Leaderboard

Popular Content

Showing content with the highest reputation on 07/12/23 in all areas

-

To conclude my last project; on the picture it all comes nicely together; the monitor-arm for the microscope and the belt-driven Jacot tool. The microscope is equipped with the original 1:1 lens (7x-45x magnification) which gives, positioned above the jacot tool, the perfect working height. Initial test, everything works a treat7 points

-

can we see pictures of whatever you using the phone and or the other software in other words we want to see what you're looking at that's telling you you're having a problem. oh minor little clarification here there are two things to adjust in the watch your using the software to adjust the beat error and what he using to regulate the watch? Then before changing things we really need a better explaining a better what's going on? okay so it had been serviced and it was inactive for 30 years. So it's really saying is it had been serviced prior he wore it to let off and 30 years later were seeing this problem? By the way your watch needs a complete servicing because whether it's inactive or not the lubrication's are all don't disintegrate anyway which can be an issue. Someone trying to figure out is right out of the drawer this is what the problem was or have you worn out a while and then suddenly this problem has popped up? ideally because the problem is in the watch we need better views of the balance wheel and hairspring in the watch. Because as soon as somebody who's never done watch repair removes the balance wheel from the watch interesting things will happen and probably none of them good. and yes this would be good thing to do except we've already indicated you've done that you really need to share the results with us. Often times interpreting phone apps are very very bad very unreliable. Don't know anything about your other software we need to see how that's all working because depending upon how that's working that is extremely unreliable also. This is why we need pictures to see what were using for diagnostics3 points

-

I once couldn't understand why I couldn't see better with my glasses on. Simple answer, I was using sunglasses instead of my reading glasses. I can be incredibly stupid at times hehe.2 points

-

2 points

-

I would be inclined to put it on a timegrapher or the like and check the stats, amplitude, beat, rate etc to get a true pic5ure of 2here we are at the moment, the arc of vibration looks to be small. ( low amplitude). Needs checking.2 points

-

Probably ebay forced the refund, and now he is trying to get the money by the back door and skedaddle with it. Pass any further dealings to ebay and let them sort him out.2 points

-

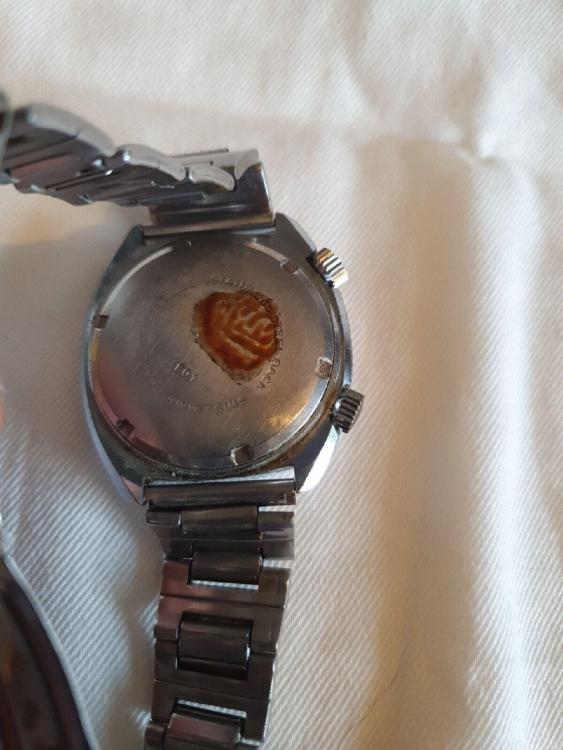

This Omega Genève, cal 625 from 1974 was a non-runner. I cleaned the dial a little bit too, but stopped before making it worse. Simple movement that went back to a strong beat after a good clean and oiling. BTW: pegging the jewels holes made a huge difference. I didn't do that at first and got around 270° amplitude (dial up, full wind) and lines were a bit choppy in the vertical positions. So I then disassembled again and polished the jewels with pegwood... and it went up to 290/300 with nice straight lines. I hope you like my "movement art"2 points

