Leaderboard

Popular Content

Showing content with the highest reputation on 07/05/23 in all areas

-

You won't have any fear when you are dead. In fact you won't have anything at all.2 points

-

Today, I decided to go with something old. So I'm carrying a little Swiss cylinder Galonne, which I have named "The Mysterious Number 3" (because that is the only identifying mark I could find on it). It is not a very valuable antique and after I repaired it, as practice, it did not sell on Ebay, so that makes it permanently mine. And it's an endearing little thing. While it is fairly accurate for a cylinder watch, it's nowhere near a quartz. And if I could sell it, given the residual wear to the case, I could probably only get $60 US. If you want accuracy, about $15 will buy a cheap but moderately reliable quartz. So, in terms of Imperial measurement, that must mean that... Four quartz equal a galonne! Well, I'm going to leave to get some groceries today (before people start coming after me with torches and pitchforks).2 points

-

would that be because you have the silly notion that watchmakers should be able to make a living? outstanding congratulations for volunteering. Yes from your description it sounds simple and easy this should be repaired in no time. Let's look at the message board rules specifically were not supposed to profit off of the website. In the case of his Facebook group the definition of profiting would include posting links to your YouTube video's. I really hate when people on this group say look at my video as opposed to just answering the question for instance. But here were not supposed to directly sell parts and make money off of the website. Because realistically if you did you should be giving a big cut to mark who pays for the website and we don't want to go there because he'll tell us how expensive it is so were happy he has a website. now you can profit off the website by gaining knowledge and sharing knowledge. Like I'm looking forward to where the bezels come from inexpensively. But it does mean you can list where all the parts could be had and found. Just as long as you're not the person selling them. So the number one thing is we're still missing something? were still missing a key component but based on the above evaluations shouldn't be an issue at all but it really would be nice to have a picture of the watch movement or in the absence of that the serial number. no no no that's a very bad attitude we can't have that on this discussion. We've already determined that $800 is by somebody who's extremely greedy and it can be done for considerably less. haven't you been paying attention? so we seem to have discrepancy here and we're going to carry this discussion through to its finality. In other words this is an excellent learning opportunity. One of the places where I get very annoyed is whining about the high cost of watch repair. The last person who did it on this discussion group I happily blacklisted that person never to see anything from that person ever again. fortunately while there is some whining about the greedy watchmaker we are having a discussion about what things cost this is an excellent learning opportunity. Which is different than somebody whining about the cost of watch repair with zero comprehension of what their whining about. Of course we still have a problem we need the serial number the movement. then you're right it could be a key a wound watch. Yes I've seen that it's hard to find key wind cases sometimes they will use a stem wound case and yes that is a reason it might have rotated. Which is why we still need a serial number or a picture of the movement. So yes of its key wind things become much more simple. We need better pictures of the case even though I've seen a case like that before I do not conveniently remember who made it so we need pictures of the inside makers marks etc. Then where exactly do bezels come from to be replaced and that question is not for @nickelsilver to answer because I know what he would suggest so for right now are the skip over that answer. So were going to go with the off-the-shelf solution and just purchased a new bezel shouldn't be that hard to do based on this discussion.2 points

-

You can get even with her in advance, start selling her belongings now.1 point

-

Amazon is on top of it. They have already told him to issue me a refund. They also said they are going to look into the seller as the feedback is concerning. Which is where the seller has been sneaky. Most of the 1 star feedback has been struck through by Amazon with a message by Amazon of, "The fulfillment issues associated with this order were not due to the seller". Because it's a "shipping issue". But it isn't a shipping issue. So hopefully Amazon is now on to their shenanigans.1 point

-

1 point

-

I've been looking at pivot file burnishers to use with the jacot tool i've just cleaned up, there are a couple of online write ups about making an homemade pivot burnisher, one using a drill bit the other a tungsten carbide. Links below. https://joyofprecision.com/post/11833625959/making-a-burnishing-file https://www.snclocks.com/TechnicalInformation/Tid-Bits/Tid-Bit-11-Making-a-Burnisher/ https://abouttime-clockmaking.com/downloads/Burnishing.pdf I will have a go at making a couple of burnishers at the weekend, one finished with 600 grit the other 400 grit, see if they work or not.1 point

