Leaderboard

Popular Content

Showing content with the highest reputation on 07/07/23 in all areas

-

Here is my one of a few Mickey Mouse watches. Timex 2471, 35mm case. Except for 1 scratch on the dial very clean. Chrome plating intact. Caseback kind of scratched from others removing. First picture crystal as purchases, second polished and 3rd is new crystal. My understanding is the last digits of the dial number are the caliber and year. So caliber 24 and year 1971? @JerseyMo this one is inspired by your many informative posts on Timexs. Have a telephone dial on the way, we will see if the seller comes through, as I previously bid on the lot and lost but it was relisted.4 points

-

You do the end after the diameter. You want to pick a lantern that rests on the conical part of the pivot, both to avoid scratching and so that enough pivot is exposed so you can work on it. The cylindrical part of a typical wristwatch pivot is perhaps 0.3mm long. The burnisher looks like the photo, and resembles the last image in John's post above. Whether one makes a flat pivot, slightly flat pivot, or rounded pivot, is a matter of discussion (isn't everything in this field?). I recall in school our instructor saying that when the Swiss started supplying replacement staffs for American watches, folks had issues with rebanking. The story is the Americans tended to make flatter pivots, the Swiss, rounder. A flat/flatter pivot reduces the horizontal amplitude somewhat, and can aid in equalizing rates between horizontal and vertical. On the left is a Bergeon normal burnisher, the right the pivot rounding burnisher. It's essentially a flat escapement file with the teeth ground off, with straight grained lines just like the normal burnisher. It's really important to finish off by knocking off the burr formed when rounding the pivot; this does take some practice and a bit of a knack to get it to break off cleanly without scratching the cylindrical part. Basically, you come around with the burnisher until it's almost in contact with the cylindrical part. I do the pivot rounding in the lathe, with microscope, so it's clear when it lets go. Again, John's image actually depicts this, but it probably isn't clear the reason why the burnisher is going all the way to the cylinder like that. Also, I don't use a stone at any point in pivot finishing, it's all from the graver (cutting tool) then burnishers. That's how we were taught in school. You can see the rounding burnisher isn't particularly small width-wise, but it has a very low profile, which allows manipulating it around the pivot in the small space around the lantern.3 points

-

Printed in PLA and I copied the dimensions of the Robur parts etc. Mine printed very well, let me know how you get on, or if there are any improvements needed. I did needed to sand the ID of the adapter to let the bolt pass through, but only took 2 or 3 mins.2 points

-

Everyone here is of a differing age ability, disability, race, creed knowledge and attitude, there is no judgement. We all help each other and have fun, thats what life should all be about. When you are ready to start we have your back, let your questions flow as WW often quotes no question is stupid. Make sure you accompany it with plenty of close detailed photos of the dial, caseback, movement dial side and watchmaker's side as initially you want to identify what you are working on. So measure the movement's diameter accurately and take photos of any makers logos, marks, numbers, letters and serial numbers. Catch you later2 points

-

You are one funny man! But about using the tiny tools, right? I can't even write legibly, and forcing myself to do so has my hand cramp up in under a paragraph, it's awful. Might even be hazardous to my health, which I am trying to preserve! And then, I can't see either! It's almost impossible, but the job gets done. Guilty secret, my tinkering landscape is slightly dotted with the casualties of my never-ceasing curiosity. There's a steep learning curve, and sometimes things go sideways on me. I am trying to keep all that in the microscope area. It came as a great surprise to me, to find that a microscope is a a far more complex and highly-engineered tool than is a Thinkpad laptop. They require such rigorous adherance to protocol and procedure! Guilty confession: I think I am avoiding starting the courses here until I think I am ready, because I don't want to wreck anything, my watches are so nice really...make no sense. I did go buy a couple more today, got the database started, and ..here we go! I will start by the end of this week.2 points

-

Home made hairspring bottle. 1 small bottle of ink emptied, a cut to size and shaped mesh filter from an old cafetiere and a 3/4 rubber plumbing washer. I may swap out the washer and filter for a 3/4 filter washer if there is enough stretch in the mesh to accommodate a balance cock. And 1 litre of Perc. Total cost inc. the Perc 22 quid the bits were all scrap.1 point

