Leaderboard

Popular Content

Showing content with the highest reputation on 07/16/23 in all areas

-

Just a quick update. The untested movement arrived on Friday. It was all in pieces, packed in a double envelope. I heaved a big sigh when I saw it as it didn't look good. But it only cost me $2.75 and $30 in postage. I cleaned up the motor and fitted it in my movement. Powered it up. Bigger sigh. It was only twitching. I swapped the circuit boards and prayed hard. But alas.... only twitching. Then I did what @JohnR725 said he did years ago. I peeled off the transparent plastic sticker on the bottom of the motor, squirted in lighter fluid because I didn't have freon. Blasted it dry with compressed air, then fitted it in my movement again. Miracle! It works! I left it running on my bench and will check on it tomorrow. It's already past 1am here in Singapore. Wish me luck, guys!6 points

-

As a cabinetmaker, I have made a couple of long cases to house recovered movements and my recommendation is ,as above, to use a beeswax polish. We have a saying on polishing wood with beeswax: once a day for a week, once a week for a month, once a month for a year. This is how very old tables and furniture have built up beautiful deep finishes over the years.4 points

-

3 points

-

3 points

-

2 points

-

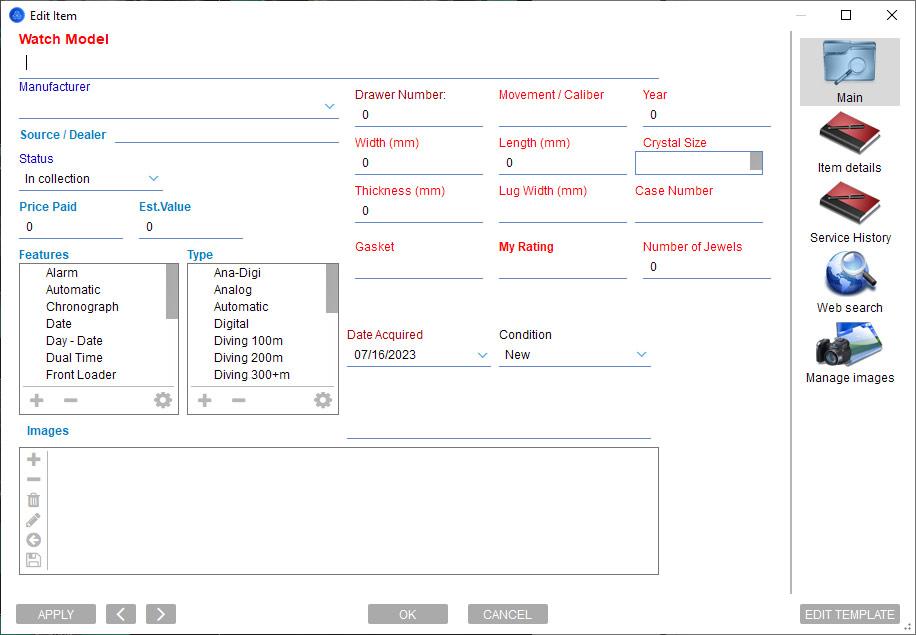

As my watch collection is growing I am starting to loose track of them, so I looked around for some software to help me out. I am aware that there are some products out there, but I have shifted to an open source life, so none are compatible with this ethos. So I have decided to 'take the bull by the horns' and create a database using the free and open source software (FOSS) LibreOffice Base format (software link here) which will be compatible with all OS formats and be 100% FOSS and should be compatible with MS Office (TBC). I'm currently putting the various fields (below) together and wondered if anyone could spot anything missing or have any suggestions as to what to add/remove? Being an open source junkie I will of course share the database on this forum completely free of charge and free of adds or any other nasties for anyone who wants to use/modify/redistribute it. NOTE: In an effort to avoid scope creep AKA 'growing arms and legs' I want to play the 80:20 rule and keep the fields limited to essential and useful data that would cover 80% of all my watch data needs, I know there are additional fields that could be added that would only be relevant to 20% of watches, which if included in the database would increase the size/complexity exponentially turning the whole thing into a chore, rather than a useful tool, so please keep this in mind when looking at the below : Currently I plan to have the following fields: Photo after - this will be displayed up front to provide a visual reference for the finished watch Nickname - easy way to identify the watch eg: "Watch I did for mother-in-law" or "Captain Willard" etc Make - eg Seiko Serial No - manufacturers serial number is present eg 2O12345 or if there were no manufacturers serial number I would use my own serial number based on the date started (see below) in yymmddxx format where xx is the sequential watch started that day, eg 23071601 would be the first watch i started on this date and 23071602 would be the second started that day and so on... Movement Cal. - eg 7009 Movement Type - thinking a drop down box with: Manual, Automatic, Quartz ....... I know this could get very complex with options like chronograph, moon-phase, etc.. so just wanted to play the 80:20 rule and keep this basic. However, I am open to adding options if I have missed something essential Case - eg 7009-4040 Previous service history - this is usually obscure scratchings on the inside of the case back, so thinking to make this a free text box where I can enter the date (if describable) or type yes/no if I cant make out the date(s) Date purchased/acquired - when I purchased or was given the watch, thinking yymmdd format? Date work started - when I first