Leaderboard

Popular Content

Showing content with the highest reputation on 07/09/23 in all areas

-

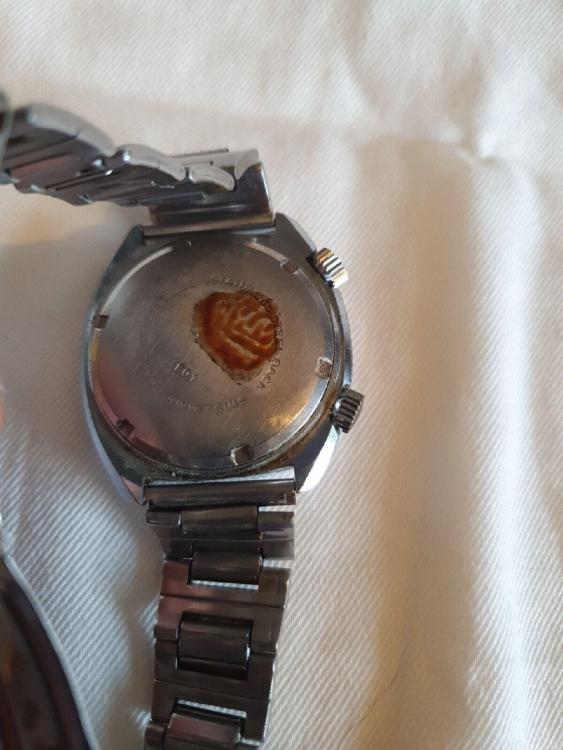

I have this Tissot Antimagnetique Stainless Steel watch winging its way to the UAE. I tried a few Tissots when I was first starting out with poor results, so I am hoping to banish that daemon and end up with a good working Tissot..... I also have a job lot on the way and each of them will all qualify for the 404 club, so should keep me out of mischief for a while.3 points

-

Jewels are definitely an issue. I recently made some parts for a customer, for which I need almost the same jewel as Murks, 0.22/1.30. I think one of the material houses had it, but I need 30 of them, and at 15 bucks a pop, that comes to 450. I can go to a jewel maker and have 100 made for 550, so that's what we're going to do. And these are much better quality than most Seitz jewels I've seen, especially older ones. Which got me thinking, if someone had some cash to invest, you could replicate about all the Seitz references for around 250,000 bucks, with the exception of pallet jewels (still looking for a maker of those). Actually not that much of an investment in a new business. I mean, a decent 3 axis CNC milling machine is in that ballpark, and you'd have to run it at least 8 hours a day plus all the side costs (10k for a compressor, 20k for software with 5-6k yearly upkeep, tooling, expendables etc.) and of course have the work and the skill and so forth. You could store the whole jewel assortment in a cabinet not bigger than a 3 deck file cabinet, run the business from home, set up a good easy to use site, hit the post office once a day... I bet if you were the source for jewels (and they are very high quality), it would take off. Every watchmaker in the world would be coming to you. If only I had a quarter mil on hand...3 points

-

Hi LWS. You don’t need a bushing tool. ( 1,250,00 £) worth they ca. e done by hand, I cut/ drill them out on a press and Broach to size then use the bench drill to press them in. Always try the bushed wheel with its adjacent wheel in the plate alone to check the depthing. The big cam top right is the snail cam never worked on Jauch clock, a bit of an odd front plate setup. From what I can gather Jauch are now obsolete and are replaced by Hermle movements I think yours is a JAUCH772 points

-

2 points

-

2 points

-

2 points

-

The 404 club recruiter has chased so many Ronda 1223-21 17 Jewel Memocalls, always without success, that I finally admitted defeat and stumped up a little more than the rules allowed (but not much more), for this "slightly chipped" version. There are quite a few variants of this watch, including some rather nice blue dialled ones, which I'm still keen to pick up. Other than the damaged crystal, it looks complete, and in reasonably good (if somewhat grubby) condition. These were not particularly high end, or complex watches, back in the day, but the quirky alarm movement scratches an itch for me. Next problem will be sourcing a crystal for it. I'll keep you posted on progress when it arrives.2 points

