Leaderboard

Popular Content

Showing content with the highest reputation on 08/09/23 in Posts

-

3 points

-

Well, big thanks to @LittleWatchShop, as the donor movement was exactly what we needed. I cleaned and replaced the index wheel, and the pawl wheel was definitely locking the wheel when I moved the fork manually, which it wasn't doing before. Apply power and...nothing. No hum! Turns out the coil was bad. After testing and installing the coil from the donor movement, it started humming! I adjusted the pawl and index fingers to get ready for phasing, and it instantly jumped to life.3 points

-

3 points

-

2 points

-

2 points

-

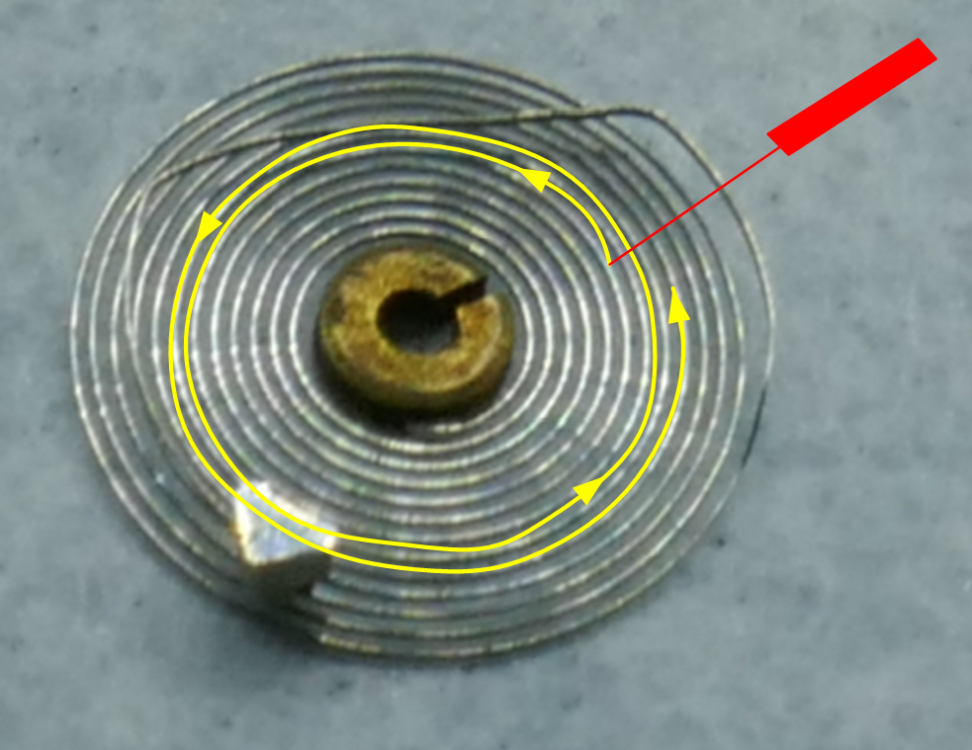

Still working on the watch from hell...been a year now (not continuous). In the mean time, I have serviced maybe 20 watches and ten clocks...so all is not lost. Anyway, yesterday while working with the balance the thing flipped and the overcoil jumped inside the spiral. This has happened before on other watches...at least once. Because I have no backup, I had to solve this problem. No choice. First thing I did was push the collet into rodico to stabilize it and then, while under high microscope magnification, I used an old oiler that I had sharpened down to maybe 100 um to start in toward the inside of the collet, gently working my way to the outside of the spiral. This continually pushed the the tangle outward. At some point I hit a tangle and that was the first place to move the stud under the tangle and then out--hard to describe. Thought I was done but I was not. Repeated the process and found the final tangle. Again, lifted the end where the tangle appeared and slipped the stud underneath and around. Done. Scary as hell. Here is a crude picture of the idea.2 points