pickup the screwdriver, thinking yymmdd format? Date work finished - when I declared the watch is finished, or beyond repair, thinking yymmdd format? Before Rate (s/day) - timegrapher data used to determine effectiveness of repair/service/refurb Before Amplitude (Degrees) - timegrapher data used to determine effectiveness of repair/service/refurb Before Beat Error (ms) - timegrapher data used to determine effectiveness of repair/service/refurb After Rate (s/day) - timegrapher data used to determine effectiveness of repair/service/refurb After Amplitude (Degrees) - timegrapher data used to determine effectiveness of repair/service/refurb After Beat Error (ms) - timegrapher data used to determine effectiveness of repair/service/refurb Cost - how much did I pay for the watch (or average price if purchased as part of a job lot) Changed Parts - open text box to list what was replaced eg crystal, strap etc... Parts Cost - total of the complete cost of all new/replaced parts Repair successful - did I repair or junk the watch, thinking yes/no format Price - how much did I sell it for Date sold - when I sold or gifted the watch, thinking yymmdd format? Sold to Name - who did I sell/gift it to Sold to contact info - contact information: email phone No etc Assembly picture 1 to 10 - pictures I took during disassembly/assembly (see note below) Other - Open text (MEMO) to add any notes not captured above, can also add the other/missing 20% of data in the 80:20 rule here Note: I'm trying to think of a way to embed a zip/7z file rather than have 1-10 assembly pictures (or are the individual pictures better?... I'm 50:50 on this), but having trouble finding a way to embed a .7z file (FOSS archive format - similar to a .zip file only better) into a Base form/table - can anyone provide any help? I also want to avoid having links to outside data sources eg manufacturers web sites, data/service sheets etc as these links often become dead over time and these dead links can then cause problems, so planning to have enough information covered above so a quick web search (eg DuckDuckGo) will point to the external data needed. Also, my plan is to keep my copy of my database on my synced (and therefore backed up) cloud storage and access it from my home PC (or my laptop) that way, but it would also work on a hard-drive if that is your preferred method.1 point

-

When the jaws are empty, the scale on the bottom is pretty much perfectly zeroed. I suppose if I measure something else and it's also off by 0.45, then it would be millimeters. EDIT: Now that I think about it. The bottom scale has a hard stop on it. When the jaws are empty, if it's not perfectly closed (a tiny 0.45 mm gap), then the zero would be at the hard stop, and the scale would be off.1 point

-

No stud screw and I rest my case! Rolex watches are truly high-quality watches. Too bad 19 out of 20 spotted Rolex watches are fake, so unless you're already known to be financially successful no one will think you're wearing a genuine Rolex. Anyway, if you really love a particular brand, like Rolex, you get it anyway as you don't care what other people may or may not think. But I'm with @Neverenoughwatches on this...1 point

-

For this one, I think you're right; I think someone filed the hole bigger. Maybe for a crown that had a larger shaft on it or something. But yeah, these cheapo cases aren't good for keeping anything out. None of them come with tubes. The cheap pin lever movements have always been filthy when I found them.1 point

-

There are so many possibilities, it's hard to know where to start without more information. What is your understanding of the terms automatic (your "Rolex" isn't automatic) and vintage, and what qualities do you expect in such a watch? Is the brand name (recognition, prestige) important, or are you more interested in its objective characteristics? Most important of all, what is your price range?1 point

-

Only thing I can think of is the 0 hour positions data and the 24 hours positions data then you have a baseline for the future. Tom1 point

