Leaderboard

Popular Content

Showing content with the highest reputation on 08/14/23 in Posts

-

One more update: While I was getting ready to phase the watch, I noticed the finger jewels had skipped under the index wheel. Turns out there was an absurd amount of end shake. After some quality time with the Horia clone (and a lot of practice aligning pivots in a bridge), I got the shake down to an acceptable level. Phasing was actually super interesting. I used the method described here. Started at 1.05v and turned the pawl adjusting screw until it ran smoothly. Jumped up to 1.75v, and the train started spinning noticeably faster. The method above says, "See if the index wheel is running normally or fast." I thought there was no way I'd be able to tell, but looking at the speed of the second wheel it is completely obvious. I was able to get it to run smoothly up to 1.80v, and I called that good. Re-cased, popped in a Renata 344, gave it a little tap, and off she went!3 points

-

This a project I did over the weekend, a Lucerne. Watch was a non-runner due to dire need for a service, gummed up with old oil and a damaged balance hair spring. This is the first time I have taken on rebuilding a hairspring was was smiling all day when I got it not only working, but working well! Before and after pictures: Finished watch3 points

-

I went with the CNC-ready package, so I had to supply my own motors. I've written a rudimentary "CNC" program in Python that takes an SVG outline of a balance staff that I create and moves the motors to cut accordingly. But I haven't stitched all the pieces together yet. They are also closed loop stepper motors, meaning they have an internal feedback mechanism to accurately control the position.3 points

-

They still make alarm clocks for us old fogies. Besides, they are more reliable than my phone, 'cos I have a habit of forgetting to charge that. https://braun-clocks.com/collections/analogue-clocks/products/bc22-brahttps://braun-clocks.com/collections/analogue-clocks/products/bc22-braun-classic-analogue-alarm-clock-blackun-classic-analogue-alarm-clock-black Mine is the predecessor of this little beauty. I also have a couple of wind up alarm clocks too. The batteries *never* go flat on those.2 points

-

Hamilton cal 972 from about 1912 sent off today...literally grandpa's pocket watch. I knew it once existed but thought it went away in the estate sale over thirty years ago. Dad kept it and pulled it out last week. Who knew I was getting an inheritance? It's missing a balance jewel screw but otherwise looks in fine condition. Someone serviced it carefully... Fun watch fact about grandpa- he lived most of his life a few minutes from the K&D factory in Lebanon, New Hampshire USA...2 points

-

Alarm clock, what is it 1952? Hehe. I have just found out that Certina is a brand from KF, learn something new every.2 points

-

I believe this is an identical machine in action, amazing for 1870s!2 points

-

thinking about temperature compensating here's a hand out on their balance wheels. Index TD 113 Page 2.pdf Index TD 113 Page 1.pdf2 points

-

2 points

-

actually it's hard to tell what the original thread is because the title doesn't reflect what the discussion is about. a suggestion in the future would be to appropriately title the discussion to reflect the subject of the discussion that helps people to find your discussion. now you may be grasping my lack of enthusiasm for using a vibrating tool for purpose that it wasn't really intended for. The goal of vibrating a hairspring would be a replacement new hairspring in other words are starting off with a long spring you know where you stand versus here we're not sure. Then you have to keep moving the hairspring through the tweezers until you reach a time where your sample balance exactly stays in frequency with the master balance and as you can see it's a pain in the ass to get there. this is why when you look at is a video on YouTube of one of the modern schools they talk about keeping the old traditions alive. Like turning a staff between centers and doing all this hand filing manipulation keeping all the traditions alive. Then they get to the hairspring vibrating and they use an electronic Greiner machine and they do not do it with the old-fashioned vibrating tool I find that actually quite amusing. Even they grasp what a pain in the ass this tool lives. Oh and of course the other problem they have is the infinite supply of raw hairsprings that were once available to torture the students learning how to vibrated hairsprings is no longer available.1 point

-

if you're lucky this translates to just needs servicing. In other words the balance wheels swings hopefully both pivots are still intact. The watch is wound up tight and it doesn't run. In the olden days of organic oils that we used to love because they would get sticky with time it just means sticky and dirty oil. Unfortunately with modern synthetic oils it means they just quit working and the watch grinds itself to dust with time especially if you can throw in a little rust for grinding compound. so basically if it's wound up tight the staff is broken it's probably just a cleaning. Which is why a lot of times the sellers will spray it with lighter fluid the universal hobby is cleaning fluid and see if they can free things up so it can at least run then they'll sell it as a running watch even if it only runs for a few minutes before it comes to a stop.1 point