-

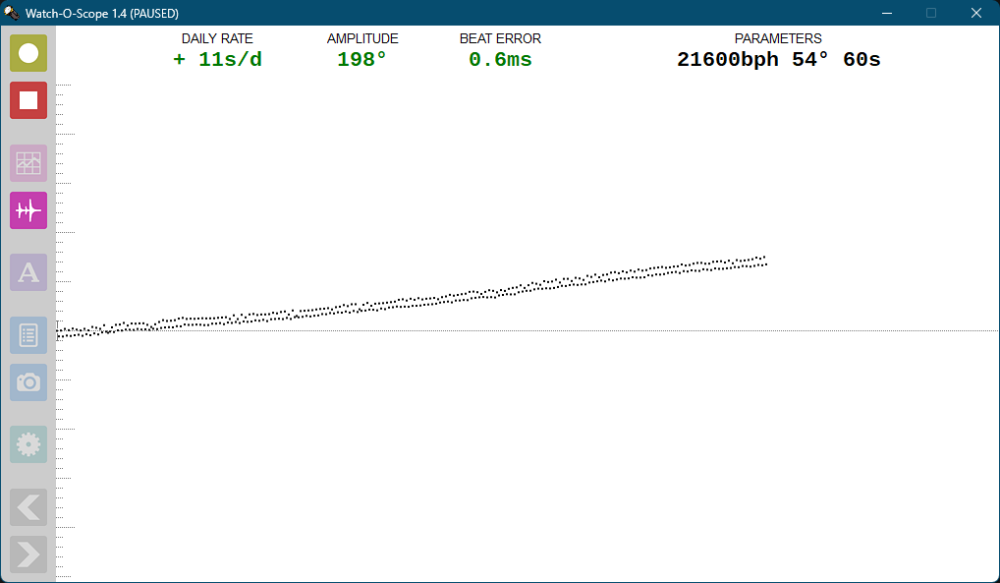

While I'm waiting for the seller, I decided to put it back together with the cracked jewel to see where I'm at, and get practice assembling the chronograph. Timegrapher looks solid other than the low-ish amplitude. I have a feeling it's at least partly because I realized after I got the lower balance jewel in that what I thought was 9010 in my oil cup was actually HP1300/9104 I may also replace the mainspring, because why not? So when I get the new jewels I'll take the whole thing apart and re-clean and lubricate. BUT it works, as does the chronograph. So that's pretty exciting I've been trying to find o-rings for the pushers and stem. Any suggestions on where to find those?2 points

-

The two nut on the pendulum might be because the first ones thread might be worn so the second was added. I prefer not to remove the cannon pinion unless you have wear.1 point

-

Looks like the Canon pinion could slip while the chime cam still maintains accurate. I have never seen two nuts on a pendulum. Looks like a hack to me. But, I am an amateur with limited experience.1 point

-

Hi the canon pinion/ star cam are pressed on to the center wheel which is a tapered shaft. The star cam has either. 2. Projections, for the half hour/ hour strike. Or. 4 for one for each quarter the longer on in each case is for the hour and lifts the long lever higher than the quarters to release the strike from warning state to strike. There are different opinions regarding removing it some say if it is not worn or needs bushing Lea it alone others say remove it but in the latter case I made a tools to take it off a nd put it back, but care needs to be taken not to bend/warp the shaft. regarding the pendulum most have just the one nut for regulation but there is no reason not to use a second as a lock nut depends on how slack the first is on the shaft.1 point

-

the problem is this is the second page of the discussion with bonus things to distract. You need to go back to the first page then you'll say oh that watch. Then you scroll down and you get the name on the dial in the numbers make a lot of sense. You just need to refresh your memory like I did. then it probably is 14 karat gold because I've seen a case like this before.. You'll notice the back with its various colored gold's it probably is solid but ideally we should have the picture because as others have pointed out there may be clarification words associated with that number. there might be words like 20 years case which tells you it's really a rolled gold plated case but they don't say that because it looks more impressive to say 14 K but really do need a picture just to clarify.. tthen from the picture on the other page I know that that's a serial number we can go to the pocketwatch database we know who made the watch and there it is. https://pocketwatchdatabase.com/search/result/waltham/835687 then yes I went looked at the list of movement sizes and obviously the diameter does include the case otherwise that would be a really big movement. then the problem pocket watch database is the source of the information was not meant to be doing what were doing now.. The watch companies had listings for parts availability. Often times like for instance Elgin a whole bunch of separate watches get lumped together as one category for parts while are actually a whole bunch of separate watches. Then we have Waltham which tended to have for parts and other things lots and lots and lots of variations. So basically we get close but we may not get a exact match because that's not what the database numbers are based upon1 point