-

1 point

-

So many quality brands to choose from. Omega, Longines, Zenith, Movado, Hamilton, Vulcain, Benrus, Bulova, Tissot,Tudor, Certina, Eterna, Vertex , Roamer, Seiko, Buren in fact any original brand that made military watches were capable of producing good quality watches. Most brands made watches at various price points as well.1 point

-

I like to apply lube with a manual oiler i can then see exactly how good a job i have made. Jewel flat side up and held so the oiler doesn't lift it up . And that would be the chaton placed on top, the oil grabs the cap jewel and both parts can be turned over and placed into the setting easily.1 point

-

I use this exact same post-it-note method! I first steep in naphtha for about 5 mins to loosen any gunk, then with the flat surface of the jewel facing down against the paper I rub with my finger so that the flat surface is rubbing on the post-it-note paper to physically remove any gunk, then I let it fall off my finger into my container of naphtha another quick 5 min dip to remove anything my fingers or paper could have introduced. Now I let it dry with the flat surface up ready for oil. Currently I oil first with a regular oiler and then put on the chateau (spelling??) but I'm now considering changing this and applying the chateau dry first and then oiling with an auto oiler... any thoughts?1 point

-

Do you think there are any more categories needed? Only the facility to look at mp4 Disassemble and assemble and fault finding. You already have them in you original, but at each stage, as you said, a photograph or MP4? Daily log. Date of work and what done on that date. You have date started and date ended. Because of shopping requirement a retired man's needs to obeys his wife's instructions and this overrides any watch repair. Facility of time allocated to the particular watch? This would allow the seller to realistically understand the costings. To explain to the buyer why they should understand why they are getting if for such a cheap price, as most of the time is not charged for. We are hobbyists. Imagine if a company did the costings and time charges? I'm sure Chronoglide, Omega, Rolex etc does. Not anything is a nit pic. Overall it does look good.1 point

-

Wish you well. Take your time. I've got this on follow Here is my free book. Please let your family read it. It has helped a lot of people Regards Ross No_Man_Has_The_Right.pdf1 point

-

I would agree, the balance looks all wrong, the modern rolex balance is adjusted using a special tool and not a by moving the adjustment arm used in most other watches, so this would either have to be something posing as a Rolex, or an older type. However the older types would not have a spring loaded balance jewel system so this rules out this explanation. In addition to this, the text on the movement is different the "seventeen Jewels..." appears to be etched or raised, but the "...Rolex Geneva" seems to be printed, which indicates to me that this was added at a later date, again to make it appear it is a Rolex. Finally, the movement is absent any decoration (perlage, striping etc...) which I have not seen in a Rolex. I'm no expert on Rolex and (of course) there are exceptions to what I have shown, but this would raise alarm bells if I were looking to purchase it.1 point

-

1 point

-

Hello and welcome. I don't know for sure but it looks like the smaller wheel is friction fit and should push down to hold the larger wheel against the barrel.1 point

-

Look at the case together the hole isn't round. Ether a tube is missing or someone has filed part of the case away. No way would you have a hole that big for the stem and button, there is a part or parts missing. The amount of dirt that would get in is crazy. Even a dust proof button would be useless.1 point

-

1 point

-

I have an Esslinger stem extender kit and just tried that but I didn't have any sizes that were big enough to fit over the movement side of the stem. I guess they must come in bigger sizes.1 point

-

Here's a direct link to the chrono bridge jewel upgrade: https://www.ebay.com/itm/195602019941?hash=item2d8ac9f665:g:fu4AAOSwuQ5jg-cr It comes with jewels for both the minute recording wheel and the intermediate minute recording wheel. They worked like a charm on my 6139-6005. It took a bit to get the end shake adjusted correctly for the minute recording wheel after installation, but it has been running like a champ since the upgrade.1 point

-

Thank you, I will definitely check that out! I put the automatic works back on and it's clanking around in there. Looks like I'm going to need to replace the bearing, too. Argh!1 point

-

Picked this little throwback piece up at a flea market, or boot fair is it called across the pond? $12US and was not running and missing the minute hand. Took it out of the case and the missing hand falls out on the bench! Put it back on, flipped it over and saw that the balance wanted to kick in. Gently pushed on the hair spring and then noticed the screws next to the balance were loose. Tighten them down, hit it with a puff of air and off trigger galloped! This seems original, the crystal is yellow but not noticeable at first. Edit: set this an hour ago and is running a bit fast but absolutely keeping time well.1 point