-

2 points

-

Thanks to all! We got this one solved. I disassembled the balance again and put it under the microscope and noticed that somehow, 1 or 2 turns of the balance spring were touching (GROAN), so I thought I must have bumped it and bent it at some point. First, I tried demag in case they were magnetically sticking, they were not. So I started to get ready to do some spring bending and as I loosened the eccentric (maybe wrong term, the thing you turn to allow the balance to come out away from the timing pin) by less than a hair, the spring vibrated a little. I put it back under the microscope and to my surprise, no spring turns were touching anymore, all nice and even. Remounted the balance in the watch and back on the timegrapher. Minor adjustment, a Viola! Problem solved. The balance spring must have been caught up a tiny bit on the timing pin and the slightest turn of the eccentric let it free up. At least that's the only explanation I have based on what happened. Just glad I don't have to do any more balance spring bending!2 points

-

Think I got it!!! Looking through the microscope it didn't see any signs of magnetism, but just to cover all my bases (shotgun approach!) I de-magged the watch and prior to working on it I demaged my tools also. I then soaked the balance in hexane for 24 hours and then naphtha for 10 mins, then IPA for 5 mins, then acetone for 5 mins allowed it to dry out for an hour and then oiled the jewel. I took a good look at the hairspring under the highest magnification and noticed no coil sticking, but I did notice the tiniest of kinks in the spring, usually I would have ignored it as it was so minor, but I corrected it this time. Anyway, something or a combination of things above seems to have done the trick - its not an expensive watch or particularly beautiful, but I wasn't going to let it beat me! Thanks everyone for your help and suggestions - it's nice just to have a sounding board and bounce ideas off people rather than working in isolation and heading down a 'rabbit hole'!2 points

