Leaderboard

Popular Content

Showing content with the highest reputation on 07/24/23 in Posts

-

4 points

-

I have mixed emotions when i hear a beginner call their practice pieces victims. I laugh and then cry a little Yes John we know, if you had your way you'd have the Chinese fit thumbscrews to the Weishis . You are not alone Ross, i didn't start with a new working movement either. When buying something the non working aspect doesn't deter me either, I'm happier having this challenge, it actually forces me to learn and understand how watches work. I can have a watch with multiple faults, i just work through them one by one. Initially my learning jumped backwards and forwards from newbie stuff to some quite advanced, its mostly just evened itself out now. But i do have some criteria that the watch has to fill and i do have to feel reasonably confident that i will make it run acceptable. Certainly a good idea to stick to one or two brands, firstly you can build up stock and secondly you are generally in familiar territory. You are learning the pros and cons of those particular brands, its a bit like cramming for an exam. Instead of bits and pieces of information coming from different brands you are memory forcing information on a focused subject. It relates to watch repair in general but also specialises. When you've done with those brands move on to a couple more. Then its always nice to take a break and reacquaint yourself with an old favourite. Also helps to completely weed out the ones you really hate, no need to punish yourself3 points

-

@Aroxx welcome to the addiction, as Yoda said "once you start down the dark side forever will it....". If I may offer some unsolicited advice, if I was starting out again I would start with a cheap runner to work on, this way, if it doesn't work at the end of the repair at least you know it was something you did. I see the logic in starting with a non-runner, as you have nothing to loose if you junk it, but you will never know if it was possible to repair it in the first place if you can't get it running. The guys on here will help you out with any questions you have, as someone will have had the same issue you are seeing. Good luck and welcome again!3 points

-

2 points

-

If there are manufacturing residues in paper I doubt there are any hard enough to abrade sapphire. If there were a few particles equal to sapphire in hardness, even in some relatively high concentration, it would take some effort to get it to scratch. Calcium carbonate is a common additive, which is abrasive enough to dull steel (why your mom would yell at you for cutting paper with her fabric scissors), but nowhere near hard enough to hurt sapphire. Calcium carbonate= 3 Mohs scale, sapphire 9, diamond 10. I have made hole and other jewels from scratch, using diamond, and it's a tedious process. I know that diamonds are cut and faceted using diamond, and it's a very tedious process. That aluminum oxide causes scratches on sapphire is no surprise... but man, I would hate to have to make a jewel using it! Lens paper is especially free of anything abrasive, and even then there's a less-is-more approach to cleaning lenses. Glass averages around 6 Mohs scale, so harder than calcium carbonate, but that scale is practically logarithmic, so it's a lot harder. I have used a lot of really old cameras and scratches on the lenses wasn't really an issue (degradation of cement or propagation of fungus, yes), but scratches on lens coatings is a very real issue. If you want to get into really hairy territory check out the process to clean a precision front surface mirror, yikes!2 points

-

Thanks all for the comments and helpful advice! I should clarify a bit. I have a small pile of running and non-running movements that I received for free. I did not purchase those with the intent of fixing or to use as a good starting point. Unfortunately, all of my running movements are minuscule ladies calibers that are about the size of a finger nail. Also, I did not go into these movements hoping to diagnose or fix anything. The idea was just to take major things apart and get a feel for working with tweezers and tiny screws and to get a better understanding of how the large components interact with each other. I think I accomplished that small goal and most importantly I had some fun with it. I've already noticed as I read a bit more that I'm understanding the diagrams and descriptions better even from just this small experiment. It sounds like I should just start working on my practice movement next and not worry too much about breaking it. I have this ST36/6497 practice movement shown in my last picture above. I just didn't want to break the thing on my first go trying to do any of this stuff. But alas, I suppose this is what it's for after all. Sorry! Just a bit of self deprecation I suppose since I don't know what I'm doing yet!2 points