-

I would like to share a check list made up by a master watchmaker. I take no credit for it, only think it would be helpful for us hobbyists. Here it is! CHECK LIST I decided to write up what is called a 16 point check that is meant to be a guide to steps required to service a watch this is slightly bias towards a wrist watch but very relevant to pocket watches also: This is a guide and not the definitive answer after going through it a few times add you own additional tests and observations. This is of course for a basic time only non-automatic or any with additional features, I also leave out things like demagnetizing, actual cleaning procedures, a good chunk of common sense needs to be applied also as I say its meant as a good starting point to a correct disciplined procedure, This is version 1 may add or edit/delete later. Check number 1 a Check the winding to see if the mainspring is broken. b Check to see if the setting bridge or sleeve is broken by pulling the stem out and testing the proper snap of stem. A broken setting bridge/sleeve is easily detected c. The balance wheel should be oscillated to see that it is true and the balance pivots should be checked by looking through the upper jewel to see that there is not a flash on the pivot. d. The hairspring should be checked to see that it is not damaged. e Check setting of hands f. The watch should be looked over in every respect, paying particular attention to any rust spots that may appear on any part of the movement. When rust is evident around the stem or setting mechanism, it is most important to remove the dial and hands in order to check this mechanism to see if the rust is very extensive. Check Number 2 a. Examine each part as it is being removed from the movement. b. Check for rust on every part. c. Check every pivot to see that it is not damaged or bent. d. Check the jewels in the watch, to see that there are no cracked jewels. e. Check pallet stones to see that they are not chipped or damaged. f. When removing barrel cap, make sure that it snaps off only after sufficient pressure has been applied to it. g. In the examination of each part, a close check is not made at this time as many of the parts will not be clean enough for that purpose. a much closer check will be made on the parts as each part is handled in the assembly of the watch Check Number 3 a. Upon completion of cleaning and parts removed from the basket into the assembly tray, each part should be checked over with the use of a watchmaker’s loupe special attention should be paid to the jewels, because if there is gum oil still remaining on the jewels, the cleaning job was not done satisfactory . It is also worthwhile at this time to examine the pivots. If the jewels are clean, and the pinion leaves are clean, it is almost certain that the cleaning operation was performed effectively. Check Number 4 a. Examine the condition of the mainspring. b. Check the width, strength and length of the mainspring. c.. If correct, replace mainspring using correct mainspring winding tool, not by hand d. Check the lubrication of the mainspring if required e. Check the fit of the mainspring around barrel arbor. f. check the mainspring end for proper shape to catch in barrel. g. Check the snap of the cap on barrel and replace in correct position h. Check the end shake and side shake of barrel arbor is it also sometime recommended to do this without mainspring fitted to test for free run and end shake i. Check the cleanliness of the barrel and barrel teeth. j. Check the oiling of the barrel arbor after the cap is on. k. Check the condition of the barrel teeth to see if they are bent or worn. Check Number 5 a. Jewel holes must be cleaned with peg wood if necessary. b. Jewels must be checked for chips or cracks. c. Check the train wheel pivots for rust, polish, cuts and straightness. d. Check the pinions for rust’, pits and polish. e. Check the pivots for pitting check that clean pith wood is being used. f. Check plates for tarnish, fingerprints, and polish jewel settings. g. Assemble time train and check end shake and side shake. h. Check wheels for trueness arid upright. i. Lift each wheel with tweezers to check for end shake and to see if each wheel is free enough to fall back to its original position. j. Spin train to see that is spins freely, in dial up, dial down and a vertical position. Check Number 6 a. Replace barrel and barrel bridge and check the oiling of the barrel arbor upper and lower bearing. b. Check oiling of crown wheel. c. Replace ratchet wheel. d. Note: do not oil remainder of movement until after kick-back is checked or cap jewels are present oil those now e. Wind watch slightly to check kick-back and recoil. This check should be made in dial up and dial down positions. If the watch does not have kick¬back, this indicates that the train is not as free as it should be. First, however, before checking into the train itself to determine if there is some frictional error, it would be worthwhile to examine the mainspring around the barrel arbor. Many times the loose fit of the mainspring around the arbor will prevent kick-back from occurring within the train. In such instances, the arbor is simply slipped in the mainspring instead of the train receiving the reversal torque, that normally occurs. If the barrel is found to be satisfactory, then the train. should be checked to see if the trouble can be located. first, the train should be examined carefully to see if each wheel is free, and if no trouble can be found, then it is advisable to remove the train wheels from the watch and replace each wheel in the watch individually and to check the spin of each wheel. If each wheel spins freely, this indicates that the pivots and the jewels are in good condition and that one need not look further for defects or faults in those areas. Next, place two wheels at a time in the watch and check the spin of the wheels. Thus, any error of improper depthing or a badly formed tooth on a wheel or pinion will be detected. It is simply a process of elimination in order to locate the particular trouble, and of