Leaderboard

Popular Content

Showing content with the highest reputation on 08/04/23 in Posts

-

4 points

-

Just checked and amplitude is at 266° so a 34° improvement from bedore the service/restoration3 points

-

2 points

-

2 points

-

Oh knebo , thanks for asking for advice, but I don't think you need any advice, not in this case anyway. " Bearing of the driving gear is worn and there is clearly too much side shake " I don't see how anyone can locate the whereabouts of a fault better than you already have, so every arbour and hole/ jewel must be inspected and the bad guys fixed. Oh, folks then keep fingers crossed in the hope of see ing improved amplitude. Good luck Pal2 points

-

Just finished servicing a Seiko 5740. The first watch I've done which was working (after a fashion) before I touched it. It had a 2.3ms beat error which needed to be addressed, but was nervous because 4 movements ago, my screwdriver tip slipped off the stud carrier (quite stiff to move) mangling the hairspring. After a bit of thought (and a nappy change), I used a triangular diamond file to cut a V shaped notch in the end of a 2.5mm screwdriver blade (a lot more difficult than it sounds) and I have to say, the tip (provided its placed accurately using a loupe) feels much more stable and less likely to slip. Are there any other techniques or tips I need to be aware of? Its not quite Ian Drury, but its close enough!!1 point

-

I may have mispurchased ........ my lathe weighs 800Kg is 1.8m between centres, 0.5m over the bed, runs off 400V 3 phase, so I'm guessing a tad too big! However it does give major bragging rights and more than makes up for my diminutive genitalia.1 point

-

I forgot to attach the Hamilton PDF on replacing jewels in a watch like this. Hamilton technical data 102 improved friction jeweling.pdf1 point

-

You will find at some point you will need to adapt tools when it comes to some repairs, it happens to us all. Part of the fun in having a lathe is being able to make tools for your work.1 point

-

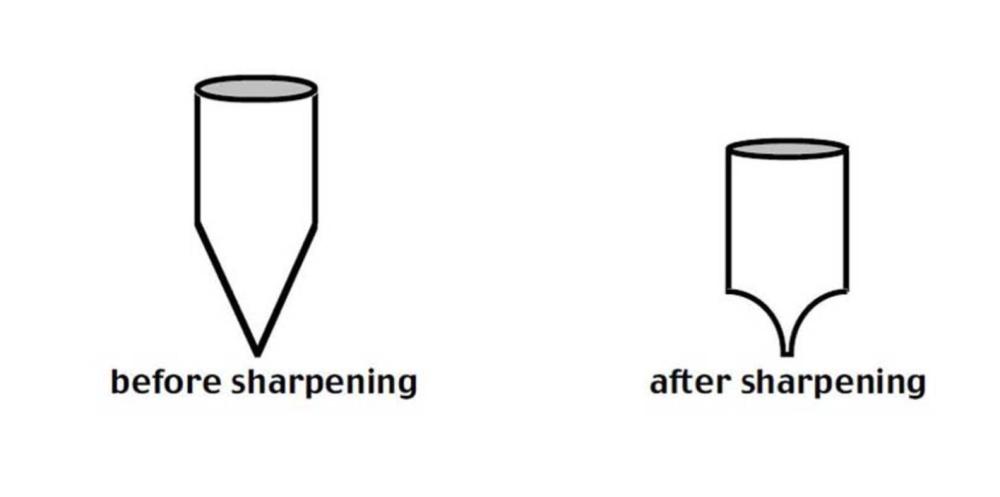

Hollow grinding works very well with chisels and is the natural shape achieved from using a grinding wheel in a vertical position. With a chisel this makes sharpening the edge and subsequent sharpening fast & easy and as Doc says gives the tool an insane edge. Something you obviously don't need to have with a driver's blade. I curiously wouldn't mind having my memory refreshed on the positive aspects of the T profile blade though.1 point

-

That sounds safer than my brute force tool and I'm pretty sure the peg wood would be easier to shape. This is the reason for coming to the forum, field tested solutions which just make sense. Now I think about it, I could have made life a bit easier by using my diamond file to flatten and then undercut one of the screwdriver bevels (across the width of the blade ) as opposed to cutting a notch in the end of the blade, so thats half a "T" True to form, my 2D handwriting is illegible so goodness knows what my 3D printing would look like! My hollow grind woodworking chisels allow me to get a scarily sharp edge quickly.1 point