-

John. There you go again. It's not often you are wrong, but you are right again. I wish I had done as you suggested. Started to learn on functioning watches. Due to financial restraints I found watches that were in my price bracket, usually 3 weeks savings and purchased them as they were 'broken and would benefit from repair'. I now have 30+ watches of various state of repair, all of which need replacement parts. The parts needed are nearly always the cost of the watches, and haven't prices gone though the roof since I started? If I had stayed on the same make I would have been able to use spare movement parts. I do as you suggest now. Stick primarily to one or two makes. Even then, within the range, many of the watches are not compatible. Still, as you say, I now have a more structured learning curve. Experience brings sensibility.2 points

-

usually the recommendation is something large like a pocket watch but it presents a problem. Basically exactly what's quoted above you start with a broken pocket watch practice taking apart putting it back together hopefully more than one time and of course it doesn't run but after all you're learning you don't care and it was not running in the first place. But are you really learning? the problem with the approach above is it's a broken watch. the problem with a nonfunctioning watch is cleaning doesn't fix everything. So ideally for repair you'd have to make a diagnostics what is the problem, what do you do to fix the problem and when you're starting off that's not really what you should be doing. We should be mastering the art of successfully disassembling reassembling the watch without having issues. So my recommendation is eBay look up 6497 or 6498 purchase the Chinese clone version brand-new. Then sooner or later than I need a timing machine anyway they're not just for timing there for diagnostics either the Chinese 1000 or 1900 are excellent machines. Yes I really do like to torture newbies with the timing machine you wouldn't have to have one but it makes things more fun. So if you have your timing machine and your new watch you can see what the watch looks like on the timing machine. Then you start to practice taking the watch apart put it back together putting it on the timing machine verifying it still looked more or less the the way it did before. If the watch survives this you can move on to cleaning lubrication and continuously practicing taking apart and putting it together. If for some reason the watch ceases to function you can blame poor Chinese manufacturing or gremlins or depending upon where you live you may have cats are really good at playing with your watch when you're not looking other people may play with your watches as these would all explain why you're running watch mysteriously is no longer running. The other advantage of a running watch is it gives you something to look at and it's big. I was you look at how the balance wheel oscillates how the hairspring looks notice it should be flat versus much later on where it probably got stretched because hairsprings love to get stretched and they loved not be flat anymore. so yes you practice on your broken watches but don't have the illusion that you going to fix the thing and it's going to run that might happen but probably not. You ideally at some point time should have a running watch and make sure you take it apart put it back together and it still running. As there's a lot of things that might cause it never to run again far too many to even list. Oh and your Waltham pocket watch were you paying attention to things? I snipped out your image notice how the watches in the setting mode versus the winding mode? When you reassemble the watch your watch is going to try to drive the entire setting mechanism to that's currently in setting mode which is what happens we take the pocket watch out of the case this is what it does. Later watch is put in mechanisms that would allow you to put the watch in running mode or winding mode out of the case. The notice in the image I circled something normally that should be where it is but if you pull it out just a little bit at the although in the winding mode. This is in place there by the manufacturer for this specific task to allow you to run the watch out of the case with the hands and dial on. Although I usually prefer not to put the hands and dial auto watch Toy verify it actually will run for a while. Yes I have a habit of assuming that running watches may not actually run and I hate them all case stopped to discover oh dear there is a problem it's better to verify that they run and they look reasonably decent on timing machine before you even think of casing them up. oh and the other thing in the image below notice the disc with the screw? You want to be really careful if you disassemble less of noting where the parts are noting the spring if you're not careful it likes to fly away. Then in general disassembling the keyless a wall from 10 spew pain anyway because in order to get the stem assembly out there's a screw on the other side you have to take out. In general Waltham's are not my favorite watch and then a course there is the mainspring barrel assembly for this in interesting way of doing things.2 points