-

If the wife knew how much money I spent on tools she would probably have a heart attack (and me too if I started to count on it). Fortunately, watch tools are so small and seemingly inconspicuous that she suspects nothing and I can keep being in denial1 point

-

Ha, yes, much less painful on Ebay! And secondhand, they are rarely worn or abused, since folks don't use them much, haha. The Vallorbe is an ok tool, but the file side is useless for watch work, and the radius on the burnisher side is huge- might correspond to a balance on a hairspring vibrating tool or maybe and 18s pocketwatch with a pronounced radius. More of a clock tool (though you woulnd't need the radius there).1 point

-

I think this sums it up well. I've seen folks who learned its use in school, but hadn't touched it in quite a few years, sit down and do balance staff pivots, it was literally the first time they used it since school. Another, who went to a school notorious for making everything seem scary and like some sort of witchcraft, who obviously managed to use it at school, struggle like heck when they tried to do a simple pivot after just a couple of years post school. Yet another went to a school that just sort of said, "this is a Jacot tool, it works like this, try it out if you want"- they struggled a lot too (just out of school when they got to my shop). Both of those guys were knocking out pivots after just a few minutes of instruction; for the former, it was removing the fear factor, for the latter, it was simply explaining and showing how to do it correctly. So yes, it takes a bit of practice to get used to the tool, but not crazy practice. Yes, doing balance pivots is harder than a regular shouldered pivot. I fully disagree that it takes daily practice, or anything close to it. One thing I will say is you want a good burnisher, and here Bergeon actually does hit the mark, their burnishers in tungsten carbide are fantastic.1 point

-

After a tiny stroke about 6 years ago my short term memory is hopeless. I can't remember what I did last week. But what I did years ago I can remember quite well.1 point

-

Expressing oneself in writing is difficult for everyone, even for me, and judging by your reaction, I did not succeed very well, which I sincerely regret, but I would like to try again and hope that I succeed better this time. If I fail again, you can at least rest assured that the only thing driving me is my goodwill to promote our shared interest in watches and repair. I don't know if it helps but I can honestly say that I neither implied nor explicitly stated that your teacher would be an "incompetent idiot" or that practice is not necessary to master the Jacot tool. I'm sorry that what I wrote was perceived that way, especially as I have great respect and admiration for your know-how and your long experience, which you also generously share and for which many of us are very grateful. You are one of the most appreciated pros on WRT! What I'm trying to say is that I personally believe that practice is not needed every day to master the Jacot tool, but of course, one must initially practice and practice a lot to master it. My main point and personal experience is that once you get the hang of it, you don't need to practice every day to maintain it. A few minutes of warm-up and repetition is all it takes to get going again if you feel shaky. I am not writing this to question you or your teacher's statement, but because as I said, it is my personal experience and is intended as an encouragement to those who are thinking of getting a Jacot tool but may think it is very difficult to learn themselves to use or have to build a motorized solution to be able to master it as an enthusiast repairer who can't practice every day. Then it goes without saying that for some individuals (I think they are very few) the learning is almost insurmountable, while for others (I would think a majority) the learning only takes a few hours to a day or two. I myself spent a couple of days practising before I started to feel confident with the technique, but I think it is an unusually long time because I had no teacher or mentor who could show and help me "hands-on". It is of course individual how easy or difficult it is to learn to use the Jacot tool, but regardless, I respect, admire and am inspired by everyone who tries.1 point

-

1 point

-

1 point

-

I would like to post pics, however I would likely be blacklisted or highly admonished for bandwidth hogging. I am thinking that I will share one certain type of watch at a time in the My Collection thread. Like, the Wyler through Zodiac WW2 military group, the big fat square 70's group, the gaudy highly decorative group, Deco... highlights of the Bulova watches of the 40's and earlier, of course the railroad grade pocket watches, the all gold ones and the all gold with diamonds...all Gruen super classy dress watches of the 50s and 60s, ... then of course the tricky watches - jump hour like the Dial-o-rama and the Chevron ( the Elgin one), mystery hands and Borels ...oh and the Benrus parade, maybe including the Helbros highlights...or the one-offs with funny names and high jewel counts, like the Hebe watches ,, wait or russian watches, then of course the tools and parts and books... There are so many more groups, right? Not sure I would be making anyone jealous, just maybe nauseated. Too much sugar for a dime. Thanks though, I will figure it out but also feel free to ask for any specific items you might want to see. Oh and lets not forget the iconic second class watches- the Lucernes, Chateaus and the Caravelles, for instance and th...stopping haha.1 point