-

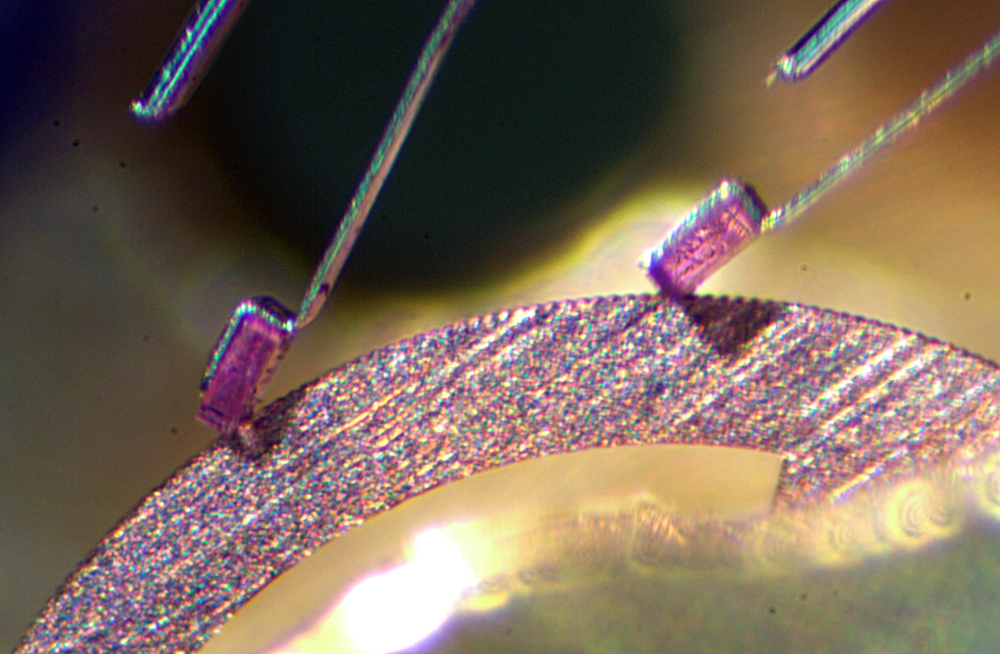

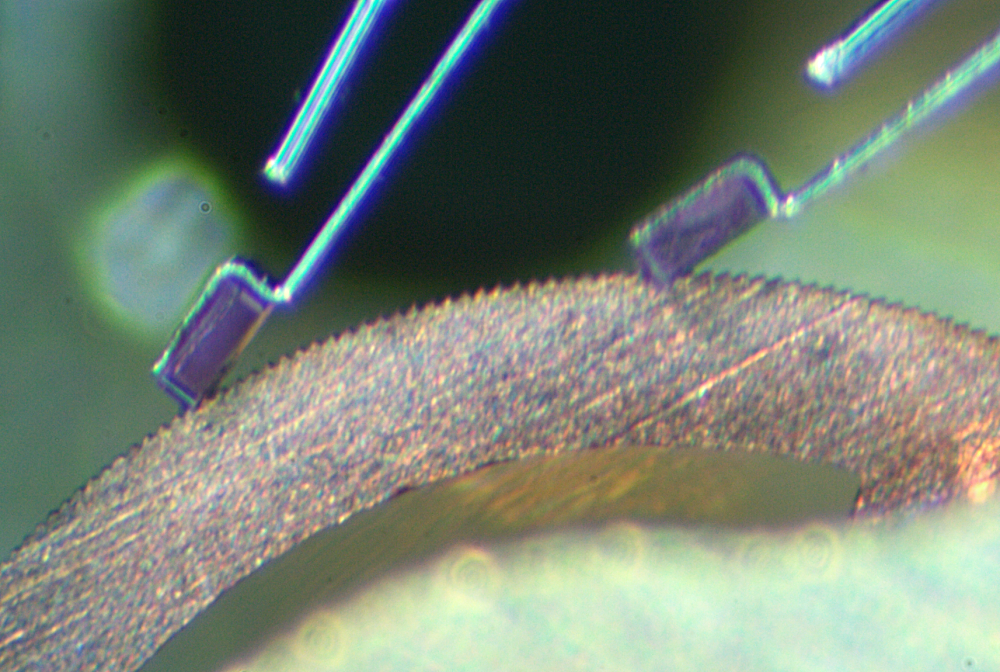

New forum member @ChrisMcKeith saw my previous thread about fixing the electronics in my 219 movement and was foolish trusting kind enough to send me his to work on. It's been an interesting journey and I thought some folks might find it useful or interesting. The capacitor, resistor, and coils were all within spec, and a little pluck got the fork humming, so we were off to a good start. Full tear down, clean, oil, rebuild. Got to break out the Horia clone when the second wheel jewel surprisingly popped out of the main plate. After depthing the wheel, I inly had to tear it down twice more because I forgot to put the hacking lever under the train wheel bridge...then forgot to put the fork under the train...good practice, I keep telling myself. Then I started phasing it. Adjusted the tension on the index and pawl fingers by the manual, applied voltage from my power supply, and it ran...for a half revolution of the index wheel at a time, no matter how I adjusted it. After some more diagnosis and manually moving the fork, I had the hunch that the index wheel has some bad teeth. 45x is as high as my microscope goes, but it sure looks like those teeth are rounded/flattened: I compared it to the index wheel on the 219 I have that runs: Seems like a big difference in the sharpness of those teeth. Literally as I took this picture, I got a message from our friend @LittleWatchShop, who generously offered to try re-pivoting the 4th wheel on my 219. Since it didn't work, he's sending me a spare 219 movement! Hopefully we can use the 4th wheel for my 219, and the index wheel for Chris'. The kindness and generosity here does not cease to amaze and delight.1 point

-

1 point

-

it depends upon whose guideline your following. Originally when I was in school I was taught that if you can't see the lubrication around the pivot you've done good. But if you look at modern Rolex or Omega the rule is as long as you can see the top of the pivot you've done good. But you go beyond that well then you've done bad. the problem with this discussion is the title is Alternative cleaning machine chemicals which brings up the problem of exactly which chemicals you using? Usually the commercial cleaning products will give you timing recommendations sometimes whether you should elevate the temperatures or not.1 point

-

Exactly - especially when oiling . You may find 5 mins isn't enough, but it's best to do the minimum needed.1 point

