Leaderboard

Popular Content

Showing content with the highest reputation on 08/15/23 in Posts

-

The fact you had to use something to push out the broken piece is important. When choosing a hole in the plate, the staff should be a free fit. Not tight, not sloppy, definitely some freedom. Then as John mentions, alignment is very important. Some alignment punches are bent. Then, your round and flat face punches should have- some freedom. If they are a super close fit, but free, go the next size up. All this freedom adds up to things staying flat during the rivetting process. My take on your situation is the staff was a snug fit in the plate, and you used a close fitting punch, and things literally went sideways when the hammering started.3 points

-

If these is the only means you have. There is nothing wrong in doing so. Ronsonol lighter fluid is also shellac friendly and will not harm it. You will need a jar with a screw lid as it evaporates quickly. I always used Ronsonol for cleaning hairsprings. Don't expect first class results as you would get with a proper watch cleaning machine. Go on enjoy your watch cleaning.3 points

-

Get Archie Perkins' book Watchmaker's Lathe and How to Use It. Read the book. Think about what you learn. Experiment and practice. In a few weeks of dedicated work you will know a lot more about lathes, how to maintain, and use them. Seriously. Do your homework. You're not going to learn to use this fundamental machine tool by soliciting gratuitous advice on this forum to a few random questions. My two cents. Best to you.3 points

-

I would agree with you but unfortunately there are those of us who live somewhere where you can't buy or import those fluids. FYI many of the cleaning fluids have a naphtha base, for example L&R rinse 3 is 30% straight naphtha and 70% white spirit (Stoddard solution). Where Stoddard solution is just naphtha with some of the more aromatic elements removed. Hence, if you use this commercial product you are in fact rinsing your watch in lighter fluid (naphtha). As a side note, L&R 111 is about 80% naptha/Stoddard solution which means you are also cleaning in something which is 4/5 lighter fuel. At the end of the day you need a clean watch, how you got it clean is not important. Clean is clean.2 points

-

The dial appears to have been repaired before. The "VII" doesn't look original. Is it above one of the dial feet? Probably someone tried soldering a dial foot and damaged the enamel.2 points

-

I use a 4x clip-on loupe Behr (brand name) loupe on 2.5x reading glasses (which I need to see anything close.) Good for most lathe work for me, but I'm sure a boom mounted stereo microscope would be great, especially for tiny work, if you can swing the price. Agree there's no one solution. Depends a lot on your vision and any required correction. If you do use a loupe, it should go on your dominant eye (Google "dominant eye" if you don't know what this means) and practice working with both eyes open.2 points

