Leaderboard

Popular Content

Showing content with the highest reputation on 08/02/23 in all areas

-

Well it all depends what you want to do now you have a lathe I suggest you start by getting a complete set of chucks. You can never have to many gravers, I always used an arkansas stone to sharpen them.2 points

-

I use airline oil which is ISO 22 for my lathe and also for my oil stones and pretty much everything in between. What you have there is exactly the same. Maybe cost a bit more as it is Mobil after all. Here's a vid I made on disassembling an 8mm lathe headstock which might help. I did an assembly one as well2 points

-

You haven't lost the screw, its only temporarily misplaced. Its there somewhere in the vicinity, you only have to find it. Big magnet ! Clear your desk carefully, the surrounding area and check the floor, its there i guarantee it.2 points

-

I think its good to cover all angles of a test. Scratching the jewel with wet and dry was a pretty obvious outcome but I'm sure somewhere it had been suggested that it wouldn’t, so that just seemed like a good place to start. I did try using plain paper from a notepad 3 times on 3 different jewels, i couldn't see any damage at x100 magnification. I thought about metal fibres that may become mixed in with paper pulp, so i tried to mark a jewel with a craft knife blade. After shooting it a few inches across my bench a couple of times i stopped before losing it. Under the same magnification i also could not see any damage. Still might be inconclusive but i do feel reasonably confident to continue with a notepad. The jewel must still be rinsed afterwards. Who would think cleaning a jewel on paper could cause controversy eh ?2 points

-

You have most things you need to begin practising and turning simple parts free-hand. If you want to make winding stems, you will need a filing rest to file the square. That is a centre, not a punch. The first thing would be to strip it, clean it and lubricate the bearings. You will need to keep adding a little fresh oil at frequent intervals, so get a supply before you start. Get some good lighting, magnification and measuring equipment too.2 points

-

This is my Keystone Standard Watch Co specimen. (Not to be confused with Keystone Watch Case Co) It is a 9ct hand engraved case front and back. The Keystone Standard Watch Company was started by Abram Bitner with the purchase of the factory and production of the Lancaster Watch Company in 1886. Almost 9000 Lancaster watch movements had been completed but not sold when Bitner assumed control of the company, and these were sold by Keystone Standard under the Lancaster name. Keystone continued to produce a relatively small number or watches, about 48,000 in total, until their sale to the Hamilton Watch Company in 1891. This watch is one of the Lancaster watches.2 points