-

10 mins in an ultrasonic should be fine in naphtha - you might find less cleans OK. I find 5 mins does the job. 1-2 mins is IPA is fine for any parts without shellac, BUT for parts with i.e. pallet and balance, 30 seconds is the maximum recommend time. For old aged shellac, you are probably OK with 1-2 mins, but shellac does dissolve in IPA. There are endless discussions above about this, some people refuse to use IPA at all on shellac, but the manufacturers of pro cleaning machines recommend a 30s rinse, so I do it.1 point

-

1 point

-

That is the correct way, IF the balance has shock protection. I remove the shock protection, and clean the balance+cock fitted to the main plate in the ultrasonic. BUT If like your Bulova, there is no shock protection, I remove the balance, and clean it in the ultrasonic in a small mesh container alone (just the balance+hairspring), so it can't bounce around and damage he hairspring.1 point

-

If you did the balance, you need to check that the roller jewel is secure, and re-shellac if necessary.1 point

-

You were doing 25 mins in IPA . If that includes the balance or pallets, you won't have any shellac left - that's why it's only recommended to do about 30s in IPA. 25 mins is way too long. The instructions on Elma WF Pro cleaner suggest 2-8mins, and Suprol Rinse about 3mins. I do 5 mins in Elma WF Pro cleaner. Then 3 mins in Elma Suprol Rinse in rinse jar 1, then the same again in rinse jar 2, Then 30s IPA. If using naphtha, you need at least 2 jars of naphtha, then rinse IPA1 point

-

I put lids on the jam jars I use for cleaning solutions in the ultrasonic - just to reduce the smell in the house. There is no increase in pressure in the jars, and no risk of fire or explosion (assuming you don't have any naked flames nearby). I don't usually put a lid on the final rinse IPA, as it's only 30s, and I don't mind the smell (but I have, and again, no rise in pressure in the jar). I set the U/S to slightly warm, about 30C. Room temp is OK.1 point

-

Good job- that's the textbook way to do it!1 point

-

I hate to say it but that is the way to do it. It got me out of it many times.1 point

-

1 point

-

In third image, you have shown the two slots facing us, push on those, this will unlock the back plate which( the back plate) houses the movement. the bracelet covers the slots. Good luck1 point

-

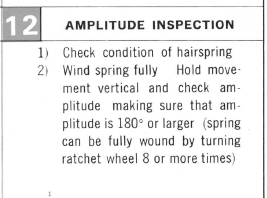

The 180° is with the watch in a vertical position, this is from the 4006 service sheet. So horizontal, that's probably 210-220° ? You may think it too low, but they, the designers of the movement don't I agree with @wudce and @Waggy : about 220 - 240° is fine for these movements. I've spent a long time trying everything to get some movements higher, but they just don't want to. I have a couple of higher grade movements (23J Lord Matic Cal 5606) which do get 270-280°, but not the bog-standard movements.1 point

-

1 point

-

Have fun servicing the Ricoh. I seem to remember lots of loose springs (4 or5?) ready to fly out. All good fun and pretty good watches.1 point

-

Looks like you have found the movement for sure, maybe they have replaced a damaged shock jewel setting in the balance complete with a Swiss version. But the rest of the movement seems far too similar to your Rioch to be a coincidence.1 point

-

1 point

-

Does the pendulum have the same number stamped on it that is on the movement, that is the way of knowing if the pendulum is the correct one, you might need to get a longer s/spring. I love the antiques you have.1 point