-

Time appeared to move 5 times more slowly in 1st billion years after Big Bang, quasar 'clocks' reveal -space.com More fuel for that particular fire published in the last few days.1 point

-

How fast is crazy? If it runs a minute in a few seconds then as said its the fork fluttering, check the fork, escape pivot and relevent side/ end shakes. A vid of the fork when its crazy helps. Shaking the watch on bench is like wearing it. Welcome to the forum pal.1 point

-

Looks like that idea has happening for a hundred years or so. Swiss banking initiated mergers like Omega and Tissot to become SSIH. Then ASUAG and then the Swatch group , gradually taking over and aquiring all dormant companies from the quartz crisis period. I often wonder if this monopoly is some kind of payback for that time or an assurance that nothing like that can happen in the future. If you control everything then can anything control you ? Initial prices tend to be high until the investment is paid for then drop, sometimes quite dramatically. Like medication, example costs of pennies for Ibuprofen and paracetamol when the investment of research is paid off. The demand might be a hard one to figure but there must still be literally tens or even hundreds of thousands of us coming and going from the hobby.1 point

-

I'm surprised that it hasn't been done already, its a very small investment. Anyone that knows the industry well would jump on it.1 point

-

I've been thinking about this problem ever since I noticed the diminishing inventory of Seitz jewels from various supply houses. Does this mean that once the existing stocks are depleted, new jewels will never be available? I have been buying assorted jewels from India, which I suspect are harvested from dead movements. I've also bought a box full of scrap ladies watches which I scrounge for things like screws and possibly jewels in future. I rarely find a jewel that fits the jewel that I'm looking for and end up modifying things. So far, I've fitted bigger jewels by resizing the hole, as John suggests. I've ground down larger cap jewels to fit Incabloc settings. Possibly in future I may have to rebush a hole to fill smaller jewels scavenged from the ladies watches. I pray that this trend does not signal the end of the vintage watch industry.1 point

