, and one can see that also the gib screw was removed. That allows the rotor to be removed even with the mov't in the case. For regular service to the auto works it's enough to remove the larger bridge. One of its screws is thinner due to more limited space. Note the use of a single reversing wheel, yet the winding in bi-directional and the overall manufacture is just amazing. I used HP-1300 on the pivots but probably that another synthetic type might have been better. Note the space above the balance, which hosts the automatic work. At the time of its introduction this was the thinnest automatic movement with sweeps seconds and calendar, at just 4.5mm. And the Reed regulator is nothing less than amazingly beautiful. The balance is then removed and inspected. Note the multiple tiny "drill kisses" on the rim for poising. To save height, the train is different from the common design. Seconds pinion is driven by a pinion sitting above the the barrel bridge, and has a tension spring which controls its end-shake. Releasing power is not easy as the space around the click is very limited, remember to use only something soft like a toothpick to do that. Only then we can remove the pallet bridge, another beautiful execution with two locating posts and screws. Then remove crown and ratchet wheels. We start to see the sophisticated design and the one-way automatic winding clutch. The machining of a cord on the crown wheel round holds precisely the hub of the crown wheel, with an off-center screw. Wow. The auto winding wheel has special profile inner teeth which allows one-way power transmission from the ratchet wheel to the barrel arbor. The small pinion catches only one way to said wheel, otherwise it turns freely. That makes so that turning the crown in the opposite direction has no effect whatsoever, and also that a single reversing wheel is needed in the automatic work, because movement is transmitted only in one direction from the wheel on the arbor to the auto works. I for one find difficult to understand what I wrote above and the principle of operation of that mechanism. We can now remove the train bridge which only holds third, fourth and escape wheel. Al-tough, that does not make it particularly easy to fit back. Finally the seconds pivot spring, pivot, barrel bridge can be removed, followed by the barrel and center wheel. Speaking of the barrel, once opened it I found it quite dry, with the lid slightly corroded and heavily grooved. As an experiment I hand polished this surface with a wide micro-fiber stick, and car polish compound. Grooves were gone, but it remained scratched. I switched then to grade 20 or 30 of Chinese diamond paste until it got better. And better with finer paste, to an acceptable smoothness Now, I must say that I did not replace the mainspring, and not even removed it from the barrel as I don't have a winder, and wanted to avoid any distortion to it. In the end the watch performed well with plenty albeit not stellar amplitude. The stripped main plate in its equally magnificent A and B sides. Cleaning and reassembly was uneventful even if some screw are small enough to require full attention. I had some doubts about the seconds pivot being supported by jewel on the auto works when refitting hands, but in fact that worked OK. After lubricants settled the timegrapher response was completely positive, One last note, you know you're holding a genuine vintage Omega dial when it has a fine clove watermarking, a recess for the balance anti-shock device, and the feet are shaped for the screws to hold without damage. After a long time spent hand polishing the acrylic crystal and other details the complete "Omega Geneve" watch came out stunning, sorry I didn't take a picture Hope you have enjoyed this article.1 point

-

Send it to me. I will attempt a repivot. No guts, no glory! Free1 point

-

it's a shame the pivot wasn't on the other end. Then you could try to re-pivot. But it's very difficult to hold the wheel and pivot the end that you have not impossible just difficult. So now you're going to have to find a another watch movement on eBay which is interesting thing unless the seller tells you what idiots. Usually the 218 has the crown of the 4 o'clock position but they can't remember if the 219 follows exactly the same position. On the other hand will give you more tuning fork watches the play with. Then if you reassemble with out the wheel are you getting enough fork vibration to move the index wheel?1 point