-

1 point

-

No, sorry clearance is the wrong term- 0.14mm pivot for a 0.15 jewel. 0.01mm side shake.1 point

-

For a pivot that size give about 0.01mm clearance. When you get down to 0.07mm diameter pivots you should go to a proportionally smaller clearance, but at that size 0.01mm is fine.1 point

-

Might need something stronger than one dip to remove that.1 point

-

1 point

-

Hit it Doc your new tool sounds like a good addition. Personally i use pegwood to do this. I tend to prefer wood on metal ( steady boys and girls ) for these sort of applications. My choice here being that steel on steel has little friction and the impact of steel damage is much higher than timber. One reason ive started to look at various timbers for jewelling and staking accessories. Another example is the shaped tooth pick kif spring removal tool compared to purpose manufactured ones. I have a few of those and they can be a bit aggressive on the spring and dont especially grip that well ( low friction contact ). Just throwing other ideas at you matey . We had a good discussion about these 18 months back. The general consensus was # a bit gimmicky and not really practical # I was taken in by the idea but various opinions quickly had me rethink. First thought once shaped to what is known as hollow ground, the blade will only fit accurately one size slot of screw offering lower stability to a wider slotted screw ( slips easily ) The wedge shape blade can grip the slot of more than one size, with much better side friction the main advantage of a wedge shape. Hollow ground blades mean more drivers to accommodate varying screw sizes and slot widths. Coupled with extra maintenance time puts them more into a specialised bracket. The wedge profile is quick and easy to maintain.1 point

-

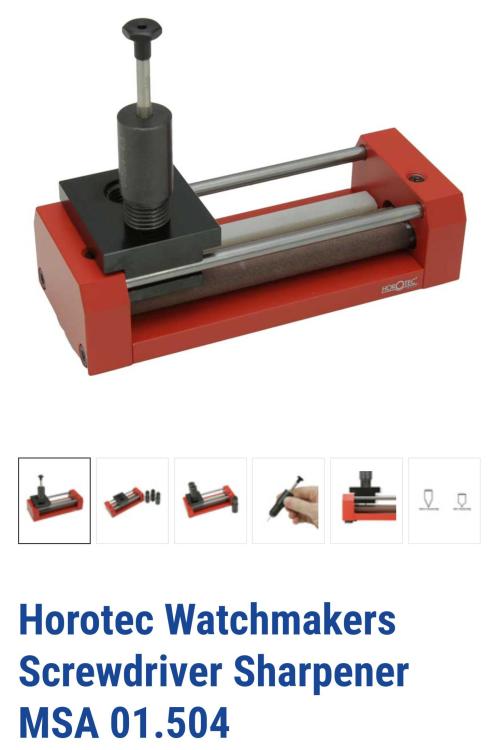

There are T profile screwdrivers, which i am waiting on to try, but the feedback i have seen is positive, see the difference below: They are made with a very fancy and crazy expensive sharpener: The potential good news is that I am designing a 3D printed version of the sharpener, so if you have access to a printer and can wait a week or two (need a new cooling fan for my printer) I can share the files needed to print one.1 point

-

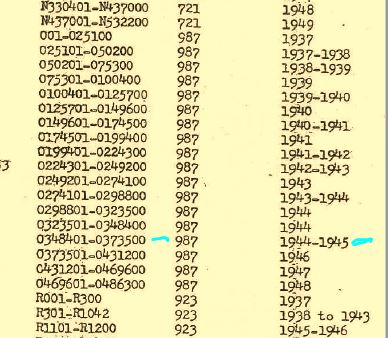

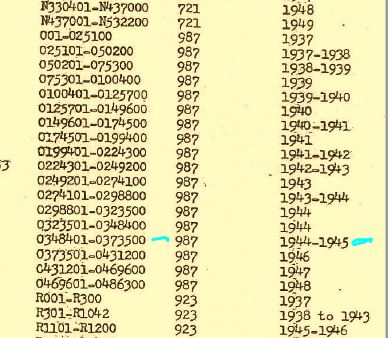

you just need to know where to look and it helps to have a membership in the Association who scanned a lot of the Hamilton records to files. if you look on eBay you'll find military packaged parts for this watch. Did a quick look didn't see the jewel for the fourth wheel but I would keep it on eBay sooner or later the parts will show up or plates or something else. Then replacing the jewel for the lower main plate only requires a staking set according to their technical literature as the jewel is in a setting.1 point