course, proper corrective measures must be taken to correct an error when one is found. Check Number 7 a. Oil all the train jewels in the watch, and at this point it is advisable to oil also the balance jewels. b. Check to see that there is a ring of oil around each train pivot and that the jewels are not over-oiled or under-oiled. c. Check the jewels that have caps to see that the globule of oil has been formed properly between the flat cap and curved hole jewel and no keyhole shape if so remove re clean jewels and check seating the re oil and repeat check for perfect ring. Check Number 8 a. Oil stem properly. b. Oil friction parts of setting. c. Oil wolf teeth of clutch wheel and winding pinion. d. Oil clutch wheel groove. e. Oil points on setting lever that contact the setting bridge or the clutch lever. f. Never oil dial train. Note: ‘dial train means all wheels following center wheel staff. g. Seek expert advice on some types of intermediate wheels connecting clutch at setting positions that require oil. Check Number 9 a. Check condition of pallet arbor pivots. b. Check for chipped or loose stones, shellac or gummed oil on pallet stones. c. Check guard pin for straightness and proper shape. d. Check polish of pallet arbor, pivots and fork slot. e. Check end shake of pallet fork. f. Check height of pallet stones in conjunction with escape wheel teeth. g. Check matching stones. h Check drop lock i. Inside and outside drop. j. Draw. k. Hang-up of stones on escape wheel teeth. Check Number 10 a. Check tightness of roller jewel in roller table - uprightness of roller jewel. b. Check the height of the balance wheel in conjunction with the fork bridge and the center wheel. c. Check the clearances. d. Check the height of the guard pin in relation to safety roller. e. Check the proper length of roller jewel and fit of roller jewel to fork slot. f. Check the guard clearance. g. Check the corner clearance. h. Check the jewel pin shake. i. Check the guard test, j. Check the corner test. Check Number 11. a. Check the hairspring in-the-flat. b. Check the hairspring in-the-round. c. Check the quadrant of the hairspring to see that it is formed properly between the regulator pins and stud d. Check for beat of the watch by equalizing the force to receiving and discharge pallets. e. Check for the collet wobble. f. Check for trueness of the balance wheel, and for the flash of the balance pivots g. Check for trueness of roller table. Check Number 12 a. Place the watch on the timing machine and take a rate in the dial down position, then turn the movement over to dial up position and take a rate. There are three things that should be observed from the rate that was taken: 1. Dial up should indicate the same time as dial down. 2. Observe the closeness of the lines to determine if the watch is in perfect beat. 3. Observe how the watch is running in reference to the time error over a 24-hour period. b. Adjust the mean time rate of the watch so that the dial up and dial down positions will record on time. Do not move the regulator more than one degree in adjusting the mean time rate. Any other alteration must be made by adjusting mean time screws or by adding or removing weight from the balance wheel in such a manner as not to affect poise, static or dynamic,. c. If the rates in dial up arid dial down are found to be different from one another, then this indicates a mechanical error in the watch which must be traced out before proceeding. d. If the watch is found to be out-of-beat, then of course, it should be put r in proper beat at this time. We might emphasize that if the watch was put in proper beat in accordance with the proper procedure at the bench, then an out-of-beat condition or minimal amount would not be indicated on the timing machine. e. When the above conditions have been satisfied, the next step would be to take a rate in positions and errors corrected. If everything has proved to be satisfactory, the watch should be tested for isochronal test be made on the timing machine, which consists of re-testing at different winding levels and rate in the dial up position. Check Number 13 a. Check for proper lubrication of cannon pinion on center post. b. When replacing the cannon pinion, be sure that the leaves of the cannon pinion do not come down on top of the minute wheel teeth so as to bend the teeth of the minute wheel. c. Check tightness of. cannon pinion d. Check to see that cannon pinion does not ride up when watch is being set. and smooth consistent operation. Check Number 14 a Make sure that the hands are fitted securely to the parts to which they are attached b. Make sure that the hands are adjusted so that there is equal space between the hands and the hands are set as close to the dial as possible. c. Check to be sure that the hands are shaped to the contour of the dial. d. Check to see that\ the hands are positioned so that they are synchronized with one another. Check Number 15 a. If there is no case for the movement, simply disregard this check and proceed with the next check, number 16. b. Check for proper snap/screw back of the case. c. Check for the clearance of the hands under the crystal. d. Check the crystal to see that it is securely fitted into the case. e. Check to see that the crown is next to the stem and reasonably close to the case. f. Check for tightness of movement in case. g. Check the spring bars to see that proper spring bars are used for the particular type of case so that the band is held securely to the case. h. Check the lug holes to see that they have not been worn badly by the spring bars to a point where the hole may break through and allow the spring bar to come out of place. Check Number 16 a. Set the watch on time with a master clock. b. Let the watch run for a period of 24 hours and check the error in the time repeat in several positions. c. Allow the watch to run until it completely runs down and check the length of run. The watch should run a minimum of 30 hours, preferably 40 hours, if it is in “A. I have no answers to any of the steps since I didn't make this up. Maybe Mark might.1 point

