Leaderboard

Popular Content

Showing content with the highest reputation on 08/10/23 in Posts

-

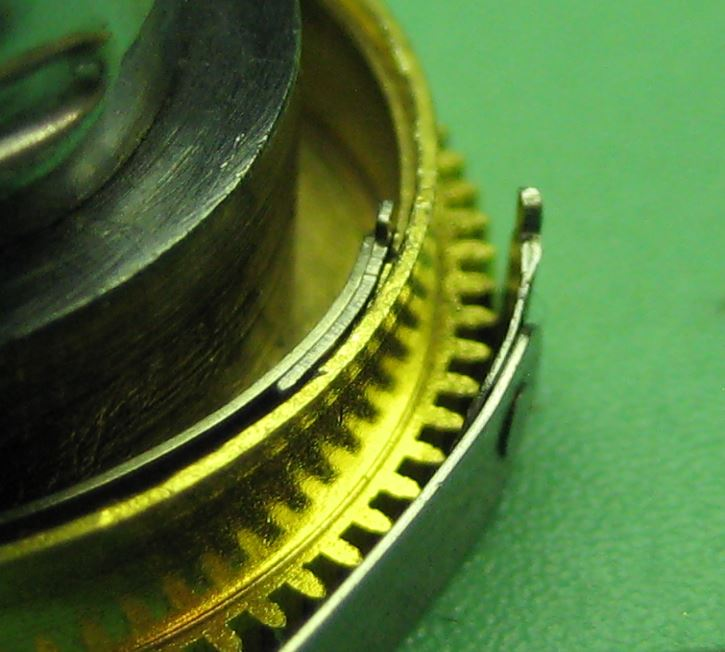

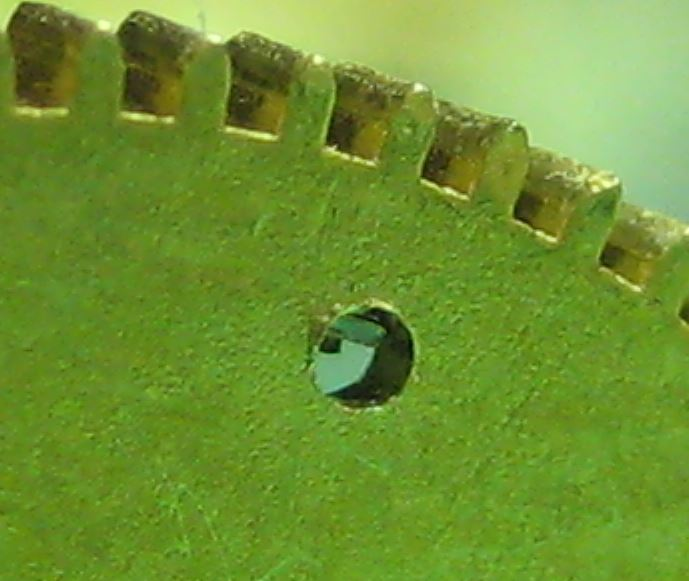

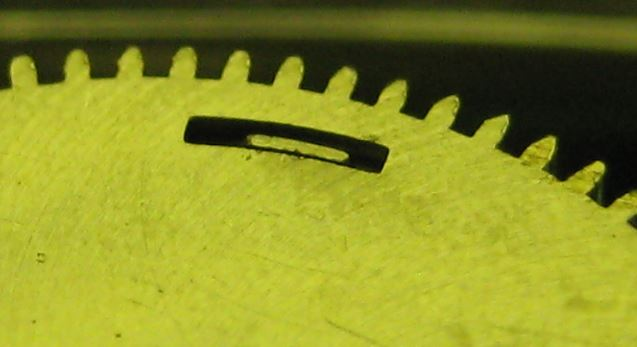

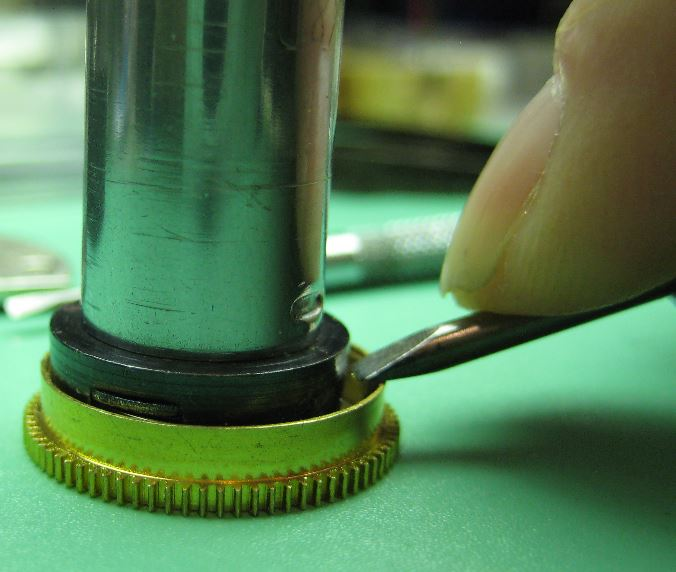

I explained up above but maybe pictures would help. I deal with this all of the time when doing American pocket watches. The most part it works really well it's only when the replacement spring and is an weight of the same design as the original first insert mainspring into the winder like this leaving a little bit out here's another example of a slightly different end type here's an example of the new spring which is currently in the barrel where the end is been riveted to the outside of the mainspring. Versus the original spring which I have setting on the outside with a end was riveted on the inside. This presents the challenge of trying to get that into the hole because they're not quite the right place. Fortunately this does not occur a lot but it does occur. now comes the next step rotating until the protruding part is over the whole it's supposed to go in and you need to push it down until it's in the whole turned over and look on the other side and verify it actually is where it's supposed to be. here's one example here's an example from the Elgin spring it uses both the T and it has a hole in other words they use both but as you can see the tea party is in the middle typically sometimes the slot isn't as big as this though now you still cannot push the mainspring out as even though it's in the whole and/or slot it will not stay you have to hold it down with something usually I use my largest screwdriver sometimes you can use the backside of the backend your tweezers now spring is where it's supposed to be the end is in the hole or slot and you are holding it down you can push out the spring.3 points

-

3 points

-

Hello all, Just joined this forum from Coral Gables, Florida. That's really Miami. But like most people in Florida, I'm not originally from here. I am originally from Venezuela, but lived in 7 countries growing up. My first watch was a Timex that I got when I was 11 years old. When I turned 16 I got my first automatic mechanical watch, an Omega Genève. And I've been a big fan of Omega since then. I own a good number of them, mostly sports Omegas from the 70's and 80's. I have dabbled in repairing watches but I haven't taken on anything too complicated. I hope to learn a bit from the folks here. At any rate, I look forward to being part of this forum.2 points

