Leaderboard

Popular Content

Showing content with the highest reputation on 08/16/23 in all areas

-

as you like the illustrations how about the entire technical document? Hamilton technical data number 129 replacement of broken balance staffs.pdf4 points

-

4 points

-

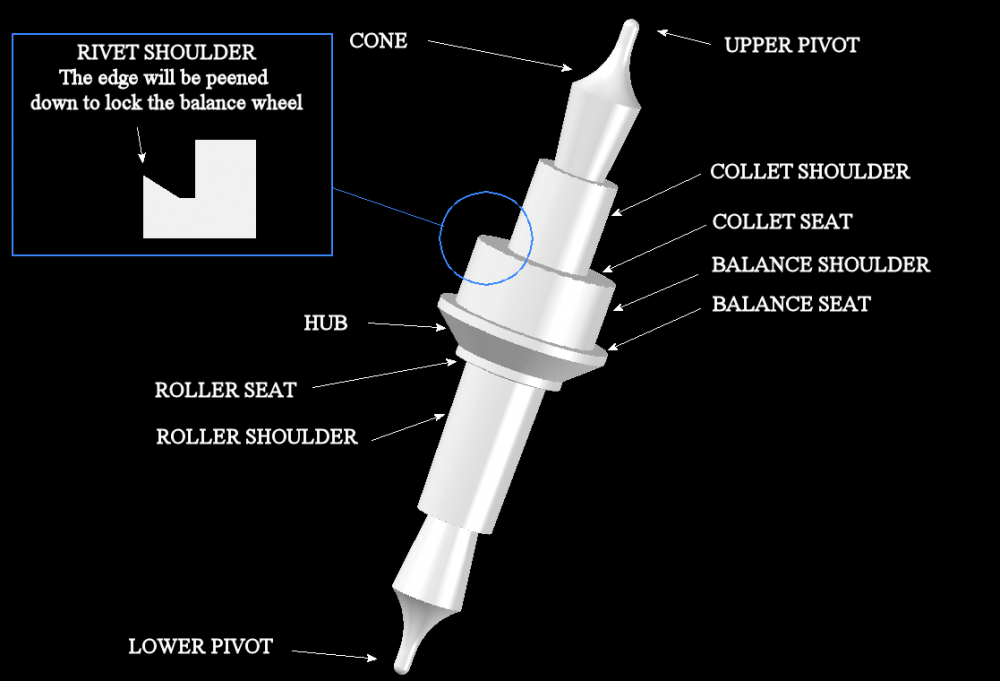

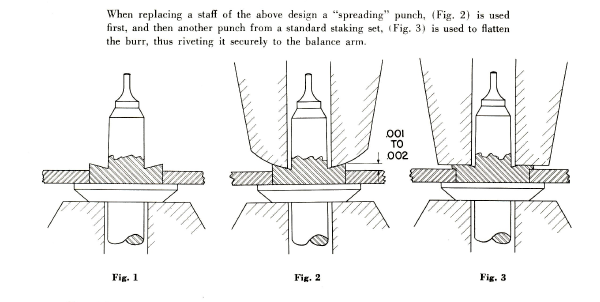

Yes. But, not too much! Haha. Seriously, there should be freedom with the punch around the collet shoulder from that illustration. The collet seat is effectively the rivet, so there must be contact there.2 points

-

2 points

-

That ring is called a slinger. It is to prevent liquids from riding up the shaft and into the motor. This is where a bearing puller comes in if you do not have a hydraulic press. They are like oversized hand pullers. There are various sizes and lengths available. You'll need one that is long enough to reach the bearing and yet have jaws fine enough the go into the gap to grip the ring.2 points