-

yes the discussion group has a problem. For instance one of the other unofficial moderators yes a moderator but not always listed as one loved things in boxes. So every time somebody and start a new discussion it end up in existing box of literally hundreds of pages making it basically worthless. Then the entire message board you got reorganized into thousands of little categories. How cam exaggerating a little bit but it's why I typically look for new messages. I used to come and look at the watch repair section only and look for discussions that had low quantities of answers and I would see how I could contribute. But I don't even typically try that any marks is just too many categories oh and don't worry about browser hijacking it occurs all of the time now but if you're looking for answers to specific problems it's best to have a title that reflects your question so other people will see the discussion. So in other words if somebody use the I will go to this category and I don't care about this title they won't respond to your question here because of no idea what were discussing anyway as long as interesting as valuable and you could make some sort of sense out of it were okay. I suspect my answers are too long on multiple occasions and then the details fall through the cracks. I thought I answered that up above? It's sort of covered. In your original documentation actually list and oil but in the later Swatch group document that I attached any go to the particular section they don't list the oil at least they don't think they do but they do say to lubricate. And as our choices are 9010 and HP 1300 I believe I was supposed to have up above I would use the HP oil. My suspicion is a vagal back the schedule for the they do have I think a lighter HP oil may be like 500 is the lightest will they have which from casual memory I think is twice as heavy as the 9020. But you need the oil it with something and HP oil will work fine.1 point

-

Yes, that almost three years have gone and the watch has not been returned for work. That means, if it's being worn, whatever not hyper-specialized oil is in there it's behaving well enough. And if it's not, said oil is slowly drying up like any other (synthetic) one and won't make a difference when somebody will want to use it again.1 point

