Leaderboard

Popular Content

Showing content with the highest reputation on 07/28/23 in Posts

-

Ross you never know my friend, i always wanted one of the Dirty Dozen military watches, there probably isn't many that have survived over the years. Not many for sale and when they do come quite pricey. Then one practically fell into my lap one day after a discussion with someone about them. It happens Ross, from what i know about about you, kind, helpful, polite, caring all round decent sort of bloke ( much like myself , if someone says yeah right there will be trouble ) If the universe knows you want a Rolex and it thinks you deserve one, then believe and one will find you all by itself, hang in there and keep being you x2 points

-

I got a 12" wide magnet with telescoping handle at the local hardware store. It is meant for picking up nuts, bolts, washers, and other hardware. Works great on finding steel watch parts. I don't even need to get down on my hands and knees. Just telescope out the handle and sweep the floor with the magnetic head. https://www.homedepot.com/p/Anvil-Telescopic-Magnetic-Pick-Up-Tool-95212/3009987362 points

-

2 points

-

Spurred on by the folly of others, I decided to do some follying of my own......... DIY Watch Cleaning Machine1 point

-

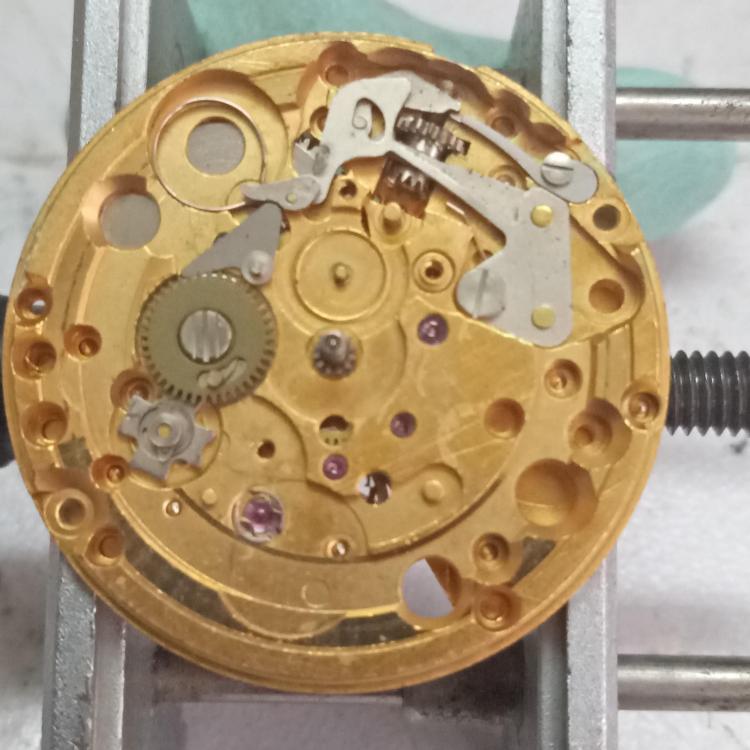

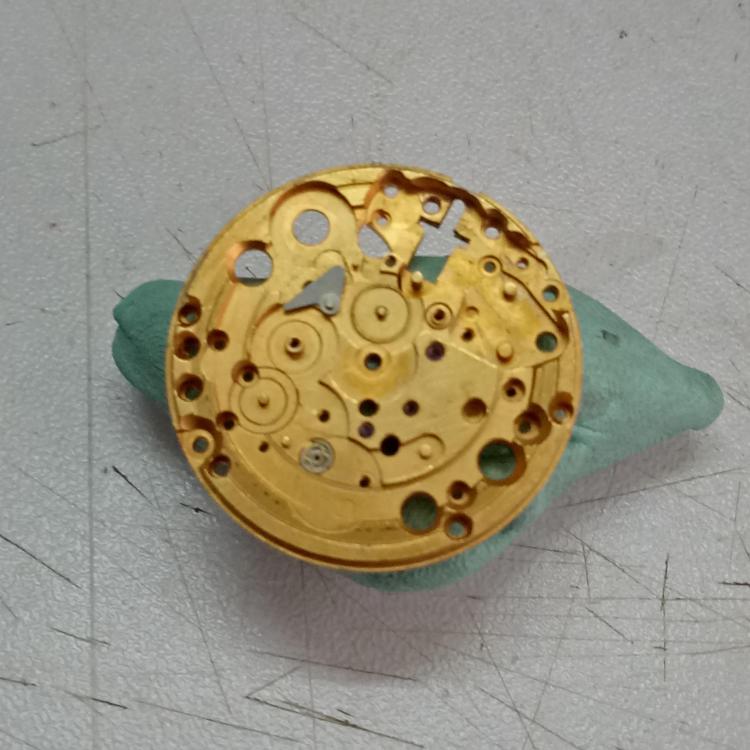

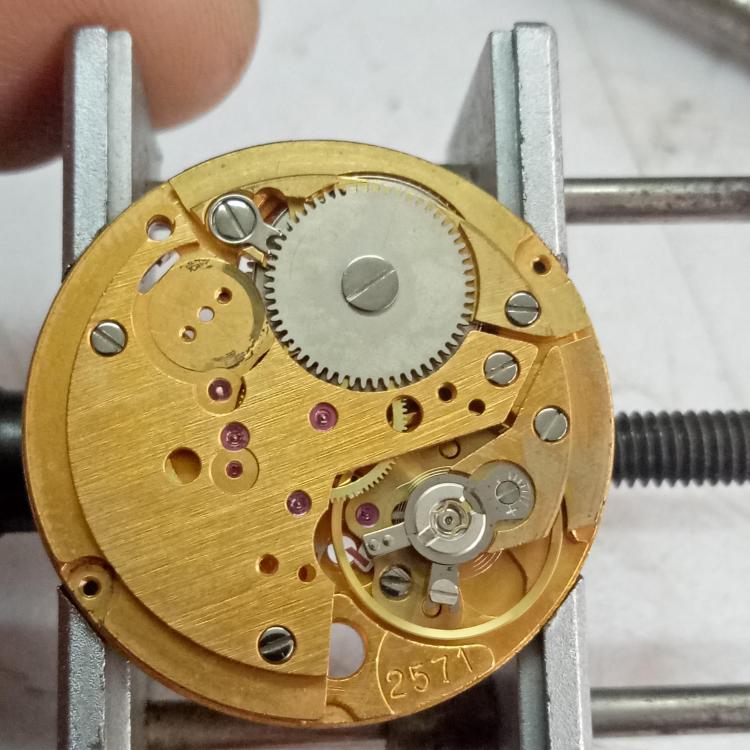

Hi guys, Started to work on the Tissot Seastar I posted below.. I received this watch at my weekend home and didn't have any tools handy so I started on cleaning up the case. (I borrowed the use of a case-back opener from a local store). Here's how it looks in the beginning, You can see