-

I have a couple variations for this Clinton watch with a bezel. I am not sure if it is supposed to be a diver or a world timer as it has a bidirectional bezel. Could use a new crystal. This is an FE3612 I beleive. I don't know why they didn't go full stainless case on these. This one has a bit of wear showing brass on just the underside edge by the crown. My other blue dial auto has the original band but is not a comfortable as this nato band. I ordered a black silicon band with red stitching and we will see how that wears later this week I am hoping.1 point

-

1 point

-

Looks fantastic and I especially enjoy the wall clock! Warning OT, but I hope I may be excused! Well, I don't have a belt-driven Jacot tool, so for now, I will just have to settle with my extendable Yoyo keyring, but it works well enough for me so I'm certainly not complaining. Had my wife record a Youtube short video while I was working on restoring a centre wheel. I really appreciate the Jacot. Without it, many fine vintage watches would not get a second life.1 point

-

and eBay refunded the money. OK, now I understand. Could be either. Attempted scam, or ignorance and frustration with the rules. Either way, best to report it in case he tries it again.1 point

-

Source a replacement from the likes of Cousins uk or the American material suppliers. Esslingers, Otto Frei, Timesavers etc.1 point

-

Don't you find all that reflection a hindrance. Or do you wear sun glasses.1 point

-

1 point

-

ebay dont release the money until after delivery, in fact i think they still hold it for a while after that. Maybe he was under the assumption its paid straight after the sale. Even without getting the payment the seller still has to authorise a refund initially for ebay to return the money, unless it drags on then ebay steps in and takes over. I had a similar situation with a non working watch i received, the seller wouldnt follow the returns proceedure and wouldnt buy a reurns postage from ebay or send his own with tracking. It went on for two weeks then ebay automatically refunded because he wouldnt play ball they also said i could keep the watch.1 point