-

I haven't come across this issue myself, and maybe I am over simplifying, but the automatic works interacts with the winding mechanism which interacts with the mainspring (reminds me of the song: the ankle bone's connected to the leg bone, the leg bone's connected to...) which is a key component of the amplitude. I don't believe the automatic works can decouple itself from the watch movement as a whole once it is installed. As @Nucejoe points out you have probably already identified the issue and best placed to troubleshoot. In an ideal world you could substitute the suspect automatic works with another just to confirm beyond any doubt.1 point

-

1 point

-

1 point

-

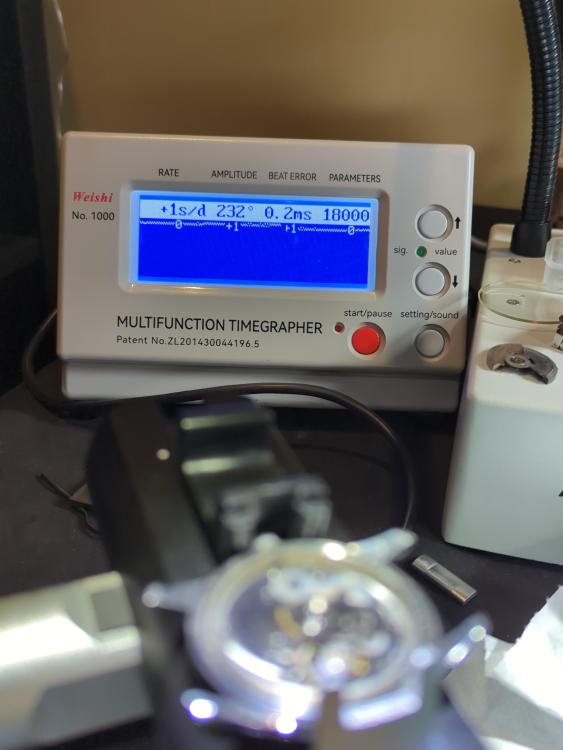

Hi there, I got home early from work and needed a watch fix! Started work on it around 5:00 and then looked up and it was 11:15. This is a Zodiac that I got on eBay and the case was a wreck, strange scratchings on the bezel, the picture below doesn't do it justice. The watch was running quite well and fairly clean inside, well compared to some of the other watches I take on! I took a quick time graph footprint before I started and the rate was +10 s/d, the amplitude was 235° and the beat error was 2.0 ms. After I finished the full service I took the following timegrapher snap: All better, except the amplitude, but this was already pretty good and I expect it to improve over the next 24-48 hours. I worked on the case and got most of the damage out but had to stop before I over polished and changed the shape of the case. Apart from the crystal and strap everything else is original. Here is the finished watch: Let me know what you think.1 point