that the chapter ring is separate and has come adrift. Beginning sanding with some fine sand-paper.. I started with some used 1000 grit.. And progressed onto finer grade. Getting better.. autosol is my preferred polish..they key is to keep using fresh polish paste and move to a fresh area on your cloth. Otherwise you'll be polishing plastic with plastic. The bezel cleaned up but theres a lot of scratches...way better than before though. You can see some scratches but with the naked eye its not too bad. That'll do for now. One of the lugs had seen some damage. A little light tapping had it looking better, here the springbars and case have been cleaned and the bracelet installed. I may get around to polishing the rear, more to get the scratches off but I may remove the engraving. I'm in Malaysia and Hebrew words won't help if I decide to sell it. Hands and dial are pretty clean. Looks like the case kept all the dirt on the outside, kudos to Tissot. A light coat of dust. At first glance the movement is nice and clean, it tries to tick .. hopefully a clean and service will see it right. I'm a bit cautious with these Tissot movements as I have had a few problems with these movements (2571). For one thing the centre wheel pinion where the seconds hand goes is quite fragile. I have broken a few.. probably because the hand-puller was not absolutely at right angles... but I dont have this problems with other watches!. Also the I have broken the Inca spring on a few Tissots but never on any other brand of watch. (KIF are another story!). Perhaps its just co-incidence but as a result I remove hands and balance jewels with extra care! coming up.. servicing the movement. Anilv1 point