-

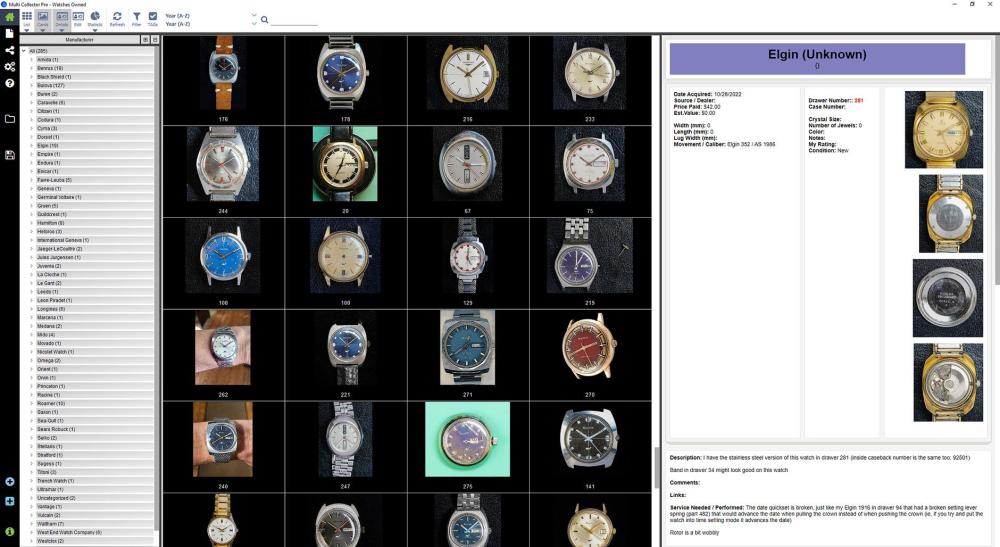

I use the program 'Multi Collector Pro' to keep track of my collection. You can customize the templates to look the way you want and can edit templates to add fields you would like to track. For example, I added a "Drawer" field. I keep my watches in plastic parts containers and number the drawers. That lets me easily find a particular watch by looking at what drawer it is in within the program. All of the fields are searchable which is very handy for quickly finding things. For example, if I get a watch that has a nice strap I will put "nice strap" in the description field and then later if I am looking for a strap to put on a watch I will search for "nice strap" and get a list of all of those watches. It's basically a database program and you can do normal database things with the data. In the screenshot I have it sorted by "year" and I use that view a lot and I also sort by "drawer" a lot too, depending on what I am trying to do. You can sort on most any field, including caliber, # of jewels, date acquired, etc. You can also include web links (and local links to things like service sheets) and when you click on it, it will open the linked webpage/PDF. Handy for when doing research on a movement and you want to remember what website had the info on the watch in question. When I first started using it I found a review that had a template the person customized which I used as a starting point and then customized it further.1 point

-

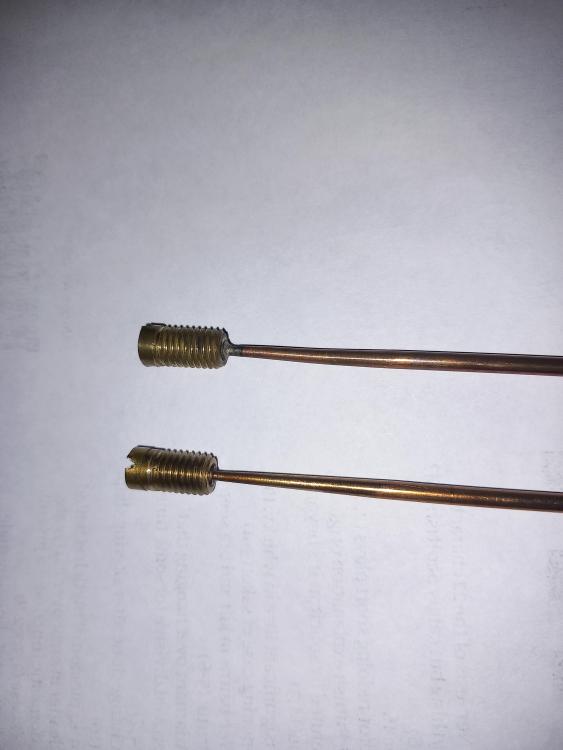

Thanks. I'll try to soften the leather. Had a look at the rods and now I can see why the long one is out. It has snapped and been repaired with solder at some point in its life. You can just about see in the photo (top rod). The other rods have no trace of solder. This will have had the effect of dampening the sound of that rod. Have seen a replacement set (used) on Ebay with the same dimensions for £7.99 so will get those.1 point