-

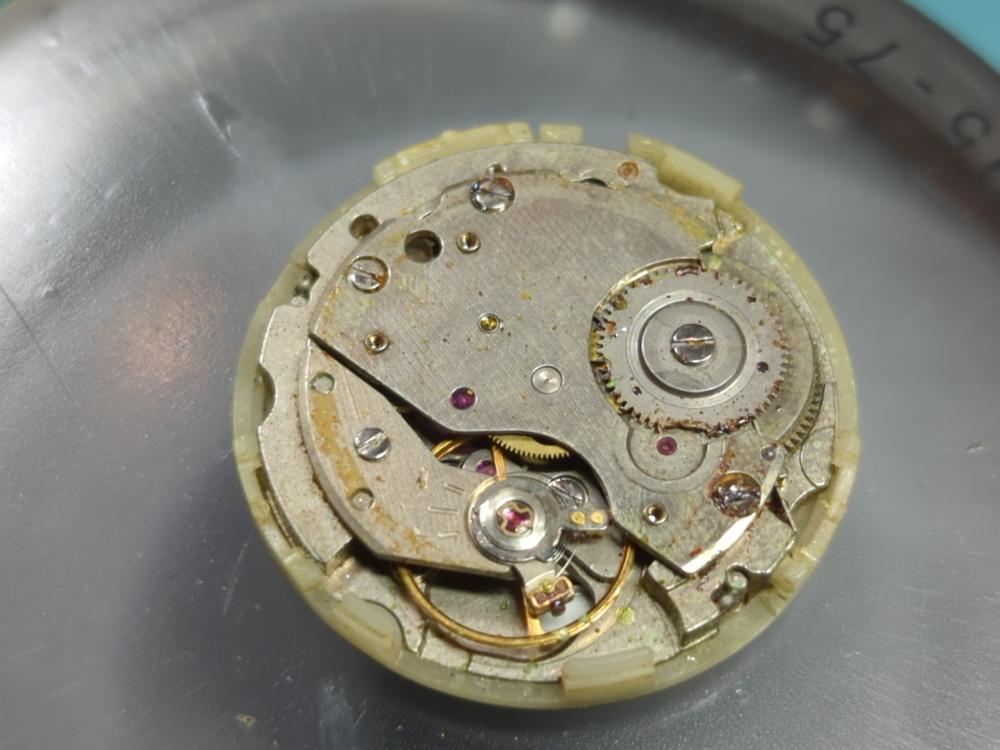

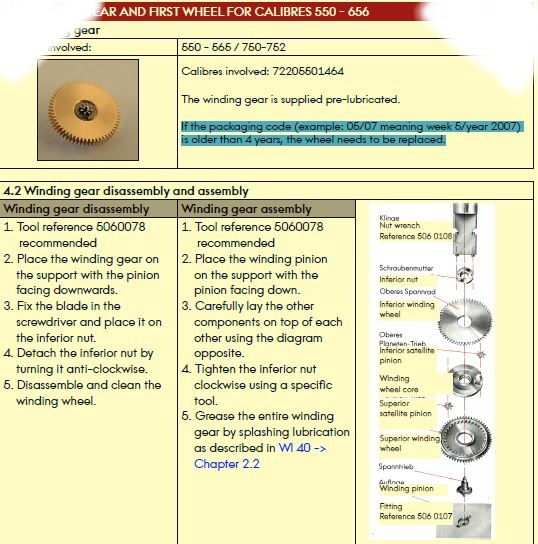

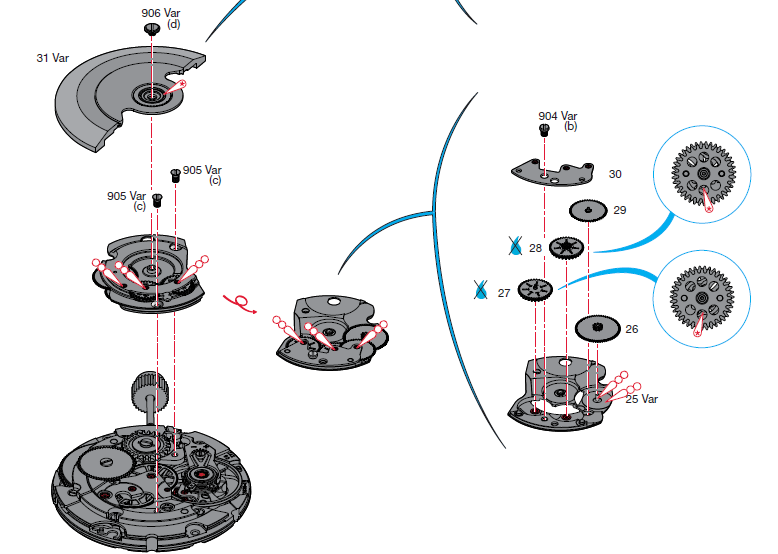

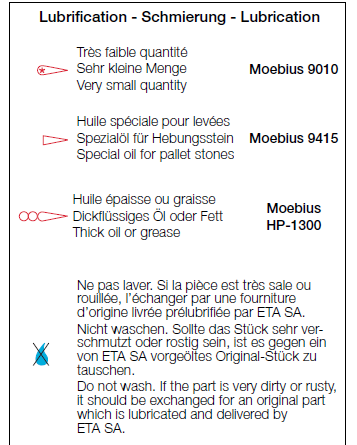

actually nice of you to say that because I was confused with your answer and now I'm confused with some other stuff let's see what we can do to analyze our confusion. okay so this discussion were currently answering question a beginner who's working on a ETA 2789. We get answers and we notice the discussion is from 2020. That looks all well and good except our confusion starts with this as you can see it's a new discussion. Just a reminder for all of you are reading this I regard each watch as an individual watch and this really should have been a new discussion as it's now considered in my mind a discussion hijacking were taking the discussion in a new direction. this unfortunately has consequences of? then I will explain things that slightly different order which the answers were given and/or asked @mikepilk gives his answer he's working on something similar this is what he did and by the way your answer was really confusing to me because oh wait you are answering the question the question of the title the question a discussion so you did outstanding but your answer was confusing of what were currently discussing as we been hijacked. Discussion hijacking starts with this so we find out that now were discussing an Omega a very specific omega not what the title of this discussion says then I get confused with my answer because of other confusions we have lots a confusions in this discussion by the way okay should we go the convenient method or should we do the Of course, not as good as disassembling it, but better than breaking something without the correct tool. just a reminder of a problem technical information what year was your service manual printed? Is it possible unlikely of course prison possible that they revise the information? For instance watch companies have a whole bunch of background information typically you'd never see it for variety of reasons. First we go to various sites and download service males often times you don't actually get the service information because the material house websites have information for hearts with bonus servicing. So a lot of the background information has nothing to do with parts sort of and typically they do not exist plus Omega for reasons outlined above doesn't typically give out their information which leads to all kinds of problems of well like this problem so for instance did you know Omega has a document called General information for Calibre 550, 551, 552, 560, 561, 562, 563,564, 565, 750, 751 and 752 ? Some of the stuff I have above came from that and I deliberately skipped over the section because I thought it worked I disassembled but okay let's go with disassembling a better method as you stated except it's a waste of time. So first off if you purchase the part brand-new it comes prelubricated you don't have to do anything unless of course and there's a revision down there typically things are highlighted a revisions if it's an old one you'll have to get a newer one at a course you buy it off eBay knows when it was made there is that problem. Okay oh and I supposed to keep you happy this document came out in 2019 it's newer than yours. okay as you stated the better method of disassembly they show how to disassemble it they show how to reassemble it and how dear lubrication takes you exactly back to where I gave you before the new method they don't lubricate the way the manual used to say they