Leaderboard

Popular Content

Showing content with the highest reputation on 07/21/23 in Posts

-

I finally got around to ordering a genuine crystal replacement for my Seiko sportsmatic 5 weekdater 6619-8010. It came today and with a little bit of research and having the correct tools got it installed without messing up the dial. I liked this as a daily wearer before and now it really pops and I love it! Probably top 5 of my collection. Aftermarket Barton silicon elite band that is super comfortable. I do have the original/ signed bracelet as well.6 points

-

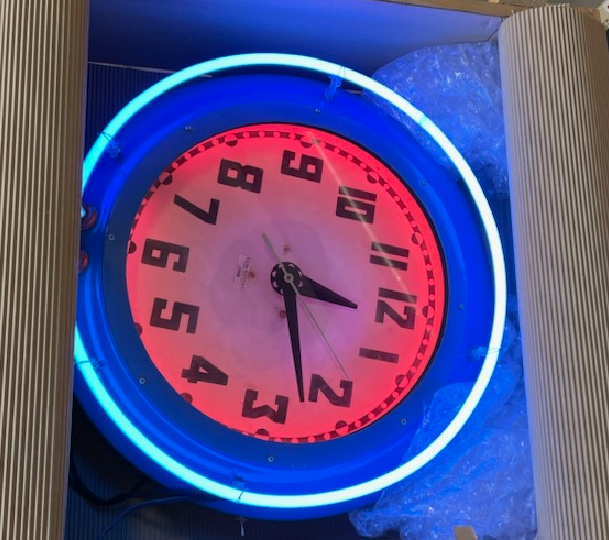

I always look at the balance (I know you know this @Nucejoe )- the glucydur balance as used in Top and Chronometer grades, have curved spokes, as on the right in the pic. The nickel balance (used in Standard, Elabore grades) has the straight spokes. Other than that, I don't know. From what I've read, all the differences are balance, shock jewels, pallet and escape wheel. So you need to see the balance.3 points