-

2 points

-

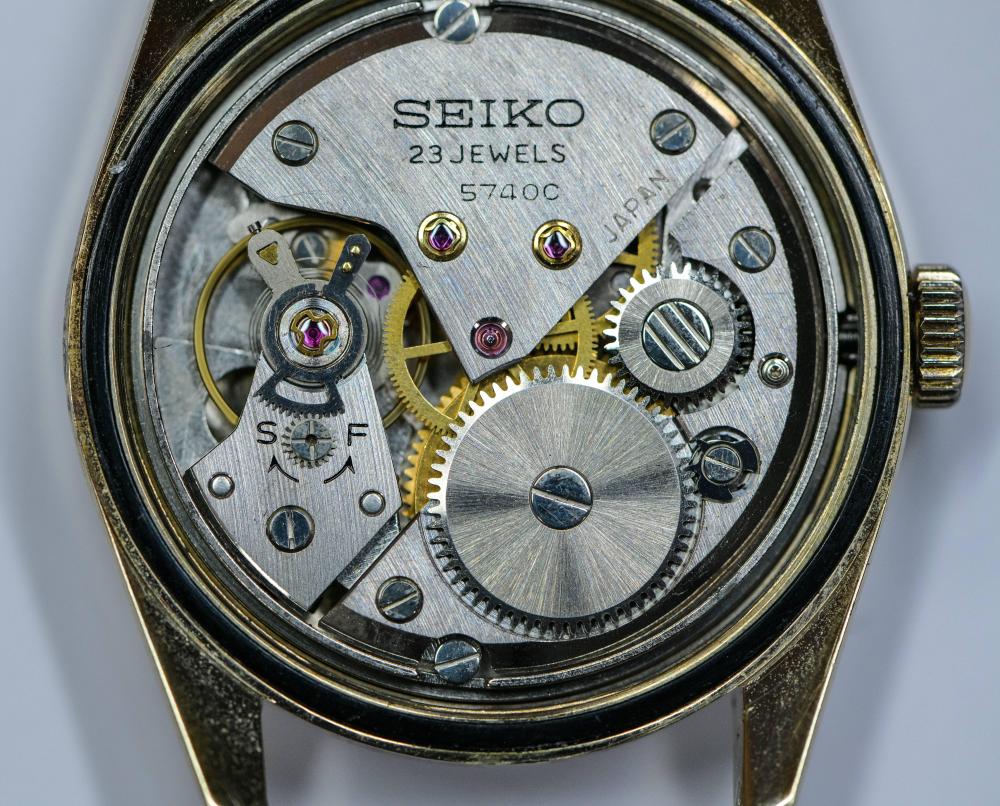

This was picked up as a non runner. The linen dial clinched it for me. Broken mainspring was replaced as was the crystal. Great movement for a beginner. Not sure if the 3600 VPH made it easier to make it look good on the timegrapher, but it was the first to come off the bench with a single flat line. Not sure how long it will last as I only had Moebius 941 for the pallet jewels, which I guess will be being splattered all over.1 point

-

1 point

-

I busted a pivot the other day because I grabbed an unchecked punch that was blocked. Grrrr...I was mad. Such an easy thing to avoid.1 point

-

corset punch sounds interesting- if it's for removal I'm all for it!1 point

-

Not sure what to tell you. When I had placed my pallet fork in One Dip, it made the shellac nice and soft and the stones fell out. I was under the same impression that One Dip was safe for things with Shellac and so I wrote to Troop-Balas Labs, and you saw their response above basically saying do not use with shellac as it (one Dip) will affect it. They manufacturer the stuff, so I would think they know what they are talking about.1 point

-

It's vintage so part of the enjoyment. Leave alone I say. It's another thing if a dial is completely shot but this is far from it.. A shiny new crystal hides those minor imperfections- lost in the highlight1 point

-

Others may disagree but I wouldn't attempt it myself, the colour of the paint? And lume would have to be a perfect match not to stand out. If you want to have a go practice on a cheap dial first.1 point

-

No, I replaced the plate after having my wrist slapped. I have never wound the watch because it was fully wound when I started. At least I presume it is because the winder doesn't move. Mike Thank you for that. The dial has three pillars secured by brass wires (although one is missing). I shall remove it tomorrow and post a photo of the movement underneath. Mike1 point

-

Sorry, looks like you may have a typo as I have no idea what that means. Yes, mistype on my side though... hexane IS okay for things with shellac, One Dip is not.1 point

-

1 point

-

If the question was for me I'd definitely say chest height. That said I imagine it to be a matter of individual preferences. So, try different positions and see what you prefer, but I wouldn't be surprised if you'd also say chest height.1 point

-

apparently in your case it was and as somebody else noted what happened to the pivot? Before we even get to the staking set use as a reminder when you get a replacement staff you want to measure it and verify this exact same size as the original staff you took house. Typically with vintage or all American pocket watches there can be variations. Typically whatever catalog you're looking at may not list all the variations. So you want to make sure that you have the right size staff otherwise other unpleasant things can occur I really hate to use my imagination because that is a very bizarre broken staff. It would've really been nice to have pictures of what you're trying to do great questions. If it's a newly acquired vintage staking set or basically anything other than a brand-new staking set you do want to check everything out. Especially the base plate the staking set often times things get lodged in their. The other thing you want to be careful doing is making sure that the base and the punch itself exactly line up I'm wondering if maybe you are slightly out of alignment? this is why before you lock the lower played in place you have them punch that comes down that goes into the whole typically a very pointy punch and then with that pressed in place you can tighten the base plate otherwise there's always the chance is going to move and then it moved any whacked it that might be the reason fractured there's the other problem of how well was the original balance staff heat treated. the normal procedure would be more than one punch. Usually need a couple of punches to spread the rivet out. Then you can follow up with the flat price to make sure of these nice and flat.1 point