-

https://buildingourpast.com/2017/05/10/the-story-of-h-samuel-britains-largest-jeweller/ I suspect this one has more rust than jewels. A gun metal 7 jewel "Herbert Wolf Ltd. London, Liverpool & Manchester" "Magno" pocket watch... in need of a lot of TLC. This is obviously a 404 club candidate, and will need a lot of cleaning and more than a little luck to get it going. I suspect the watch may be roughly the same age as the date of the picture of the shop, some time around 1900 to 1910.2 points

-

The problem we (Amateurs/hobbyists) have is our volume of repairs/ servicing is low compared to a full time pro. As a result replacing a jewel is not a common repair. So IMO spending a large sum of money on a tool that might be used maybe once a year is a waste. When I have had to change a jewel I have used my very old Seitz jeweling tool. It works just fine using care.2 points

-

2 points

-

I don't think paper is the problem, it's the contaminants in the paper that are causing the scratches. In the paper pulping process, maybe bits and pieces of metal from the machinery get mixed up in the pulp and ultimately end up un the paper. If paper was the problem, you wouldn't be using lens paper for cleaning camera lenses, which use optical glass that is much softer than ruby. Maybe lens paper can be used for cleaning jewels.2 points

-

now you just need to make a jewel magnet. I'll be the first to buy one from you1 point

-

This little beauty arrived today! An Omega "tank" from thr 1930s. Cal 12.6 (or T12.6). I love it and its blued hands. It'll be a birthday present for my mother after I service it. It was supposed to cost 200 EUR - already a great price for such a piece, I find. But the seller admitted that it was running 30-40min fast per day. So we agreed on 160 EUR. Since I wanted to service it anyway, I was happy. Well, when winding it, I immediately felt that the mainspring must be broken. The obvious click-slip sound after every 2-3 turns of the crown. Well, I had already ordered a new mainspring anyway Then on the timegrapher... complete snowstorm. So I demagnetized it. And yes! that created some clear lines and at least some output on the Weishi. But running super slow now. When I looked at the regulator, I saw it positioned all the way to R/slow. The seller must have tried to compensate for the magnetism (making it run super fast). Sliding it back to a more neutral position, I was able to get some more horizontal lines. But still wavy. I will report back after the full service1 point