-

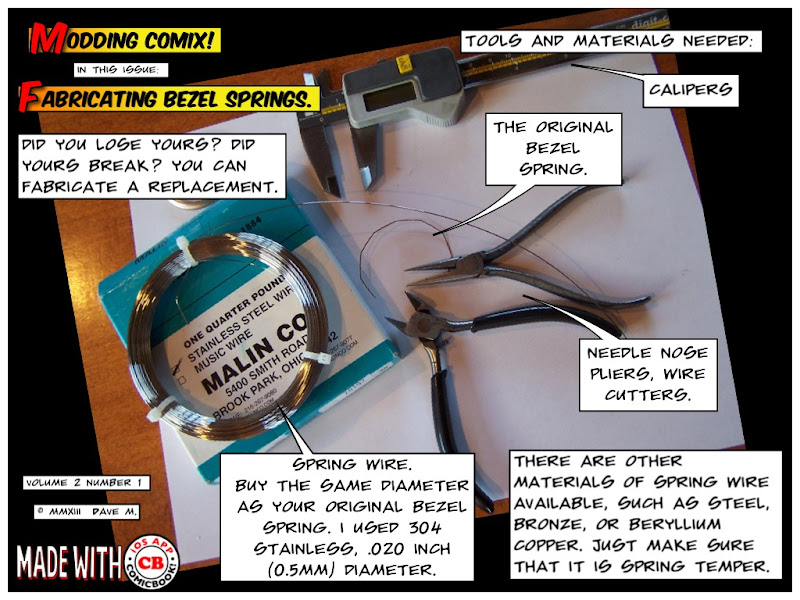

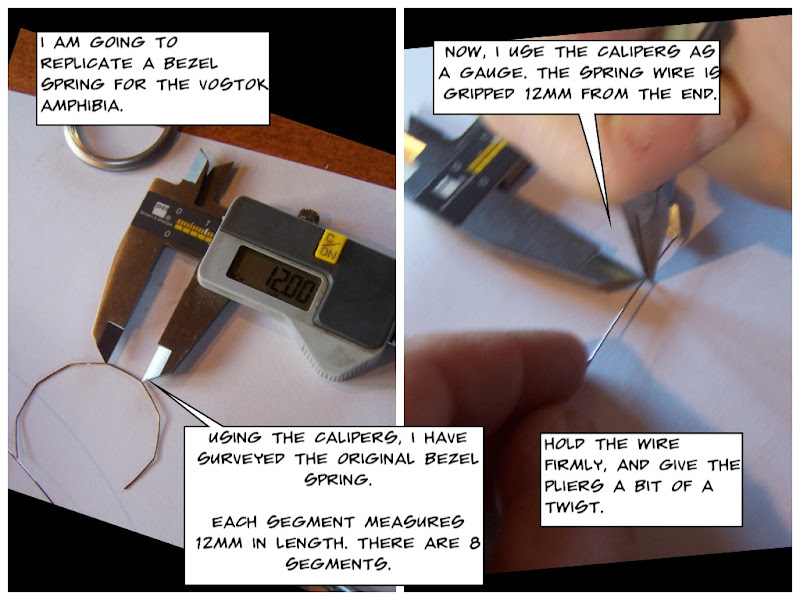

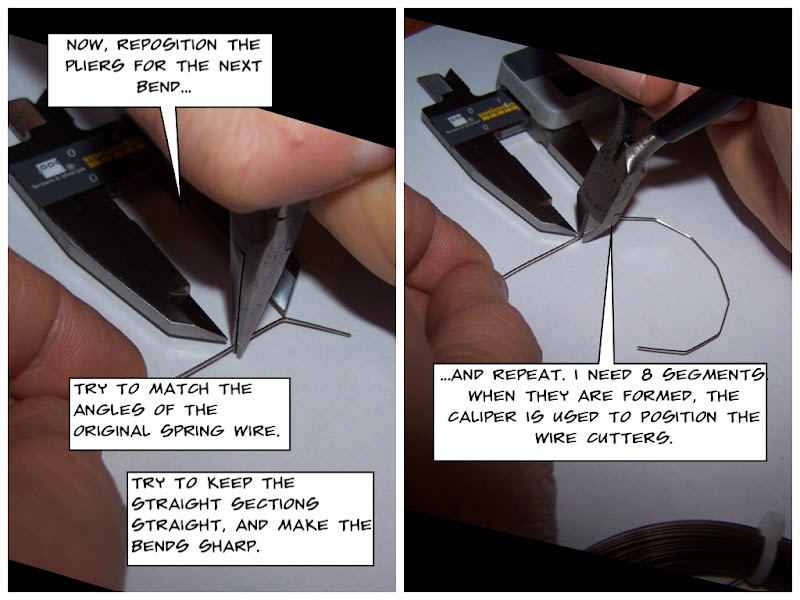

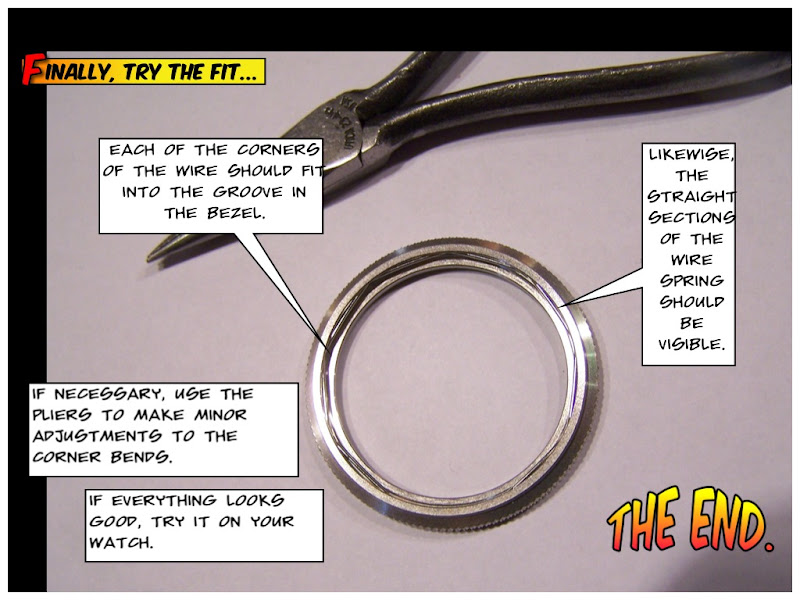

I am working on a Swiss Army watch and the wave type bezel spring is rusted away (see below) - looks like the previous owner glued the bezel in place, but I would like to try to get it working again. I have had a look online without success as the only options seem to be to TAGs or Rolex, at Tag and Rolex prices. Does anyone know where I can get generic ones, or is the best option to make my own? Here is the type I need, also not sure now many sides the original had, there are 5 left, but most I have seen online (Tag etc have 8 ) - any ideas? Here is what's left of the one what was in the watch: I did find this online.... worth a try???2 points

-

Hello everyone I have made a video of the tear down of my Sekonda 2427 and opened a YouTube channel.- Watchmaker Novice. I don't intend to do many, but I will add periodically. I've done this so that I can thank all of the members of the forum and others for giving me the skills to be able to understand watch making. It's not a great video. I'm not expert in video editing, nor are my tweezer skills great. Can't believe how much my hands shake under magnification. Here goes Watchmaker Novice - Sekonda 2427 - Large Dial Tear down - Disassembly is the title I gave it as I have a number of 2427's and the dials appear smaller. I used my Digital Microscope -(G1200)2 points

-

What I did to get a feel for it was first to set my micrometre to 2/100mm and have a look at the gap in my stereo microscope. Next I looked at a lone mounted wheel to compare from memory. In this way, I think that I can now visually determine the distance quite precisely.2 points

-

A quick addition after re reading. I meant to write that hardness is a material's RESISTANCE to plastic deformation . Something i was going to mention Joe. I doubt it very much. Depends on the manufacturer and the consistency of the manufacturing process wouldn't it. Just found this matey, makes quite an interesting read . https://www.gemsociety.org/article/understanding-gem-synthetics-treatments-imitations-part-4-synthetic-gemstone-guide/2 points