-

yes playing with your new toy I don't suppose we could have a picture of your watch? Basically aiming down at the balance wheel assembly. As I have questions.1 point

-

as others are telling you that dial never came with this movement. For one thing the movement is supposed to have a small secondhand and that seems to be missing? then interesting looking dial which of course is definitely porcelain. The original porcelain dials had the feet silver soldered on so they can withstand the enameling process. it looks like somebody basically tried to cut the old feed off for grind them off to fit them to the wrong movements. then did this watch come with a case1 point

-

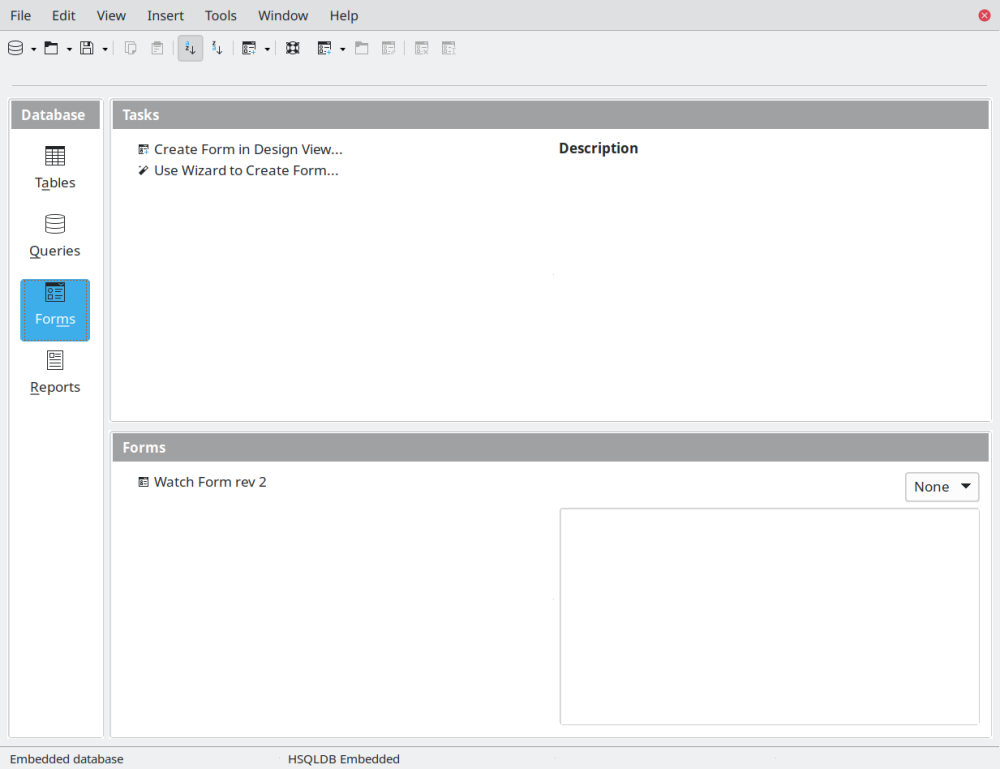

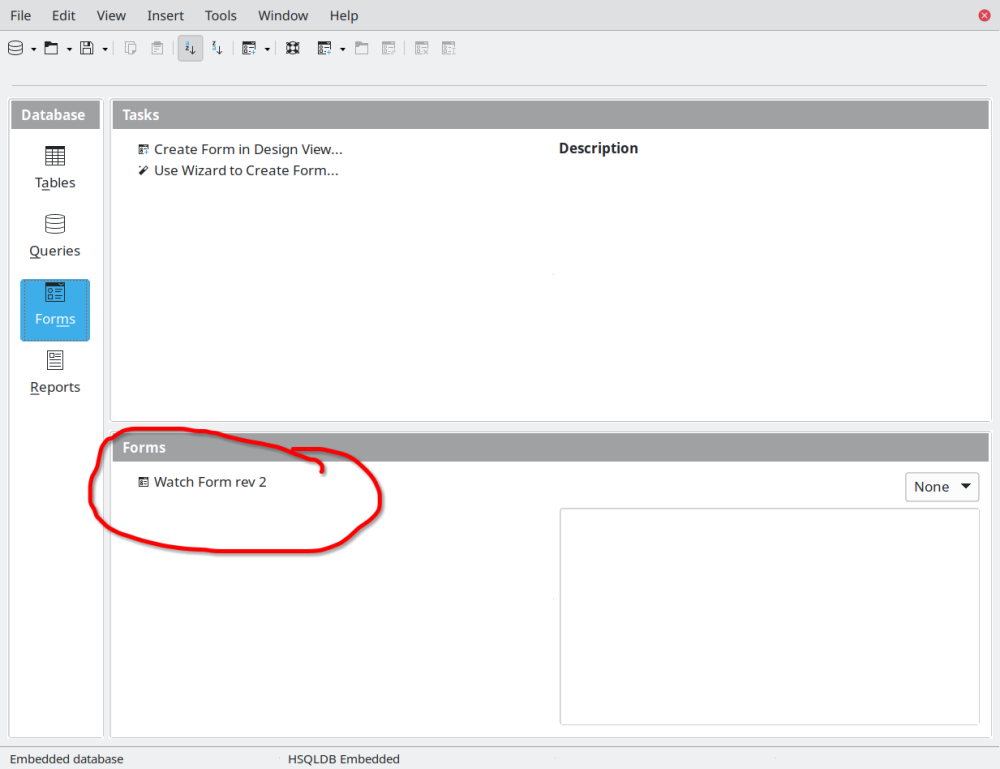

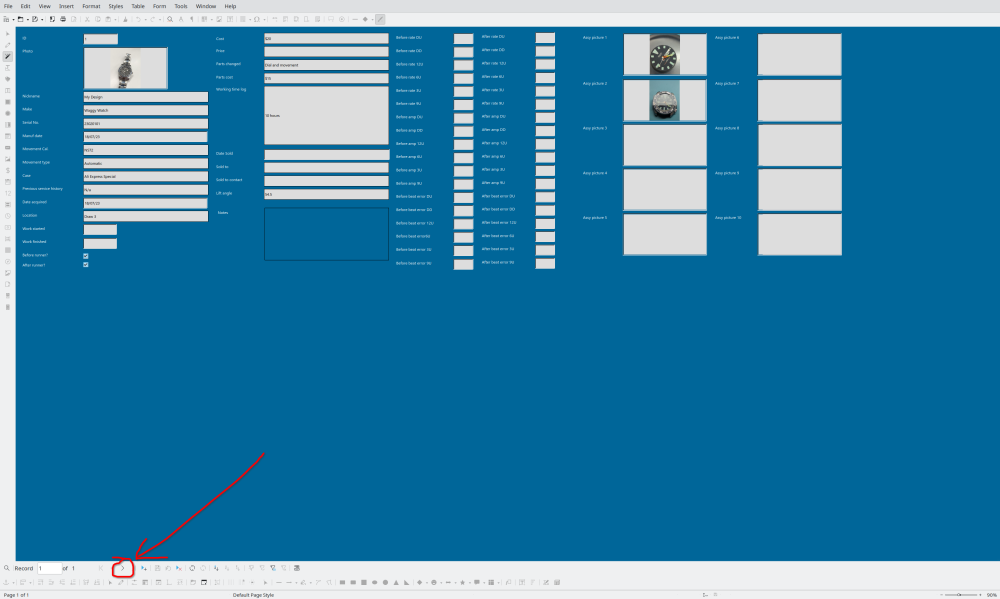

Hello everyone, Well it has taken a while, but I have completed the first draft at my watch database and as promised I have made it available for anyone to use/edit/re-distribute completely free of charge, download link here Please remember that I am not a professional and I do this as a hobby, so any constructive comments and suggestions are welcome. For now, you will need libreoffice to open/use it (which is free) link here, I plan to port to MS Office in due course. When you download you will get a window like this, if Forms is not already selected (in blue below) please select it. You need to double click on the form, see circled red below: Then the form will open: I have populated the first record with some dummy data just as an example, please overwrite this with your first watch record, you can add a new record by pressing the forward button (circled in red above) and move between your records by using the forwards and backwards buttons. To add a picture, just double click on one of the picture boxes and you should get a box asking you where the picture file is located. I am sure there are errors and it needs some polish, so lets call this an early beta version - please let me know what you think. Forgot to mention, no fields are mandatory, except the ID field (top left) just make it the next number in sequence, so you can add as much or as little data as you want Sorry I missed this comment in the current draft, you could add this in the notes section until my next revision.1 point