-

outstanding attitude I'm always worried about offending or annoying somebody. had to go back and look at your original introduction I see Northern California. Location is needed because it depends upon where you are on the planets. EBay obviously is a great source to sell things. but the phrase build it and they will come does not apply to selling things. Things have to be properly described otherwise no one's ever going to find what you're selling. Then of course they have to want whatever you're selling. then there's the other options which is why needed your location for instance the link below. A group of watch and clock collectors primarily located in the US but there are chapters worldwide. They have chapter meetings regional meetings that are several chapters that come together and national meetings which are big. Unfortunately the Association is crashing and burning it might be a bit harsh but downsizing considerably from what it once was. and typically for all the various meetings they will have what's called the March where they will sell things a great opportunity to pick up things. I've purchased a sizable quantity of tools from regionals and nationals usually at very good prices because eBay wasn't in existence and they didn't have any way to price things. Plus unifying clock people who acquired watch stuff and could care less and watch people it had clock stuff etc. so there are always outstanding things to purchase and yes is a lot of people it still won't sell on eBay. There's also a huge variation in chapter size. California used to have some big chapters for instance. One of the local members was visiting a California chapter and went to a chapter meeting. Somebody asked if this is what your chapter meeting Mart look like and he said no this is what our regional meeting would look like. At that time our regional meeting was 200 tables. The last I heard the Portland regional because we alternate between Seattle and Portland I think that about 140 tables. In the old days the nationals were big meetings I can't remember if Denver or Chicago was the biggest I suspect there are literally 1000 tables there. I never did get all the tables in Chicago is just too big and there are too many other things I needed to be doing. https://www.nawcc.org/ what I would still like to do in this discussion is for us to finish what we think the repair should really cost? The reality is will never be able to do that because there's too many varying factors. The biggest varying factor is location of where the watch repair will be done. will be nice to have is the point somebody in a direction when they're complaining about watch repair costs and know they probably will never read this discussion anyway. We can't really compare cost because it depends upon where somebody lives. But we can work out other things like if we knew what the watch was what would be a realistic time to disassemble clean it put it back together and get it running providing it doesn't have other unknown issues but until we get a better watch description that's to a certain degree problematic. the thought for the new case was based on needing a bezel. For the entire repair that is going to be the biggest challenge of all unless somebody knows a source of bezels. Let's look at a wall from parts Log you will note that cases are not in the catalog. dials, hands stems are in the catalog casually didn't see any cases? https://archive.org/details/catalogueofwalth00walt/page/n1/mode/2up there's also the other problem of depending upon how vintage the watch is conceivably the bezel will have to be made custom-made or I don't know if you can modify an existing bezel if we found something really close whether somebody could make it fit for instance oh and even if we found another case on eBay a lot of these things were hand fits so one bezel may not fit on another case. I suspect is only one person the group that give us one of the answers unfortunately lives in Switzerland the cost of living is expensive so maybe we'll look at this a little differently. Plus if we discuss prices its border lining on violation of the rule and selling things on the discussion so we can look at it differently and possibly get an answer so the only person is probably ever made a bezel would be @nickelsilver so you I give us a clue as to how you make the bezel and how many would you think it have to make to get it right? My wording is because conceivably you might have to make a test bezel just to find out how the things snaps together etc. you might be lucky and make up the first time I don't actually know. So were not good discuss money because of the service you could provide so approximate estimation of how much time you think it would take to make a bezel? Then approximate price of all of the equipment you have to make that bezel. then based on that will become suspicious that $800 seems a little too cheap? I wonder if there is something that they know that we don't know? Although I could be wrong on the cost of a custom-made bezel but added into the repair I don't know it seems cheap but1 point