-

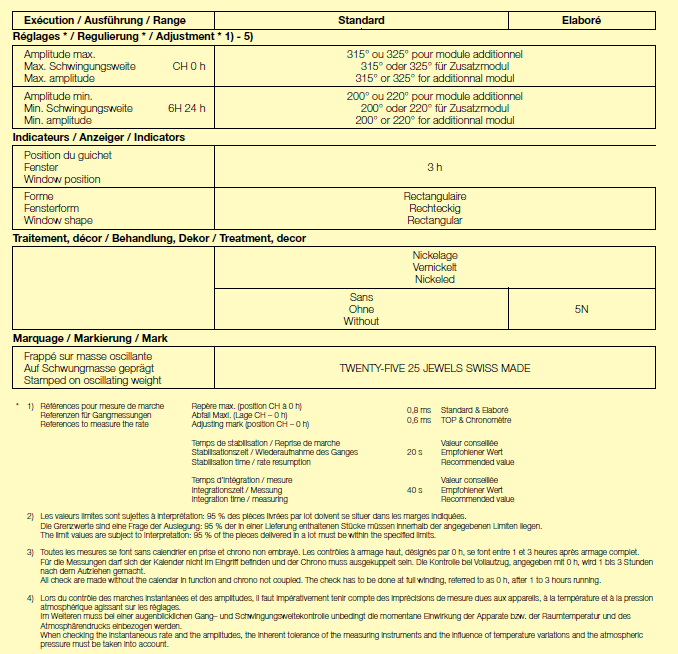

I thought I would compared to Rolex so I snipped out some other specifications. When you're looking at the chart you do need to find a watch comparable in diameter size as others have pointed out that will change things. You'll notice that your beating out there specifications you're much tighter than you really should be especially with a watch of that quality. When I'm reading this it's reminding me of clock repair typically by a watchmaker but not necessarily. But usually when a watchmaker looks at the clock things seem really sloppy and there's an obsession to put bushings in. Typically only need a bushing if the hole is no longer is round. No matter how sloppy it is if it's still round that's the way it was made. So then obsession with bushings you can end up with clocks that will not run on the weight there designed for because it's just too darn tight. So yes if you get carried away with getting your tolerances super super tight you're going to have a running issue in the watch. Especially if the watch was manufactured with more liberal tolerances that requires greater spacings possibly bigger hole diameters for pivots.2 points

-

Just a quick update. I still feel like a beginner. Slow learning but hopefully reasonably thorough. State of play. Working watches. Left to right. First two. Battery changes. Seiko 6309. Full service and parts. Sekonda 2428. Full service Sekonda 2427. Full service Sekonda 2427. Full service (my favourite) I do have many others that are work in progress Seiko's. 6119. 6309. 6319. 7009. 7S26 Citizen 8200 3 Enicar with differnet movements. St69. 2 x AR167 I watches of Switzerland Seafarer. Ross1 point

-

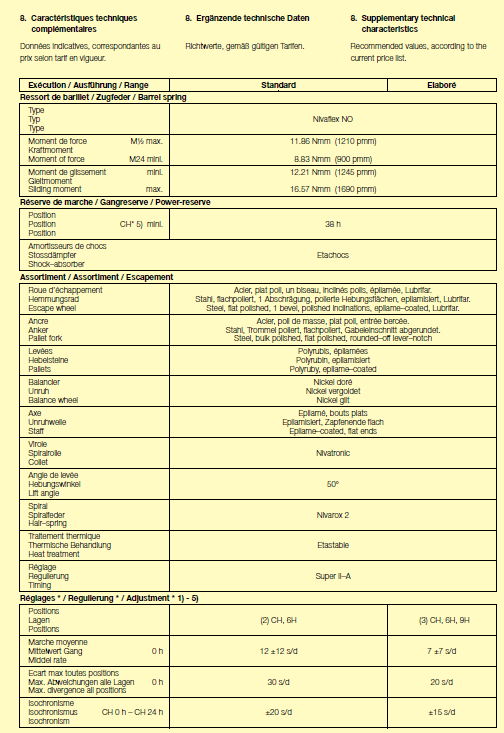

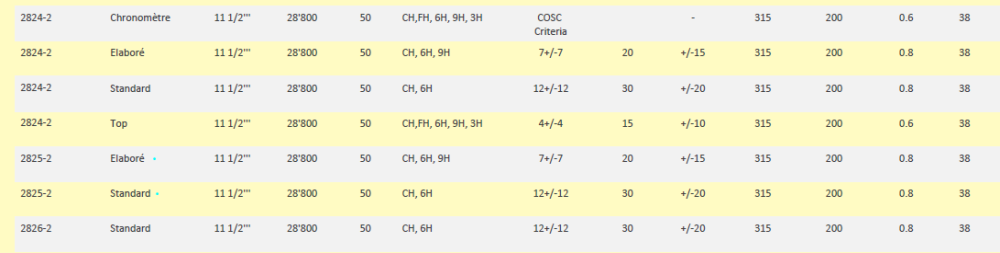

I suppose technically this gets complicated. For instance Seiko almost any Seiko you can bring it to the shop where work and he will charge a fee just under $100 varies between the watch he will regulate it to chronometer timekeeping. So on the timing machine it will look really good but you know that chronometer specifications aren't necessarily measured on a timing machine. But still he'll regulate the Seiko is down the really close so they look really nice on the timing machine it still doesn't make the watch a chronometer. So by theory yes on the timing machine it should look better if it's chronometer grade. except your caliber only comes into grades and they're not chronometer. Suppose you weren't getting a chronometer grade watch from the brand you indicate you should get one of these Heather was chronometer grade watches are supposed to come with chronometer grade certification like this then I really have studied the pictures on the link above does look like you have a certificate. I guess it all really comes down to do you trust the seller or not and if you don't like it could just send it back. now just a reminder Swatch group is paranoid over who gives out there documentation which is why they market with watermarks and other security features because? So this means if somebody did have access the best you're going to get is them to snip out things for you. So for instance the manufacturing information for the 2825-2 is similar to the other documents that you can find out in the wild there is only two grades which are Standard Elaboré no chronometer grade. Now the various brands themselves conceivably of change stuff like how the watches regulated. so for instance if you had but you don't manufacturing information he would find out two grades and their timing specification1 point