-

Hi. Check if the feet platings match this movement, if not they were as Klassiker said cut off so the dial fitted the watch. So before putting new ones on check.1 point

-

Great advice and already done! I'm studying that and watchmaker's and model engineer's lathe: A users manual as well. BTW, T&T&T on youtube is an amazing watchmaker with the lathe so people can see some of the techniques close up.1 point

-

Thanks John. About the title, i agree it was rather vague. Vibrating a hairspring really is a pain in the..... we say arse . Its taken me two hours to find the active point and 22 oscillations in sync is the closest i can get. Going either way with the hairspring in the tweezer and the two balances start to sycn out sooner so i must be close. The reason i started this was to see if the hairspring was timed correctly to the balance wheel ( and to play with a toy ) My tg was showing 400 seconds slow. As it happens the hairspring is timed correctly, the active point was almost in the center of the original terminal curve. So its now reassembly and back to finding the actual cause of the slow rate. Another day now as its almost midnight in the Uk. Appreciate the input chaps John and OH.1 point

-

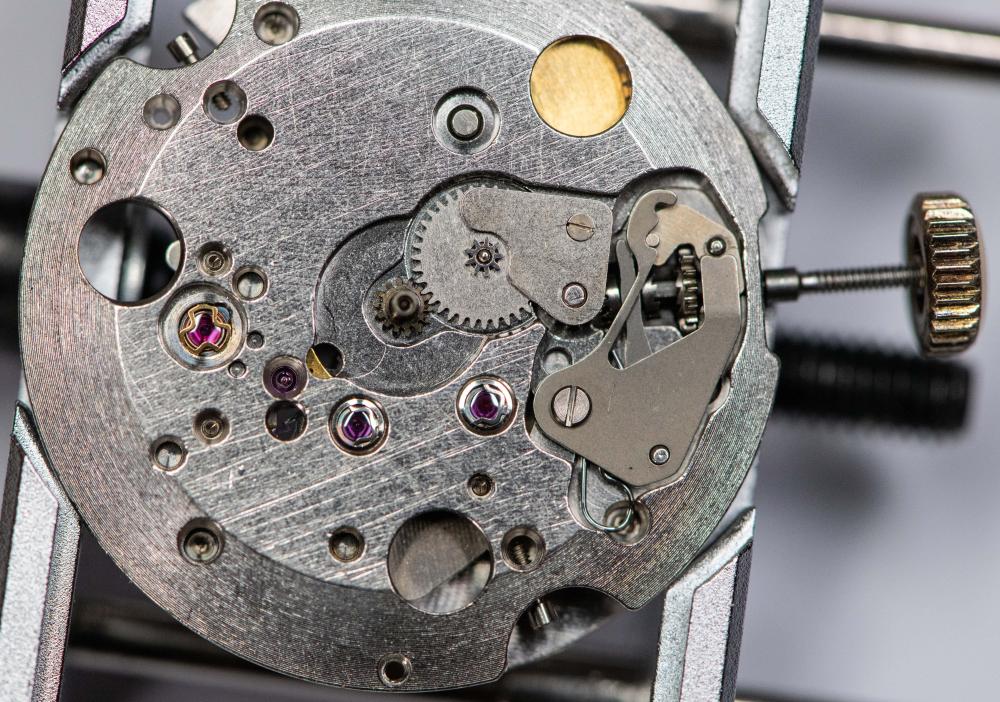

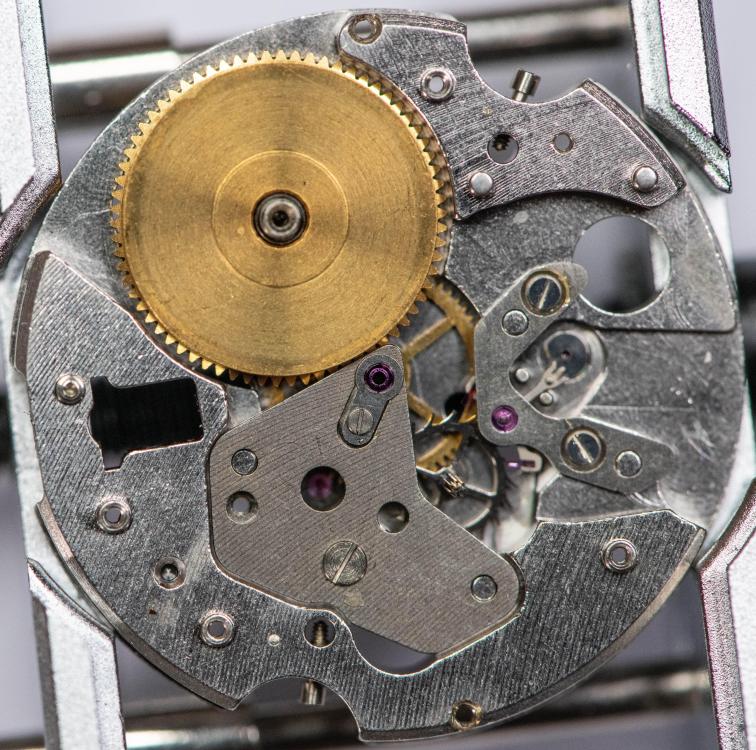

One more update: While I was getting ready to phase the watch, I noticed the finger jewels had skipped under the index wheel. Turns out there was an absurd amount of end shake. After some quality time with the Horia clone (and a lot of practice aligning pivots in a bridge), I got the shake down to an acceptable level. Phasing was actually super interesting. I used the method described here. Started at 1.05v and turned the pawl adjusting screw until it ran smoothly. Jumped up to 1.75v, and the train started spinning noticeably faster. The method above says, "See if the index wheel is running normally or fast." I thought there was no way I'd be able to tell, but looking at the speed of the second wheel it is completely obvious. I was able to get it to run smoothly up to 1.80v, and I called that good. Re-cased, popped in a Renata 344, gave it a little tap, and off she went!1 point