-

I agree. I just assume that @Endeavor's cognitive ability is normal (although my impression is that it is significantly higher than that) and that he has no physical handicap that hinders him from operating the Jacot tool in the traditional way. Yes, I could be wrong about that, but if we were to demand absolute facts and objective truths in every personal situation before we expressed an opinion or thought we wouldn't get much done. Therefore my opinions about this have not been about Endeavor, you, or anyone else but mostly about the subject in general. In general terms, I think that statement is false, even though it could of course be true for some people. I believe that for most well-motivated and interested people, it would only take a few hours to a couple of days to practice enough to get good or even near-perfect results. Being an enthusiast I only bring out my Jacot tool occasionally, and I always feel shaky (sometimes very shaky) the first couple of strokes with the burnisher. So, I take a scrap wheel, practice on it for a few minutes to get warm and then I'm ready to go, and I can proudly say that most of the time I get beautiful results. Or, perhaps the watchmaker who taught you didn't instil the needed trust in the tool (having to "use it every day to be any good") and it subconsciously bugged you enough that you eventually gave up on it? Well, that's just a thought based on a personal experience. See, when I was about 10 years old, my gym teacher told me not to do ball sports ever again after he saw me playing soccer. After that, I didn't touch a ball for over 25 years when I discovered by chance that there was nothing wrong with my ball sense and I started playing tennis. For better or for worse, we are very impressionable when we are young, especially by authorities. There are basically three scenarios where I would consider a motor/belt-driven Jacot to be well-motivated: 1. If despite your best efforts you're unable to get good results after having practised using it the traditional way for about a day and a half. 2. You have a disability that makes it impossible or very inconvenient to operate it the traditional way and a motor/belt-driven solution helps overcome that disability. 3. You have the desire and ability to make the Jacot tool motor/belt-driven and think that it would be a fun and/or rewarding project and perhaps even believe that it will make burnishing pivots more efficient and/or precise. Yep, and I was not looking to be in the "right" and tell someone that they were in the "wrong". I was simply trying to instil some confidence in operating the Jacot tool in the traditional way. As I understand it in the case of Endeavor, the Jacot tool is new to him and my impression was that he just assumed that it would be difficult to operate it in the traditional way and that a motor/belt-driven solution for driving the pulley somehow automatically would facilitate operating it. To me that sounded a bit like someone assuming that it would be easier and more convenient to use an electric wheelchair rather than trying to walk despite very likely being more than perfectly able to walk. After all, we are very used to motor-driven gadgets and in 99.9 per cent of the cases, we know that a motor is more effective than doing something manually. However, to make sure, I think a motor-driven Jacot tool could be a brilliant idea for those who for whatever reason are unable to operate the Jacot tool in the traditional way if it alleviates a real problem. And I would be the first one to ask Endeavor if he would consider making one for me in such a situation. I worry about possible side effects on the result as the motor only spins in one direction while the burnisher moves in alternating directions, but hopefully, that worry is uncalled for. Also, learning how to synchronize with a motor that spins in alternating directions would probably be difficult. Possibly not a problem, if one has a decent sense of rhythm and the motor is consistent. Using a bow (yoyo keyring), altering the direction of the bow and the burnisher feels very organic (after practice) to me, and I would expect it for most people, but yes, there are always some exceptions, of course, and I honestly respect that.1 point

-

John makes a number of valuable points, among them are 1) we still don't all know every single thing that needs to be repaired upon this watch, and 2) we still haven't seen pictures of the movement, which could influence our opinions (as it may have influenced the other watchmaker). But we also don't feel the same immense sentimental attachment to the watch, as its owner might. And if it is that precious, the owner may be tempted to spend $800 on restoration. What we should be doing is requesting all the information we can, and trying to advise as well as we are able, to ensure that the $800 seems reasonable and necessary. That is a heck of a lot of educated guessing. We don't want him to be cheated. In an ideal situation, the watchmaker would show a beautifully restored and well-running watch, customer is satisfied and then pays $800, and from the owner's view it is well worth it. Perhaps others could do it for less, and perhaps the quality of the work may or may not be different. I guess, if the repair technician is reputable, even a master, then he would not ask for money until he could provide the utmost service. I have been cheated before, more than once. I am just hoping he will get good work for the price.1 point