-

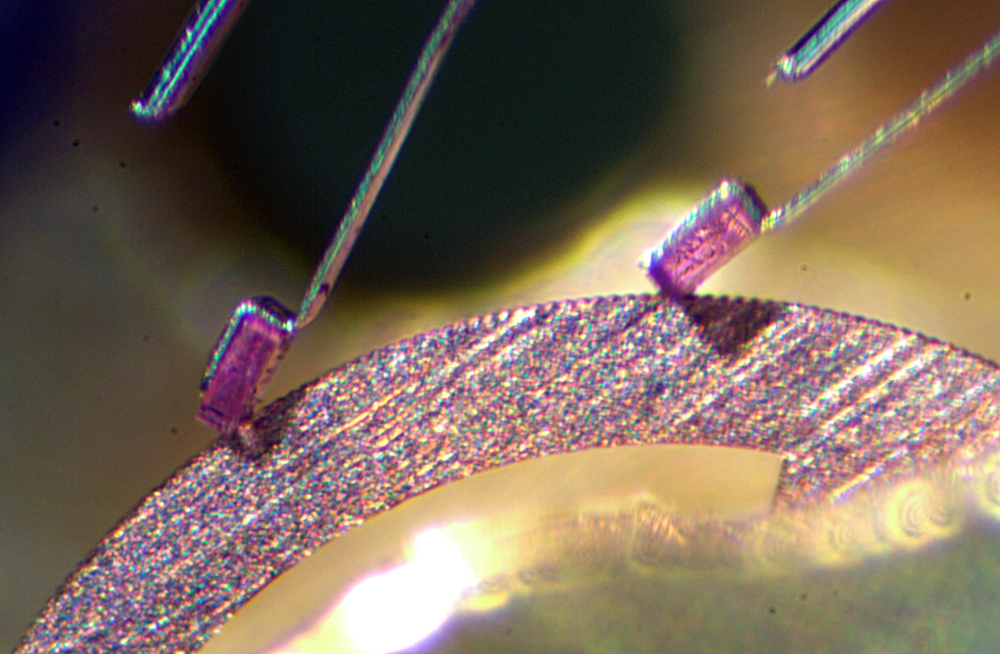

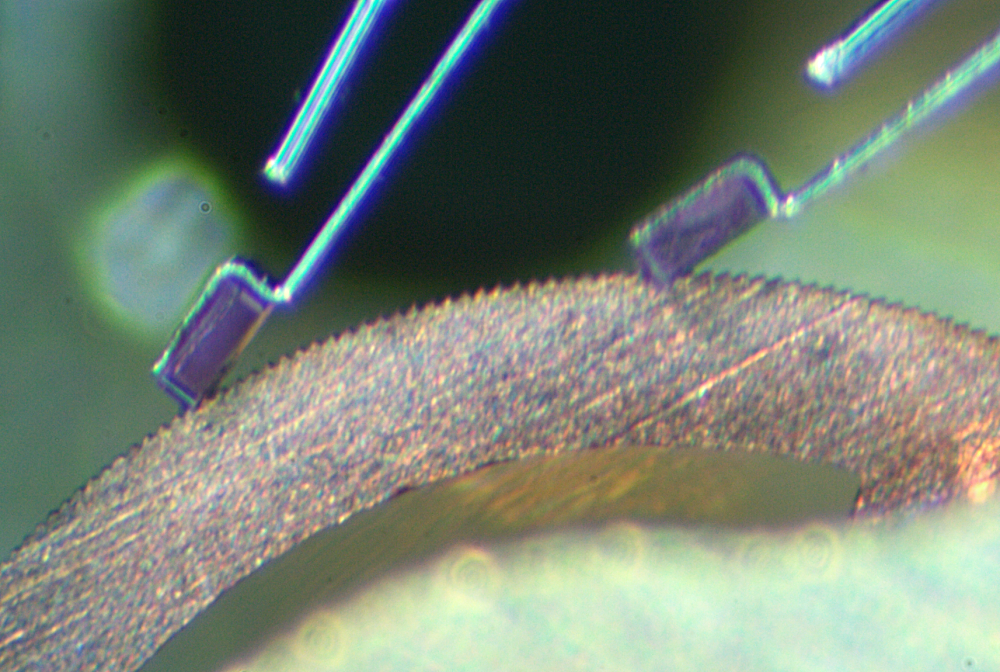

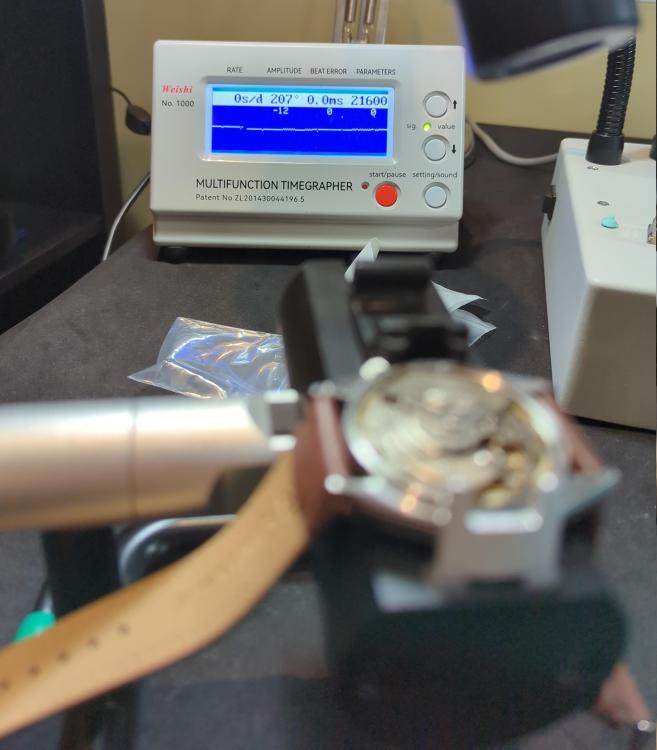

New forum member @ChrisMcKeith saw my previous thread about fixing the electronics in my 219 movement and was foolish trusting kind enough to send me his to work on. It's been an interesting journey and I thought some folks might find it useful or interesting. The capacitor, resistor, and coils were all within spec, and a little pluck got the fork humming, so we were off to a good start. Full tear down, clean, oil, rebuild. Got to break out the Horia clone when the second wheel jewel surprisingly popped out of the main plate. After depthing the wheel, I inly had to tear it down twice more because I forgot to put the hacking lever under the train wheel bridge...then forgot to put the fork under the train...good practice, I keep telling myself. Then I started phasing it. Adjusted the tension on the index and pawl fingers by the manual, applied voltage from my power supply, and it ran...for a half revolution of the index wheel at a time, no matter how I adjusted it. After some more diagnosis and manually moving the fork, I had the hunch that the index wheel has some bad teeth. 45x is as high as my microscope goes, but it sure looks like those teeth are rounded/flattened: I compared it to the index wheel on the 219 I have that runs: Seems like a big difference in the sharpness of those teeth. Literally as I took this picture, I got a message from our friend @LittleWatchShop, who generously offered to try re-pivoting the 4th wheel on my 219. Since it didn't work, he's sending me a spare 219 movement! Hopefully we can use the 4th wheel for my 219, and the index wheel for Chris'. The kindness and generosity here does not cease to amaze and delight.1 point

-

This response is not automated, you crack me up (that's American for you are sort of funny, lol). But in the watch realm, what do you call that tool? I cannot imagine I would need one, but... I suppose those who can, do - the rest of us just buy all the gear and stall.1 point

-

1 point

-

You have so many wonderful automated replies, i cant wait to see the toilet break one. An hour up to lunch should be plenty of time to know as much as i do. I learnt it in half the time .1 point

-

Ah yes i can see how that mistake is easily made , the words are so very similar Stick with it , it will get easier.1 point

-