-

Just catching this, might be moot by now, but hold up,@dazzystar, hard stop. Don’t buy an Amscope, and don’t try to reason out what to buy instead, because you won’t be able to. Why not? You cannot buy an Amscope because there is no such thing. It might seem like splitting hairs, but this distinction compounds significantly. Amscope does not make any microscopes. Like many other brands you might be considering, it buys and rebrands microscopes made in China. What’s wrong with that? · Reason #1) House brand/rebranded Chinese optics are notoriously sub-standard. · Reason #2) Customer support and product documentation, is lacking. Since Amscope doesn’t make microscopes, it cannot and does not offer a meaningful level of customer support. Example: A brand-new Amscope microscope selling on Amazon for $1000 gets a 1.5 page set of instructions and a dead link for more. Yes, it might get better/different with the various products, but I haven’t seen that, and I’m not going to buy any to find out, either. · Reason #3) Myriad companies also selling the scopes Amscope offers makes informed buying impossible, see below. The various system and devices like visors, digitals, surgical loupes, stereoscopes, watch maker microscopes and more types have surely been discussed here already. When it comes to buying any of them, please keep the landscape in mind. Say we are talking about handheld digital microscopes offered on Amazon. That’s where a great many people start. Maybe $13 on the low end and $100 on the high. When placed side by side, the two scopes and everything in between look the same. Read the specs and still…very similar. Scrutinize the photos, read the reviews and ask for recommendations, and really, you won’t see much of a difference. Nobody can make the best decision when information is grossly lacking. It is very possible to get the exact same microscope for $13 and/or for $100, because of Reason #3 above. This example can be recycled for other systems, like visors or stereoscopes. It’s bewildering. You can research it, price check it, get reviews, ask others, download specs and buy it, but chances are very high that you won’t get a good system. I am writing this long post because I really want others to have a good system – a system that enhances the experience, accelerates the workflow, brings the “aha” to the party and pleases the user. On the flip side, nothing just fits, nothing is smooth, things slip and only come into focus briefly, sweat and condensation and other plagues can make a person swear the whole thing off, move to the next hail-Mary. I don’t want that for anyone. I can’t tell you what to get but I can give some guidelines and tell you what I do. Forgive the generalizations, but my 30 years of professional experience with these systems is hard to synthesize here. · Don’t buy Chinese optics. Buy Japanese, German or Swiss… to keep it simple and real, let’s stick with these. The difference is in the glass and the finish. · Even if you can afford a brand-new high-end microscope, I would suggest you don’t if you are a beginner. Buy top quality but buy used and old, and buy cheaply. You might be trying out a few types. · I expect to have pies thrown at me for saying this but stay away from visors. Neither I nor anyone I have ever worked with has been able to get the danged tensioning adjusters on the headbands/straps to stay put and we have tried our best. That means things slip, which is compounded by the fact that one sweats anywhere straps contact skin. Furthermore, those interchangeable lenses and short working distance mean you will spend a great deal of time flipping things up and down, moving plates in an out, and wiping the sweat and sometimes condensation out of the way…then dealing with hathead once…. Just don’t, please. · Don’t buy on Amazon. While quality microscopes are available there, they will not come up in a search for microscopes. To get there, you’ll need to know the exact make and model you are looking for. If you knew what you wanted, I doubt you’d be reading this post, and you would not be looking on Amazon, because the prices are far too high. Here is what I use. Disclaimers: I cannot anticipate what will work for you, and I don’t do the same things to my watches that I see other people here doing. Like, I don’t use a lathe, I don’t vibrate hairsprings and I don’t count the seconds in a year. But: · My digital daily driver microscope: Dino-Lite Premiere 4113, a Japanese handheld. I like all Dino-Lites. They do look like all the other handhelds, but they are not. I might not have tried every brand (or maybe I have) but Dino-Lite is my choice, light years ahead of the pack. The software alone would be worth the cost. Output is to a Surface Studio 2, which is a big desktop I cannot recommend highly enough. · My stand: I often just hold the Dino-Lite for quick looks. Or I tape it to anything handy for repetitive fixed focus work. The focal range is phenomenal, which gives me whatever working distance I want. If I need to vary the focus for whatever I am doing, I tape it to my Bulova 9020 (see next), and hijack that worthy stand. · My non-digital daily driver: A Bulova Microloupe 9020, for watch makers. Mine is magical. Despite the fact that a tenth of a turn on the focus knobs moves me from fuzzy to focused and back to fuzzy, and even though I am on my own with respect to illumination, I am addicted to that moment of focus, and keep it there for the session. It’s like dropping in from elsewhere, straight through the looking glass, instant clarity… perfection, really. I never fail to find my bliss there. Ahhhh. Other notes: Stereosopes? Sure. Not daily, but they are handy. I again recommend buying used. Nippon Kogaku KK and what it became, Nikon, tops my list, and it’s what I use today. I also like AO, and sometimes old Swift. I like the models made in the 70s, generally speaking, What does any or all of this cost? I am out of time, send a message if you have questions. But my setup above – exclusive of the surface 2 – cost me about $400. It takes me a long time to find what I want, I stay on top of auctions until a fluke or lucky day happens, but I am patient and wait for those killer buys. Good luck.2 points

-

I've used ST36 watches for four years to teach to beginners, so must have gone through about 80 watches/movements and find them a good choice for the money. I buy them directly from Hong Kong and China. The students work on the same movement for three months and still have them working within Chronometer standards. Seriously. these movements are that good to adjust and regulate in my experience and opinion even having them taken apart and put together so many times. I've come across two broken screws in all that time and a couple of movements had some issues. Maybe a 1 to 2% fail rate, but those can still be used for spare parts. I'm not disputing the BHI findings, but they aren't all made in one place, so quality is also going to differ from supplier to supplier. China is a big place! I've never seen wear like that on a clutch (sliding pinion) in the BHI picture, on any movement I've worked on and there have been many! As they say, 'One swallow a summer doesn't make'. Granted, the lyre springs are a bit questionable, but from that fault, they learn how to push out the main plate Inca setting enough to replace the spring as though it really was a captive spring like an ETA 6497 and also disassemble the whole balance assembly to replace the balance lyre spring in the correct manner. If someone asked me what watch movement to first work on, it would always be a fully working movement to understand slowly how a big movement is meant to work to its optimum. Working on 'scrappers' is great for manual dexterity skills, but frustrating, as already mentioned, if you think you're getting it going with little experience and knowledge. It can make watchmaking really unenjoyable, self-defeating, and with nothing to show apart from broken parts in lots of pots. I was first shown and taught old pocket watches that had 80 years of tinkerers before me playing and fiddling with them and only found my passion again in wristwatches that worked or I could get working and find parts for. I'm not slating pocket watches, I just think they are niche for some rather than the mainstream. A working movement will better teach a student how it works, why it works in that way, the optimum end shake, side shake, amplitude, etc, and when it doesn't work in that correct way later down the line or in other movements then one is more experienced and knowledgable from the working movements to now remedy the ailing ones.2 points

