Leaderboard

Popular Content

Showing content with the highest reputation on 07/22/23 in Posts

-

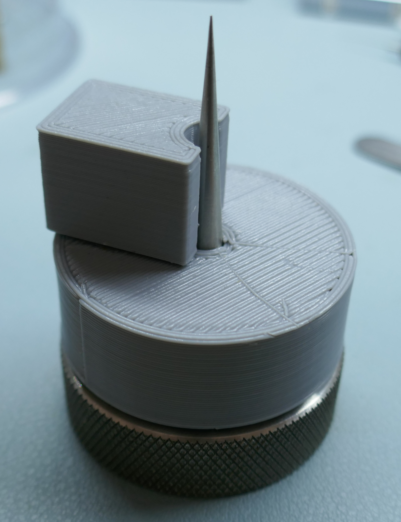

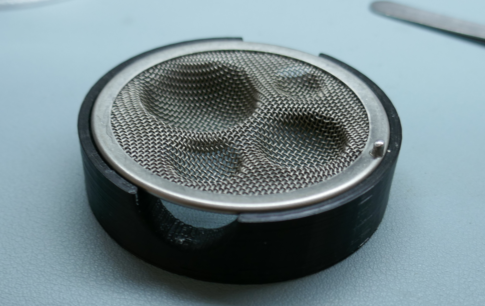

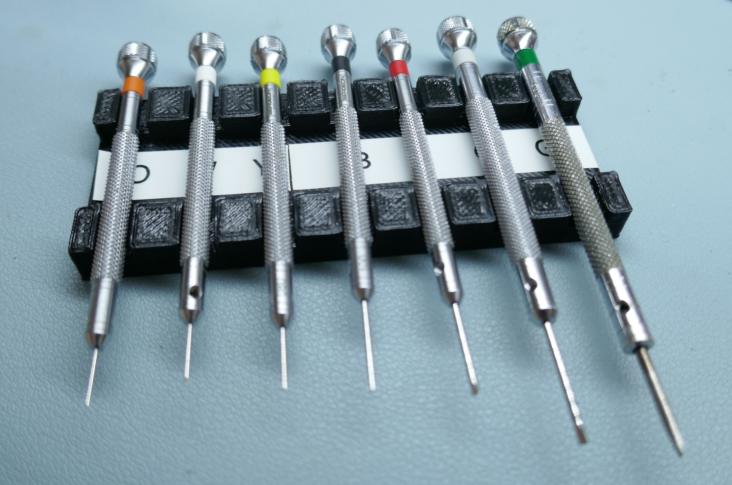

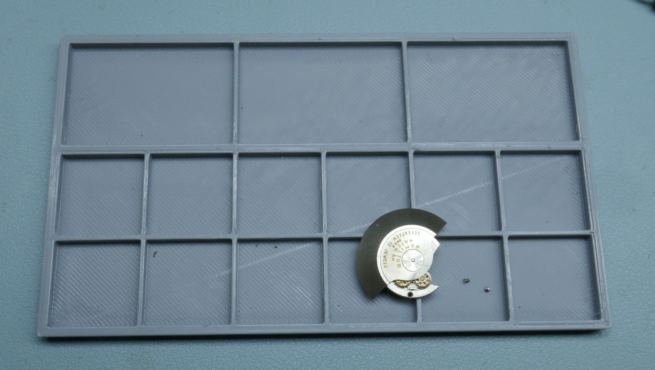

Good Morning from Texas...it is only 84 degrees F!! Cooler than it was during the Cretaceous Period. I thought I would share some of the 3D printed tools I use regularly. First up is my balance tack addons. The 3D printed elements provide support for the balance wheel. Next up is a basket holder for the L&R watch cleaning machine. Some people like the round carousel for holding screwdrivers. Not me. Though not very visible, I have labeled the positions by color code!! Ahhh, gotta have a place for my Elgin M-56b. The other five bottles are in a drawer!! These are various custom die for my BB Crystal Press--very handy. I have the main set of BB aluminum die, but seldom use them. When I teardown a watch, I place the parts in this tray. Each plate/bridge is placed with its associated screws. I do not run screws through the cleaner (unless there is an obvious need), so I will know which screws go with which plate/bridge. Here is one of MANY custom movement holders. While typing, the temp increased to 86 degrees. Yee Hawww!!4 points

