Leaderboard

Popular Content

Showing content with the highest reputation on 07/14/23 in all areas

-

4 points

-

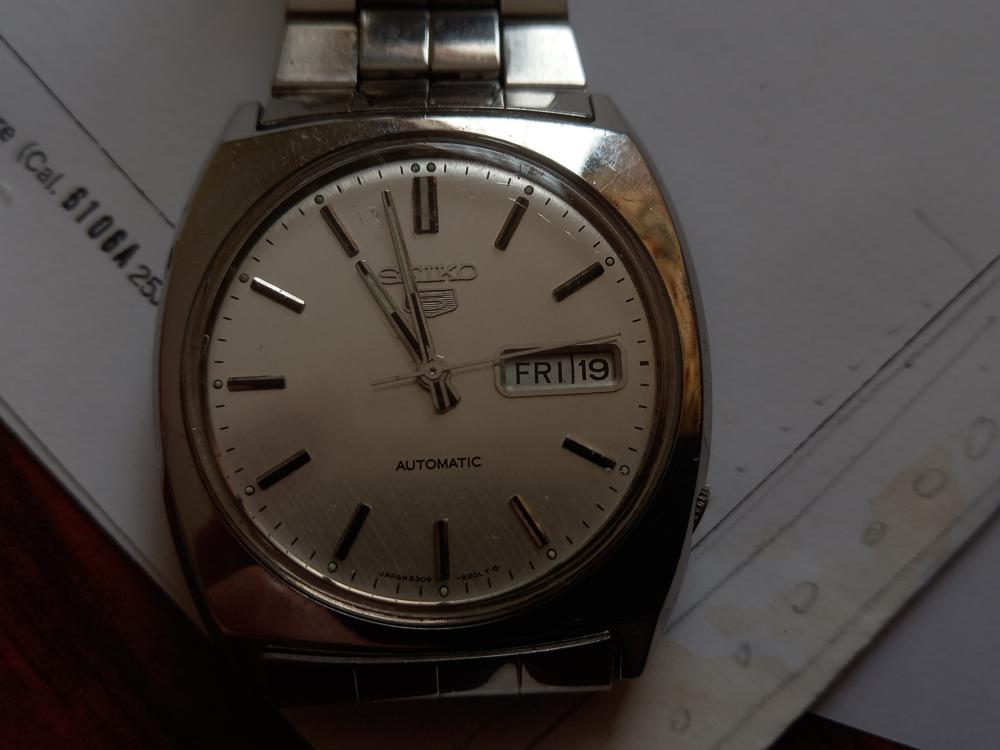

Seiko Elnix 0702-6010 from August 1973 eBay buy just arrived today. In really fantastic unpolished condition. Looks like it's been in a drawer for 40 years. So pleased with it. The bracelet and case are so sharp. Will be getting a full service soon enough. This watch has an electronic balance and the movement was only produced for 2 years so quite rare. Note it still has a sticker on the clasp in Japanese showing how to adjust the bracelet.4 points