-

Thanks for the comments there, some people can get a bit funny if someone disagrees with what they say. yes thee pivot does protrude a little bit further than what I would say is ideal , but it’s the same as it was to begin with so I left alone. The brass colour was a good match and the join is invisible between plate and bush. A verge, and original, the pallet/paddle arbor only has one pivot, the other end of the arbor has the V block that sits in a brass cut out.1 point

-

1 point

-

I'm confused. How can he have refunded you when eBay never released the money to him?1 point

-

1 point

-

what if any of the rest of us would like to do this this is a public discussion group will you share the secrets in your private email with us? if you look at the specifications the newer ones are supposed to not as evaporate as fast. Omega uses it as the final rinse in the cleaning process because the cleaning processes aggressively strip off the old stuff. Because it's now supposedly more environmentally friendly I think that's what they said don't quote me on that one but because it doesn't evaporate practically instantaneously they can keep it in the final rinse jar. Whereas the original epilam was so incredibly volatile that it would evaporate out of a sealed jar so eventually all you'd have is a brown residue in the bottom or some sort residue with no fluid left at all. some of us have a problem with this? The problem is how many people in this group document what exactly they're doing and keep track of it over several years? In my case typically all the watches I've serviced are in the hands of other people so I for the most part have no idea what happened. Then I did have one watch which I sold that I hadn't serviced for more than five years so I could observe the effect of lubrication choices. I also did not use any epilam at all and on that particular watch it didn't seem to be an issue. On the other hand I didn't wear the watch every single day. One of the ways you get around epilam is better choices of lubrication that don't run away.1 point

-

oh just a couple of things to remember. Often times people go bushing crazy because they perceive the hole is too big. As long as the hole is round it's okay even if it does seem to big. then typically anyone who's primarily in watches who replace bushings in a clock will make the holes way too small for the pivots and the clock won't even run at all. Just remember clocks need more breathing room for the pivots if you expect the clock to run1 point

-

That looks good, the only thing to me that makes it looks odd and I only can see the center wheel pivot is the one you bushed the pivot is protruding out more then the center pivot. but I'm nit picking But you also have the right colour brass. With very old clocks colour is just as important. Some times cast brass should be used, it can be made really hard and wears so much longer. That movement has a nice apron so it must be a verge with the original pendulum. You are correct by the way about invisible bushing.1 point

-

1 point

-

When you have the watch on wrist ( dynamic state ) a shake of the hand can imparts energy to balance wheel and increase its amplitude then as the hairspring coil recoils each circle can come in contact with a neighboring one, so in case the spring is dirty/ sticky/ magnetized the two neghboring circles stick together thus shortening the active length of the hairspring, which results in reduction of amplitude and increases frequency. Just so you know why we need to see the coil, which might need a bit of sorting out or a clean and reinstal/demag. Regds1 point

-

Ok here’s my two penneth worth. I do agree with Oldhippy but also disagree on some aspects here. The video, yes I agree bad work, also using power tools again they are way to fast etc. With regard to the bergeon set up I do have to disagree there, the system is great, reamers, bushes, chamfering bits, the whole lot works together,as for invisible bushes, I’ve just finished a bracket clock and if you look at the inter wheel on the strike side ( the one in line with the bracket on the right ) That bush is a bergeon graded bush fitted using the bergeon tool. Now I may be misunderstanding what OldHippy means by invisible bushing but my understanding is to blend the bush into the plate so that the join between new bush and old plate is not visible. Please correct me if I’m wrong as I know oldhippy has many more years knowledge and experience than my self. For the OP I was taught to broach/file in the opposite direction to the wear in the pivot hole the same amount as the wear, then centre the hole on the bushing tool then ream the hole to slighty under the bush size ( which is easy using the bergeon system if graded bushes and the bushing tool). once reamed out you press fit the new bush from the rear and test fit the arbor assembly into the hole , the check between plates. once checked by itself I also check with the next wheel either side for correct depthing just incase.1 point