-

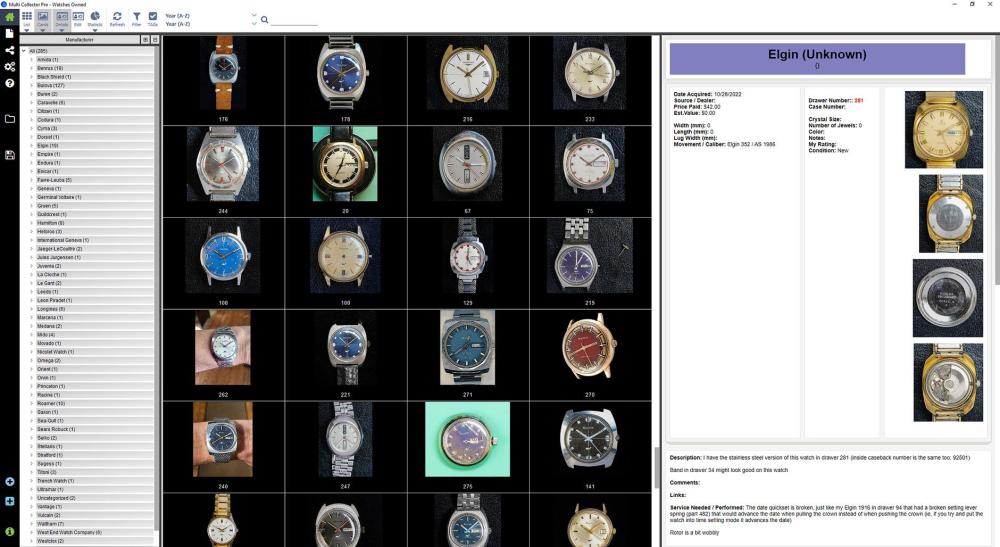

I use the program 'Multi Collector Pro' to keep track of my collection. You can customize the templates to look the way you want and can edit templates to add fields you would like to track. For example, I added a "Drawer" field. I keep my watches in plastic parts containers and number the drawers. That lets me easily find a particular watch by looking at what drawer it is in within the program. All of the fields are searchable which is very handy for quickly finding things. For example, if I get a watch that has a nice strap I will put "nice strap" in the description field and then later if I am looking for a strap to put on a watch I will search for "nice strap" and get a list of all of those watches. It's basically a database program and you can do normal database things with the data. In the screenshot I have it sorted by "year" and I use that view a lot and I also sort by "drawer" a lot too, depending on what I am trying to do. You can sort on most any field, including caliber, # of jewels, date acquired, etc. You can also include web links (and local links to things like service sheets) and when you click on it, it will open the linked webpage/PDF. Handy for when doing research on a movement and you want to remember what website had the info on the watch in question. When I first started using it I found a review that had a template the person customized which I used as a starting point and then customized it further.1 point

-

If the seller has half a clue they often name the movement calibre in the description of the watch and often the listing itself. Just looking now for AS 1002 has thrown up Titus Accurist Trojan Rotary Liga Waltham and half a dozen others i haven't heard of. The calibre isn't exclusive to the brands but a starting point of where to look for more of that calibre. The brand may have kept to using just a few makers if they were happy with their contracts with them.1 point

-

Do we know what the cut is on a burnisher and that it burnishes the same in both directions. I thought i remember Nicklesilver saying to let up on the burnisher as its drawn backwards. I haven't found an explanation as yet as to why it is used in both directions on a jacot ( is it just all about control and safety of the pivot and nothing to do with how the pivot turns out ) looked through books of de Carle, Fried and Gazeley. Though they do explain how to make a burnisher. Old Hippy is adamant about lathe driven burnishing, i dont think it was clarified that it pertained to watches or clocks.1 point