-

3 points

-

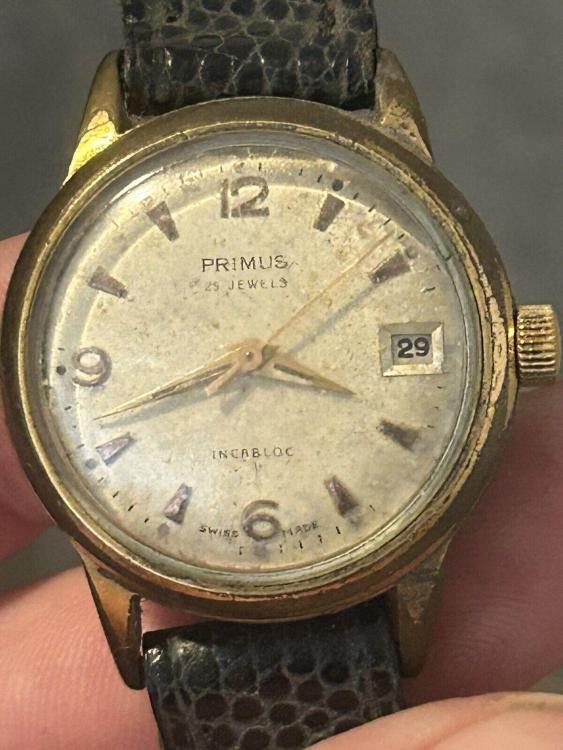

Not much to go on with this 0.99p gamble. I'm guessing late 1950s, possibly automatic, but the dial doesn't actually say that. Its a 25 Jewel Swiss movement (probably), but since the seller didn't include any pictures of the movement, it could be a potato in a shiny box. The Primus branding suggests it might be Ernest Gorgerat / Ernest Gorgerat & Fils / Jean-Raoul Gorgerat / Raoul Gorgerat so it may be a reasonable quality piece, and what little I can see of the thing makes me think it may be gold plated. Lets see what shows up. EDIT: My guess is that it is a Felsa 1572 (which would be nice) as I did find a couple of other Primus 25 jewel (non date) automatics that have the Felsa 1560 in them.3 points

-

3 points

-

Some Where in the group we've already discussed breaking grease and you might try P125 which is what Omega recommends. Then there are pictures in that discussion which show how much are supposed to apply etc. because If you get carried away with it it's really really sticky Also conveniently I can't find it right now but Omega is recommended going to the modern style mainspring versus the older two-part style. It's a problem at the tech sheet where showing how to do it the old way and yet there might be a much newer reference which says do this instead. Then yes flying mainspring barrels can be quite interesting as to how far they can fly. I was doing a Hamilton deck watch which is a bigger spring a much bigger and the barrel wanted at a 45° angle to the room bounced off the door and went ricocheting down the hallway. Fortunately it didn't enter into any of the other rooms or it would've never been seen again. Although it could be much worse I had a friend doing a clock he said the barrel got away and it had so much force it fluid hit the wall and actually went up the wall before it ran out of energy. This is why people doing clocks typically wear face protection and very heavy gloves. I always try to remember to use a towel when I'm removing anything related to the mainspring so nothing will go flying away it's all contained in the towel. Then we didn't get a movement number yet did we? The reason I ask is I will see if I have Omega timing specifications for the movement. Because as I've pointed out before all Omega cares about is timing specifications or if the amplitude is too high and then the minimum amplitude it 24 hours varies between watch to watch the lowest being 160. So while this group is very concerned about amplitude and does not care about timekeeping at all the watch companies are more concerned about does the watch keep time?1 point

-

1 point

-

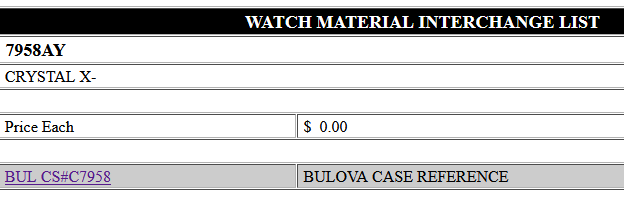

Case 7958 takes crystal 7958AY, so an armored crystal with gold tension ring. My crystal size cross reference doesn't have that one so not sure of the exact size. Try giving Ofrei.com a call (510-832-0355) with that crystal number, I've had good success with them and Bulova crystals.1 point

-

1 point

-

Hello community and thanks @Waggy!! A friend kindly printed your model and I'd say it works perfectly. I used a hammer to beat in the bolt and it holds nice and strong, just by friction. And well, when you screw it into a die, it actually reinforces the hold. You are right, 14mm length is better. I got 12mm and that works just find for flat dies and larger convex dies. However, for smaller convex dies (if they are also convex on the backside), the bolt will not reach the thread.1 point

-

Michael1962 asked: what do they mean when they say gold filled? A quick Google search yields the answer: Both gold filled and gold plated jewelery are made by applying a thin layer of gold over a base metal. Gold filled jewelry is more standardized and must contain at least 5% gold, whereas gold plated jewelry can contain any amount of gold (usually the absolute thinnest layer possible).1 point

-

I don't know about the law, but it would be very nice to opt-out on 3rd-party tracking cookies. The rest of the world doesn't need to know that & when I logged in on WRT. It would be very nice if the opt-out option would be provided. Thanks1 point