-

1 point

-

Unfortunately I can understand this. We end up with interesting problems here. First off let's look at the winning lottery ticket problem. In other words the probability of this occurring is the same as purchasing lottery ticket it's not like it's never going to happen is just unlikely to happen and you should be aware of it. That is that just because you purchased the watch cheaper or it came in a bag of watches or somebody gave you a watch doesn't necessarily mean it's a worthless watch. Or maybe even of the official watch out of the the trash because somebody threw it away doesn't necessarily mean it's worthless. So for instance goodwill stores I took a quick look apparently their international. People donate lots of stuff with the watches probably breaking into three categories in fact all these watches will break in the three categories. Stuff that you really don't want to repair typically. Stuff that can be repaired perhaps like as 17 jewel Swiss watch something with jewels in its Swiss even Japanese watches but typically a 17 jewel Swiss watch. Then your lottery ticket watch unfortunately it will probably won't be worth millions but still have to pay attention and can't assume that everything is a victim to be Destroyed in the process of learning. Yes there is always the stories of somebody came in once and said they bought a Omega chronograph for $45. Obviously at $45 goodwill recognized it had more value than being tossed a bag of watches. Or we had a Somebody bring in a nondescript square quartz watch a don't remember if it had any fake looking diamonds are not. They traded the watch for a Bulova watch that retail probably for a couple hundred dollars 400 may be of course we would get the watch wholesales of behalf that. So why would we trade is several hundred dollar watch for crappy quartz watch may be because it had that name Patek Philippe. Yes it was a broken quartz watch because it was a gold watch and the name and it was a legitimate watch that's the other problem here there are so many fakes. It was sent the factory of Asheville come back it should be running and eventually we will sell it for several thousand dollars. Personally one of my amusements with this group was somebody purchasing I believe off of eBay an early Seiko watch what didn't say Seiko. They purchased the sheep so now it's a cheap watch they are practicing and they broke the pallet hole jewel because my interpretations basically because I felt like it. No problem is a Seiko except it's a vintage Seiko so it was a problem getting a new jewel. In the meantime I found out it wasn't like a big winning lottery ticket but was a several hundred dollar watch. So having said that there is a tiny percentage of something valuable most of the stuff out there nobody's going to care a few destroy it. But the learning point of view it would be nice if the watch was not a victim and if it would live. It's very satisfying and watch repair if the watch runs after you service cents. Which is one of the unfortunate problems of people like me who work on vintage way getting it to run satisfactory isn't always instantaneous process and its met with a heck of a lot of frustrations. If you stay with something newer 17 jewels not an automatic as you noticed stay away from the ladies watches there really tiny you'll have a better chance of success oh hell on the watches you have in your picture don't have 17 jewels and even though they have screws and they can be serviced they really weren't sort of meant to be serviced and that will probably lead to frustrations. Then ideally this is right. It's hard to get people to practice with broken watches. You often see people wanting to fix their broken watches. And then they and they end up with a broken watch and move on to breaking other watches were not fixing them. Oh and the other thing that people discover who are paying attention the YouTube videos make everything look easy the parts look big very big versus the reality of the situation. Especially if you take apart one of those ladies watches. The unfortunate reality of watch repair all of us a broken things. With time the number of things you break should decrease. Maybe you should think about having fun. Let's break fun in the two categories those things that you're going to take apart and not worry about whether it ever goes back together again or whether it mysteriously falls on the floor whatever were not to worry about those. Then we reach the point of time you want to see something running which watches would be the best to practice on with the hopes that they may still run or will run after you take them apart and possibly clean etc. so is looking at your picture you'll notice I circled some watches I skipped all the ladies watches for the most part. As yes the really tiny. What you want to be looking for is 17 jewel watches basically Swiss would be good a lot of times the Japanese get creative on how they do things but they still has a really decent 17 jewel watches. But I think Swiss would be better to go with a lot of the early Seiko is actually have conflicting Valley especially the non-automatic once and getting parts could be really a challenge versus the Swiss watch that they made a lot of them. Sun damage I circled a bunch of movements in blue and you should take at least one of those apart and try to put it back together again. Notice all of those what do they have in common basically almost 0 jewel count. Plus no jewels is indication of inexpensive they also tend to have one plate covering everything is all the pivots and everything have to be perfect or it doesn't go together. So other than practicing taking apart and trying to put back together and getting a feel for how tiny things are I wouldn't call these desirable watches for practicing for the purpose of running every again. But it's still okay to practice on within the parameters by the way hopefully this is making sense? Then the two watches in pink both of those are 17+ jewel Swiss there may be some others lurking that I couldn't quite see and these are automatic watches. Self winding would be another term that means they add complications. Sometimes the automatic can be removed with a couple of screws other times not but ultimately these we watches it could take apart and put back together either with or without the automatic. So try to remember to have fun. Your approach is right practice just holding things it's typically in the group where people don't want to practice they wanted his dig right in to repair and that's why they need something that's running to find out that accidents happen and you can see that the accidents happen. For the other stuff that you taking apart look at the pivots see that there there see if they're still there later on1 point

-

Thanks for everyone’s help and tips. Got it finished today and now just running it for 7 days or so, to gauge the rate and power reserve. No issues to speak of; the wise words of Oldhippy regarding the softness of the brass plates saved me from being over-aggressive with the reamers! Oldhippy, I did not lubricate the balance, but after reading your tip, I will go back and do it, as the amplitude seems a little low, although it it is keeping good time.1 point