-

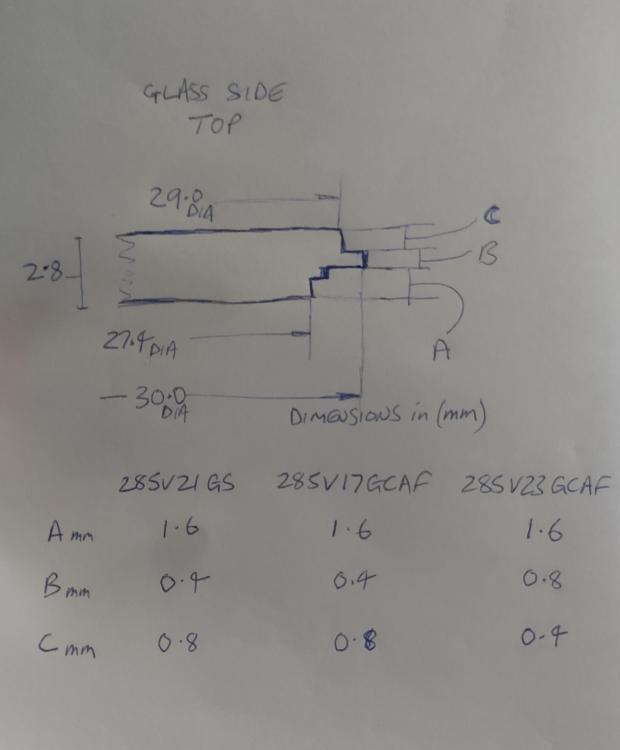

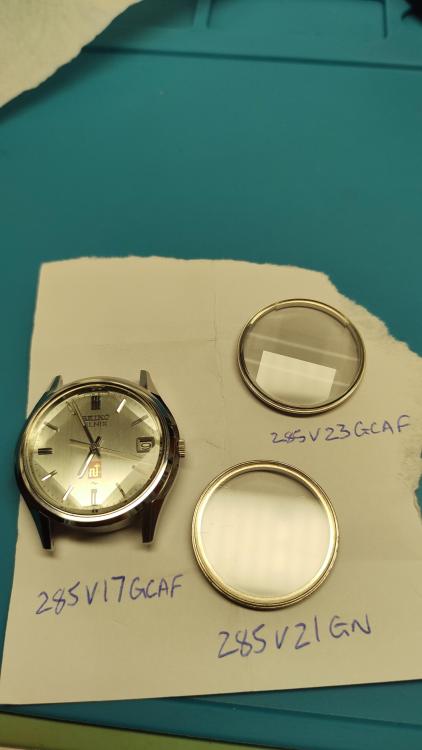

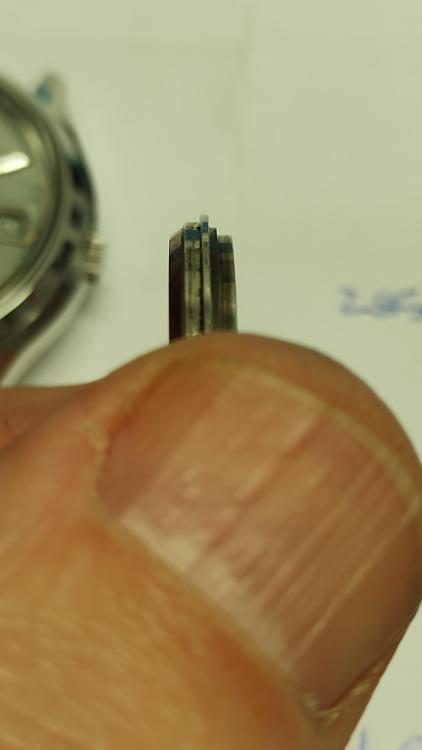

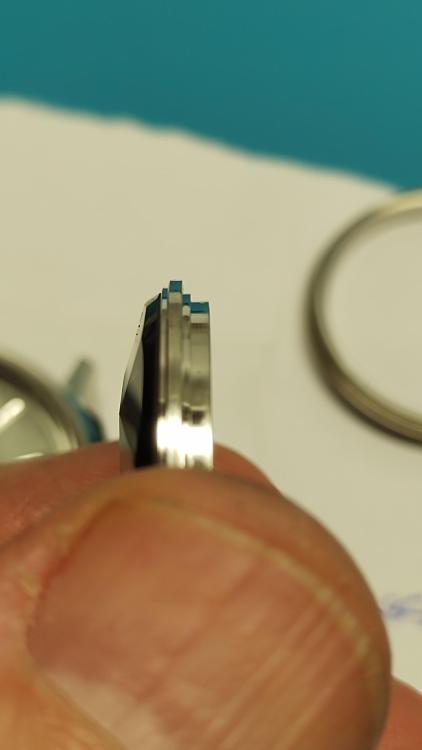

Hi, I did some research and decided to change the 285V21GN flat faced crystal on my Seiko Elnix 0702-6010 for a faceted style. I ordered both 285V17GCAF and 285V23GCAF to see which I liked best. I figured that they would have a good chance of fitting as they all use the same glass gasket (EZ2718B). I found that the V17 was a straight swap with the V21 with identical glass frame dimensions. The V23 frame however had the same diameters of the various frame sections but the thickness B and C were different. The portion A that the gasket fits to was the same. If I had tried to use it on the Elnix then the bezel would not have pushed down fully. Photos and dimensions posted for future reference.1 point