-

Well, I've done it. Purchased a very dead Seiko 6309. Obtained two, also dead, donors. All looked horrendous on purchase. dirty, screws missing, only one very dirty case. Disassembles all. Checked every item for condition. Picked best. Assembled, oiled. Everything checked on install before moving on to the next part. Biggest problem was balance. All had motion after a while, but none kept motion. 3rd one worked. Demagnetised, Timegraphed, took an hour (+3s, Amplitude 168 - can't get it better, beat error 0.3). Used case from original purchase. Strap from 7009. It works, been wearing it for 3 days now. I know it's not much, a low end watch. But I did it. I've done other automatics, but none have actually maintained their beat without having to be wound manually. So, I'm here...ish. Going away in a few days for my 75th birthday. Back to the enjoyable hobby on return. Regards and thank you to you all.1 point

-

Yes Windows snipping tool works fine. My preferred snipping tool is Greenshot. My "real" job is patent litigation and in that role, I write many reports requiring many snipped images. Been using this tool for ten years are more. Set up your preferred hot keys and you are good to go. But, Windows snipping tool is OK too.1 point

-

I like this, good or bad we enjoy it or deal with it as it comes. Back to Monty Python " always look on the bright side of life " enjoy the rest of your day matey , i have houses to turn into Palaces .1 point

-

1 point

-

Aw mate that sucks, i dont really know what that means but it sucks . Lots of information that you are missing out on. Leave and come to England, my neighbour is selling his house, i can build you an amazing watchroom1 point

-

1 point

-

I have tried to register as a private customer (non-business) so I'll let you know how it goes. They also sell on eBay: http://stores.ebay.de/evergreenparts The business address is in Germany, parts made in Switzerland, according to the website. There are facilities springing up in Germany like Makerspace in Munich which allow anyone to book time on a range of machines including cnc. They are usually associated with a technical university. Maybe there is something similar nearby.1 point

-

? Joe you wait till now to mention you cant read the pdf files that everyone adds, after how many1 point

-

1 point

-

It really would be preferred to service the watch rather than putting a stronger mainspring in the watch was not designed for. As you introduce other issues. Servicing the watch it's amazing what clean the watch with fresh oil properly applied will do for you. Timing procedure dial-up and dial down and at least one crown position Like crown down Is helpful we can really gain a lot of knowledge and pictures of whatever you using so we can see what the display looks like. I don't suppose it has a number like a model number? Oh and typically the watch companies are only concerned about amplitude either when it's too high or at the end of 24 hours. They are much more concerned about timekeeping than amplitude. Then because typically Omega watches run really well the lowest amplitude it 24 hours depends upon the watch which is why I'd be nice to the model number. Repairing-Omega-self-winding-watches-bumper.pdf1 point

-

I put it back together and cased it up without the automatic works to get an idea of the reserve, and so I can wear it for a day or two. Wound at 10pm EST The second and chrono minute hands have been really poorly painted red, and I'm fairly certain the dial is a refinish. The price I paid kind of reflects that, so I'm not too upset about it. I'm not looking for a perfect collector's piece anyway. It'll give me an opportunity to try my hand at refinishing hands. That is a lot of lint!Sure looks good on the wrist, though. https://www.youtube.com/shorts/vE-nsV6jYMQ1 point

-

I use the Bergeon (the one on the left) when on the bench and need a basic measurement. I use the JKA (center) when measuring a staff (or wheel pivots, etc.) and willing to go to the extra effort of fetching it and opening it up. It consumes bench space, so I use it only when its features are necessary. I use the caliper on the right when working on my lathe. I used a Mutitoyo digital caliper (not shown) for crystals, stems, crowns, etc. BTW, I picked the Bergeon for $47 plus shipping and tax on ebay. It was a steal.1 point