-

1 point

-

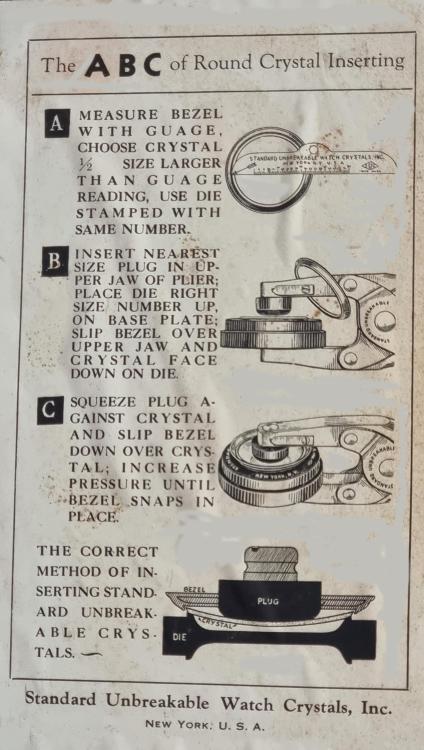

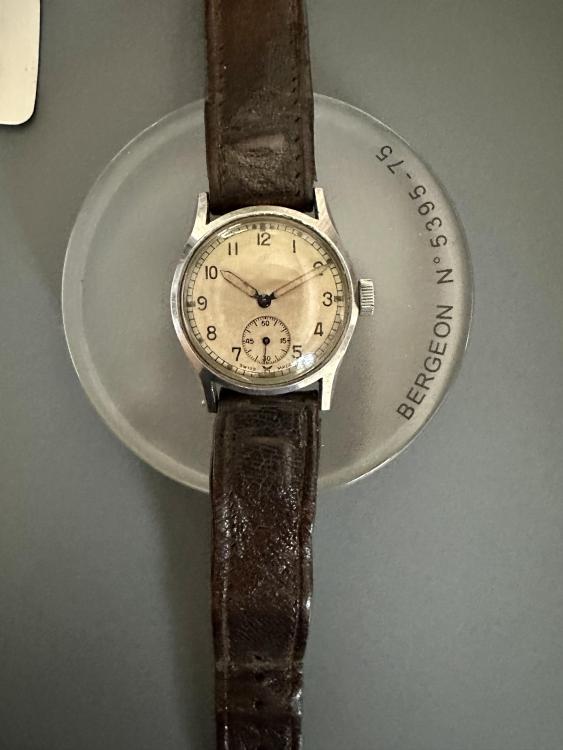

I was talking about this topic today in another thread and said I would post pics of a kit I have. I hope this is the right place. I should mention I cannot give any advice because I am new and have never replaced a crystal this before, not successfully anyway. I am a seasoned collecter but a baby at repair. The kit I have (but haven't yet used) is vintage and I hear it does an OK job. It was put out by the Standard Unbreakable Cyrstal Company, aka SUC. It came with round crystals in most sizes, measured in LC units and mm, for pocket and wrist watches. I was concerned that the crystals had yellowed, but it is not as bad as I'd first thought. I did a photo comparing brand to brand, and opened vs. never opened, but the differences are minor. Time will tell how I do with it - I am starting the courses here tomorrow.1 point

-

Ah, that I've never tried. Amazingly useful tip as always! That seems like a very good rule of thumb. However, in this case, the movement has never run well. Not before service and not after.1 point

-

Welp, right on cue for once...my nephew tried to give me pointers on lighting for macro...apparently it didn't take. Anyways, here you go...sure looks like FHF 150. There's no winding but I can set the hands and the balance wheel is free and jiggly if a bit too ambitious based on the regulator position. Civilian service last left chicken scratch in maybe '55 and '60...1 point

-

If evenly ballanced, the fork should stay still if the plate is rotated.1 point

-

It might be useful to point out to those not familiar with these tools that in the post above showing the Robur and the 5500 clone, it's a bit of apples vs oranges when it comes to the included dies. The Robur has smooth radius-rounded concave and convex dies that are meant to sandwich and flex the crystal from both sides while you slide the open case or free bezel up and over the crystal. This is a precise but low-pressure operation. The other types of dies that are flat or have beveled sides are meant to forcibly bear down on the plain crystal, armored crystal, bezel, case or whatever else you are trying to press fit together, which is when you will still want good control and good alignment but you may need it to function with much more pressure. The same press can be made to work for both functions, but it might take adapters as mentioned above or other modifications to get both types of dies to fit if you want to do it all with one tool. You should be careful to understand what you are buying. But then again, as a tool addict, I would ask "Why not just search for a good buy on both?" ;-)1 point

-

TryingToLearn Welcome. As someone who is a relative beginner. I still rate myself as such after 19 month. If I may make a suggestion. Your Seiko, although not expensive in the price range, is infinitely so to you. Don't begin on your watch until you have had practice on other watches of the same number 2906. I made the mistake of beginning with my own watch. Sorry I did. I can easily do a service now. But the cost of replacing the parts that I knackered has far exceeded the cost of the watch many times over. Not sure where in the world you are https://www.ebay.co.uk/itm/193298594737?hash=item2d017e7bb1:g:T~wAAOSwO7pchuT-&amdata=enc%3AAQAIAAAA4GrtYCxOQ2K%2FGmaxUibhJo8L5357e8tVsb8IQpqGv0dtHK%2BDZCnookyoj7U93J3%2BakOYxnMI7zJsnaDKKtnEhVSiKyHYDUK9FJqBwBYIRWH%2FMV3c5MaKGJDmhDMBJ9NGug0F15g38CUR6utrxLNI%2BAwUXugaEwDJem4TQVd5VpzF94TFv0hxJ%2Bb%2F8YzH%2BHheeXzzxuWB81hhqimge7vcMCcb6lKOkS%2FvKz4NLwcGI9Y8RUxV%2BlOzd19eJ222ksel0SGTCLQs4ylUUELjojqq3SyocD6VDhI%2F7%2BI1xC7Qisyf|tkp%3ABk9SR8SQ_KOmYg Hope this helps Ross1 point