-

outstanding attitude I'm always worried about offending or annoying somebody. had to go back and look at your original introduction I see Northern California. Location is needed because it depends upon where you are on the planets. EBay obviously is a great source to sell things. but the phrase build it and they will come does not apply to selling things. Things have to be properly described otherwise no one's ever going to find what you're selling. Then of course they have to want whatever you're selling. then there's the other options which is why needed your location for instance the link below. A group of watch and clock collectors primarily located in the US but there are chapters worldwide. They have chapter meetings regional meetings that are several chapters that come together and national meetings which are big. Unfortunately the Association is crashing and burning it might be a bit harsh but downsizing considerably from what it once was. and typically for all the various meetings they will have what's called the March where they will sell things a great opportunity to pick up things. I've purchased a sizable quantity of tools from regionals and nationals usually at very good prices because eBay wasn't in existence and they didn't have any way to price things. Plus unifying clock people who acquired watch stuff and could care less and watch people it had clock stuff etc. so there are always outstanding things to purchase and yes is a lot of people it still won't sell on eBay. There's also a huge variation in chapter size. California used to have some big chapters for instance. One of the local members was visiting a California chapter and went to a chapter meeting. Somebody asked if this is what your chapter meeting Mart look like and he said no this is what our regional meeting would look like. At that time our regional meeting was 200 tables. The last I heard the Portland regional because we alternate between Seattle and Portland I think that about 140 tables. In the old days the nationals were big meetings I can't remember if Denver or Chicago was the biggest I suspect there are literally 1000 tables there. I never did get all the tables in Chicago is just too big and there are too many other things I needed to be doing. https://www.nawcc.org/ what I would still like to do in this discussion is for us to finish what we think the repair should really cost? The reality is will never be able to do that because there's too many varying factors. The biggest varying factor is location of where the watch repair will be done. will be nice to have is the point somebody in a direction when they're complaining about watch repair costs and know they probably will never read this discussion anyway. We can't really compare cost because it depends upon where somebody lives. But we can work out other things like if we knew what the watch was what would be a realistic time to disassemble clean it put it back together and get it running providing it doesn't have other unknown issues but until we get a better watch description that's to a certain degree problematic. the thought for the new case was based on needing a bezel. For the entire repair that is going to be the biggest challenge of all unless somebody knows a source of bezels. Let's look at a wall from parts Log you will note that cases are not in the catalog. dials, hands stems are in the catalog casually didn't see any cases? https://archive.org/details/catalogueofwalth00walt/page/n1/mode/2up there's also the other problem of depending upon how vintage the watch is conceivably the bezel will have to be made custom-made or I don't know if you can modify an existing bezel if we found something really close whether somebody could make it fit for instance oh and even if we found another case on eBay a lot of these things were hand fits so one bezel may not fit on another case. I suspect is only one person the group that give us one of the answers unfortunately lives in Switzerland the cost of living is expensive so maybe we'll look at this a little differently. Plus if we discuss prices its border lining on violation of the rule and selling things on the discussion so we can look at it differently and possibly get an answer so the only person is probably ever made a bezel would be @nickelsilver so you I give us a clue as to how you make the bezel and how many would you think it have to make to get it right? My wording is because conceivably you might have to make a test bezel just to find out how the things snaps together etc. you might be lucky and make up the first time I don't actually know. So were not good discuss money because of the service you could provide so approximate estimation of how much time you think it would take to make a bezel? Then approximate price of all of the equipment you have to make that bezel. then based on that will become suspicious that $800 seems a little too cheap? I wonder if there is something that they know that we don't know? Although I could be wrong on the cost of a custom-made bezel but added into the repair I don't know it seems cheap but1 point