-

Did it pass any tests for water resistance before going out? Fogging on the crystal is pretty much a 100%* sure proof that water has entered the watch. *We were taught this in school. The volume of air, even if there isn't a movement/dial in place, is too small to allow enough water in the form of humidity to actually condense. I've read somewhere that in extreme cases there can be some condensation- but these cases are, extreme.1 point

-

We kinda love you John, for taking the time to answer our questions.1 point

-

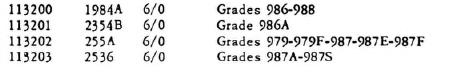

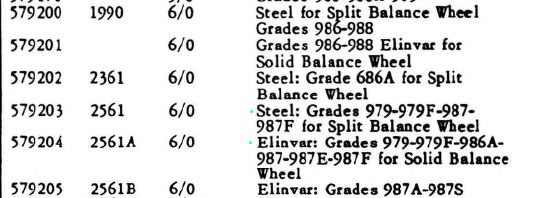

I'm sorry that you don't find me very helpful. But I don't find it helpful to get numbers and not know what I'm dealing with. So that makes us even of being not helpful. except now I have a picture so I know what I'm dealing with that's helpful. I just a note on compatibility because when you start looking for eBay you might wonder about this. Notice how the 987 is compatible but it comes in a whole bunch of variations some of which are compatible and some of which are definitely not compatible. I snipped out an image from the bestfit book it has the smaller number which is the old number and the large number which is the newer number. then for the hairspring things get more complicated which is why a picture was required. You will note there are two separate hairspring is available for your watch. Each of the hairspring's has a description like for instance steel typically this would be a blued steel hairspring like what you have in your picture. This also goes with the bimetallic balance wheel. The other one would be a white colored hair spring for a solid balance wheel you'll notice that they're different as they do not interchange.1 point

.thumb.jpg.e1737221d1bb91b37331a627546ff250.jpg)