-

I assume this is a vintage staking set? Based on the fact that the pivot is also broken, I'm going to guess that there was some debris inside your stake that put enough lateral force on the staff to snap it off. I know my set had bits of metal stuck in all the holes of the plate, so I wouldn't be surprised if there was debris in your stakes.1 point

-

1 point

-

The brand on the dial is fun- you have a Tell...1 point

-

1 point

-

This one arrived a while back, and I finally got a chance to look at it tonight. It was a bit of a mess unfortunately. However the 1223-21 17 shares a lot of parts with the other movements in the Ronda 12xx -xx series and I happened to have a suitable donor, so parts were not an issue. Fortunately the damaged parts were not part of the alarm mechanism, but rather, two of the train of wheels and the mainspring. Initially when I first tried to wind it, I thought it just had a broken mainspring, however it appears that when it let go, it must have done so rather violently as the train wheels were sitting askew. It has been a while since I worked on a 12xx Ronda, and I had forgotten that the barrel doesn't actually have a lid. When I popped the mainspring out, I dropped it, and just for a second I thought I'd lost the lid on the floor. I have it all back together and it is running nicely. I'll let it run for 24 hrs just to be certain that nothing else is amiss, then do the final adjust and regulate probably tomorrow. I've still to look through my stash of "fancy" crystals to see if I have a replacement. Either way I'll post a few pictures of the finished article soon. I'm not sure the alarm would be sufficiently loud and obtrusive to wake me up in the morning however, so I may have to stick with my alarm clock.1 point

-

1 point

-

Andrew Berry knows his stuff, i watch a lot of his videos. It did feel like he was promoting the Foredom though. I'm still tempted to buy the clone at almost a quarter of the price, i suspect i do a bit more case polishing than you watchie and will do more myself when i get around to plating, but still maybe only an hour or so a week. A lot of power tools come from china, i have a few for my work job and some are ok, so thinking i might take a risk.1 point

-

Just sneaked this a few quid under my maximum bid. Just the style of watch i love , raised numerals, a minute track which also looks raised ( nice to keep clean and no worries over loosing any print, simple hands , sub dial , lovely patination with that and contrast against the cream dial and horned lugs my favourite and it look fairly big. Any guess as to the movement, the brand Tell seems familiar, I think ive seen TellTime before.1 point

-

1 point

-

1 point

-

here's a book that talks about things like this unfortunately not the kind of detail I would like but still interesting. The Evolution of Automatic Machinery: As Applied to the Manufacture of Watches at Waltham, Mass https://archive.org/details/evolutionautoma00marsgoog1 point