-

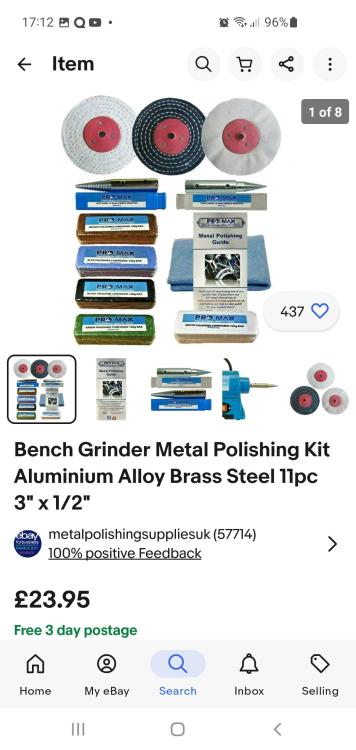

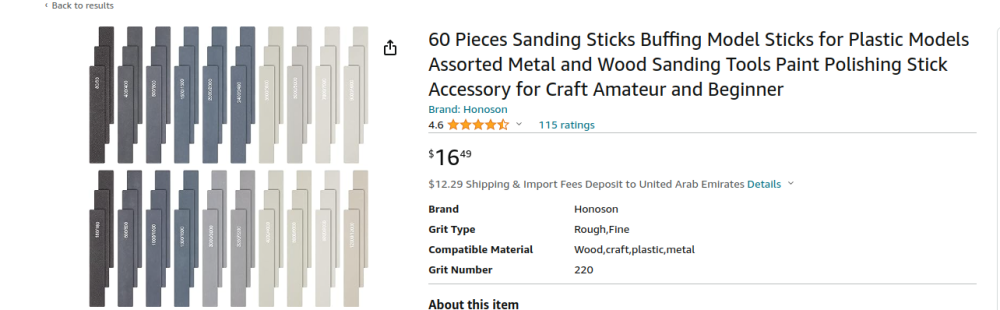

I have a small buffing machine (will take a 4"/100mm wheel) but as several people have mentioned its easy (too easy) to round off sharp corners, our old friend Kalle Slaap of chronoglide just did a video series, see link below, on buffing and polishing which is good and Michael of My retro watches also does a good video on the subject- but to be honest for such a small area that you are looking at with sharp angles, I think there is a great danger of rounding something off and spoiling the look of the watch. When I'm in this situation (and i'm no expert by any stretch of the imagination) I prefer to use disposable buffing sticks (see Amazon screenshot below), the lollypop type, as these give you much more control and are a flat surface so you reduce the risk of rounding. It does take longer, but you keep the control, I just start with the lower grits and work my way up, by the time I get to 12000 grit its a mirror finish. These also have the advantage that they are waaaay cheaper than the mechanical tools. My go to when I need to keep a sharp edge:1 point

-

Looks like the staff is obsolete. By the size of that mainspring the movement has an 8 day duration. You can have a staff made if you are unable to make one yourself. The trouble is it will cost more then the clock is worth.1 point

-

For some reason i can deal with heavy age defects, history scars and dial patination ( tropical dials are gorgeous). But one or two lone scratches or marks completely twist my mellon. Its like that first scratch that happens makes you want to launch it as far away as possible If i know you watchie you will throughly enjoy everything that it involves.1 point

-

Hi you have to remember De Carle wrote that in the 50s a lot has change since then. You can use IPA but dont soak the balance or Naptha, Benzine etc there have been many discussions on this subject so I suggest you look it up on the site for further in formation. Hi you have to remember De Carle wrote that in the 50s a lot has change since then. You can use IPA but dont soak the balance or Naptha, Benzine etc there have been many discussions on this subject so I suggest you look it up on the site for further in formation.1 point

-

Welcome to the forum! As you may (or may not) realize, even among Swiss watches, Ulysse Nardin isn't among the typical "top ten". I don't know (but strongly suspect) that the production volume for any particular watch is very low as they seem to specialize in really exotic builds. I'm not at all surprised that they no longer have parts. I further suspect that their assumption would be that anyone buying one of their watches would have a fair number of other (expensive) watches. They do have a few offerings in the 4 figure range but they're mostly known for watches that sell for $50,000 USD or more. Depending where you are located, your best bet may be to find an actual watchmaker who is capable of making whatever part may be needed (which won't be inexpensive). It would also help the rest of us to see a photo of the watch in question. Good luck!1 point

