Leaderboard

Popular Content

Showing content with the highest reputation on 07/08/23 in all areas

-

Hi LWS, I had recently updated about my activities in the not-watches section. I surely want to go back to more watch repair, occasinally posting what is my direct experience and reasoning, in the hope of helping others avoiding some mistakes I did,3 points

-

If it was okay before, I always go by; "what has changed" ?2 points

-

It's a fun rabbit hole to explore - many options have popped up over the years. One thing I find interesting is the different ways toolmakers provided us with a means to load up a crystal for installation – it's important to get just the right depth of grip. The two terraced rings that are part of the Electro-Vice set (see below) tend to work better for me than the sliding tray shown above, but it isn't obvious that they go along with the crystal lift tool so you often see them being sold alone in watchmaker tool lots.2 points

-

There's not a lot of timepieces about on ebay. This Smiths Enfield is just fine it is quite easy, lots of spares and lots of help will be given. I can go step by step with Waggy with this.2 points

-

1 point

-

1 point

-

Does pivot not fit in the jewel hole on mainplate either? I now suspect the jewel on cock, might be a wrong one. All ETA 1080 balance pivots fit and run in your watch, that is a 11.5"' fits 10.5"' and you wouldn't know the difference, mostly would not even affect the amplitide if you were to test it on timing machines. Yes , can be seen even in the picture, so I guess the jewel hole is too small a round. This all points to small jewel diameter on cock side. Rgds1 point

-

If it's clean and you have endshake, it could be balanced enough that it needs a nudge to move, like tapping the movement holder on the bench. If it really is free, then the smallest puff from a blower should move it.1 point

-

That is good to know. Now don't forget to wind it up.1 point

-

1 point

-

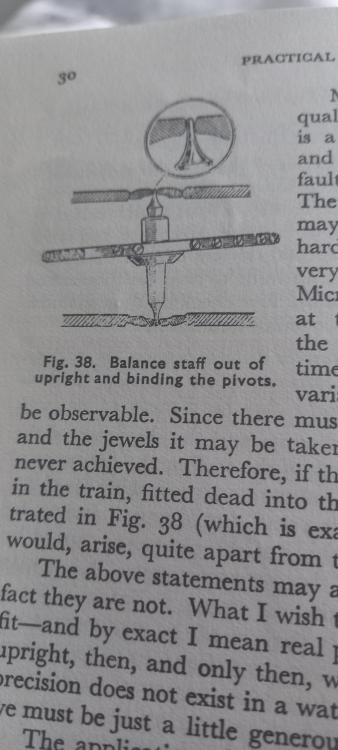

Eyup Watchie, I guess it can be either or both of two things, the weight of the pallet fork doesn't shift over until its reached a particular inclined angle ie. more than you are anticipating. Or friction, in one or many places. Even though you have endshake could a pivot still be resting on a jewel as you tilt until it releases from the jewel ? Or could it be a binding of the two pivots across their jewels while at an angle, one reason that olive shaped jewels are used in quality watches as opposed to straight sided jewels. I think there is an illustration in one of de carle's books, i will try find it and pop back with a picture. De Carle practical watch repair page 30. That might just create enough friction. I suppose there is no set ruling as to when the lever tips over with gravity as long as it does move.1 point

-

If evenly ballanced, the fork should stay still if the plate is rotated.1 point

-

1 point

-

Hi the Enfield will do ok it employs both the basic going train and striking train. If you are following the course work on the going train first untill you understand it then the strike it will give you the basics of both.1 point

-

The basket shipped from China. Looks like that seller is on the UK eBay site.1 point

-

Very handy for the size , the one i made up is a little tight to fit a balance complete in. I haven't come across a seller like that in the uk but now i know what to search, cheers me dears .1 point

-

This is a common problem with gold plated base metal bezel, more discouraging is the news that stainless cases were probably never made for this dial to fit in, but this movement with different dial plate has been put in many stainless steel cases, so best is if you can find a case and dial for this caliber. Lots of search, patiance and luck. Rgds1 point