lubricate with V105 exactly what I showed above. So basically there's no reason to disassemble unless for some reason you want to try to replace a component which you can't because you can't get the individual components anyway. this brings up a problem. If you had access to Swatch group like I once did not anymore then you would find that there's the general instruction which is interesting that it even exists. Because basically a 500 series is vintage and they have almost nothing. They do have a nice shiny colorful parts list but no servicing. My guess is servicing has to go back to Switzerland which is why we don't have a service guide that I have attached the service guide which is basically a reprint of what you have and we know it's modern because it says Swatch group. Then lubrication it doesn't actually say what the lubricate with. So PDF page 11 covers the lubrication 9010 would be to light 9020 would be better but as yet the HP I would use the HP. Probably if we go back the number 40 which are not going to do you find that there's a lighter version of HP that they're using but as you have a choice of incredibly light and much heavier I would go with the HP and just not worry about it. So hopefully all the questions a been answered now. in the future if your watch differs from whatever the discussion is a be best to start a new discussion because one thing people will see that you're discussing this versus the original title and more likely other people might give you an answer may be perhaps I'll I see these things because I always ask for new messages and I'm not looking at titles typically. omega 551.pdf1 point

-

I found a replacement jewel. It is running better now. Still not great. More work to do. FYI, my dad had a little box of "pocket watch jewel assortment." Found my replacement in the little box!1 point

-

You will need a clock mainspring winder. I will be able to help you with this movement. I have repaired loads of them.1 point

-

Can you let me have the freecad files also for the dies? Also for the others out there I have designed 2 adapters. The first lets you use the threaded type dies on a Robur (you will need a standard M6 14mm bolt) and the second let's you use Robur dies on the threaded type presses, link to thingiverse Here1 point

-

I own the Robur and is is very good but be aware the dies are made of hard plastic and off not careful they chip. I don’t remember where I purchased them but but also I have some Aluminium dies that fit as well I have also a cheap Chinese Crystal fitting pres s that has plastic dies which is rubbish1 point

-

Ooooohohoho. Venison! I have not cooked with venison in so long. I have also not been hunting in a while either. But my day job has been slow and my budget has been tight lately; I think it is a good excuse to join up with a couple of my friends and go hunting again soon. I don't yet know any hunting buddies with a watch who would trade service for game meat. So I will need to go and kill my own.1 point

-

I have a couple Helbros and a couple Benrus, all of which have ordinary removeable backs. I'm afraid I know of no standard. Sometimes, a watch manufacturer will make models that are front loaders. And of those models, sometimes they will have a front bezel which must also be removed, and sometimes not. Over time, you learn what to look for. And EVEN STILL (as was the case above) you can still be wrong. Some watches just make it hard for us at times. When it comes to opening watch cases, the best advice I ever received was "Proceed with caution".1 point