-

1 point

-

Just catching this, might be moot by now, but hold up,@dazzystar, hard stop. Don’t buy an Amscope, and don’t try to reason out what to buy instead, because you won’t be able to. Why not? You cannot buy an Amscope because there is no such thing. It might seem like splitting hairs, but this distinction compounds significantly. Amscope does not make any microscopes. Like many other brands you might be considering, it buys and rebrands microscopes made in China. What’s wrong with that? · Reason #1) House brand/rebranded Chinese optics are notoriously sub-standard. · Reason #2) Customer support and product documentation, is lacking. Since Amscope doesn’t make microscopes, it cannot and does not offer a meaningful level of customer support. Example: A brand-new Amscope microscope selling on Amazon for $1000 gets a 1.5 page set of instructions and a dead link for more. Yes, it might get better/different with the various products, but I haven’t seen that, and I’m not going to buy any to find out, either. · Reason #3) Myriad companies also selling the scopes Amscope offers makes informed buying impossible, see below. The various system and devices like visors, digitals, surgical loupes, stereoscopes, watch maker microscopes and more types have surely been discussed here already. When it comes to buying any of them, please keep the landscape in mind. Say we are talking about handheld digital microscopes offered on Amazon. That’s where a great many people start. Maybe $13 on the low end and $100 on the high. When placed side by side, the two scopes and everything in between look the same. Read the specs and still…very similar. Scrutinize the photos, read the reviews and ask for recommendations, and really, you won’t see much of a difference. Nobody can make the best decision when information is grossly lacking. It is very possible to get the exact same microscope for $13 and/or for $100, because of Reason #3 above. This example can be recycled for other systems, like visors or stereoscopes. It’s bewildering. You can research it, price check it, get reviews, ask others, download specs and buy it, but chances are very high that you won’t get a good system. I am writing this long post because I really want others to have a good system – a system that enhances the experience, accelerates the workflow, brings the “aha” to the party and pleases the user. On the flip side, nothing just fits, nothing is smooth, things slip and only come into focus briefly, sweat and condensation and other plagues can make a person swear the whole thing off, move to the next hail-Mary. I don’t want that for anyone. I can’t tell you what to get but I can give some guidelines and tell you what I do. Forgive the generalizations, but my 30 years of professional experience with these systems is hard to synthesize here. · Don’t buy Chinese optics. Buy Japanese, German or Swiss… to keep it simple and real, let’s stick with these. The difference is in the glass and the finish. · Even if you can afford a brand-new high-end microscope, I would suggest you don’t if you are a beginner. Buy top quality but buy used and old, and buy cheaply. You might be trying out a few types. · I expect to have pies thrown at me for saying this but stay away from visors. Neither I nor anyone I have ever worked with has been able to get the danged tensioning adjusters on the headbands/straps to stay put and we have tried our best. That means things slip, which is compounded by the fact that one sweats anywhere straps contact skin. Furthermore, those interchangeable lenses and short working distance mean you will spend a great deal of time flipping things up and down, moving plates in an out, and wiping the sweat and sometimes condensation out of the way…then dealing with hathead once…. Just don’t, please. · Don’t buy on Amazon. While quality microscopes are available there, they will not come up in a search for microscopes. To get there, you’ll need to know the exact make and model you are looking for. If you knew what you wanted, I doubt you’d be reading this post, and you would not be looking on Amazon, because the prices are far too high. Here is what I use. Disclaimers: I cannot anticipate what will work for you, and I don’t do the same things to my watches that I see other people here doing. Like, I don’t use a lathe, I don’t vibrate hairsprings and I don’t count the seconds in a year. But: · My digital daily driver microscope: Dino-Lite Premiere 4113, a Japanese handheld. I like all Dino-Lites. They do look like all the other handhelds, but they are not. I might not have tried every brand (or maybe I have) but Dino-Lite is my choice, light years ahead of the pack. The software alone would be worth the cost. Output is to a Surface Studio 2, which is a big desktop I cannot recommend highly enough. · My stand: I often just hold the Dino-Lite for quick looks. Or I tape it to anything handy for repetitive fixed focus work. The focal range is phenomenal, which gives me whatever working distance I want. If I need to vary the focus for whatever I am doing, I tape it to my Bulova 9020 (see next), and hijack that worthy stand. · My non-digital daily driver: A Bulova Microloupe 9020, for watch makers. Mine is magical. Despite the fact that a tenth of a turn on the focus knobs moves me from fuzzy to focused and back to fuzzy, and even though I am on my own with respect to illumination, I am addicted to that moment of focus, and keep it there for the session. It’s like dropping in from elsewhere, straight through the looking glass, instant clarity… perfection, really. I never fail to find my bliss there. Ahhhh. Other notes: Stereosopes? Sure. Not daily, but they are handy. I again recommend buying used. Nippon Kogaku KK and what it became, Nikon, tops my list, and it’s what I use today. I also like AO, and sometimes old Swift. I like the models made in the 70s, generally speaking, What does any or all of this cost? I am out of time, send a message if you have questions. But my setup above – exclusive of the surface 2 – cost me about $400. It takes me a long time to find what I want, I stay on top of auctions until a fluke or lucky day happens, but I am patient and wait for those killer buys. Good luck.1 point

.thumb.jpeg.b4d5eadac7c890ae4c9a75a1801de013.jpeg)