-

Lack of end-shake is more likely to be the issue, loosen the bridge screw to create some end shake. Side-shake isn't easily noticable and is an unlikely cause, no matter which 1080 balance you bought, it will run. According to master Nickelsilver micrometer can damage balance pivots the way shown in previous pics. Good luck pal.1 point

-

1 point

-

I use a small jam jar and found a seller on eBay that sells stainless baskets of various sizes. He had one that fits the jar pretty well.1 point

-

This ATP is an add-on to another lot at a country auction I won a couple weeks ago. I think it’s the Fontainemelon version but please correct me if I’m wrong. I had no pictures of the movement so it could be a Chinese quartz in need of a battery…dunno… …the other lot had two watches and a batch of ‘costume jewelry’ but there’s a suspicion from women in my life what know pearls there’s two strands of legit. I keep telling them I’m not that lucky…1 point

-

It might be useful to point out to those not familiar with these tools that in the post above showing the Robur and the 5500 clone, it's a bit of apples vs oranges when it comes to the included dies. The Robur has smooth radius-rounded concave and convex dies that are meant to sandwich and flex the crystal from both sides while you slide the open case or free bezel up and over the crystal. This is a precise but low-pressure operation. The other types of dies that are flat or have beveled sides are meant to forcibly bear down on the plain crystal, armored crystal, bezel, case or whatever else you are trying to press fit together, which is when you will still want good control and good alignment but you may need it to function with much more pressure. The same press can be made to work for both functions, but it might take adapters as mentioned above or other modifications to get both types of dies to fit if you want to do it all with one tool. You should be careful to understand what you are buying. But then again, as a tool addict, I would ask "Why not just search for a good buy on both?" ;-)1 point

-

Welcome. I would second Ross’s advice regarding learning on your own watch. You can obtain a scrap 2906 movement from SpeedTimerKollektion for 7 Euros. Great for practice and a source of parts. The learning curve in watch repair is steep. It takes time to develop skills, acquire tools etc. You will break/lose things so a few scrap movements are ideal for learning on. btw, here is the 2906 tech guide 14 2906A.pdf1 point

-

A file, even a 10 cut, is far too coarse. It doesn't have to be polished, but all the teeth must be ground off and the lined surface made. A coarse India stone is about right, or a coarse (about 280 grit, 45 micron) diamond hone. It takes a while to get the teeth off, so still best to start with the finest file you can find.1 point

-

You do the end after the diameter. You want to pick a lantern that rests on the conical part of the pivot, both to avoid scratching and so that enough pivot is exposed so you can work on it. The cylindrical part of a typical wristwatch pivot is perhaps 0.3mm long. The burnisher looks like the photo, and resembles the last image in John's post above. Whether one makes a flat pivot, slightly flat pivot, or rounded pivot, is a matter of discussion (isn't everything in this field?). I recall in school our instructor saying that when the Swiss started supplying replacement staffs for American watches, folks had issues with rebanking. The story is the Americans tended to make flatter pivots, the Swiss, rounder. A flat/flatter pivot reduces the horizontal amplitude somewhat, and can aid in equalizing rates between horizontal and vertical. On the left is a Bergeon normal burnisher, the right the pivot rounding burnisher. It's essentially a flat escapement file with the teeth ground off, with straight grained lines just like the normal burnisher. It's really important to finish off by knocking off the burr formed when rounding the pivot; this does take some practice and a bit of a knack to get it to break off cleanly without scratching the cylindrical part. Basically, you come around with the burnisher until it's almost in contact with the cylindrical part. I do the pivot rounding in the lathe, with microscope, so it's clear when it lets go. Again, John's image actually depicts this, but it probably isn't clear the reason why the burnisher is going all the way to the cylinder like that. Also, I don't use a stone at any point in pivot finishing, it's all from the graver (cutting tool) then burnishers. That's how we were taught in school. You can see the rounding burnisher isn't particularly small width-wise, but it has a very low profile, which allows manipulating it around the pivot in the small space around the lantern.1 point