-

This is beginning to remind me of the IPA discussion. I have my reality and others have theirs. I was taught we all live in the same reality but I'm beginning to doubt it Hell, some people even claim that men can become pregnant, and they are dead serious about it! Anyway, I'm just 99.9 % sure that common printing paper scratches the flat surface of cap jewels so I will just have to make another experiment to make that 100 %. Hopefully I was wrong and we can all begin to use sticky note pads, which seems a lot more efficient than using flimsy watchmaker tissue paper.1 point

-

1 point

-

out of curiosity how do you know it comes in those four different grades? The reason I ask is to look up the movement I get a link like this https://calibercorner.com/eta-caliber-2825-2/ now the problem with the link above is this movement appears to only be found in Swatch group movements. That brings up the problem of it probably isn't out in the wild and it probably only comes in configurations for Swatch group in other words it wouldn't come in all four grades that you indicate it probably came in 2 grades neither one of which you can look at and tell the difference. Oh and if you look at the above link it tells you the balance jewel protection system now it is based on 2824-2 for which I can attach a file the manufacturing information. This is where you get all the technical specifications of the various movements. Where you will see this movement comes in four grades. let's look at the differences for the Standard Elaboré looking through the list which isn't as nice as nice of all of them are together it makes it easier to compare but still balance protection system Etachocs. Pallet jewels you get this Polyruby, epilame–coated. balance wheel will be the most visible you get this Nickel gilt in other words is white colored easy to spot. Then you have differences like they hairspring but you can't visually see that I've even occasionally seen were mainsprings are different for the different grades but you can't see that either now for the Top Chronomètre balance protection system of course different it's Incabloc. pallet jewels Red ruby, epilame–coated. Balance wheel of course visually a pretty gold color Glucydur gilt, blind holes. then basically the difference between these two top grades are whether one gets chronometer certified or not they're basically identical somebody has to take the time to tweak it and then they send it off to get chronometer certified. So otherwise they're basically identical. Also while you're looking at the manufacturing sheet notice the interesting descriptions of balance staff for instance Epilame–coated, flat ends. For all those people who like to aggressively polish their pivots the ends are supposed to be flattish and their epilam coded to keep the oil from running down the staff. Which you never see mentioned in the technical sheets. oh and back to the original question what makes you think the 2825 comes in four grades? I do according to Swatch group it only comes into grades here's the easy way to show you timing specifications complements of Swatch group ETA 2824-2 - Manufacturing Information.pdf1 point

-

Its not harder to observe with adequate magnification. More mag equals more observation of focus points. What you can see at x40 you might not see at x20 , what you can see at x20 you might not see at x10 and so on.1 point

-

Consider water eroding rocks or the soles of shoes wearing stone steps. The softer material wears much faster but eventually the harder material wears too.1 point

-

You think that smearing the crap over the jewel once is going to cause scratching whilst rubbing on wet and dry doesn't ! (Wet and dry is aluminium oxide - as are the jewels, so I did expect some scratching)1 point

-

Really got to see the balance and shock system to tell really, it’s just as @mikepilk tells above. Tom1 point

-

I think the difference between standard and elabore is that standard has no decoration. There is a difference in number of adjusted positions 2 vs 3 respectively. I seem to remember being told the only difference between top and chronometer is that the second has done full certification. this link has more information and might help Joe https://calibercorner.com/eta-grades/ Tom1 point