-

I agree. I just assume that @Endeavor's cognitive ability is normal (although my impression is that it is significantly higher than that) and that he has no physical handicap that hinders him from operating the Jacot tool in the traditional way. Yes, I could be wrong about that, but if we were to demand absolute facts and objective truths in every personal situation before we expressed an opinion or thought we wouldn't get much done. Therefore my opinions about this have not been about Endeavor, you, or anyone else but mostly about the subject in general. In general terms, I think that statement is false, even though it could of course be true for some people. I believe that for most well-motivated and interested people, it would only take a few hours to a couple of days to practice enough to get good or even near-perfect results. Being an enthusiast I only bring out my Jacot tool occasionally, and I always feel shaky (sometimes very shaky) the first couple of strokes with the burnisher. So, I take a scrap wheel, practice on it for a few minutes to get warm and then I'm ready to go, and I can proudly say that most of the time I get beautiful results. Or, perhaps the watchmaker who taught you didn't instil the needed trust in the tool (having to "use it every day to be any good") and it subconsciously bugged you enough that you eventually gave up on it? Well, that's just a thought based on a personal experience. See, when I was about 10 years old, my gym teacher told me not to do ball sports ever again after he saw me playing soccer. After that, I didn't touch a ball for over 25 years when I discovered by chance that there was nothing wrong with my ball sense and I started playing tennis. For better or for worse, we are very impressionable when we are young, especially by authorities. There are basically three scenarios where I would consider a motor/belt-driven Jacot to be well-motivated: 1. If despite your best efforts you're unable to get good results after having practised using it the traditional way for about a day and a half. 2. You have a disability that makes it impossible or very inconvenient to operate it the traditional way and a motor/belt-driven solution helps overcome that disability. 3. You have the desire and ability to make the Jacot tool motor/belt-driven and think that it would be a fun and/or rewarding project and perhaps even believe that it will make burnishing pivots more efficient and/or precise. Yep, and I was not looking to be in the "right" and tell someone that they were in the "wrong". I was simply trying to instil some confidence in operating the Jacot tool in the traditional way. As I understand it in the case of Endeavor, the Jacot tool is new to him and my impression was that he just assumed that it would be difficult to operate it in the traditional way and that a motor/belt-driven solution for driving the pulley somehow automatically would facilitate operating it. To me that sounded a bit like someone assuming that it would be easier and more convenient to use an electric wheelchair rather than trying to walk despite very likely being more than perfectly able to walk. After all, we are very used to motor-driven gadgets and in 99.9 per cent of the cases, we know that a motor is more effective than doing something manually. However, to make sure, I think a motor-driven Jacot tool could be a brilliant idea for those who for whatever reason are unable to operate the Jacot tool in the traditional way if it alleviates a real problem. And I would be the first one to ask Endeavor if he would consider making one for me in such a situation. I worry about possible side effects on the result as the motor only spins in one direction while the burnisher moves in alternating directions, but hopefully, that worry is uncalled for. Also, learning how to synchronize with a motor that spins in alternating directions would probably be difficult. Possibly not a problem, if one has a decent sense of rhythm and the motor is consistent. Using a bow (yoyo keyring), altering the direction of the bow and the burnisher feels very organic (after practice) to me, and I would expect it for most people, but yes, there are always some exceptions, of course, and I honestly respect that.1 point

-

Today, I decided to go with something old. So I'm carrying a little Swiss cylinder Galonne, which I have named "The Mysterious Number 3" (because that is the only identifying mark I could find on it). It is not a very valuable antique and after I repaired it, as practice, it did not sell on Ebay, so that makes it permanently mine. And it's an endearing little thing. While it is fairly accurate for a cylinder watch, it's nowhere near a quartz. And if I could sell it, given the residual wear to the case, I could probably only get $60 US. If you want accuracy, about $15 will buy a cheap but moderately reliable quartz. So, in terms of Imperial measurement, that must mean that... Four quartz equal a galonne! Well, I'm going to leave to get some groceries today (before people start coming after me with torches and pitchforks).1 point

-

Indeed! For me to repair that watch would take me "forever" (several days, not to mention the time to source the parts) and in the process, I and my family would starve to death if I could only charge a mere $800. That said, where I live, I only get to put about 30 % or so of the invoice amount in my own pocket.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. Just starting then you might find this helpful. 704789946_TZIllustratedGlossary(2).pdf1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. Are you into watches or clocks or could it be both.1 point

-

Are the hammers leather or plastic. Leather can get hard if leather then brush oil on them, it will take time to soften them up. I suggest trying before replacing the rods. If you need to replace buy a complete set as they will already be in tone. All good clock materiel suppliers will have them in stock.1 point

-

Some of us may not have noticed, i dont think i looked past the first picture. But john pointed out that the bezel is missing in the pictures that might be a real problem, i hope you have it.1 point

-

1 point

-

Let's have a look at the front too. Some of these front loaders need the crystal to be "blown" off with air pressure. I think mark has a video on YT showing how it's done. Found it.1 point