-

Members of this forum who have been here for several years may have noticed my posts showing my projects have reduced greatly. I have now reached the grand old age of 70 and last year I was diagnosed with osteoporosis, it is in my back upper and lower and both hips. Hence I have had to reduce my workload greatly but luckily I do not need my horological work to make living. It’s now purely a hobby but I still do get a regular amount of horological work. I therefore thought it worth sharing the adjustments I have made to my workspace and lifestyle to manage my condition. Workspace Ergonomics: the biggest issue with my osteoporosis is pain and aches in my back particularly the upper. Leaning over a watch or clock for several hours really does become very uncomfortable. So the first adjustment I made was to make the work bench considerably higher. The front edge of the bench is now level with my upper chest area so now my elbows can rest on the bench and this reduces the strain on my upper back. My second adjustment was to change my static height chair to an adjustable height chair with wheels. This greatly helps when I need to be higher when using my microscope. The third change I made is all my regular tools are now at hand by being on either the work bench or stored on a bench by my side or in a cabinet. These can be easily reached by just moving around on my new chair with wheels. Work Schedule and Rest Breaks: I now take regular breaks to avoid overexertion. Prolonged periods of sitting or standing can be challenging for individuals with osteoporosis. I now work with manageable timeframes never promising a quick fix. The exception being battery changes for quartz watches. Clock and watch services I give a minimum of one month as a timeframe. Medication and Medical Management: there is little help with regard to medication apart from pain relief medicines. For me personally ibuprofen helps but when I have a bad day more powerful meds are available. Vitamin D is also apparently helpful. I do take one pill a day but I have not noticed any improvement. Healthy Lifestyle: I have been given exercises from a physiotherapist for my back and hips. These exercises basically increase the strength of the muscles around the effected parts so they are supported better. This has helped greatly particularly with my hips. I now no longer have to use a walking stick. I used to drink alcohol on a regular basis and eat large meals. But now I only drink alcohol occasionally and myself and my dearest have a more balanced diet which involves more salads and a lot less red meat. We have both lost weight and my belly is considerably flatter . These are the steps I have made but Osteoporosis affects not every sufferer the same. If you think you have Osteoporosis get medical consultation first.1 point

-

No, remove the pallet fork entirely, see how the balance moves.1 point

-

Sounds plausible, you could try bending it back with a crystal press. Small diameter from below and one just under the diameter of the back from above, if that makes sense.1 point

-

If it's stopping when the balance cock screw is tightened, it sounds like an end shake issue. Remove the pallet and give the balance wheel a blow with a puffer, it should swing freely for at least a minute.1 point

-

Peg wood is good for intial clean/scrape, but you can also cut a piece of cigarete box ( hard box) to clean pallet face with it, use hexane as well, you may go through half a dozen pieces to clean the pallet faces to a shine( pallet face should shine) then you have a chance to examine pallet face and edges under microscope for defects. The coil looks unlevel and may be rubbing on balance spokes.1 point

-

I pretty much began my watch collecting journey in 1988. I also collect and restore fountain pens. I have recently begun working on quartz watches and I would like to learn as much as I can. Regards Roy1 point

-

I think you may need to slightly reform the caseback, what I have seen a couple of times is the caseback is slightly concave with it being pressed on the middle, works this time but won’t the next. Tom1 point

-

You can take some tension off bewteen the barrel wall and mainspring by fitting the arbor while is has a arbor vice attached to it . Wind up and the spring t end can be slipped round into its slot.1 point

-

I agree, I would be surprised if the case back is supposed to be glued in position. Perhaps its a substitute case back that didn't quite fit so the person before you used glue to fix the problem?1 point

-

I'm still learning myself, but I don't think glue is ever used for a case back. What kind of watch is it, and better yet, can you post some pictures?1 point

-

I'm pretty sure we talked about it at the time, and the seed of the idea has been germinating in my mind ever since. Maybe ill mention back pain to Mrs W so I'll get approval to purchase a system1 point

-

Just about to mention this, that a lot of Russian watches use this type of spring arrangement. As you point out it can make life difficult, especially if you are using mainspring winders, hitting that little slot working blind (ie you cant see the slot or spring because the winder obscures this) when you insert the spring can make a difficult job almost impossible. I have tried marking the barrel with marker pen, but with only partial success as you have to be accurate to a fraction of a mm or just plain lucky. And once the spring is in the barrel there is no coaxing it into the slot. So today if I come across this configuration I hand wind, not perfect, but until I find a better solution its the only reliable way to do it.1 point

-

I always used loupes of different strengths for balance staff work a 2 it just depends what I was working on. It depends on the individuals eye sight.1 point

-

1 point

-

1 point

-

we've covered this kind of thing before on the message board. If you have a main spring winds and it's easy to do otherwise people do it by hand but it can be a pain in the ass to get everything to line up. They vanished with the mainspring winder is you basically wind almost the entire spring into the winder leaving a little bit out then you put the little bit out and the winder into your barrel rotated until the tea party is over the slot. Push it into the slot I usually use the back of my tweezer or very heavy screwdriver verifying it is indeed in the slot. Then while holding it into the slot firm way you can now push the mainspring out and it will stay word supposed to be. If you attempt to just push it out and hope it will hold in place it will not. If you have a brand-new spring with a T tight end and to push it out of the ring it will not stay word supposed to be trying to manually rotated pastorates out in the barrel is problematic. so the best way really is with the mainspring winder and that it goes quite effortlessly for the most part. By time we have problems with the method I describe is if the modern spring is not exactly the same shape as the original specifically how they welded the end part on then getting it into the slot can be an issue1 point