-

Any choice of magnification will work. Its just about differentiating one depth of endshake or one width of sideshake to another1 point

-

That's smart and practical. Unfortunately, it would require another big investment for me : a stereo microscope.1 point

-

End-shake is an interesting and crucial topic, and reminds us quite a bit about shoe sizes. In my experience, too little or too much end-shake is bad, but as it is difficult to get it to be perfect it's better with too much end-shake than too little. The same goes for shoes. It's better with one size too large than one size too small, but any extremes should be avoided, as it will impede your ability to walk and run.1 point

-

I missed this thread when it was originally posted, so this made some interesting reading for me regarding tolerances and the binding up of pivots in jewels. Something i see not mentioned here would be the addition of another component that can affect the side shake tolerance. And that would be the lubrication between the pivot and jewel. The oil has a consistency whatever that is for the oil used for a particular bearing. Having a thickness to it means some of the tolerance is taken up. The oil's molecule beads whatever has now become the bearings and replaced what was once just a space. A perceived measured minimum tolerance of a dry bearing and pivot has now become less so after lubrication. One reason a thicker oil will slow the movement of components within bearings. I thinner oil may well have increased your amplitude watchie, thinner oil, small molecule beads, more sideshake tolerance Thoughts anyone.1 point

-

Haha, John Cleese's walk is all the more funnier with his ridiculously long legs . Still developing mine after 35 years of study, its almost perfectly silly now, it just takes me ages to get anywhere on foot and when I've had a few pints it practically disappears which is one reason I gave up drinking. Next year I'm seriously thinking of visiting our Watchie in Sweden with every intention of going for walks together. His fast paced marching arm swing is going to be a shit for me to keep up with though, every stroll we take is going to be a major workout for me. Mechanical watches will have to be left at his house while we jolly along. You up for that Watchie ?1 point

-

I've read most of this interesting thread now, but all I can think of is visualizing @VWatchie "moving my arms quite vigorously" Please don't take offense when, in my head, this Monty Python episode is playing:1 point

-

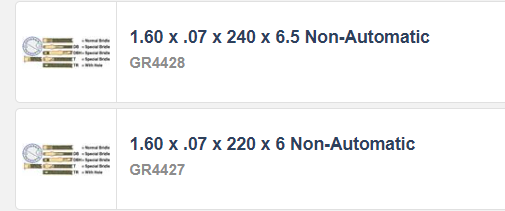

I don't think there was anything wrong with your answer! I used WatchGuy before and I hasn't failed me until this time. Thank you anyway!! go for it! As much confusion as you may try to create ;-), your sources and attachments are always of great value! I always learn. In this case, however, your post is rather reaffirming, not confusing. It confirms that I should go for either of the following. If the 6.5 diameter of the GR4428 fits, perfect. If it's too large, the GR4427 will be the next best thing. With regard to the center curvature, I'll have to cross my fingers. Thanks again!1 point