-

1 point

-

I would have thought about £250. If you do decide to have it serviced make sure it is cleaned by hand and not in one of those ultrasonic baths as they can harm this type of movement.1 point

-

1 point

-

1 point

-

1 point

-

ISO 68 is much too thick (though it would be good for the slide rest if you get one). Something between ISO 10 to 22 would be fine.1 point

-

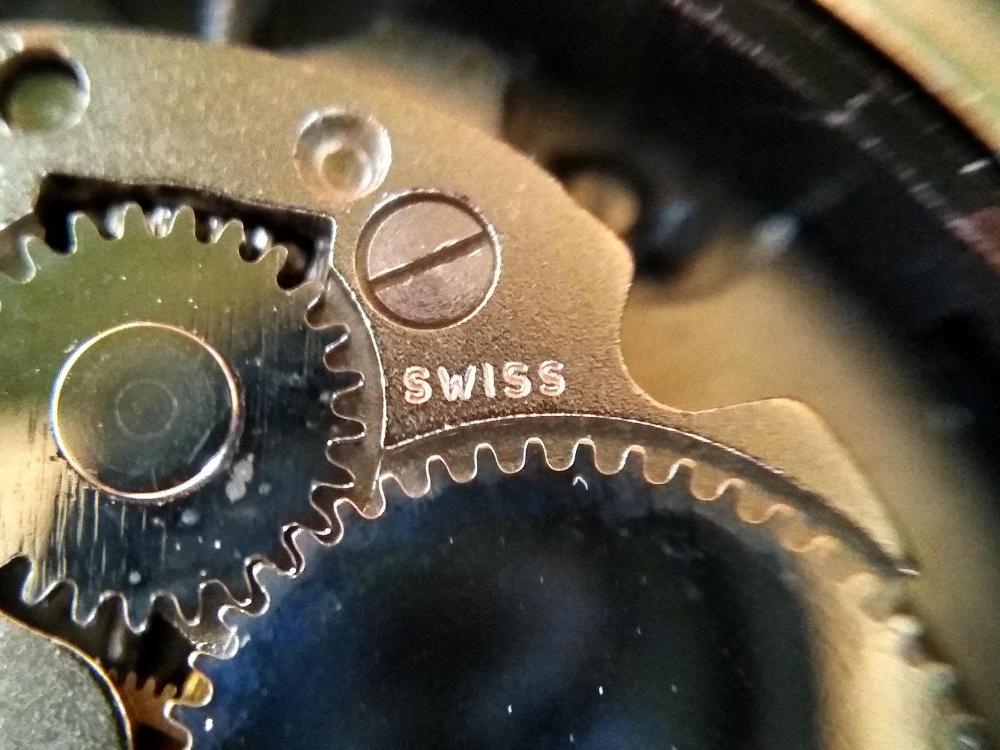

After working on it for a few months I've think it's time to create a specific thread about the Ingersoll Sealion that @Johnnie offered me on that thread here. I already had made a custom bezel for it, as neither Johnnie nor me ever found anyone available on the web, but I had made it a little too "aged" and to "orange" so it didn't really matched the color and condition of the dial. So yesterday I've decided to redo that bezel and, while there, do some more renovation work. So I've dismantled it once again, polished the case, crown and caseback a little more, used some toothpaste and polywatch to get a nice clear and shiny plexi. After polishing the caseback I took a close picture and saw that it certainly had, at a time, some brushing on the flat part which is engraved ... so I've decided to try to redo that brushing and here is the result ... CASEBACK AFTER POLISHING CASEBACK REBRUSHED After casing the movement and before putting the caseback on, I've took some pictures of the Ronda 1217-21 movement ... RONDA 1217-21 INGERSOLL ENGRAVING 1217-21 MODEL ENGRAVING SWIIS ENGRAVING ... so that movement is definitely Swiss And the nice Ronda star with RL inside ... probably meaning "Ronda Lausen" And now today's wristchecks ... showing the "finished" watch with it's new bezel, less aged and more reddish ... Maybe some day I'll dismantle it again to redo the lume, which is almost "dead" ... of course if I do that I'll take care to make the lume really low, as it should be on a 43 years old watch ...1 point