-

we still need a picture to know what were talking about. Quartz watches do become interesting as a lot of companies to purchase them. But there are companies that do make high-end quartz watch movements in getting parts can be a bit of a challenge. Usually requires purchasing something off of eBay if you're lucky.1 point

-

1 point

-

it depends upon whose guideline your following. Originally when I was in school I was taught that if you can't see the lubrication around the pivot you've done good. But if you look at modern Rolex or Omega the rule is as long as you can see the top of the pivot you've done good. But you go beyond that well then you've done bad. the problem with this discussion is the title is Alternative cleaning machine chemicals which brings up the problem of exactly which chemicals you using? Usually the commercial cleaning products will give you timing recommendations sometimes whether you should elevate the temperatures or not.1 point

-

Then how is the crystal held in if it's small than the hole - glue? Is 42.55 the inside lip of the bezel? If so, a 42.8mm crystal would do. How deep is the acrylic? A low dome might be OK : https://www.cousinsuk.com/product/low-dome-sternkreuz-n For the spring, you need to determine the calibre, or measure the old one.1 point

-

I never did the pallets (luckily). What the heck was i thinking... Dammit Jim!1 point

-

1 point

-

Welcome to the forum! As you may (or may not) realize, even among Swiss watches, Ulysse Nardin isn't among the typical "top ten". I don't know (but strongly suspect) that the production volume for any particular watch is very low as they seem to specialize in really exotic builds. I'm not at all surprised that they no longer have parts. I further suspect that their assumption would be that anyone buying one of their watches would have a fair number of other (expensive) watches. They do have a few offerings in the 4 figure range but they're mostly known for watches that sell for $50,000 USD or more. Depending where you are located, your best bet may be to find an actual watchmaker who is capable of making whatever part may be needed (which won't be inexpensive). It would also help the rest of us to see a photo of the watch in question. Good luck!1 point