-

I use Mitutoyo digital calipers for large stuff, where I don't mind being off +- a hundredth of a mm. When I need to split hundredths, it's a micrometer. I prefer non-digital ones as they are lighter and more compact, I find digitals cumbersome. Then there's an array of bench mics, with various shaped spindles and anvils, horizontal and vertical, and some indicating bench mics that will reliably measure to microns. Large mics for diameters up to 75mm, internal mics, I think there's at least a couple dozen around the shop haha. But a good caliper and regular 0-25mm mic covers most everything. Digital or vernier is a matter of choice. Mitutoyo for digital calipers are by far the best on the market, mine are over 20 years old and run at least a couple years on a battery (I never turn them off), and check out spot-on on gage blocks like when they were new.1 point

-

Callipers are fine for “rough “ work, micrometer is better for finer accuracy but for pivot and jewels you need something like a JKA feintaster. Different levels of accuracy and fine measurement. Tom1 point

-

Back in the '80s...perhaps late '70s, Honda (car or motorcycle...cannot recall) had a commercial with the lyrics: "Get yourself a Honda...made like a watch that was meant to last a hundred years..." Didn't specify "Swiss" though.1 point

-

1 point

-

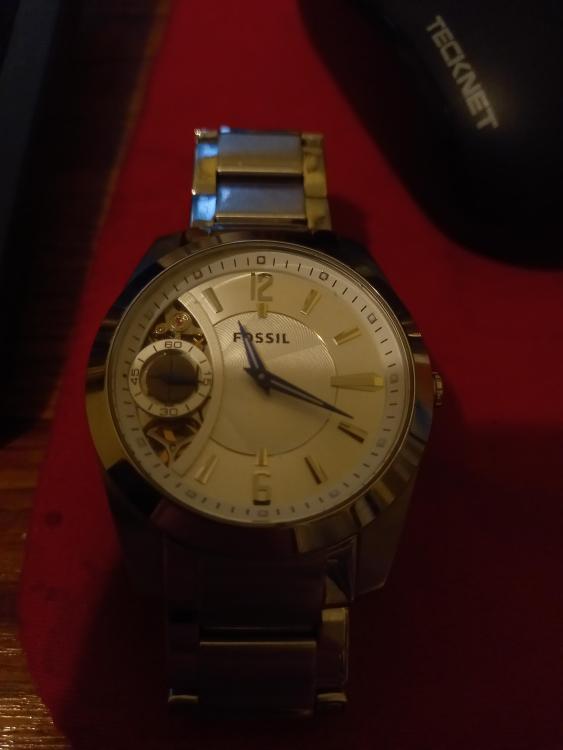

I had a stubborn screw on the back of a Fossil watch. One of four on the back, they were crosshead. It was solid and someone had tried before and almost made the cross head round. I tried with heavy pressure, but not heavy rotation, to move the screw. It was solid. I sort advice from the members. I placed WD40 on a cotton bud and placed it over the screw to soak. Did this a number of times. I used a flat edged screwdriver to allow purchase on the edges of the crosshead, then I applied rotational pressure. Only a few tries. It did not move. I did this system every day for nearly 1 month. WD40 followed by heavy pressure but not heavy rotation. Did not want to damage the crosshead anymore than it was. Nearly 1 moth later the screw moved! It was like it had never been tight. 10 minutes later I had changed the battery and the Fossil watch is like new. Good advice from the members. If you have to use heavy force, then you force a break.1 point

-

I had some rusted and broken screws on a Rolex 2135 the other week. I couldn't remove them with a screw removal tool, so got some Bergeon Vissin heated up in a dish, which is Sulphuric acid. I guess about 20 to 30%. I didn't want to have to remove all the steel posts, such as the minute wheel post and yoke post which were pressed in steel posts, or the shockproof springs, so I suspended the part that had the offending broken screw in the Vissin and within 10 minutes it has completely dissolved. Here's a video I made for my Instagram account https://www.instagram.com/p/Crx14thLdsy/1 point

-

1 point

-

1 point

-

There's a lot of stuff out there on removing stubborn screws. Depending on the movement and the screw's location I've used Liquid Wrench(tm) and also Kroil(tm) penetrating oil. Under certain conditions alum will work but you have to be careful. It goes without saying that you strip down the movement as far as possible and then make a determination whether these approaches will be safe. Attached is a PDF with some more ideas. Hope this helps. Broken_and_Rusted_Screws.pdf1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.5bd474e8169c40e92fc6c5ae2e622e81.jpg)