-

Hello community and thanks @Waggy!! A friend kindly printed your model and I'd say it works perfectly. I used a hammer to beat in the bolt and it holds nice and strong, just by friction. And well, when you screw it into a die, it actually reinforces the hold. You are right, 14mm length is better. I got 12mm and that works just find for flat dies and larger convex dies. However, for smaller convex dies (if they are also convex on the backside), the bolt will not reach the thread.1 point

-

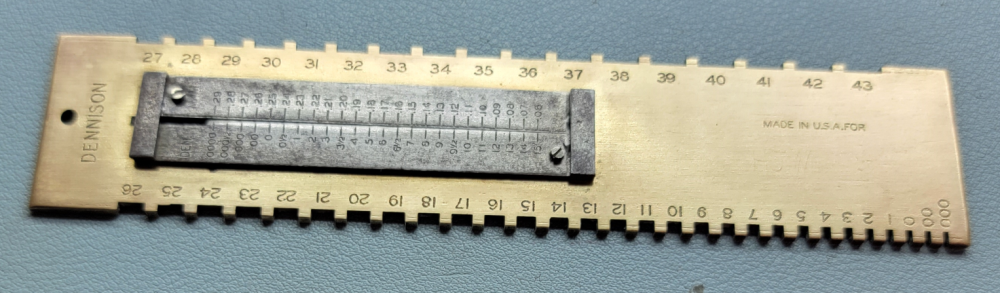

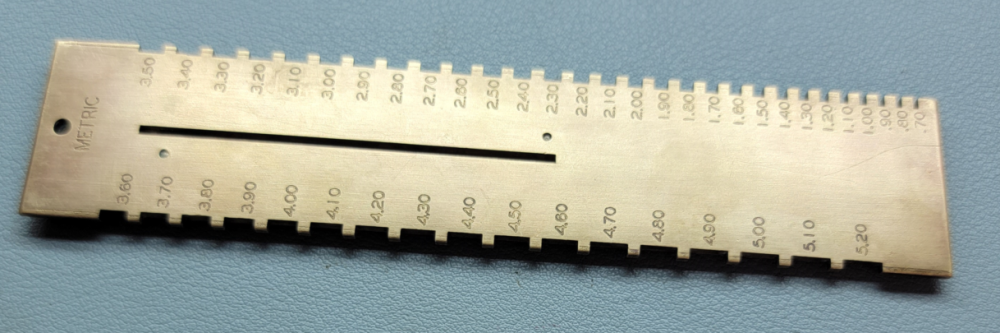

I acquired this a couple of years ago when I bought a watch bench full of tools. Until very recently, I did not realize how useful it is. It has Dennison on the front and metric on the back. The strength gauge is not super useful unless the spring is broken, because you cannot fit the end into the slot unless it is a "hole" end style.1 point

-

EDIT: I have since found that a 14mm M6 bolt is a better size1 point

-

This Omega Genève, cal 625 from 1974 was a non-runner. I cleaned the dial a little bit too, but stopped before making it worse. Simple movement that went back to a strong beat after a good clean and oiling. BTW: pegging the jewels holes made a huge difference. I didn't do that at first and got around 270° amplitude (dial up, full wind) and lines were a bit choppy in the vertical positions. So I then disassembled again and polished the jewels with pegwood... and it went up to 290/300 with nice straight lines. I hope you like my "movement art"1 point

-

it's why I try really hard not to look at eBay. Because there's always something that I'm sure I need. So this means now I exert a lot of energy to try to avoid any place that has the resemblance of wanting to take my money and sell me something.1 point