-

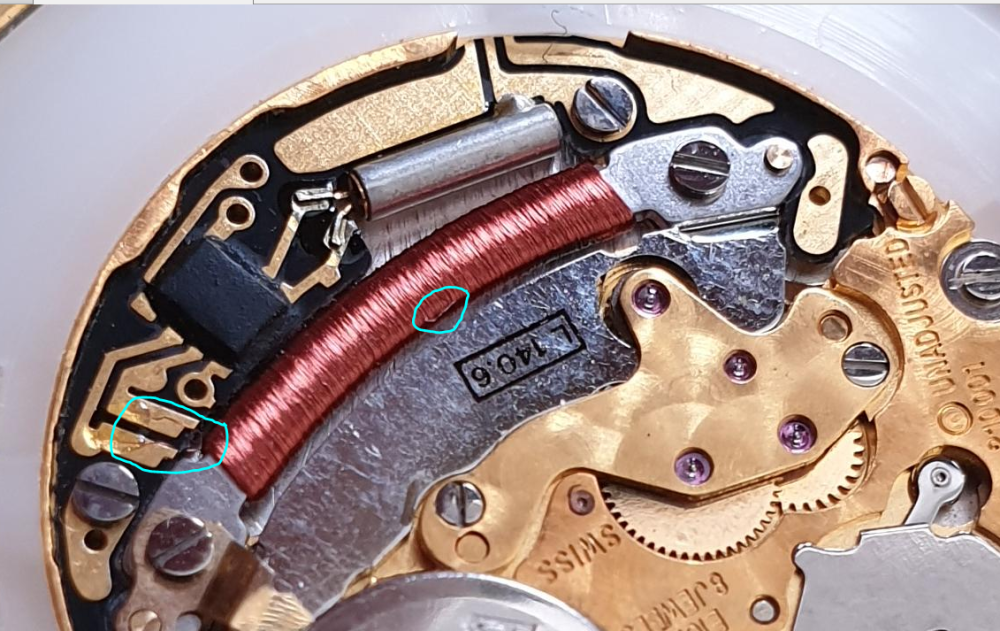

when you are changing the battery did you make sure that the battery insulator on the other side is still in the correct location? then for troubleshooting you really need the technical sheet which I've attached. Then you also need some electrical test equipment. PDF page 14 as the diagnostic information but it does require the test equipment that you probably don't have. then if you look at the tech sheet you see that it should impulse every 20 seconds or as they state three times per minute. then test equipment like measuring the coil resistance to make sure it's not damaged. Being careful when you do that the stay away from where the leads actually touched the circuit board because you could damaged the leads right there trying to test. I've circled where you want to stay away from for testing and I circled something in the middle the coil which looks suspicious maybe it's just dust particle then personally for me I like to test the current consumption but that requires a micro amp meter and a suitable power supply. we've had different experiences. Some quartz watches will run without lubrication others will not. Dirt particles dust falling of the watch will definitely cause an issue. but I usually find a holder quartz watches the lubrication's gone bad and typically it's sticky. Sticky lubrication a quartz watches is bad the watch really needs to be serviced that means complete disassembly just like a mechanical watch. CT_210001_FDE_502580_09.pdf1 point

-

If the train of a quartz movement is stuck it is most likely a dirt particle blocking a wheel. Lubrication plays no major role in a quartz movement which can run fine without any.1 point

-

The movement is an ETA 210.001 Here you get parts: watchmaterial.com/eta-210-001 Repair: Youtube1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. You might find this helpful. 704789946_TZIllustratedGlossary(2).pdf1 point

-

Seiko 2119-0090 P June 1969 Replacement crystal, Setting lever spring. Loose cannon pinion and sticking hairspring. All fixed and running properly again + 2 SPD on wrist. My uncles watch since early 70s. He gave a stranger a lift home from the pub. The guy left his coat in my uncles car and was never to be seen again to this day. The watch was found in the coat pocket. No way of contacting people in those days like there is today to be able to hand it back.1 point

-

1 point

-

1 point

-

High folks. I had the escapement apart and found a tiny piece of lint hiding around the escapement wheel. I could not see thus even under the microscope. Problem now gone away and running to 2 secs a day when worn. Thanks again.1 point

-

1 point

-

1 point

-

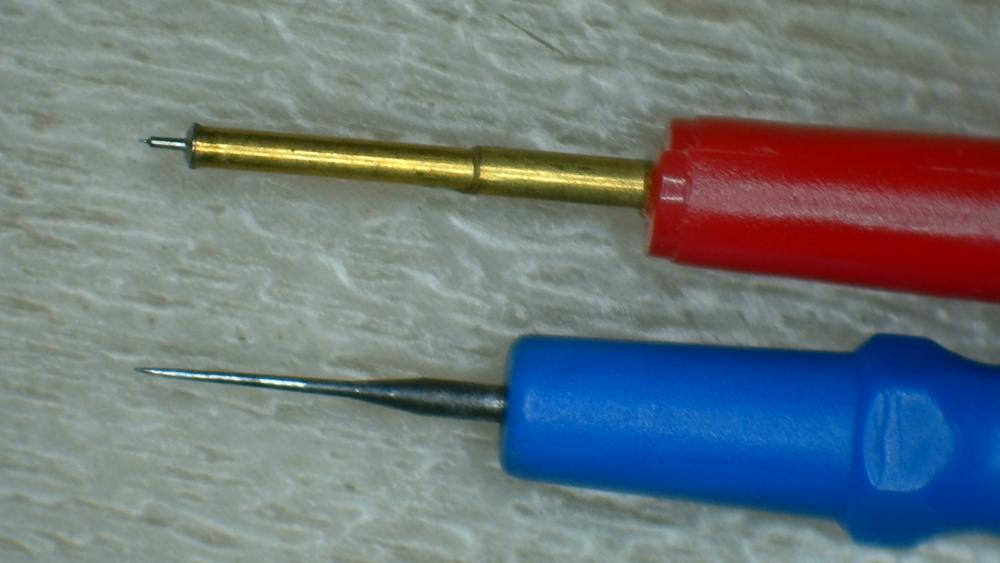

Thanks for the info. So I guess they are German. I will likely never use the tiny ones as I am sticking with pocket watches for now, but I'll have them just in case. I figured out how to make them last year when I couldn't find a #12 Bergeon anywhere. A few weeks ago I managed to grab brand new 10, 11, and 12 Bergeons on eBay. With these aluminum ones I now have a 1, 3, 5, 6, 7, 11, 12 and 13 so I am set for mainspring winders for now. I will probably have to fix the tiny catch pin on the wider stems, but I already figured that out from making one from scratch. I was going to reverse engineer a Cannon Pinion Tool until a French company dumped some brand new ones on eBay for cheap.1 point

-

1 point