-

If I'm wrong, I will happily swallow my pride and say no more...but I would bet all the money in my pocket that this watch is a front-loader. The case back is so much smaller than most, such that trying to remove the movement through there would seem too unusual. And the way there's a bump over the stem entrance; I see that a lot with front-loaders. I know it has steel mated to gold, but I have a front-loader that is like that myself. It fools you. If it is a front-loader, you will need a crystal lift to remove the crystal, or if there is a tension bezel on top, that will need to come off. It is likely to have a two-piece stem, so you will need to *gently* pull out/off the crown end of the stem - it will snap free. The movement *should* lift right out. (Unless it is one of certain models of Omega, in which case you will need to unlock it.) I can better advise you if you could post pictures of the front, and crown-side edge, and opposite side edge, so I can see the make, model, style, and whatever else there is to go on. I still could be wrong, but I feel we are looking at a front-loader.1 point

-

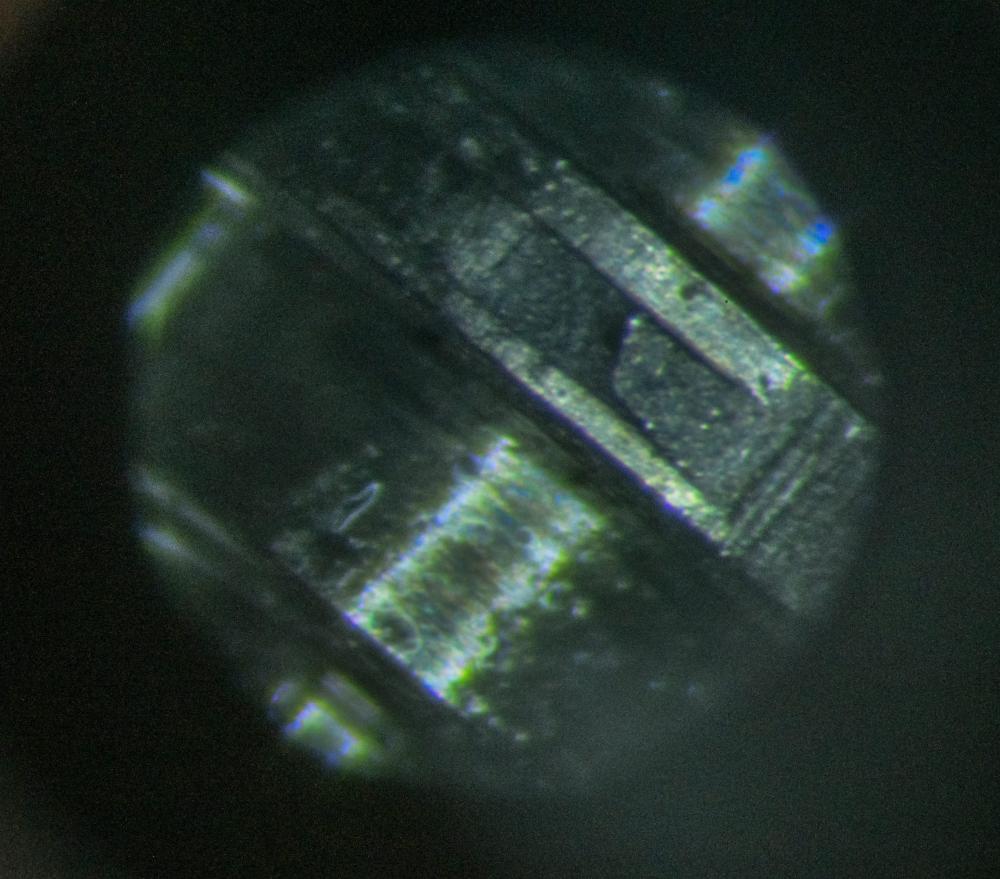

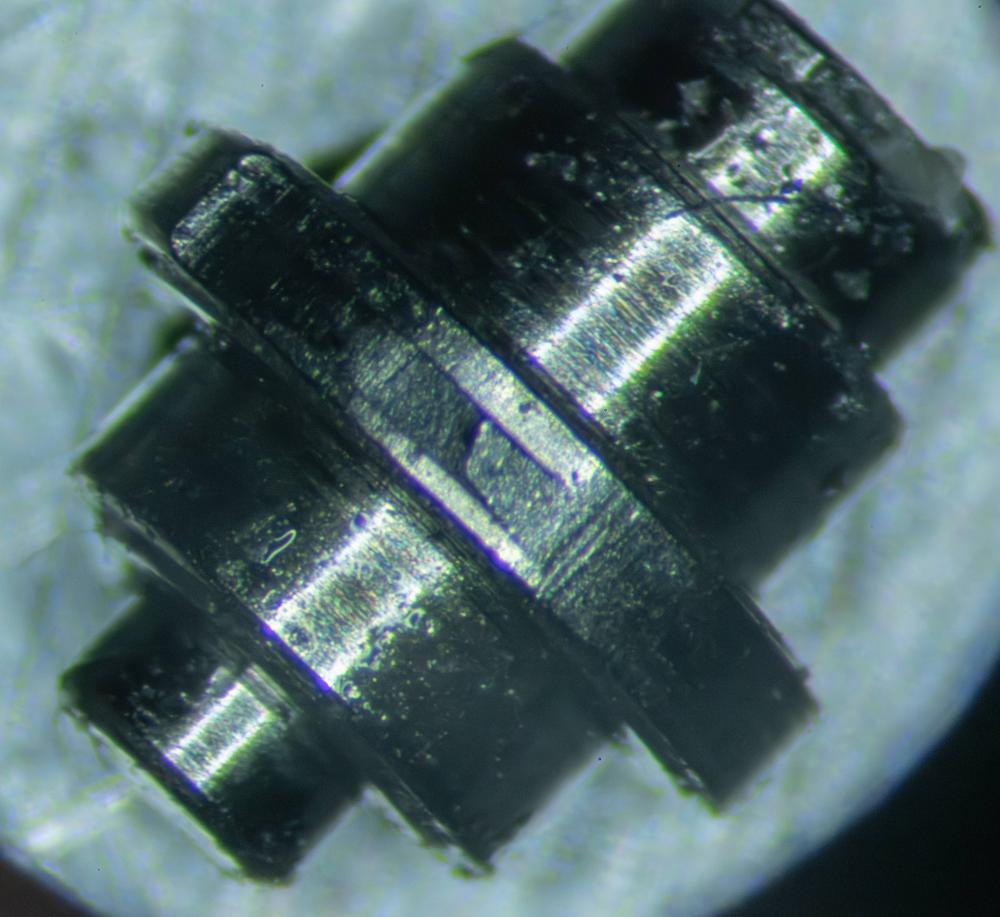

After a long wait for parts and tools, I'm back to work on this guy. Decided to try reaming out the barrel pivot hole in the main plate for a jewel. Never done this before, so I tried it out on the plate that I'm not planning to use. Ended up getting a reamer holder for my K&D staking set. I bought it and reamers from 1.09 up to the 1.59 that I need from Dave's Watch Parts. So I took my time and went through each 0.10mm step, then deburred it with a 3/32" Dremel engraving tool in a pin vise. Worked an absolute treat. I may have gotten a little overzealous with the chamfer, but this is why I tried it here first. You can see in the first photo just how oval this hole was when I started.1 point

-

I picked up this Elgin pocket watch today for $12 US at an antiques fair. It wasn't running and the sub seconds hand was floating around under the crystal. I think I scored. Everything is there except for 2 small screws, one on the rate adjustment bracket and 1 on the bridge holding a jewel on the 3rd wheel (I think). Anyway, spent about 20 minutes taking apart and pegging some old grease off. Finally got it to where I could put a wind in it and got it going. I count 9 watchmakers marks and the serial numbers dates to 1925. Not sure why I picked Anthony7s thread to post this one but saw the title and thought it was a more general thread and seemed appropriate at the time, so to speak.1 point