-

you should really go to the Seiko Japanese site Lookup servicing information and don't take you to the nearest service center. Unfortunately they know where I live and keep sending me to the US service center which isn't helpful https://www.seikoserviceusa.com/ but either always reach out to them and asked them if they had service it. Unfortunately it's a complicated watch and nothing lasts forever so it would need to be serviced eventually. Note regarding complicated I found the service manual for it would not recommend anybody doing it it requires special tools but just in case you're curious as to what's inside your watch there is the service manual seiko 4f56a.pdf1 point

-

I am so glad you mentioned that because one of my beginner burning questions is about that. I should look at my watches to find out which, but it is either Helbros or Benrus that has this as a standard, and I never know what to do with these. It says right on the back "Open through front/crystal", something like that. They might deal with that in the courses here (which I signed up for and anticipate starting this week) but in the meanwhile i am super curious about this. I notice you advised the OP to send pics, which I can do if needed, but if there is a standard way for the brands I mentioned, I'd like to know. Thank you.1 point

-

That sounds like it will correct itself by the next hour. By the time the minute hand reaches the 6 it will chime the 3/4 and then remain silent until it arrives back at the 12. This is perfectly normal for a stopped clock. Don't panic!1 point

-

are you trying to get a really nice round surface to reduce friction? Because you're not supposed to have round balance pivots there supposed to be slightly flat.1 point

-

1 point

-

Are you perhaps hinting that we've somewhat strayed from the topic of "A design for a belt-driven Jacot Tool ...... ?"?1 point