-

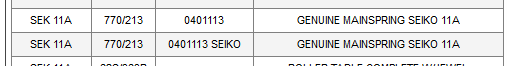

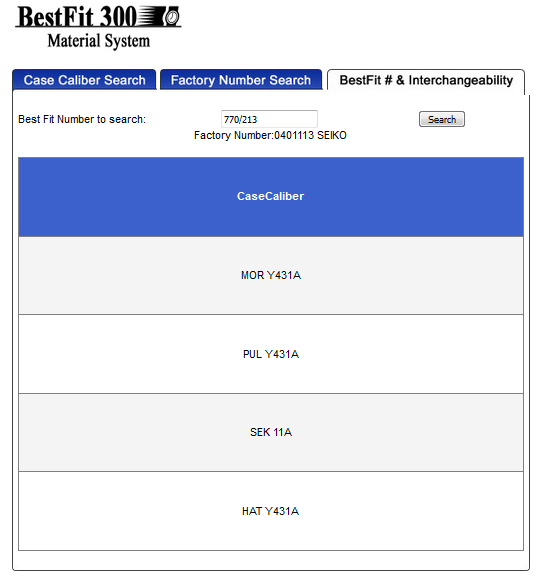

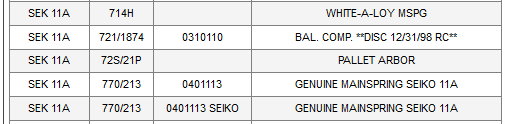

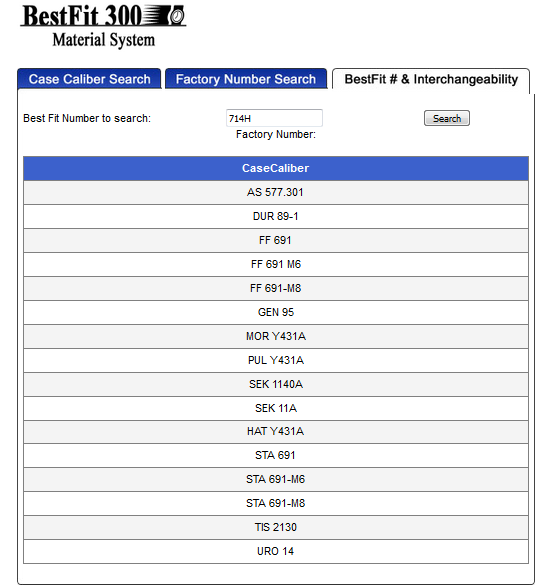

I thought we would have fun and see how much more confusion we can have today. So for this I'm going to bestfit online and we get this. So we get the generic first and then we get the original. The only minor annoyance of the online edition is is no pictures and we don't get a better description of the mainspring but we will get a cross reference first the cross reference of the original number of very few watches using that spring. then the cross reference of the substitute number or the best fit number if you want then what's interesting about the alternative numbers or the MS number is it's basically the Denison size of the mainspring with a letter for the length is brings up an amusing problem but it's not much of a problem bestfit has a different letter than we have up above but there's three springs are probably all work just fine and just in case you don't have a listing of those numbers I've attached something with the listing and a bunch of other bonus mainsprings listed also. Oh and if you want to worry about thing as their other dimensions that are not listed that are really important. Like the center curvature that fits over the arbor if it's the wrong size it's an issue and other mainspring this big it's going to be a major issue to do anything about it you can sometimes squeeze it for mainspring on a pocket watch if you're lucky you might not break it but on a tiny watch it better be right the first time I would look on eBay and see if you can find an original spring. Mainsprings Cas-Kar Catalog 2018.pdf1 point

-

1 point

-

1 point

-

1 point

-

Just to throw a spanner into your theory, I'm sure you have seen clocks with worn pallets and lantern pivots. They are made of very hard carbon steel, which is much harder than the opposing brass parts. Yet the brass parts show hardly any wear. Weird right?1 point

-

Hiya watchie, so i came up with a theory and then i researched it. I think i was sort of on the right track. My theory was that time is a factor in this and both materials would eventually yield under pressure regardless of their hardness. The material lower on the mohs scale is going to yield first how soon that would be i guess is determined by how far apart or how close the two materials are within their hardness to each other. I suppose otherwise a jewel would never wear at all as its the hardest material in a watch. In fact what i understand is happening is that hardness is plastic deformation, the material lower on the mohs scale will deform first but under continuous pressure and continuous could be considered as anything between a few seconds or last for weeks. And is really a proportionate amount of time between the materials to deform based on their hardness relative to each other, so say fractions of a second for the softer one and a few seconds for the harder one. The harder one doesn't deform due to its plasticity but rather brittle fractures under pressure. So the scratches are not from plastic deformation but micro surface brittle fractures. Of course i might have got that completely wrong as well but it sounds bloody clever.1 point

-

1 point

-

On the pars list it’s noted as. Center wheel cock. Or center wheel jewel. If you want the sheet let me know.1 point