-

Eyup fella. Are you saying you want help with repairing this yourself ? Or advice on where to take it to be repaired. This is based heavily on how much repair it entails and how much money you are prepared to throw at it. It sounds like you have little to no knowledge regarding repairing, so really that idea is out of the window for the time being, unless something very simple is wrong with it, even then a very risky venture with no experience. If you are lucky it might just need to have the inside workings cleaned and lubricated. And that by no means does it mean dunking in petrol, drying and spraying with wd40. To learn how to take apart a watch clean and lubricate it and reassemble to an average standard and not damage anything in the process can take months of practise. I'm not trying to discourage you by all means if you intend to take this up as a thing its a very rewarding hobby. You do need to have a logical mechanical mind and patience oh and spare money. Oh dear I'm not doing a very good job of sugar-coating it . That not me , i wont mislead anyone into thinking its easy. So depending on the type of person you are i hope you might work out from this if you are up to the job of repairing, just not this watch just yet.1 point

-

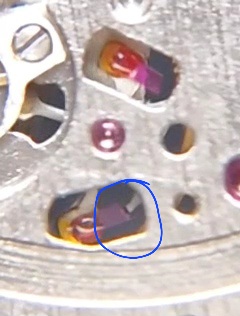

Hey guys, This is a frustrating one. I was reassembling this elgin 12s pw and discovered that the burnished-in jewel for the bottom plate palate fork was missing. This, after cleaning the movement in the watch cleaning machine and again in the US (because it got dirty again) and after buying a replacement dial and balance hole jewel. It must have just shattered as i can't find it anywhere and, of course, it was burnished in. I now have two PWs that need burnished in jewels. I could probably justify now getting the proper tools to fix them, but i'm going to set it aside to better develop my basic skills before tackling these repairs. I don't know if i was negligent in handling the cleaning or it was just old and bound to happen. Anyways, another lesson learned. Arron.1 point

-

So, Before the hookless barrel arbour debacle, I did get out my thermally controlled soldering iron and gave the heat treatment (300C if interested) to my busted spring parts. The technique worked well (in that they didn't snap). I needed to make the diameter 2mm to account for the "spring back" to 2.5mm. Thank you all for the advice.1 point

-

And after burning off the fingerprint from my right index finger, creating an art deco mainspring shaped pattern on my sycamore self built desktop and an acrid stench to rival that in my bathroom after curry night, I decided to look at my barrel arbour carefully. Perhaps I should have looked before I beeped.1 point

-

Or in this day and age no matter how many YouTube videos You watch In watch repair. So many people watch the YouTube videos where everything looks so simple versus how small a watch really is.1 point

-

I always advise you should start with pocket watches (not fusee pocket watch’s they are very different) Pocket watches are just the same as an ordinary watch but much bigger. Practise taking them apart putting them back together. This will give you good practise using your tweezers, screwdrivers and your eye glass. You will learn how the movement works. You will get to know the pieces. It doesn’t matter if the movement doesn’t work. I have said many times on this forum no matter how many books you read there is nothing better than to get your hands dirty. You might find this helpful. 704789946_TZIllustratedGlossary(2).pdf1 point

-

I've found my expertise from grade school of avoiding work by figuring out all the shortcuts is really paying off. I think some of you here are compadres in that regard... Have you seen this?1 point