-

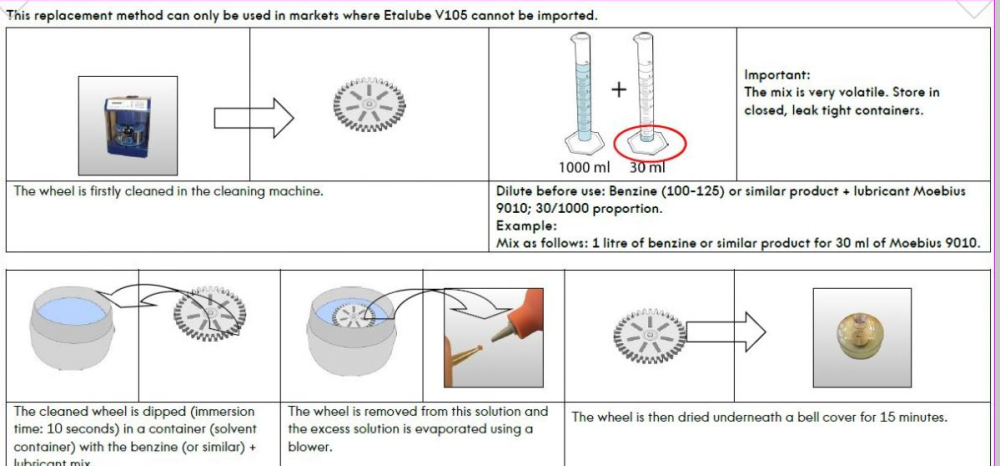

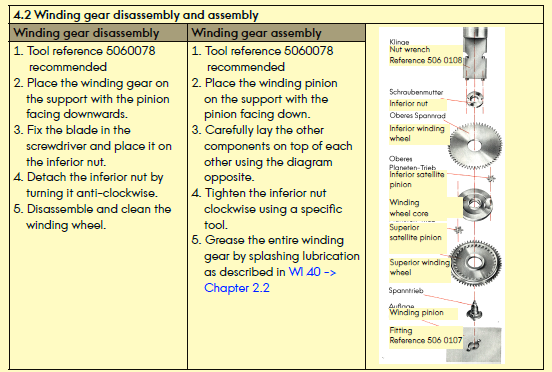

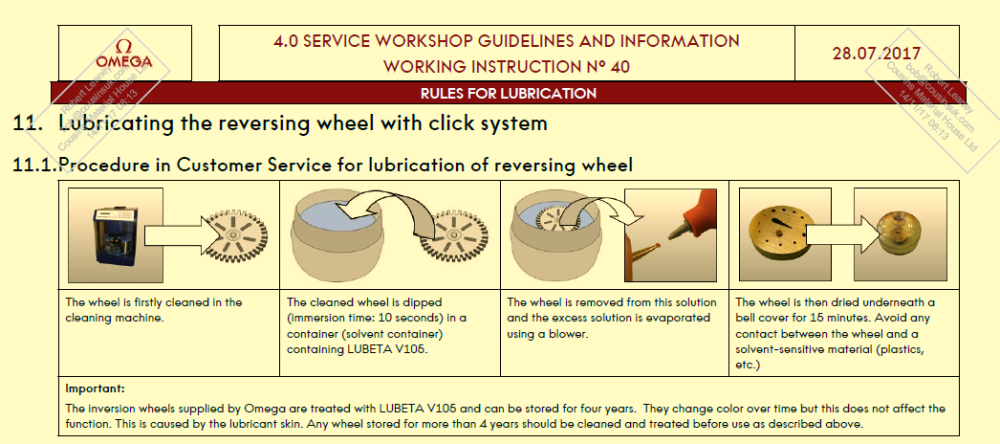

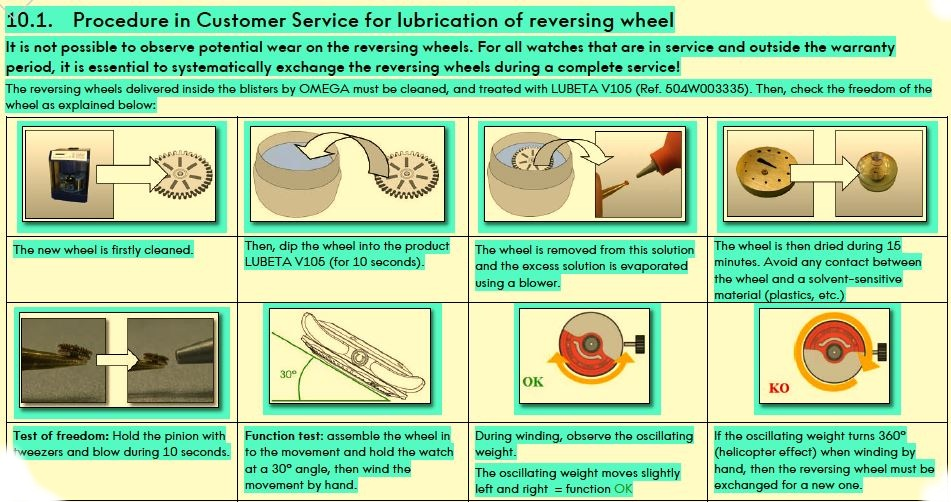

I have just finished an ETA 2783 (same movement) Here is what ETA recommend for the 2836, which has the same type of automatic mechanism. (I've attached the Tech Sheet for the 2836 which shows lubrication - you can use it as a guide for your movement). I put the reverser wheels through the cleaner (despite is saying not to clean them), then lube with a mix of naphtha/9010 (100:3) as shown below. DO NOT over oil the reverser wheels - it makes winding hard. When they wear it also makes winding more difficult, and they are not easy parts to find these days. ETA_2836-2.Asembly and Lube.pdf1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

Welcome Leo. You will want to identify the movement inside before you start looking for posts and technical sheets. Case numbers or remove the back to see what you have.1 point