-

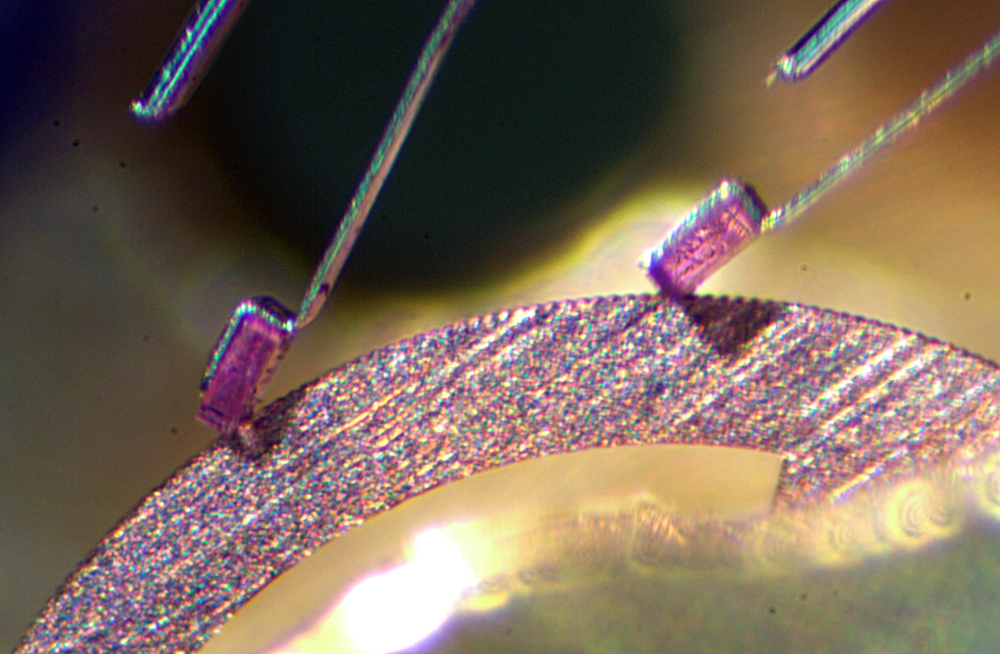

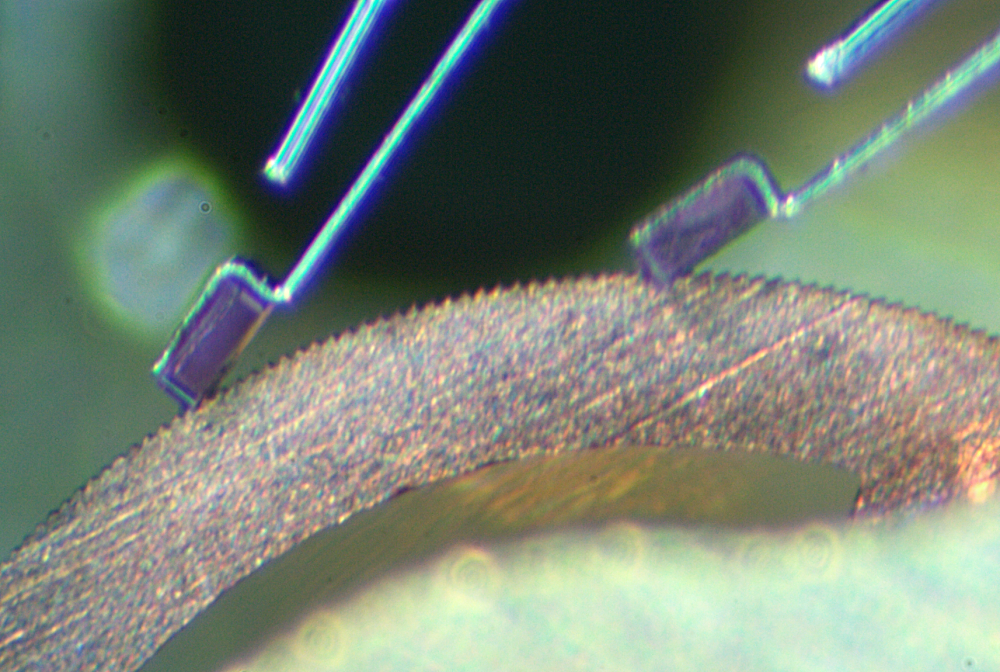

New forum member @ChrisMcKeith saw my previous thread about fixing the electronics in my 219 movement and was foolish trusting kind enough to send me his to work on. It's been an interesting journey and I thought some folks might find it useful or interesting. The capacitor, resistor, and coils were all within spec, and a little pluck got the fork humming, so we were off to a good start. Full tear down, clean, oil, rebuild. Got to break out the Horia clone when the second wheel jewel surprisingly popped out of the main plate. After depthing the wheel, I inly had to tear it down twice more because I forgot to put the hacking lever under the train wheel bridge...then forgot to put the fork under the train...good practice, I keep telling myself. Then I started phasing it. Adjusted the tension on the index and pawl fingers by the manual, applied voltage from my power supply, and it ran...for a half revolution of the index wheel at a time, no matter how I adjusted it. After some more diagnosis and manually moving the fork, I had the hunch that the index wheel has some bad teeth. 45x is as high as my microscope goes, but it sure looks like those teeth are rounded/flattened: I compared it to the index wheel on the 219 I have that runs: Seems like a big difference in the sharpness of those teeth. Literally as I took this picture, I got a message from our friend @LittleWatchShop, who generously offered to try re-pivoting the 4th wheel on my 219. Since it didn't work, he's sending me a spare 219 movement! Hopefully we can use the 4th wheel for my 219, and the index wheel for Chris'. The kindness and generosity here does not cease to amaze and delight.1 point

-

That's about all there is too it. The fork should continue to move a bit until it hits the banking, which is the total lock (drop lock + run to banking [also called slide]= total lock). Check again that you have guard pin clearance with the fork banked, rotating the balance fully until the roller jewel "rebanks" against the fork. It's not uncommon for a roller table to be eccentric for whatever reason, and you can end up with weird things happening in specific positions as gravity pulls things down. Still looks like you have a fair bit of total lock on the entry; I would try bending the banking closer to straight, which will reduce that, checking of course that there is still sufficient fork horn and guard pin clearance. Doesn't sound like this is an escapement issue though. Sometimes the way the hairspring is situated and centered can cause it to touch the center wheel or stud when the amplitude hits a certain point. That can cause a drastic increase in rate and odd looking timing machine results.1 point