-

I could not resist this one and hope that it really looks as nice as in the pictures of the seller. I'm salivating over those blued hands. An Omega ref 730.17 from 1939 with the calibre T17 that was record breaking at the time for it's 60h power reserve. In fact, Omega took until 2006 (call 8500) to surpass this number. It has a nice 22mm (without crown) by 39mm (with lugs) size.1 point

-

1 point

-

Turns out I need a step crystal but able to put it back together after cleaning the case in the ultrasonic with dawn dish soap without messing up the dial. Also able to set the hands and change the day and date after some manipulation. II think rust is in the minute wheel and that may be holding the balance from running more than 4 seconds at a time...some more pictures. The more I look at this dial the more I like the style, probably because it harkens me back to 1975 and my 12 year old self...more pics!1 point

-

Hello and welcome to the forum! The thing about the Benrus series numbers is that they just refer to the case style, not the actual watch configuration or model. Series #3061 denotes a stainless steel “waterproof” case that is designed to hold an ETA 2370-family movement and a domed dial without an additional movement ring being needed. The value comes in as a factor of what actual movement, dial and hands were used inside that case. The “Bullitt” gets its high sales price from three factors: 1) it’s somewhat rare, 2) although it is a civilian watch it has a direct military connection (the same hacking movement as used in the DTU-2A/P as well as a military-style dial), and 3) it appears to have been worn onscreen by Steve McQueen in the movie of that name. However, there were many other models/styles of watches with a non-hacking version of the same movement placed in the #3061 case. The attached photo shows two watches in the #3061 case and one in the virtually identical Belforte #9061. The #3051 case is very similar but with more linear angles on the lugs giving it a slightly different look. The non-Bullitts are serviceable, relatively inexpensive watches that are a reasonable choice for someone to use as a starting place for watch repair practice, but they don’t fetch collector prices. The modern company currently licensing the Benrus name is now making an homage to the Bullitt that they call “The Series #3061” which certainly makes it seem that the series number equates to a model number, but that’s a recent marketing label, not the historical meaning to watch buyers or repair shops at the time…1 point

-

1 point

-

My garage door busted and it is so damn hot here in Texas, I decided to pay someone to fix it. I know I could fix it myself, but at 100F...nope. Anyway, the company I called is a family business (brothers). The estimator came out this morning. He had a prosthetic leg and missing an arm. (guessing combat) He looked at the door and said it was simple...he would fix it at no charge. As he was fixing it he ran into a problem that needed another brother and the service would be $139. Meanwhile, I was trying to find one of the rollers that "plinged" away. I told him, that it was like looking for a "plinged" watch part on the floor. Then I told him I was an amateur horologist. His eyes brightened up! He showed me a picture of a clock on his phone and asked if I could fix it. YES. So he said the service would be free if I fixed his clock. That was a no-brainer. I'll trade working in the heat for working in the cool!! Yeah...I can dig that. The brothers arrived an hour later and the garage door is fixed. He will bring the clock next week. He said that it is slow...like real slow. I figure there is a stripped gear in the movement. It most likely runs off a synchronous motor (Telechron, Sangamo, or one of the others). It will be an interesting repair. The guy absolutely loves this thing. I said I would come get it today but he said that he is having a party this weekend and the clock must be in place for the party. OK...whatever.1 point

-

1 point

-

I have gotten several pies, numerous bottles of wine...wagyu beef, and a few dinners!!1 point

-

One of my buddies paid for his watch repairs with another watch. I decided to go for it. I cleaned his Bulova and Benrus, and he gave me a vintage 21-jewel Timex. It was in good shape, and he was a friend so I did the deal. I've also accepted Pizza, tailoring, and a shoebox full of watch parts and tools. I'm flexible.1 point

-

I've also seen it referred to as an anvil, and I agree with @HectorLooi, it is very useful, I use mine constantly.1 point

-

1 point

-

Wow, crystal clear, and perfect illustrations! Thanks a ton! This is the kind of stuff that should go into your watch repair book (when and if you decide to write it ).1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)