-

Thanks! In my experience, that's the only way to establish the amplitude with definite certainty (give or take a few degrees), and having done this a few times I no longer trust my timing machines all that much. Anyway, TMs are a convenient way to get a rough idea of the health of the movement. I've mentioned it before. TMs almost killed my interest in servicing and repairing. All I could see the TM telling me was "you suck!". These days I always test the watches for a couple of weeks and that will tell me if it's a good or bad (or something in between) timekeeper. The watch I'm wearing today (a well used Raketa 2326.H), and have been wearing for the past 45 days, gains on average of 0.3 seconds per day. When I put it on my TM the TM becomes a real sourpuss who wants to ruin my life. OK, I'm exaggerating a bit, but to clarify.1 point

-

My bio scope is coming out this evening to check all these possibilities. But that sounds feasible Hector, it may be just bad luck if you buy a bad batch with particles that can scratch.1 point

-

This is usually caused by a distorted hairspring. The sudden shock can flex the hairspring until it picks up a bend. If you observe the hairspring at rest, you may be able to see it bunch up more on one side. If you have never done hairspring work before, this can be a harrowing experience. I would advise you to practise on a scrap movement first, until you have gained enough experience before working on your own watch. BTW, what movement are you working on. And if possible, could you post some high magnification photos of your balance at rest.1 point

-

Are you sure you have the correct button for the case.1 point

-

Assuming the stem is the correct one and works with the movement out of the case, is the case to large? If so you may need a stem extender.1 point

-

Off to Mrs Miggins Pie shop for a pie and warm flagon of ale1 point

-

Find a local college or university that teaches graphic design to reproduce the numbers/ letters, then use the lazer printer transfer method.1 point

-

I've been slowly working through my queue of watches and was looking for some other watches to add. I won this lot for about $8 per watch. Two Wittnauers, two Benrus, two Helbros, an Elgin, and a Clinton. I was attracted to the lot by the Elgin. Love that case. Some have some obvious problems. I don't know what the movements looks like yet. Hopefully, these will be interesting projects. The last lot that I bought I was able to make some nice wearable watches out of them, so I have hope.1 point

-

1 point

-

As said , the new hairspring don't neccessarily match with your balance wheel. Screw balance can be slightly adjusted to match the new spring. Is your balance wheel a screw one?1 point

-

Yup...happened to me a few times!! Also watch out for dial screws that come out during cleaning!!!!!!!!1 point

-

Yeah. And always check your cleaning jars and baskets carefully for small parts hiding somewhere after every use.1 point

-

May I weigh in on the Chinese "Horia" tool? (My comments might apply generally to several other types of Chinese tools as well.) First, I'm struck by the amount speculation here from folks who have never actually seen or used the tool in question: the steel may not be good, fit and finish may be poor, durability and precision are suspect, etc. I suggest people considering a purchase take such comments for the unfounded speculation that they are. I have a Chinese "Horia" in hand, and I've been using it extensively over several weeks to practice installing friction jewels and adjusting end shakes. I was impressed with the general fit and finish of the tool as received but, as with many watchmaking tools it did benefit from a bit of tuning. I took a couple of hours to surface and polish each of the stumps and pushers in the set I received. I just cucked the item in my 8mm lathe and pressed a piece of emery paper (first 220, then 600, finally 1,000 grit) against the working surface using the flat face of my tailstock runner. (You could do the same on a drill press if you lack a lathe.) I disassembled the pump pushers before doing this. Then I cleaned everything in my ultrasonic, dried, lightly oiled, and put everything back together. I also took the press apart. Cleaned it and lubricated the screw and the sleeve bearing with Fomblin grease. This gave a nice silky feel to the screw advance. All this took me perhaps 3 or 4 hours. Would the Swiss tool have required similar? Used, I'm sure it would have. New? I don't know. Anyway, having completed this tune-up the tool has performed flawlessly. As to the fact the pushers are flat rather than concave I'd say, first, that in my set of 24 of pushers, about a third of them are so very small in diameter that no meaningful "convexing" seems even remotely possible. As to the rest, after dressing as described I'm confident the faces are flat, or very close to it. In any event, they have performed just fine and I've yet to break a jewel. The press has been accurate: as noted elsewhere, and as with the Swiss tool, you generally must advance the screw 1/100mm past your target depth to account for accumulated lash in the system. Now's discuss the price. I paid $160 US, delivered, for the press and a full set of 24 each, stumps and pushers. For the equivalent Swiss tool, new, US suppliers were asking about $700 for the press and $1,800 for the stumps and pushers. So I paid about 6.5% of the price of the Swiss tool. Let's get some perspective here. What's the worst that's going to happen if the Chinese model underperforms in some way? You break a $6 friction jewel? I can run that risk. Inferior steel? Well how would anyone know without actual metallurgic testing, but what result? It wears out faster? Given that I can buy 10 Chinese tools for less than the price of the Swiss one, vague speculative concern about long-term durability doesn't hold much weight. To me the question is not so much weather the Chinese tool is a good value (I assure you, it's a fabulous value) but why on earth anyone would put up with the usurious prices demanded by Swiss manufacturers. The answer used to be that there was no alternative, but now there are some. By the way, I too am left wondering if the Swiss and Chinese tools perhaps come out of the same factory in China. My understanding (possibly incorrect) is that to be labeled "Swiss Made" 60% of the value must originate in Switzerland. Given how inexpensively the Chinese can sell this tool at retail, it seems the Swiss could buy these wholesale, spend a bit of expensive Swiss labor "convexing" the largest pushers and perhaps painting and packaging the press and claim that 60% of the (ill-defined) "value" originated in Switzerland. But I suppose we'll never know . . . Someday I'll get the Chinese and Swiss models side-by-side and report further.1 point