-

With respect I think it would be better and more accurate for you (th OP) to get a quote from one or more local watch repairers. Any figures people give here would be purely speculative unless someone is promoting their own business which is not allowed on this forum. Again, I mean no disrespect but this thread is not going to go anywhere so I’m closing it. sorry.1 point

-

I have this Tissot Antimagnetique Stainless Steel watch winging its way to the UAE. I tried a few Tissots when I was first starting out with poor results, so I am hoping to banish that daemon and end up with a good working Tissot..... I also have a job lot on the way and each of them will all qualify for the 404 club, so should keep me out of mischief for a while.1 point

-

The 404 club recruiter has chased so many Ronda 1223-21 17 Jewel Memocalls, always without success, that I finally admitted defeat and stumped up a little more than the rules allowed (but not much more), for this "slightly chipped" version. There are quite a few variants of this watch, including some rather nice blue dialled ones, which I'm still keen to pick up. Other than the damaged crystal, it looks complete, and in reasonably good (if somewhat grubby) condition. These were not particularly high end, or complex watches, back in the day, but the quirky alarm movement scratches an itch for me. Next problem will be sourcing a crystal for it. I'll keep you posted on progress when it arrives.1 point

-

Don't forget to inspect the barrel and cover too. Check for scratches, concaving of the cover, etc. Also, check the barrel arbor for damage, sideshake and endshake. While you are at it, check the barrel pivot hole for wear.1 point

-

@MrBeat My Rolex Submariner has been in its box ever since I bought my first Amphibian ...........1 point

-

I've been absent for a few months, but have been soldiering on. Next to improving my leather craft skills, made some more Vostok Amphibians. All of them are serviced, modified and run with a beat-error of less than 0.5ms and a DR of max + 5 sec/day. 4x of the 2416b movements have been build from part of various other matching (scrap, 2nd-hand or new) movements like the Vostok 2409 or 2415. Instead of featuring one watch every day, I worn and present them all today This 2416b movement in a Vostok 120 case has featured before, but has now one of my self made veg tan Nato leather straps. This Amphibian in a 420 case has one of the "reassembled" 2416b movements, it runs extremely good Blue scuba-dude dial with matching bezel and Nato-strap. Here an Amphibian "Neptune" in a 960 case. Because the bracelet lugs on this case are special, the new, around $4, solid stainless steel eBay watch-strap had to be modified to suite the lugs....works very well and the strap is of amazing quality. The sun spoils the picture a bit, but still better than raindrops Next up is a "Ministry" (710) case, with 22mm lugs and military Nato-strap. A "single-dot" black bezel insert. This Radio-Room dial sits in a Komandirskie case with a hand-wound 2409 movement. Matching Nato strap. This watch needs some more tinkering. First to make it an automatic movement and I'm looking for the same black Radio Room dial, but with date window.......... hard to find Last one for today: an orange scuba-dude in a 420 case. Automatic 2416b movement with a black date-wheel at 6-o-clock. The leather-strap is not 100% to my liking, and will be replaced with a self-made one. The bezel is nice small and a bit more rare. Three more Amphibian are in the make. Still searching for the right & matching components. That's it for today !1 point

-

1 point

-

1 point

-

I guess I'm just a scam magnet. After getting the refund from Amazon I decided to look for another Mido and found a good deal (~ 40% off) for a new watch with papers and warranty on ebay. I purchased it and the seller said he would try and mail it on the weekend but if not he would post it on Monday. Then Monday I get a message saying that he can't get the payment from ebay and they won't help him so the only way I can get the watch is to have him refund me and then I pay outside of ebay directly to his paypal account. Riiiiiight.0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)