-

4 points

-

Just a quick update. I still feel like a beginner. Slow learning but hopefully reasonably thorough. State of play. Working watches. Left to right. First two. Battery changes. Seiko 6309. Full service and parts. Sekonda 2428. Full service Sekonda 2427. Full service Sekonda 2427. Full service (my favourite) I do have many others that are work in progress Seiko's. 6119. 6309. 6319. 7009. 7S26 Citizen 8200 3 Enicar with differnet movements. St69. 2 x AR167 I watches of Switzerland Seafarer. Ross2 points

-

I'm so pleased I joined this forum. You lot make my obsessionality look quite normal! Haloperidol anyone!2 points

-

Haha yes mate thats perfect Engish, i bet even our queen said it once, bless her, you are spot on . Never heard that term Rich but i like it and you are absolutely spot on. Which is a bugger for absolute perfection seekers, the obsession is never satisfied. The trick is not to spend too much lolly on a big all powerful scope or to develop a cut off point where you can think ' yeah its ok i suppose it will have to do '2 points

-

It's called "scale if scrutiny ", nothing is perfect if looked at too closely.2 points

-

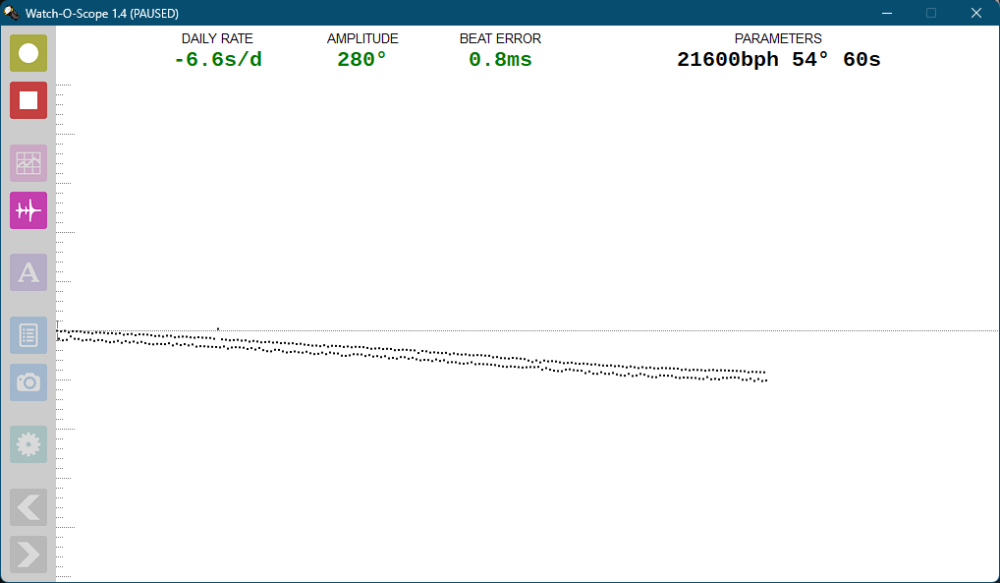

looking at the graphical display again looks like the blue line as a little more irregularities than the other? You might just touch a little more lubrication on the other pallet stone sometimes a pallet stone lubrication issue was show up like this. Sometimes you have stuff like this it also screws up timekeeping. Just depends on how bad it is so we had up with several things pivots were pivot issues anything related that would affect the pivots like to dial-up and dial down not being the same as an issue. Poise of the balance although typically on modern balances there pretty closely poised but that will give you a poising air if you want to get obsessed and looking for other things you should read the manual at the link below I would attach it but it's really big file size was better to give you a link. There are some positions of a watch where the escapement will change things. Conceivably when you have changes you'll have amplitude issues and depending upon the spacing of your regulator pins it will translate into timing issues. this is where you looking for a poising issue you'd want to drop the amplitude down much lower than things like poising issues become much more dramatic on the other hand escapement issues will also become more dramatic http://www.historictimekeepers.com/documents/Micromat.pdf2 points