-

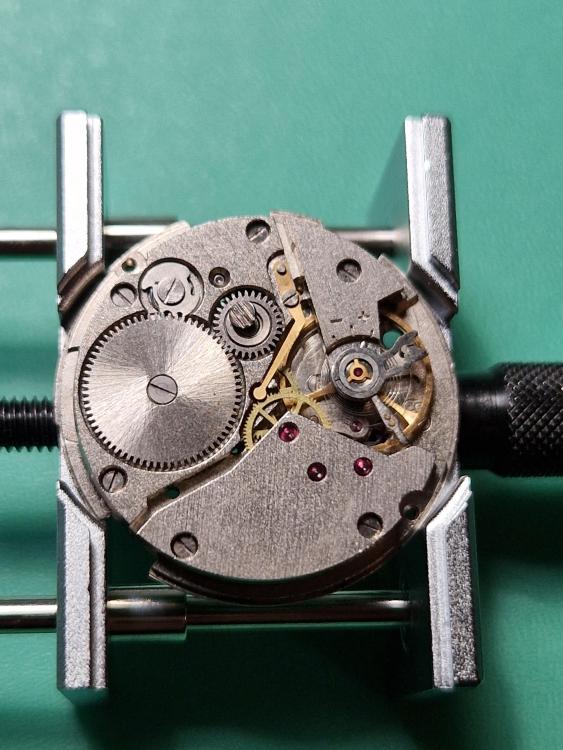

This is my Vostok 2414 from the late 1980s. It was my first ever full (and successful) service. Photos in reverse chronological order. The final product. I like how the dial colour has cracked in different levels of intensity as the shade of the paint changes. Full wind. Couldn't be happier. I'm a bit of an OCD person... note: lift angle is correctly set to 42°. Not sure if this is visible at all . But maybe you can see the small black area between the pallet (exit) stone and escape wheel tooth. That's lubricant (9415). Took me a while to get close to the recommended 60-70% of contact area (maybe I went slightly above..). And it took me the same amount of time to film it with my basic phone+loupe+slowmo technique. Oh boy, it took quite a number of attempts to get that drop of oil done well (being a first-timer). But I probably spent even more time with that bloody shock spring!!! Including 2-3 hours of searching on the floor... When I received it, the watch wouldn't wind. Upon opening the barrel and removing the mainspring, I found that the bridle had broken off... I followed a cool trick I saw somewhere (can't find the source anymore) and used a lighter to heat the spring and then bend it backwards to create a bridle. To my astonishment, it works perfectly and I get the full power reserve. Just some pics of the movement.1 point

-

1 point

-

Picked up this Croton Tropartic with the blue dial yesterday. I posted it in the blue dial thread. Since then I took it out of the case and examined more closely. I now think that the gold flecking on the blue linen dial is original...it does not affect the white of the minutes/seconds markers, which actually are on top of some of the gold. Anyway several more pictures in various lighting trying to show the nice contrast between the red seconds hand and the blue dial. I dont think this had been opened in quite a while as the case back was really tightened down and gasket was hardened but easy to chip out compared to the goo of the crown gasket. Definately will be getting a new crystal.1 point

-

1 point

-

1 point

-

I just finished another Seiko 6309 diver over the weekend and finished it off last night, see before and after shots Front: Tape was the only thing holding it together, here is the back of the case: And here is the view when I opened the case : And when I got the movement out: The hands were completely fused to the cannon pinion and the dial paint eaten through to bare metal After cleaning in my 'home-brew' 566 and rinse solutions (please see my other thread, HERE) and then polishing the glass and case, then replacing the dial and hands with aftermarket replacements and a new cannon pinion from a donor watch along with a new bezel (because I had a spare so why not), here is the final result: Very pleased with the result1 point

-

Depends what type you intend to get. I use the screw down type like the pic. Seems to give you more control but the princible is the same. The smaller die presses down on the inside of the crystal and contracts the outer rim. The watch front is then pressed down onto the crystal. Hold down while undoing the the large wheel. Hopefully the crystal will then be in place. Takes a bit of practise. A small circle of linen will prevent the top die marking the crystal.1 point

-

Its ok now, I have source one, should anyone else need a copy drop me a pm.1 point

.JPG.ebf152565316568e6b415c85730d1d88.jpeg.b1d1cfd6d768d8d9530c4c4c4ffa47d4.jpeg)

.thumb.jpg.d03c27cff25aa867e99c2e296d9cf119.jpg)

.jpg.d2efd492d8d34cd9dfe14d50c50192e9.jpg)

.thumb.jpg.ec1aab5dbcf50f2df54f0b8055746872.jpg)

.thumb.jpg.1acb6e84618b3dcb2085398c2be2559b.jpg)

.thumb.jpg.1d577fee7b5de4cf78a90cafe12a171a.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)