-

Sigh. I just love a happy ending, and it looks so nice. I'm curious - what did the movement look like when you started?1 point

-

1 point

-

For anyone intending to spend long hours at the workbench, like aspiring watchmakers, don't take this advice lightly. As a dentist for 36 years, I can attest that bad posture can be detrimental to your health. At the age of 36, I was diagnosed with cervical, thoracic and lumbar spondylosis. It was only after many chiropractic sessions and back traction that my condition was managed. But it left me with reduced stamina and had to cut down my working hours. There were good days and bad. On days that the back was killing me, I was grumpy, irritable and bad tempered. If you find your dentist like me, please understand that it could be due to back pains and mercury poisoning. @Neverenoughwatches, If you wear a pair of overpowered reading glasses beneath your loupes, you can reduce the working distance by a few inches.1 point

-

Knowledge is never a burden, and it's fun to explore and learn about the physics of the world we're living in. So, I commend the efforts to experiment and share the experiences and observations made. Anyway, for cleaning the flat side of cap jewels I'd recommend watchmaker's tissue paper. It is simply unnecessary to take any risks, like using common printing paper (although my own experiment indicates it's perfectly safe) when there is nothing to gain from it except for perhaps a bit of convenience.1 point

-

Have a look at this http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&2&2uswk&Poljot_3133 It is a useful database for many movements, including hand sizes, mainspring sizes, balance staff, etc. If you go on Cousins website https://www.cousinsuk.com/category/filter/eta-parts-search It will say the spring should be 0.14 thick. This movement is in effect the same as a Valjoux 7733. I fitted a 0.14 spring into a Valjoux 7733 this week and got 350 degrees in amplitude and bad knocking, so that spring was way too strong, by a strength (0.1 mm) The spring needed is 0.13 thick as quoted by Ranfft1 point

-

1 point

-

Hi Hector, I thing the question hangs on the quality of the clock. On many a good clock I have seen pin punch marks round the pivot hole in place of a bush. Not nice. There are many cheap clocks just not worth bushing but clients want them working and hole closing is the cheap option as they do not want to pay for bushing. Probably more than the clock is worth but closing the hole is an alternative. Again some plates are so thin bushing is not practical due to lack of metal. Yes I have closed holes to make them work but only after explaining to the client the options.1 point

-

I can respect the creativity on this one and I'm grateful for the laugh I just had. But this one is just crazy. Also imagine the amount of force it would need (at least compared to the "other way around"). The guy must have beaten it like crazy. Still, impressive actually that he managed to deform the arbor without completing shattering it.1 point

-

Absolutely it is doc, i raid my neighbour's recycled bin for them. And yes i find the chainsaw greatly speeds up the process of shaping custom parts. And no i don't give out my address to strangers. When I've broached and I'm not entirely sure this is a practised method. Broach until the arbor can just be shaken out of the hole. Then test with the arbor and barrel held between tweezers by the barrel and use a blower to spin the barrel. Its a good indication of freedom. When broaching mark the broach with a fine felt tip to help gauge how far you are opening up and broach each side of the hole equally to minimise any taper . That way you should end up with a peek in the center that should wear away quickly and leave a fairly cylindrical hole.1 point

-

1 point

-

Since I began this, ever so enjoyable hobby, I have been spending my limit each week. Over a year now and I estimate that I have exceeded my allocation of £10 weekly. I think I am at about £600. However I am getting experience but still rate myself as a beginner. Using the various avenues of self help, YouTube and this forum I am now able to successfully service watches belonging to others. Provided they are working when I get them I can do a good service by achieving a good clean and lubrication. I have limited myself to regulating the watches by using a TGBC microphone for android and pc together with TG software for pc. It does not work well unless the watch is in a case? Time has passed and savings now allow me to purchase an item that most people have said is essential. My timegrapher will arrive next week. Woohoo! I feel like I made it. My Proper apprenticeship begins.1 point

-

Recently bought a new mainspring from Cousins for a Seiko 6309 (spring code GR2534X). Had to wait a while as this was new stock arriving. This is the spring their database says is for this movement. Having fitted the spring the end was far too large to fit the arbour and would not wind. Tried tightening but the end of the spring broke off. Has anyone else had this problem? The spring is clearly not suitable. Is their an alternative that anyone has fitted that works? I ended up using a spare I had but it would be nice to know what others have done.1 point

-

1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)