Did I say until I know everything? Oh, no, that was a typo. I meant to say until after breakfast. Thanks for the tool puzzle, it was loads of fun. In general, however, most of these threads go way over my head - so back to my classes.1 point

-

That might be a minor issue I thought threads on stems were metrics there is a website that has a little information https://blog.esslinger.com/stem-tap-mm-size-cross-reference-chart/ Then did you get inch or metric?1 point

-

This is an automated response: Hi, I cannot answer your message just now, as I am in my very important watch repair courses. I'll get back to you just as soon as I know everything.1 point

-

Wow, neverenoughwatches, what on earth is it, and where on earth did you find it? That thing... how big is it? I am with all the other guesses, but what about that needle - like top? Probably the whole thing is not even really a watch tool at all. Maybe it's just me, but is it perverse? If the entire mystery has yet to be solved, then the "insertion" part.... does it blow up the little rubber balls for case back removal, and you are hiding the air tube? Or is it for making those tiny holes in eggs when you want to boil them? Can you reveal the missing part yet? Did you already and I missed it (still early here)? Also - a caliper, a hand inserter, a mainspring winder? Tattoo gun?1 point

-

You were getting warm Ross the main clue was covered, it was just the way you said it had a certain connotation . I can see the similarity and I'm convinced you have the same charm.1 point

-

Well I never? I was half right was I not? Insertion tool ...ish. Good this game innit? By the way Neverenough. Don't know if you have realised. I was a lookalike for Bruce. Lived too far from London to make it profitable for the tv company. Ah well.1 point

-

Aannd we have a winner, good gyime good gyime, Isla can you take Richard to the conveyor belt please, dont forget the cuddly toy now. Aye sir it is indeed. I took a risk as it looked a bit pants on the sellers photo and i thought it might be cheap chinese but there were other items that boosted the sale. It is made by the Farco tool company so it is actually cheap Italian . Chill amici joke. The quality isn't bad at all .1 point

-

1 point

-

Easy peasie UFO section commander's, Earth Pivot Settlement attachment for robust insertion.1 point

-

I have know repairs to do this if the teeth are worn on the clutch wheel, some call it the castle wheel.1 point