-

Lol, you noticed my earlier double entendre then Rich ? I did the same with a variable speed bench grinder with 75mm mop wheels. It feels a bit big after using a small rotary tool. I've tried a few compounds the last ones being from cousins, big blocks that had some super heavy cuts. I really like the Polinum for a final polish, superior to anything I've tried up to now.1 point

-

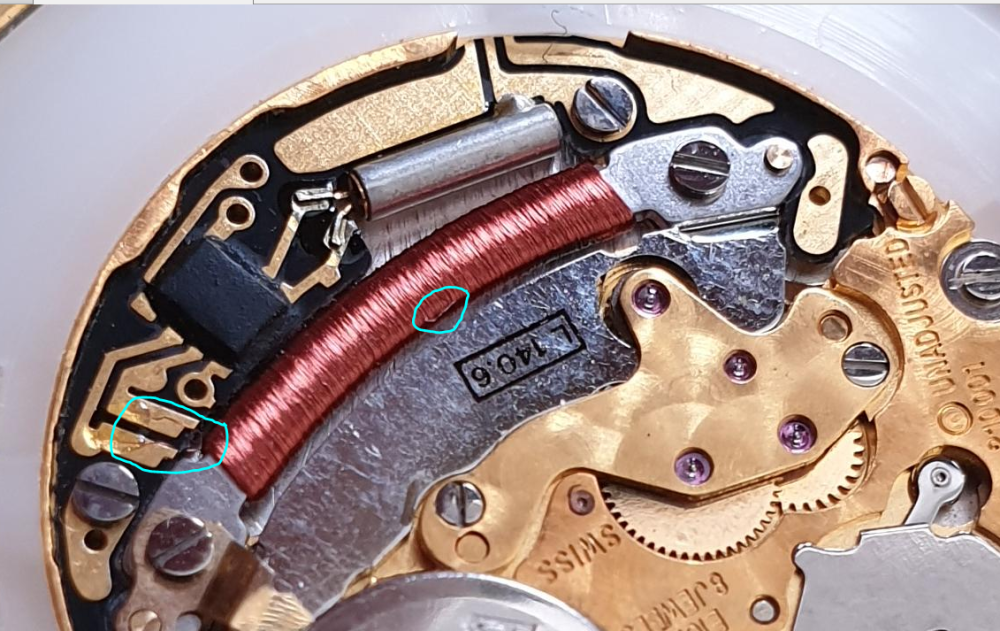

when you are changing the battery did you make sure that the battery insulator on the other side is still in the correct location? then for troubleshooting you really need the technical sheet which I've attached. Then you also need some electrical test equipment. PDF page 14 as the diagnostic information but it does require the test equipment that you probably don't have. then if you look at the tech sheet you see that it should impulse every 20 seconds or as they state three times per minute. then test equipment like measuring the coil resistance to make sure it's not damaged. Being careful when you do that the stay away from where the leads actually touched the circuit board because you could damaged the leads right there trying to test. I've circled where you want to stay away from for testing and I circled something in the middle the coil which looks suspicious maybe it's just dust particle then personally for me I like to test the current consumption but that requires a micro amp meter and a suitable power supply. we've had different experiences. Some quartz watches will run without lubrication others will not. Dirt particles dust falling of the watch will definitely cause an issue. but I usually find a holder quartz watches the lubrication's gone bad and typically it's sticky. Sticky lubrication a quartz watches is bad the watch really needs to be serviced that means complete disassembly just like a mechanical watch. CT_210001_FDE_502580_09.pdf1 point

-

I think the smaller diameter of a watch makers screwdriver, even one of the larger ones, would not give you the same torque and control that the larger diameter of the correct tool provides. Don't get me wrong, I'm all for not spending the 40 bucks but look at the design (most of the time things are the way they are for a reason) and try to duplicate that. If their decisions don't reflect your needs, you (of course) have the freedom to make your own choices. Yeah, I know what you mean, I'm getting really good at trashing hairsprings. Shane Thanks @JohnR725our previous conversation really helped me visualize and follow this thread.1 point