-

On a somewhat related note, I found a video about the American Precision Museum, and they had one of the machines used to make watch screws (at 48 seconds if it doesn't automatically jump to that point).1 point

-

I printed out your words of wisdom when you first posted them It's the first time I've really followed them. I can't imagine managing without a microscope. From what I can determine, the 'clearances' are OK, and I cannot unlock the escapement (fiddly, I used an old sharpened oiler) when it shouldn't. I'm not so clear on checking "run to banking". Looking at the pallets, I notice the point of drop, and then see if there is any more movement of the pallet fork ? Is this correct. If so, it's OK1 point

-

If you heat the watch to 40-45C, then place a drop of room temperature water on the crystal, wait a minute and wipe it off, and there is no condensation under where the drop was, the watch is dry. There are special heating plates made for this, but you can use something like a heating pad or whatever, just get the watch to 40-45C. If you have no way to test water resistance, in the case of your dad's and girlfriend's watches, I would guess that it's water intrusion, not water in the case when you closed it. London humidity level rates as very normal- if you were in Singapore or something there might be a tiny case for humidity being the cause (but still unlikely).1 point

-

I can tell you its British made, so not a swiss movement. You can get them with calendar as well.1 point

-

Did it pass any tests for water resistance before going out? Fogging on the crystal is pretty much a 100%* sure proof that water has entered the watch. *We were taught this in school. The volume of air, even if there isn't a movement/dial in place, is too small to allow enough water in the form of humidity to actually condense. I've read somewhere that in extreme cases there can be some condensation- but these cases are, extreme.1 point

-

If not the collet then maybe the new staff slipping the balance wheel ? I considered the roller but couldn't come up with a reason why it would increase the rate. I was thinking the roller would only slip during it engagement with the fork. Thinking about it again Mike, if the staff has some movement within the wheel, the most torque on the wheel is at full extension and contraction of the hairspring, it might be at that point it slips. Thats going to seriously affect the beat error though ?1 point

-

We kinda love you John, for taking the time to answer our questions.1 point

-

Just this morning I'm reading up on the Smiths cal 60466E I'm working on and the old review makes reference to the temperature compensated hairspring...1 point

-

I think the problem here is I didn't exactly elaborate on something. The blue spring is steel and the bimetallic balance wheel is to compensate for that. The white spring doesn't react to temperature for the most part at all it's made out of a special alloy. Hamilton has a handout with a talk about this so I've attached that I think that might answer your questions. Index TD 115 page 3.pdf Index TD 115 page 2.pdf Index TD 115 page 1.pdf1 point

-

Are you sure its big enough to make a watch stem.1 point

-

You should look at the ones from the dental industry. Like the Italian one from Faro.1 point

-

Big price difference between the clones and the genuine Foredom motor. I nearly bought one a while back at a silly price of less than £100 . I noticed the accessory wobble in the video, that might be just down to the shaft of the bit being bent or poorly milled. Difficult to say if it was the chuck itself, i would think any vibrations would be down to both the handpieces and the motors.1 point

-

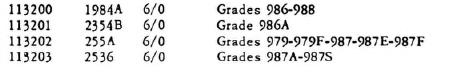

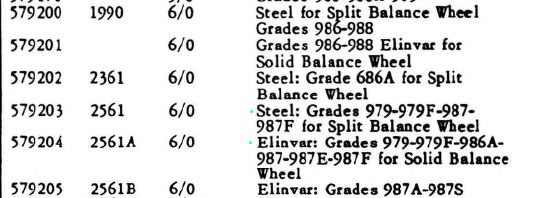

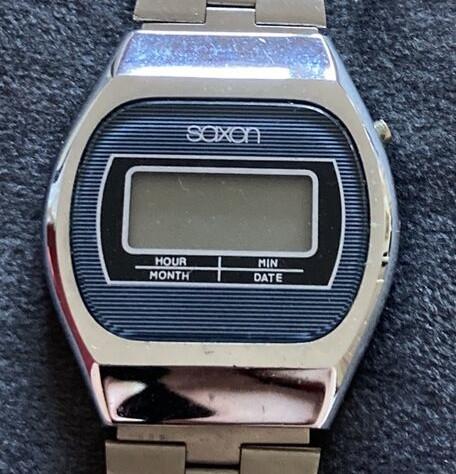

I'm sorry that you don't find me very helpful. But I don't find it helpful to get numbers and not know what I'm dealing with. So that makes us even of being not helpful. except now I have a picture so I know what I'm dealing with that's helpful. I just a note on compatibility because when you start looking for eBay you might wonder about this. Notice how the 987 is compatible but it comes in a whole bunch of variations some of which are compatible and some of which are definitely not compatible. I snipped out an image from the bestfit book it has the smaller number which is the old number and the large number which is the newer number. then for the hairspring things get more complicated which is why a picture was required. You will note there are two separate hairspring is available for your watch. Each of the hairspring's has a description like for instance steel typically this would be a blued steel hairspring like what you have in your picture. This also goes with the bimetallic balance wheel. The other one would be a white colored hair spring for a solid balance wheel you'll notice that they're different as they do not interchange.1 point