-

Always funny to hear folks' idea of what stuff should cost.1 point

-

looking at your picture you're missing your hands and that's because you don't have a crystal. You don't have a crystal because it looks like you don't have the bezel to hold the crystal in that is a major problem. then there's the other peculiar problem it looks like the movement is rotating around inside the case? This would normally be impossible if the crown was engaged with the movement and yes it would normally be impossible. That might indicate somebody broke the stem off that's a casing issue like the bezel that's a problem. Then based on the amount of damage the cases suffered the movement is probably not in a good condition. did you give you a clue of what sort of price they would charge?1 point

-

Eyup fella. Are you saying you want help with repairing this yourself ? Or advice on where to take it to be repaired. This is based heavily on how much repair it entails and how much money you are prepared to throw at it. It sounds like you have little to no knowledge regarding repairing, so really that idea is out of the window for the time being, unless something very simple is wrong with it, even then a very risky venture with no experience. If you are lucky it might just need to have the inside workings cleaned and lubricated. And that by no means does it mean dunking in petrol, drying and spraying with wd40. To learn how to take apart a watch clean and lubricate it and reassemble to an average standard and not damage anything in the process can take months of practise. I'm not trying to discourage you by all means if you intend to take this up as a thing its a very rewarding hobby. You do need to have a logical mechanical mind and patience oh and spare money. Oh dear I'm not doing a very good job of sugar-coating it . That not me , i wont mislead anyone into thinking its easy. So depending on the type of person you are i hope you might work out from this if you are up to the job of repairing, just not this watch just yet.1 point

-

The Spaceman has landed, and I have to say it's even better than I expected. If it's a repro band, it's a very good one. White leather on the back, red velour on the front. Very little wear that I can see. Winds, sets, and runs. It's so delightfully ugly. Looking forward to getting home from work to see what lurks inside!1 point

-

1 point

-

I've found my expertise from grade school of avoiding work by figuring out all the shortcuts is really paying off. I think some of you here are compadres in that regard... Have you seen this?1 point

-

I bought a Mido that was almost 50% off of list price, way less than anywhere else on the net. They had 1 left in stock. After a couple of days the shipping status showed as, "Shipment Received, Package Acceptance Pending". So it looks like USPS has received the package. However, what that status really means is that the shipper is sending multiple packages inside of one large shipment. That way the seller doesn't have to stand around and wait for the clerk to scan 50 packages. Instead, they scan the "manifest", which has the tracking info for all items in that large package. However, the status of, "Shipment Received, Package Acceptance Pending" doesn't actually mean that USPS has physically received the item, they only have the shipping information. Which is where the scam comes in, as it sure looks like the package has been received, since you know, it says "received". USPS explained to me that is a system generated message and that if the manifest had been scanned there would be a scanned message. Which there isn't. Meanwhile the seller has been telling me that he is looking into it and that he initiated a lost package search which could take a few weeks. But that is impossible, as USPS told me, because there is nothing to find, they don't have the package yet. But the seller is counting on you waiting for who knows how long until "looking for the package" excuse falls apart. So I'm guessing the point of the scam is to hold onto your money for as long as possible. There was one feedback where the buyer who was having the same problem as me said that the seller said they would refund them and then never did, and then another who said they got refunded, and then the seller took the money back after having refunded it. Anyway, file it under, "If it's too good to be true, it probably isn't true".0 points