-

You pretty well got to be at Picaso level to refurbish a dial or date dial to near perfect.The good news is, date isn't the first that meets the eye when looking down at your watch, sometimes not even noticable at first glance. Avoid the numbers and clean around them, and if your obssesed beware you can easily whipe out the numbers. PS, if your not obssesed then what are you doing here and repairing watches. lol. Rgds1 point

-

Anilv, sorry to resurrect this post but I just acquired a Tissot Seastar with the same movement (actually the 2591 US equivalent). But it came in pieces as the seller appears to have taken apart the dial side to clean and messed up by removing 95% of the calendar day and date wheels printing and seemed to give up. I think all the parts are present and currently looking at the parts list to cross check. But can't find a service manual that shows an exploded view with oiling scheme that would help in my assembly Normally I have the luxury of taking pictures of the disassembly but as I said that it came in pieces. I think your pictures will provide me with enough to assemble the dial side again. Anyone know of an oiling chart or service manual (not the parts list) that could assist? Thanks in advance, Razz. Original dial, case and back, bracelet, hands and signed crown all seem in decent shape and the goings side looks to be intact and free but not running. I can already spot that the seller has the wheel with the 3 lined screw upside down!1 point

-

Another thing you could try is to gently tap in a square broach until it binds within the pendant tube. Then heat the case over a spirit lamp gently to soften the loctite and try unscrewing it.1 point

-

Thanks for the warm welcome! I think what my wife secretly really wants for Christmas is a lathe. I'm not sure it would fit on our shelves though, and it's rather an imposing centerpiece for the living room coffee table. Maybe I'll say we can use it to power kitchen appliances? Blenders, mixers, processors... Although on second thought, since I do most of the cooking and all of the baking in the family, that excuse seems rather selfish.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

I don't think the breaking of your original stem was any fault of yours. Split stems have an inherent risk of breaking regardless of how carefully it's done. That's why when you undertake the task of servicing a watch with a split stem, you need to add the cost of a new stem and labour involved if it should break. I think the little knob adds a little rigidity to the coupling. Without the knob, the joint would be a little wobbly. But I've come across some watches with the knob is missing. I think that allows the stem to be inserted into the pendant tube first and then the key slot turned to face upwards. The male part of the stem can then be turned to face in the same direction and the whole movement can be dropped into position. This reduces the number of times the female socket gets stressed and risk breakage.1 point

-

I'll try check my stem tonight (I'm at the office now and it's 10am in my time zone). I guess the question is: will the stem hold in place firmly enough without the knob (if you file it down)?1 point

-

This set may well have different size arbors on each end of the winding drums. I have an adjustable star set with very similar drums. Worth asking. Also have the watchcraft set that MSB shows, they work ok but dont always fit the size i need.1 point

-

I am German, but this word made my laugh so hard By the way, I'm thoroughly enjoying my Seitz press. I haven't used it for any jewels, but for as many other applications as possible It gives me much pleasure - putting the hairspring collet back on the balance staff safely and evenly: - putting a mainspring into the barrel - closing the barrel:1 point

-

1 point

-

OK people are going to throw rocks at me now....... but the dial was an etched metal with no lacquer etc, so I used water on a cotton bud, carefully rolling it and it cleaned it a little without any damage and I noticed that the numbers were surviving, then I used some IPA, and again everything survived..... then I used some silver polish paste in one corner and and it came up great with no damage, so I thought "what the heck" and did the whole dial in silver polish and this is how it turned out. I decided to stop there and not get the belt sander out. I took it in small steps and would definitely not recommend hitting a modern dial with anything other than water, but I got away with it in this old dial... this time.1 point

-

ll I took a few pictures during the strip and rebuild.. First the automatic weight comes off.. Then the automatic module.. simple enough. Note below that tone of the screws holding down the autowinding mechanism also holds the winding wheel in place. With the automatic weight off the watch tries to run.. Now I flip it over to work on the dial side.. Everything comes apart well. The set lever bridges is intact. The quickset lever is also present, this can go missing as its not immediately recognizable in the parts tray! Back to the other side to get the train and barrel off.. A naked mainplate I didn't get a picture of the wheels.. sorry. Here's a picture of the movement re-assembled. In this case theres not much difference before and after as the case did a good job keeping crud out!. And here's a video.. happily ticking away! Anilv1 point

-

I once solved this issue by putting on a 'double slotted' clip clasp in place of the single slotted, sure, you can't actually use the second notch, but it gives just a little bit extra length, might be enough? https://www.cousinsuk.com/product/fold-over-double-slotted1 point

-

Thats wonderful news, if its to be when you know everything then i shall speak to you in the next life .0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)