-

I'm always impressed just looking at these, and lucky enough to own a chronometer grade one, now finally had the chance to work on a repair, and all the positive opinions got confirmed. The owner lamented water ingress and the watch stopping all the time. Seeing no major damage on a first inspection I undertook the work with good hopes. Starting with the dial side the overall feeling of quality and maniacal height saving design becomes evident. The dial fits so precisely that a dial washer was not present or needed. This being a time only version I can't do any praising to the calendar works. As soon I lifted the hour wheel the watch started running strong in all positions with good amplitude, then I pulled the cannon pinion which was quite tight. Note to myself, MUST get a cannon pinion remover. The black oxidation on the contact section was the root cause of the fault, but after 50 years it was time for a complete service, and I have the distinct impression that mine was the first one. One incredible fact is that Omega still updates their technical documents about this long discontinued caliber, I can only think of the aeronautic industry doing something similar for certain "never old" airplanes and engines. The way I did it may be called not fully professional, as I didn't do surface treatment, and used only 9010, HP-1300, and 9415 without an automatic oiler. However I'm happy with the results, and I hope that the owner will be too. That being said I plan to upgrade on the above points in the immediate future. One tool detail that I really recommend is to use soft metal tweezers whenever possible, I have got cheap brass Indian ones which I then dressed to eliminate any sharp edge. These are OK to handle most of the screws and all the bridges and plates. Keyless and motion works are rational, and easy to work with. Some dirt and micro-spots corrosion, but nothing worrying. The stem was the rustiest part, and the crumbles are all what was left of the crown gasket. It is defintely possible with some patience to open these and fit an o-ring, which luckily I had from an assortment box. Even the stem came out very decent after the due care. Just give a tap or two to the washer to make it seat nicely again. I've even refitted the steel ring which matches well the O-ring profile. Two screws hold the automatic bridge, and one can see that also the gib screw was removed. That allows the rotor to be removed even with the mov't in the case. For regular service to the auto works it's enough to remove the larger bridge. One of its screws is thinner due to more limited space. Note the use of a single reversing wheel, yet the winding in bi-directional and the overall manufacture is just amazing. I used HP-1300 on the pivots but probably that another synthetic type might have been better. Note the space above the balance, which hosts the automatic work. At the time of its introduction this was the thinnest automatic movement with sweeps seconds and calendar, at just 4.5mm. And the Reed regulator is nothing less than amazingly beautiful. The balance is then removed and inspected. Note the multiple tiny "drill kisses" on the rim for poising. To save height, the train is different from the common design. Seconds pinion is driven by a pinion sitting above the the barrel bridge, and has a tension spring which controls its end-shake. Releasing power is not easy as the space around the click is very limited, remember to use only something soft like a toothpick to do that. Only then we can remove the pallet bridge, another beautiful execution with two locating posts and screws. Then remove crown and ratchet wheels. We start to see the sophisticated design and the one-way automatic winding clutch. The machining of a cord on the crown wheel round holds precisely the hub of the crown wheel, with an off-center screw. Wow. The auto winding wheel has special profile inner teeth which allows one-way power transmission from the ratchet wheel to the barrel arbor. The small pinion catches only one way to said wheel, otherwise it turns freely. That makes so that turning the crown in the opposite direction has no effect whatsoever, and also that a single reversing wheel is needed in the automatic work, because movement is transmitted only in one direction from the wheel on the arbor to the auto works. I for one find difficult to understand what I wrote above and the principle of operation of that mechanism. We can now remove the train bridge which only holds third, fourth and escape wheel. Al-tough, that does not make it particularly easy to fit back. Finally the seconds pivot spring, pivot, barrel bridge can be removed, followed by the barrel and center wheel. Speaking of the barrel, once opened it I found it quite dry, with the lid slightly corroded and heavily grooved. As an experiment I hand polished this surface with a wide micro-fiber stick, and car polish compound. Grooves were gone, but it remained scratched. I switched then to grade 20 or 30 of Chinese diamond paste until it got better. And better with finer paste, to an acceptable smoothness Now, I must say that I did not replace the mainspring, and not even removed it from the barrel as I don't have a winder, and wanted to avoid any distortion to it. In the end the watch performed well with plenty albeit not stellar amplitude. The stripped main plate in its equally magnificent A and B sides. Cleaning and reassembly was uneventful even if some screw are small enough to require full attention. I had some doubts about the seconds pivot being supported by jewel on the auto works when refitting hands, but in fact that worked OK. After lubricants settled the timegrapher response was completely positive, One last note, you know you're holding a genuine vintage Omega dial when it has a fine clove watermarking, a recess for the balance anti-shock device, and the feet are shaped for the screws to hold without damage. After a long time spent hand polishing the acrylic crystal and other details the complete "Omega Geneve" watch came out stunning, sorry I didn't take a picture Hope you have enjoyed this article.1 point

-

This is what I use. I also wipe a very thin layer of silicone grease around the rim of the lid. When I used to work in a lab we would also use Parafilm around the junction of the lid and jar to seal and help stop evaporation.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.JPG.ebf152565316568e6b415c85730d1d88.jpeg.b1d1cfd6d768d8d9530c4c4c4ffa47d4.jpeg)