-

Always important to learn from your mistakes like always look for the inner ring before dismissing. Always remember to tighten the dial screws they don't have to be supertight but they have a habit of coming out when you're cleaning the watch depending upon how you doing it. So I think both of these for one of the first things I learned when cleaning watches. Which of course is why we all knew what the ring was instantaneously.1 point

-

1 point

-

Faster? On the disassemble yes. On the rebuild, a little. I'm far more careful. I look at each item removed to see if it has a problem. I look a the same item again before assembling, then check the motion of the movement at each stage. I use tweezers far more gently and pegwood to hold and re-position. Never screw tight on input, only after final check for motion. I am slower as I as trying to use my Digital Microscope at all times. Same working position, as I only use the microscope recording and for visual checks of problems. For this Chronoglide is a great help as 'Kalle' is like 'Mark' in deep explanations on what may have caused the problem in the first place. I do spend a lot of time looking at Youtube videos of teardown and assemblies. These do help. Still a lot to learn. Ross1 point

-

Back to controlled experiments using a jewel sample known to have no scratches1 point

-

.... or you were seeing scratches that were already there because the lighting was different? ( A mistake I made)1 point

-

I didn't know what a floating balance was, I found this article https://antiquevintageclock.com/2016/04/04/floating-balance-no-longer-floats/ Don't know if it's of use.1 point