-

Here is my one of a few Mickey Mouse watches. Timex 2471, 35mm case. Except for 1 scratch on the dial very clean. Chrome plating intact. Caseback kind of scratched from others removing. First picture crystal as purchases, second polished and 3rd is new crystal. My understanding is the last digits of the dial number are the caliber and year. So caliber 24 and year 1971? @JerseyMo this one is inspired by your many informative posts on Timexs. Have a telephone dial on the way, we will see if the seller comes through, as I previously bid on the lot and lost but it was relisted.1 point

-

In 2020 a small property went for sale in my small town. It was nothing more than an agricultural warehouse without even a firm floor, made of piled up blocks and with an uncertain roof. But the price was right, and during that time having a project or a reason to leave home was an attractive perspective, so I bought it. The ugliness was demolished, foundation and construction quickly started. By Christmas '21 most work was completed, minus doors and windows, the exterior, electrical, plumbing and what not. I took my time to refine it the way I wanted, and last summer I was using it already for what you see, an hobbyist machinist and general repair and 'making' work. The building is actually designed and intended to be a small home, by regulations is resistant to earthquakes and highly energy efficient. I plan to add solar panels and an accumulator as soon is convenient. Heating/cooling will be with a split Inverter A/C, with floor units in each room. I haven't installed yet because in our climate and the efficient insulation one does well even without it. I've arranged the unit for the purpose of doing stuff for my own interest and business, as well to service the local trade which may need turning, milling, sharpening, and the like. There is virtually nobody else doing that for quite a distance around. Above is the garage room, the leftmost in the first picture. Everything is on castors, so beside re-arranging as I want, I can also store a medium car in there. Currently I'm about to restart a vintage universal milling machine (the dark grey one), which has suffered a road 'accident'. Also a largish vintage lathe is supposed to be coming and be restored to working order. The other room with the entrance door is predisposed to be a kitchen and living room. This space is better suited for light mechanical or electrical work, studying and designing. In the middle on the left is an half bath with mezzanine storage above it, and on the back is a large bedroom and a spacious full bath. These are still unfurnished, so no pictures. After much fighting, I managed to get basic ADSL Internet, so I can also watch Youtube videos, buy more stuff, or conducing other online business. Still there are so many details that I want to add or improve, but all in all I feel well rewarded for the time and money spent. Time goes fast and for as much work one does, there is always more. I have few machining projects lined up, and hope to get more also. Because of all that I had to place watchmaking on the back burner for now, but have no intention of quitting it. I want to thank the forum friends that had asked about me, and send friendly regards to everyone.1 point

-

Maybe an added shot of ammonia solution will give you the missed gloss.1 point

-

Be thankful they don't have cucumbers or you're likely to wake up to bags full of cucumbers on your doorstep! Good looking shop!1 point

-

To me that shows how honest he is and not afraid showing the reality of the job/hobby. We all screw up, some more than others1 point

-

When I started, I thought Moebius oils were way too expensive and I still do think so. Having worked in and a lot with Germans, I know their work ethics; "Deutsche Gründlichkeit" and started looking into German watch-oils. Germany used to have an excellent, high standard Swiss compatible watch-industry until in 1945 (Februari 23rd) when Pfrozheim, in one of the largest (retaliation?) carpet-bombardment of WW2, was wiped out. Despite this, you can find very high quality stuff in Germany, also in watch-oils and this without paying the Swiss cartel prices. I've been using the German Dr.Tillwich synthetic watch oils ever since I started. Bought only once the highly touted Moebius "thixotropic" 9415 grease, but that turned out to be a poor performer compared to my Dr.Tillwich pallet-jewels oil. Of course, if you are working as a professional, you have to stick to the "industry standard"-oils, even if it was just to cover your *ss.1 point