-

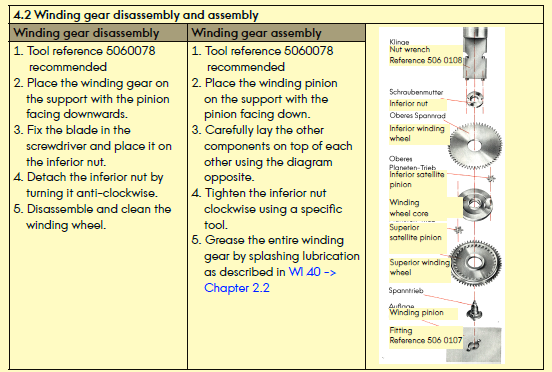

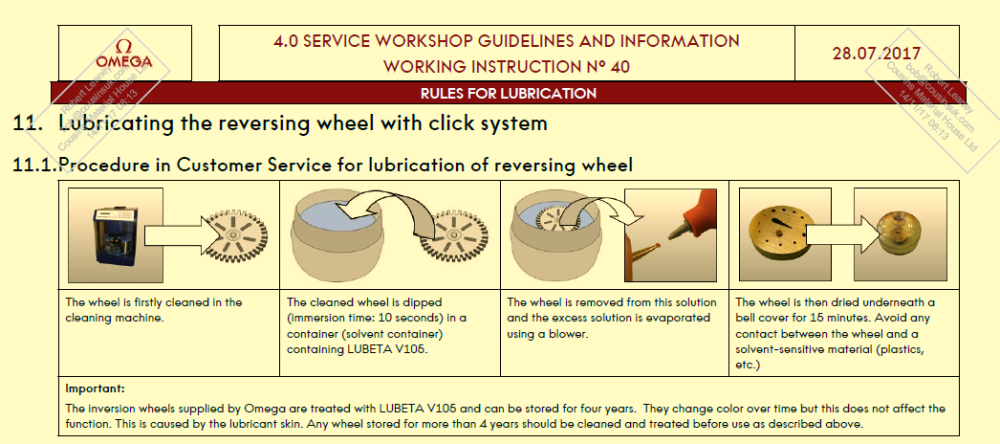

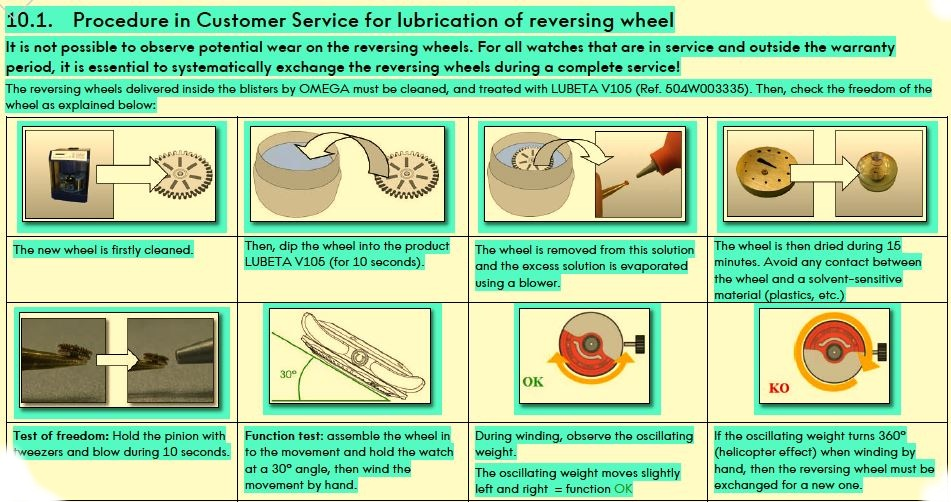

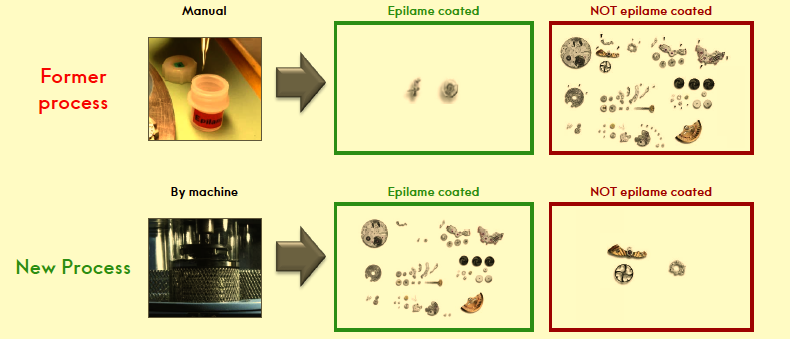

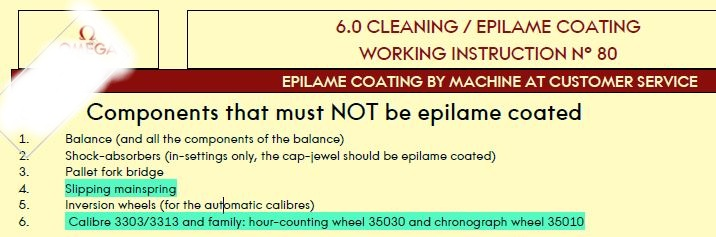

the problem with your answer is it doesn't answer the question. maybe to understand the question better let's look at what needs to be lubricated I assume that this is the part should like to lubricate? Then the reality is you asking a whole bunch of lubrication questions but let's look at this one first. then for this part of Omega has recommendations I have Omega's recommendations notice the first is if you can disassemble. Sometimes you can disassemble with out the specialized tools but most the time there too tight together and it's not coming apart. Which means you don't want to risk breaking it so you leave it together but it ideally should be cleaned and then it needs to be lubricated. So Omega has the second recommendation which means you need to read a specific paragraph in working instruction number 40. this then brings up a problem technical documentation like anything from Omega. You would have to find somebody with a Swatch group account then whoever that person is has to have access at a specific level. So some people may have access to a Swatch group where they can look up things but they will have zero technical access. So you have to find somebody at the very specific level that has the right access. Then whoever download stuff from Swatch group typically the documentation on every single page is watermarked with who downloaded it Swatch group is very paranoid over who sees their documentation. That kind of paranoia makes people nervous who has access. But fortunately at least for a little while some of the documentation was available to the general public like at the link below. so this is a search on cousins website for working instructions then Omega has way more than this now but you do get number 40 which have also gone ahead and attached to this discussion but while you're here on the link you can download everything else. https://www.cousinsuk.com/document/search?SearchString=working once you get number 40 you go to the section where it explains how to lubricate. On the next page it does cover how to mix up the lubricant if you don't have this. then this brings up another problem. the other problem would be lack of technical documentation followed by if you do have access the technical documentation the documentation will change with time. For instance if you had access to a newer working instruction 40 they drop mixing up your own V105 because it can be purchased in small quantities premixed. then they might even revise the entire section like the image below they highlight everything was revised so this is newer than whatever cousins has. this then presents a problem. As far as I can tell Omega's recommending 9010. If you look at working instruction number 40 when it list what 9010 is used for it lists that. then farther into