-

Hello everyone, A friend of mine recently asked me to look at his grandma’s watch which was not working, the movement is an AS444. when I opened it I could not understand why there was no pallet fork. I thought that is why it is not working but looking at the photos I realised there was no where for the Palette gol or cock. I cleaned and lubricated the watch and got it working but I do not understand why it goes…honestly, can someone explain please.1 point

-

1 point

-

I started out before school with some generic "French" screwdrivers, little rotating base with spares in it. In school, we got essentially the same ones but marked Bergeon, little rotating base, spares in it. They seemed a little better quality (the handles), but worked the same. Later, in Swiss school (long time ago, like '99) I plunked down on some Horotecs, the MSA01.201 line, and they were so cool because they had ball bearings in the head. Came in a hinged wooden box, with a tube of spares in it. I thought that was peak tech in screwdriver advancement. They had a little better feel than my old ones, and, they were cool- nobody I knew back in the states had such high tech screwdrivers. Then I moved to Switzerland a few years later, and started seeing what looked like Horotec copies in flea markets, but they were marked "Bob", nice ball bearing heads, pretty much identical. Figured out that Bob had been around a long time (you can tell by the wear on the heads), long before Horotec I suspect. So I got a bunch of those, just to have spares and different ones ground for different things. Some years back, small company I share space with finally bought a set for their lone employee, who is one of the best watchmakers I've met. He was using a set of my old spares up to then. He just kind of stuck a finger on a set in the Bergeon catalog, and they got those. Aluminum handle, plastic head. He was happy as a clam. I think I still have almost all the spare blades that came with my Horotec set, bought some of the smallest ones a couple of times. End of the day, if they are decent, you will be able to work just fine with them. If you are picky, then you will really have to try all the different sets. I bought about 500 bucks of stuff from Slick a year or so ago, and they stuck in a couple of their drivers with alu handles and plastic heads as SWAG, I love them! But not more than my Horotecs, or Bobs, or even my old Bergeons. Whichever one is at hand is A-OK. But they all are in good shape, all the time. You will find that tweezers are the real deal feel issue. For hairspring work, old school carbon steel Dumont or Fontax* are about impossible to beat. For every day work, go for Dumont Dumostar- absolutely worth the jump in price. If you like brass/nickel tweezers for general work (recommended), Dumont 11 or 12 nickel are great. Brass, just about whatever is good. Either way, you will learn quickly how to dress them with a file, they wear quickly. I have Dumont #12s that have lost a good 10-15mm off their length over the years. As they get blunter, they get used for heavier work, and replaced with finer ones for finer work. Same with the fine steel tweezers; one of my favorites are Dumont Dumostar #5 but ground back over time till the tips are like 0.7mm in cross section. *Fontax stopped producing, but they are still active selling off remaining stock. Their Taxal alloy is excellent, about on par with Dumostar, and worth getting if you find some. Also- most folks aren't going to know various makers' part numbers, would be good to include links to the actual drivers/sets you are looking at.1 point

-

This was exactly my concern! After thinking on it for a bit, I finally remembered that I bought a roller table remover stump from Dave's Watch Parts a while back! It worked a total treat. There was some wear on the shaft part, so I assume the parts had galled together. I cleaned it up with a polishing stick, added some grease, and reassembled. It's now setting smoothly! Now time for final assembly. Not too shabby! Edit: lift angle should be 52 degrees, but that's still an amplitude around 270, and a vast improvement from the start.1 point

-

Will have to get back to you on that. Out of time. Anyway, here's the 3M 30 Micron (Grit 600) Micro Finishing Film.1 point