-

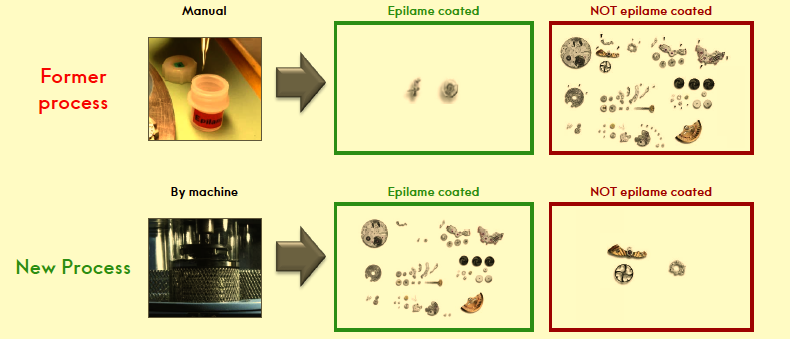

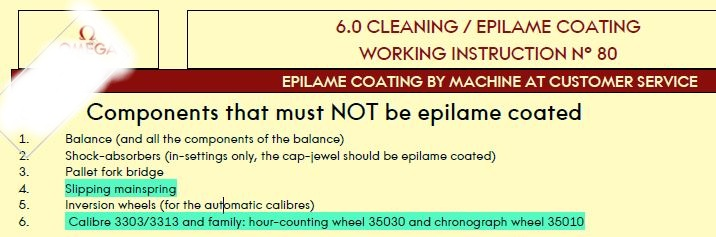

the problem with your answer is it doesn't answer the question. maybe to understand the question better let's look at what needs to be lubricated I assume that this is the part should like to lubricate? Then the reality is you asking a whole bunch of lubrication questions but let's look at this one first. then for this part of Omega has recommendations I have Omega's recommendations notice the first is if you can disassemble. Sometimes you can disassemble with out the specialized tools but most the time there too tight together and it's not coming apart. Which means you don't want to risk breaking it so you leave it together but it ideally should be cleaned and then it needs to be lubricated. So Omega has the second recommendation which means you need to read a specific paragraph in working instruction number 40. this then brings up a problem technical documentation like anything from Omega. You would have to find somebody with a Swatch group account then whoever that person is has to have access at a specific level. So some people may have access to a Swatch group where they can look up things but they will have zero technical access. So you have to find somebody at the very specific level that has the right access. Then whoever download stuff from Swatch group typically the documentation on every single page is watermarked with who downloaded it Swatch group is very paranoid over who sees their documentation. That kind of paranoia makes people nervous who has access. But fortunately at least for a little while some of the documentation was available to the general public like at the link below. so this is a search on cousins website for working instructions then Omega has way more than this now but you do get number 40 which have also gone ahead and attached to this discussion but while you're here on the link you can download everything else. https://www.cousinsuk.com/document/search?SearchString=working once you get number 40 you go to the section where it explains how to lubricate. On the next page it does cover how to mix up the lubricant if you don't have this. then this brings up another problem. the other problem would be lack of technical documentation followed by if you do have access the technical documentation the documentation will change with time. For instance if you had access to a newer working instruction 40 they drop mixing up your own V105 because it can be purchased in small quantities premixed. then they might even revise the entire section like the image below they highlight everything was revised so this is newer than whatever cousins has. this then presents a problem. As far as I can tell Omega's recommending 9010. If you look at working instruction number 40 when it list what 9010 is used for it lists that. then farther into the document they do cover lubrication a ball bearing assemblies but strangely enough they do not include V106? It's conceivable that the documentation is too old perhaps this then brings up a problem. We discussed epilam before basically are going to use it in a place where you like insanely thin oils to stay in place for instance anywhere were use 9010 should have epilam. Anyplace that insane watch companies are using superthin lubricants like on the keyless works where they should be using grease which doesn't run away. then let's look at the epilam problem I'm attaching a document from 1957. Fortunately I scanned it so there's no watermarks on the pages to hide. Sexy a really nice document on cleaning a watch and it does cover epilam. Notice practically the entire watch with a few minor exceptions. Which brings up a problem typically if he asked too many questions people will say fall with the manufacturer recommends. But typically at least until modern times they don't list all the documentation for servicing a watch typically you never see mention of epilam until you get something relatively modern even though they been using it for years. the amusement with vintage by the way is the things that they don't treat like the pallet fork. also that they treat the balance pivots and that's not just Omega as far as I can tell everybody does balance pivots which is not mentioned almost anywhere. now let's move farther into the future. I copied and pasted and italicized. Number one the jewel assembly is epilam at the factory with a special process that we can't do. But they do recommend the cap jewels. Number two is what everybody typically does pallet stones. Which is what you would see if you are looking at page 13. Number three is interesting if you worked at Swatch group they replace the entire barrel assembly. But they do have a working instruction on how to recycle the barrel and for that you see the recommendation below you do not epilam the mainspring. *1 Do not treat the shock-absorber settings with epilam; the cap jewels should however be treated. *2 Steep only the two gathering pallets in epilame (see page 13)! *3 Do not treat the complete barrels with epilam, only the drums, covers and arbours. then brings up a problem modern aggressive cleaning machines. So now they have a new recommendation for gently Omega and/or Swatch group has infinitely deep pockets so they can go through a lot of epilam and purchase it in huge quantities. So with the modern aggressive cleaning machine all that epilam that they been applying through years gets washed off. So the recommendation is the last char the cleaning machine with only a couple of components that come out. then we need another image to see what you're not supposed to epilam Oiling Omega watches 1957.PDF1 point