-

Something like this is good: adhesive head swab Honestly, clean, new Rodico shouldn't do anything. If you are just picking off dust particles, that is. If you start mashing and swabbing it all over, no. I know a girl who is an absolute expert with Rodico; she takes freshly sharpened pegwood, and twists it just so in new clean Rodico, and picks off a little piece on the end of the pegwood. That gets used to pick off little bits of dust on the movement, kind of like the above swabs. On a tourbillon with sapphire plate and bridges you have to be clean! (Of course sapphire can't stain...) Price-wise, probably depends on what one considers cheap. I bought a bar 50mm diameter 500mm long last month, that was 500 bucks. I guess considering how many parts can be made from it that's pretty cheap . I bought some 1.5mm plate that was 8 bucks a plate (50x200x1.5), but by weight it's more than twice the price of the bar. And the bar is much better quality.1 point

-

. Sizes mm Left to right top 2000 = 7.2 2671 = 7.1 2235 = 7.8 8200 = 9.8 8500 = 9.0 Left to right bottom 8500 = 9.3 3135 = 10 CO711 = 10.8 7750 = 12.0 2892 = 10.7 All Right Handed. Left as well if you use brass washers filed out to the same size. insert, then reverse I purchased some brass washers and have spent some time filing out the innards to fit the outer size of each of the Chinese winders. I now have the facility to place 10 different size springs left or right. It would have been too long to wait whilst I purchased springs of each size. Total cost £6.69p.1 point

-

Hi Nucejoe, I have a couple spare roller tables for the FHF 120 that I can compare to see if I have one that is not squashed. Basically pick the one that looks the best and give it a try to see if it behaves much better. Hi Shane, I am talking about the two jewels under the balance staff. The one with the hole that the pivot passes through must be replaced. The flat jewel below that one, is what I am referring to as a capstone (maybe I have the wrong term). It is on a separate metal piece that is screwed into the bottom plate from below. I will just replace the hole stone one that is chipped first before mucking with the other one behind it on the back. I tracked down another roller table from another FHF 120 balance that I can salvage. Quite the difference between the squashed one on the left and the good one on the right! I will be checking this in the future.1 point

-

1 point

-

These movements you quoted are very old (1940/50s era) so they are much more inclined to fault when not handled properly.my first question is are you cleaning and oiling these before reassembling? If not then that can be your issue to begin with but here’s what i think...... the one that stops on the side = bent balance staff and/or broken jewel why? Because you did not set the balance properly before screwing down the bridge. It’s should be ticking as soon as you seat it correctly if there is power from the mainspring. I always wind up the watch and check action of the pallet before installing the balance. Once you see it running put the screw in and gently rest your finger on the bridge while you screw it down, sometimes they wiggle as you screw it down and the staff can pop out of the pivot. Just use the weight of your finger do not apply any additional pressure. Do not screw it down all the way at first, screw it until bridge is secure remove finger the tighten it as much as you can from there...balance screws should be tight too loose can cause watch to stop. the one that runs fast = magnetized or sticking hairspring coil why? Because you didn’t clean the movement. Or demagnetize the movement and or your tools. You could also be warping the hairspring when you remove it or not setting it down properly after you remove it. It should be laid on its back with wheel sitting into the balance cock pivot, or put up on a balance tack...some are against this but i have used a balance tack forever and never once had an issue....i just wouldn’t leave it there too long. When a movement runs fast look very closely at the coils expanding and contracting - a cell phone video with slow motion works good. Make sure none of the coils are sticking and also make sure the expansion is even on both sides. when not laid properly the hairspring can get off center and coils will contract much more on one side causing it to run fast.1 point

-

The issue the OP is having is not breaking the seal of the caseback but getting it off completely. I think the issue is the first thread has a bent ridge which is locking the caseback up.1 point