-

I've had a busy morning as we're leaving for holidays packing our suitcases so glad I forewarned my wife yesterday that I needed an hour for my second passion in life She even brought me a cup of coffee as I was experimenting So, the results of cleaning the flat surface of a cap jewel by dragging it on different surfaces is in. Watchmaker tissue paper: No scratches detected up to 40X magnification. Common printing paper: No scratches detected up to 40X magnification. 3M 30 Micron (Grit 600) Micro Finishing Film: No scratches detected up to 10X magnification using an eye loupe. Scratches detected at 20X magnification. Scratch carnage at 40X magnification I can't tell for sure the printing paper I used this time around was the same as the printing paper I used the first time when I clearly could see scratches at 40X magnification (I simply just pick up the cheapest printing paper I can find when I need it). So, it could be that my previous printing paper surface was unusually aggressive. It doesn't sound super plausible but that's the only explanation I can come up with, or as you mentioned @Neverenoughwatches... Anyway, after this experiment I would assess that using sticky notepad paper is perfectly safe. So, I will get myself some and try it out. Until then I'll stick with my flimsy watchmaker tissue paper as I trust it to be 100 per cent safe.1 point

-

It works perfectly, just doesnt look like it would, there is tension between the two locating tabs pulling them outwards. I've not found that anywhere else up to now either.1 point

-

Thank you al for your kind and most helpful replies. I am overwhelmed by your knowledge and willingness to assist and guide a not very bright learner. I am going to take time to carefully study your input and try to be more careful in future. There is a number printed on the inside of the base which 20516. Will post a pickie asap. Believe it or not whole internet thing is fairly new. Most of my life spent in remote parts of Africa. Nearest civilisation was a two hour 4x4 drive away. Thank you all again. Anthony Watson Herewith pickia of the back of the watch. i hope it helps you to help me. Thanks again for your guidance and expertise. Anthony Escott-Watson1 point

-

One would like to think that would be the least significant parameter, but you're likely spot on (is that even English?). I mean you are perfectly right about that. I'm lucky I don't. It would drive me crazy. Never-ending finding imperfections Please do, and I'll see if I can find an hour or two during this busy family day (I've already forewarned my wife and she didn't look too upset ).1 point

-

I forgot to mention. From your description it sounds like it is a floating balance. Just clean it in Ronsonol lighter fluid then dry it with your bench blower. at each end of the balance where the wire goes through it should have a jewel, a tiny drop of oil at each end then move the balance up and down a few times so as to lube the wire, I always used a pocket watch oil, but Windels clock oil is fine for the job. Always use that oil for general clock repairs its the best and it is not expensive. Here is a photo of a floating balance I'm hoping it is something like this, if not can you post a photo of it.1 point

-

1 point

-

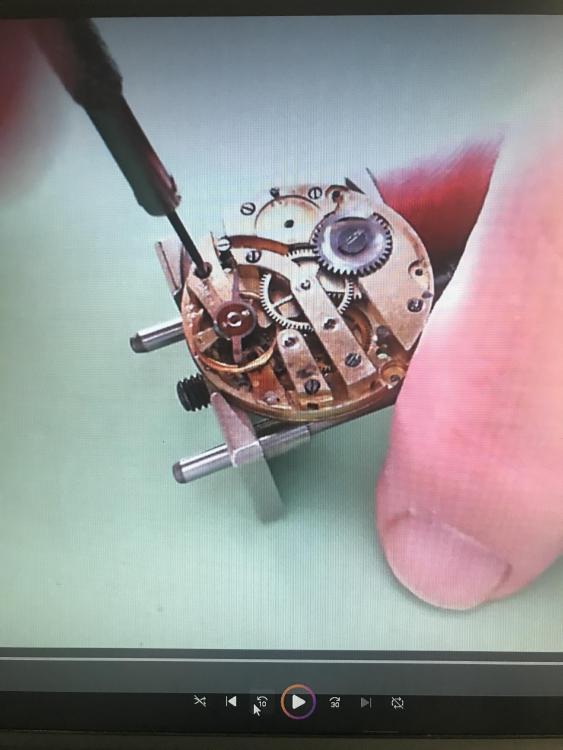

Well, well, well, I thought I had finished my service of the 551...but the seconds hand ruined my day. It's stopping, ticking, jumping all over the place. I definitely bent the pinion spring . I found this video -- indicating the correct angle of the spring. Maybe helpful for others. I'll try to get the correct bend at some point this weekend and will report back. Wish me luck please.1 point