-

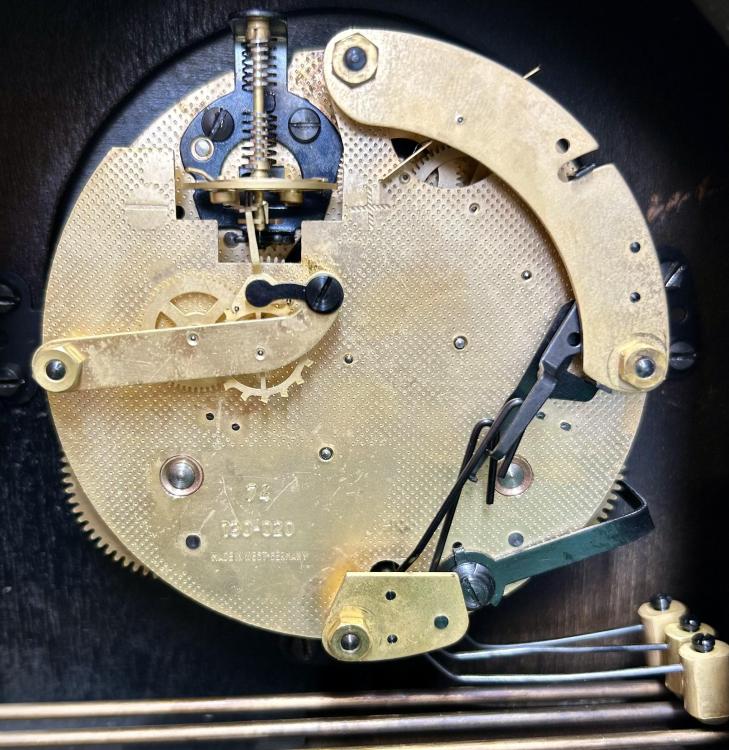

I forgot to mention. From your description it sounds like it is a floating balance. Just clean it in Ronsonol lighter fluid then dry it with your bench blower. at each end of the balance where the wire goes through it should have a jewel, a tiny drop of oil at each end then move the balance up and down a few times so as to lube the wire, I always used a pocket watch oil, but Windels clock oil is fine for the job. Always use that oil for general clock repairs its the best and it is not expensive. Here is a photo of a floating balance I'm hoping it is something like this, if not can you post a photo of it.1 point

-

watchweasol is correct. These movements are not made with strong brass or hard steel so the wear a lot and the springs are to strong for the metal a bad design. You will find how soft the brass is when you re-bush its like a knife going through butter.1 point

-

Hi Moose I think the last one I did the posts unscrew releasing the plate.1 point

-

Do you get any torque from the barrel? American watches have safety pinion incorporated with mainspring, which you can find many articles about in interweb. Manually add power to gears you have easy access to, to check power transmission in gear train. Do all arbours have good pivot and check end shake on all. Your watch will be happy to hear advice from JohnR microphone. Good luck pal.1 point

-

Ah ok thanks steve, yes it makes sense and i did know this . I was overthinking it. Our cheap timing machines are usually calculating amplitudes of lever escapements. The tics and the tocs generated through electrical pulses and magnets or something must be timed differently ? Sound different ?1 point

-

as a reminder lift angle is only of importance to people with those nifty newfangled timing machines they can measure amplitude. so this is why you don't find lift angles for any of the vintage watches typically because nobody was looking at the amplitude with the timing machines how sad the primitive watchmaker not obsessing over amplitude. then yes that's the other itsy-bitsy problem what does the waveform look like on oscilloscope.1 point

-

Well, here goes. The timegrapher when set to 52 degrees lift angle gives a reading of 192 degrees DU. However, the true lift angle is not known by myself as I couldn't find any published information. Also it is not known how the timegrapher reacts to the sound of the electronic balance. So I used the slow motion video technique to see how much the balance actually moves and found that it moves 300 degrees either way from its rest position. A good read up on the technique is here: https://adventuresinamateurwatchfettling.com/tag/el-370/ Hope that makes sense. Steve1 point

-

Good day, finally finished this LAMAR which was part of a lot of 16, so worked out at £2.32 and well under the 404 bar. The refurbishment went well once I cleaned away all that rust (probably why it was a non-runner) and I was lucky that the dial was in such good shape, here are the before and after shots: And here is the finished item, I was going to re-plate as the case was pretty beaten up, but the nickle under the original plate came up well so decided to keep it that way as I actually preferred it as silver rather than gold: My only complaint is that it has a very loud tick even for a pin pallet.1 point

-

oh dear you shouldn't have said that to this group. I would suggest finding the nearest fallout shelter and hiding until it blows over. You might think of hiring a bodyguard for a while. in the meantime I'm going to have a laugh about this and wish I had done it as it was a beautiful thing to say.1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.e1737221d1bb91b37331a627546ff250.jpg)

.thumb.jpg.ba6d481254264bd50946c298d6ee3cc2.jpg)