-

1 point

-

Foredom has many different style handpieces. If you look at the photo in my original post, that is the dental style handpiece with a fixed 3/32" quick change chuck. Of course we didn't use Foredom motors in dental school. We had German made KaVo motors. They are probably extinct by now. This video will introduce you to some handpiece options.1 point

-

Sure, sort of greenish when I would take 10 grams per day , but 5 grams (6250 per cent above the recommended amount by the Swedish Public Health Authority!) seems to be the right amount as long as I'm healthy. I'm no expert myself, but an acquaintance of mine, the one I mentioned before, who is a vaccine researcher told me that humans are the only(?) mammal that doesn't produce their own vitamin C and that animals that become sick produce it in truly massive amounts. So, his theory is that if we become sick we should try to emulate that. He also told me that patients in truly bad condition (can't remember from what) had been cured by being given vitamin C intravenously. So, his conclusion was that it would seem we have a lot more to learn about what natural nutrients can do for us.1 point

-

see what happens if I don't pay attention 100% at lectures I can't answer your question. so yesterday's lecture one of things he did talk about was and I didn't pay attention 100% was how the tell the difference between radium, tritium and basically everything else. One of the ways is with UV light things like the modern stuff will Floris incredibly well. The reason I didn't pay attention hundred percent was because I have a Geiger counter so I can tell with radioactive. Then basically the feeling at the lecture was it's not an issue we've had multiple discussions about it on the group there some people become extremely panicky and others it just don't give a darn as long as you don't go poking at it you'll be fine but even in the lecture he talked about actually restoring tritium hands for instance by taking some other hands taking the material mixing it up again and using it wearing nice facemasks goggles not reusing the tools etc. etc. but when it came to radium he wasn't really in favor of any of its. On the other hand they once made radium and refinishing kits because I actually have one lurking someplace it was in the material house ones that I thought it was quite amusing I believe I banished it someplace out of the way. if you don't have a Geiger counter one of the ways that you can tell is you put the watch in a dark box basically for 24 hours of not sure the exact time apparently the modern luminescent materials when charged up glow for quite a number of hours don't get very faint and the bill still glow city seal something up in a black box no light exposure 24 hours be safe then go into a black room allow your eyes to adjust depending on how long that takes and look at the hands of their still glowing or the dial apparently the radium itself will glow blue from my quick googling of how to tell if I have radio. His sockeye cause the zinc something to floor S because long ago that's been burnt to crisps by the radiation but apparently the radium actually does glow. Otherwise their cheap geiger counters on Amazon US have be careful a lot of them are not of the right type and are not sensitive enough maybe before you run out via Geiger counter look at this YouTube channel. He goes looking for radiation and antique stores or a prime place to find it and it isn't just the radium watches is looking for. One of my friends based on this went and bought a Geiger counter discovery sure enough some of the stuff in his house has ceramic with radiation. I think the only radiation I have each the radium hands which is a set of were banished someplace else in the house where don't have to worry about them. https://www.youtube.com/@RadioactiveDrew1 point

-

What about making a replacement dial that looks the same? Would this be a practicable option? https://www.youtube.com/watch?v=kt1nmSqS-Ps1 point

-

as you're finding out there's an unfortunate problem in watch repair. When you start off you just need a few tools to get started and your fine but as time goes on you discovered that watch repair can be extremely tool intensive. Realistically reach a point in time where you grasp that you will never have enough money to have all the tools you conceivably need. then yes having the specialty tools that you only use once pay or occasionally if it makes life enjoyable and pleasant justifies its existence. Oh and in case you like looking at tools there's a catalog down below https://archive.org/details/20thcenturycatal00purd1 point

-

1 point

-

One of the tests or a test to tell if your index wheel has a problem is to do the following. So what you want to do is pluck the tuning fork so the index wheel was spinning and you watch where it stops. As you can't actually see where the wheel stops you look at how the arms are arranged. Then you do it again and each time you do it as long as a stops in a random position your okay but if it seems to favor a particular location or an exact location you have a bad index wheel.1 point

-

1 point