-

We all do things differently watchie and the same test will encounter variables between each of us. The biggest variable will be our perception of the result and our ability to explain that result. Thats not to say anyone of us is completely wrong or anyone of us is completely right. Many experiments even simple ones are subjective unless strictly controlled. We are mostly amateurs here non of us are lab technicians. I've not done any tests as yet, very busy sorting out a million watch parts ( you think I'm kidding ? I'll send you a picture ). My surgical scope achieves X40, different eyepieces if i can get them can boost it up much higher. But i do have good Japanese biological scope that can mag. Up to around X600 with the x10 eyepieces I have. I could see quite clearly see the grain structure of a balance staff. Sometime this weekend when ive had a good tidy up of the watchroom I'll pull it out and crack off some experiments.1 point

-

This is beginning to remind me of the IPA discussion. I have my reality and others have theirs. I was taught we all live in the same reality but I'm beginning to doubt it Hell, some people even claim that men can become pregnant, and they are dead serious about it! Anyway, I'm just 99.9 % sure that common printing paper scratches the flat surface of cap jewels so I will just have to make another experiment to make that 100 %. Hopefully I was wrong and we can all begin to use sticky note pads, which seems a lot more efficient than using flimsy watchmaker tissue paper.1 point

-

1 point

-

I finally got around to ordering a genuine crystal replacement for my Seiko sportsmatic 5 weekdater 6619-8010. It came today and with a little bit of research and having the correct tools got it installed without messing up the dial. I liked this as a daily wearer before and now it really pops and I love it! Probably top 5 of my collection. Aftermarket Barton silicon elite band that is super comfortable. I do have the original/ signed bracelet as well.1 point

-

If the spindle diameter is 8mm (which almost all seem to be), then you can get a new spindle for either 3mm or 4mm pushers from Horia for a reasonable price. A Seitz spindle would work as well, but I don't see them listed at Cousins, just the reamer spindle (might be worth asking if they do have the pusher spindle), or just trawl Ebay until an orphan spindle comes up.1 point

-

Another one of these Star tools, but rebranded, came up on Ebay. Minus all jewels, all pushers and reamers but the tool itself in better condition than the one I bought before. 99 USD. I could not resist. Now wondering if I could increase the bore of the pusher spindles (since I now have two) to accommodate the Seitz pushers1 point

-

That is very understandable. I take back my words regarding childishness. It’s a natural assumption to make on the face of it without context. I wish him all the very best.1 point

-

Genuinely never heard of him, much less do I require a mole to spy on him (Austin Powers comes to mind ). Life is way too short for rubbish like that - some people need to stop being childish and chill1 point

-

I can't tell you much about the movement, but my best friend works at NIST where the signal it uses to set itself comes from. He just designed/made/installed a new FPGA based server for that signal, and will be moving all the servers to his equipment in the near future. If you have something that uses the atomic clock signal, it goes through his equipment.1 point

-

I would agree, the balance looks all wrong, the modern rolex balance is adjusted using a special tool and not a by moving the adjustment arm used in most other watches, so this would either have to be something posing as a Rolex, or an older type. However the older types would not have a spring loaded balance jewel system so this rules out this explanation. In addition to this, the text on the movement is different the "seventeen Jewels..." appears to be etched or raised, but the "...Rolex Geneva" seems to be printed, which indicates to me that this was added at a later date, again to make it appear it is a Rolex. Finally, the movement is absent any decoration (perlage, striping etc...) which I have not seen in a Rolex. I'm no expert on Rolex and (of course) there are exceptions to what I have shown, but this would raise alarm bells if I were looking to purchase it.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)