the document they do cover lubrication a ball bearing assemblies but strangely enough they do not include V106? It's conceivable that the documentation is too old perhaps this then brings up a problem. We discussed epilam before basically are going to use it in a place where you like insanely thin oils to stay in place for instance anywhere were use 9010 should have epilam. Anyplace that insane watch companies are using superthin lubricants like on the keyless works where they should be using grease which doesn't run away. then let's look at the epilam problem I'm attaching a document from 1957. Fortunately I scanned it so there's no watermarks on the pages to hide. Sexy a really nice document on cleaning a watch and it does cover epilam. Notice practically the entire watch with a few minor exceptions. Which brings up a problem typically if he asked too many questions people will say fall with the manufacturer recommends. But typically at least until modern times they don't list all the documentation for servicing a watch typically you never see mention of epilam until you get something relatively modern even though they been using it for years. the amusement with vintage by the way is the things that they don't treat like the pallet fork. also that they treat the balance pivots and that's not just Omega as far as I can tell everybody does balance pivots which is not mentioned almost anywhere. now let's move farther into the future. I copied and pasted and italicized. Number one the jewel assembly is epilam at the factory with a special process that we can't do. But they do recommend the cap jewels. Number two is what everybody typically does pallet stones. Which is what you would see if you are looking at page 13. Number three is interesting if you worked at Swatch group they replace the entire barrel assembly. But they do have a working instruction on how to recycle the barrel and for that you see the recommendation below you do not epilam the mainspring. *1 Do not treat the shock-absorber settings with epilam; the cap jewels should however be treated. *2 Steep only the two gathering pallets in epilame (see page 13)! *3 Do not treat the complete barrels with epilam, only the drums, covers and arbours. then brings up a problem modern aggressive cleaning machines. So now they have a new recommendation for gently Omega and/or Swatch group has infinitely deep pockets so they can go through a lot of epilam and purchase it in huge quantities. So with the modern aggressive cleaning machine all that epilam that they been applying through years gets washed off. So the recommendation is the last char the cleaning machine with only a couple of components that come out. then we need another image to see what you're not supposed to epilam Oiling Omega watches 1957.PDF0 points

.thumb.jpg.70e8462d302a61295125b308218d77a3.jpg)

.thumb.jpg.5a7ef50b4bfeee9050c2a710db7b27a4.jpg)

.thumb.jpg.14c51e0b75b7f6bb75e5b6d8399b0805.jpg)

.thumb.jpg.39aa464c1483063f07f0833de8ceff9e.jpg)