-

Amazing. I'm about to service one of these beauties as well and your post is very helpful. Thank you for taking the time to write it all down. PS: @jdm, you mentioned some doubts about using HP1300 on the automatic works pivots. I'd do the same. Or any new thoughts on this by you or anyone? Cheers1 point

-

Use the Jules Borel search. Seiko didn't use that many different sizes in gaskets. This stem gasket was used in very many models and they are available cheap http://cgi.julesborel.com/cgi-bin/matcgi2?ref=hvZE]DeEU1 point

-

If I'm wrong, I will happily swallow my pride and say no more...but I would bet all the money in my pocket that this watch is a front-loader. The case back is so much smaller than most, such that trying to remove the movement through there would seem too unusual. And the way there's a bump over the stem entrance; I see that a lot with front-loaders. I know it has steel mated to gold, but I have a front-loader that is like that myself. It fools you. If it is a front-loader, you will need a crystal lift to remove the crystal, or if there is a tension bezel on top, that will need to come off. It is likely to have a two-piece stem, so you will need to *gently* pull out/off the crown end of the stem - it will snap free. The movement *should* lift right out. (Unless it is one of certain models of Omega, in which case you will need to unlock it.) I can better advise you if you could post pictures of the front, and crown-side edge, and opposite side edge, so I can see the make, model, style, and whatever else there is to go on. I still could be wrong, but I feel we are looking at a front-loader.1 point

-

One of my buddies paid for his watch repairs with another watch. I decided to go for it. I cleaned his Bulova and Benrus, and he gave me a vintage 21-jewel Timex. It was in good shape, and he was a friend so I did the deal. I've also accepted Pizza, tailoring, and a shoebox full of watch parts and tools. I'm flexible.1 point

-

Wow! That's an amazing setup. It reminds me that the longer and more arduous the journey, the greater the appreciation of the destination. So in that regard, the devilish city played a role. Congratulations.1 point

-

Be thankful they don't have cucumbers or you're likely to wake up to bags full of cucumbers on your doorstep! Good looking shop!1 point

-

I was wondering just the other day why you'd not been around much lately. Good to see you are well and have been so busy. Thanks for giving us a taste of your project, which is impressive and inspiring. I wish you every success!1 point

-

Welcome back Jdm, Looks its a quiet environment, I bet theres plenty of fresh air. Where is the vegetable garden? Garden is the first place I ask to see when visiting friends home, love organic gardening.1 point

-

Good day everyone, I just completed a watch for my wife's uncle as a gift, its a Seiko 6309 which was in pretty poor condition and a non runner for obvious reasons. I had to replace the crystal and the ratchet wheel which was completely corroded (see pictures below) I also had to replace a screw and the cannon pinion. A quick lume on the hands and polish the case and it was good to go. Let me know what you think: Before Front: Before Movement: Corrosion damage to ratchet wheel and screw(s) Here is the finished watch along with the time graph after 24 hours:1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)