-

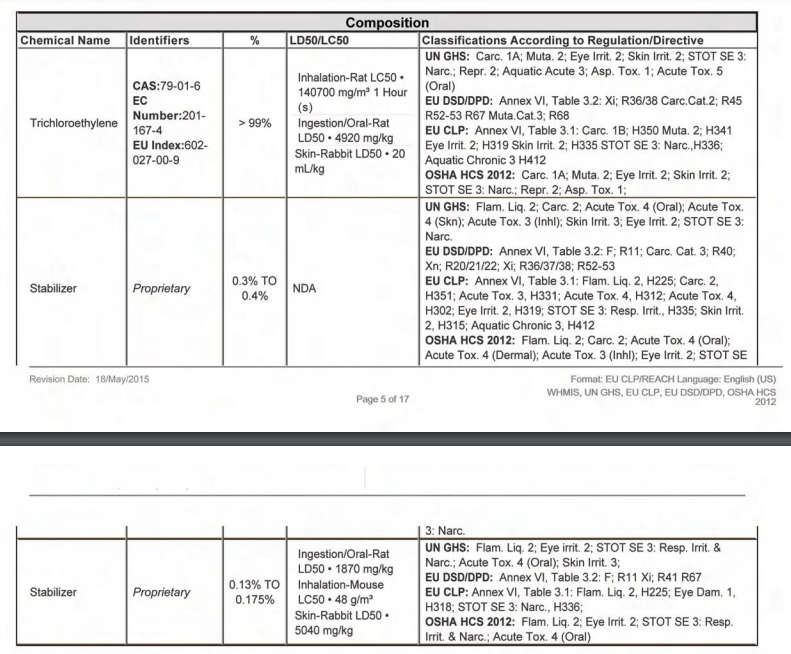

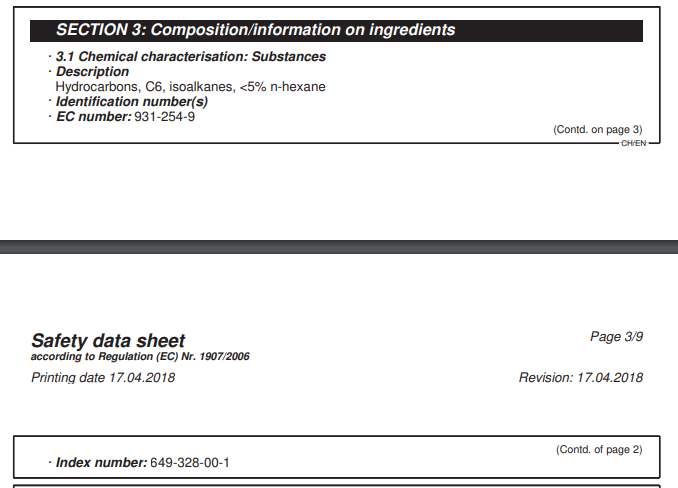

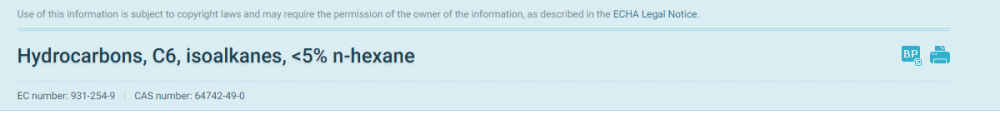

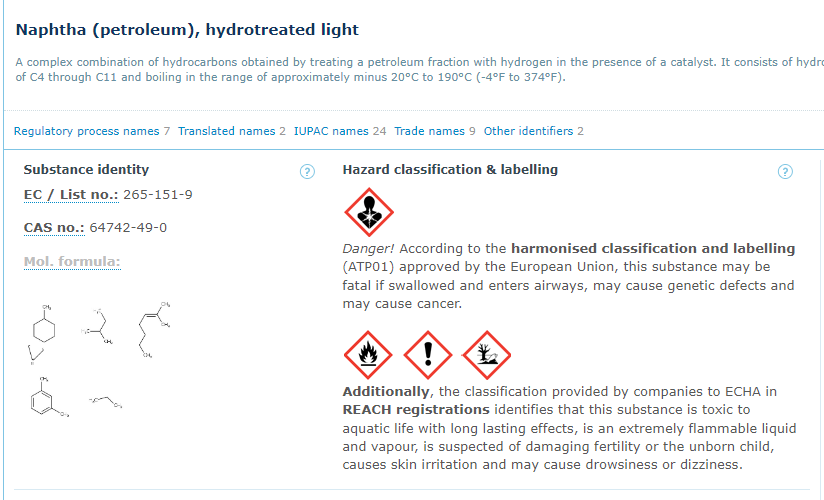

I think we may be comparing apples and oranges when looking at One-Dip and B-Dip, and it may explain the confusion over shellac compatability. One-Dip is 99% Trichloroethylene But B-Dip is not made of Trichloroethylene, it appears to be naphtha! See the route below I took to find this out ---> Here is the B-Dip MSDS sheet from CousinsUK for the version of B-Dip they currently sell: And looking up EC 931-254-9 you get a reference to the CAS number 64742-49-0: When you look up CAS 64742-49-0 you get Naphtha: Hence completely different compounds which probably explain the different recommendations and/or reactions with shellac.2 points

-

The fact you had to use something to push out the broken piece is important. When choosing a hole in the plate, the staff should be a free fit. Not tight, not sloppy, definitely some freedom. Then as John mentions, alignment is very important. Some alignment punches are bent. Then, your round and flat face punches should have- some freedom. If they are a super close fit, but free, go the next size up. All this freedom adds up to things staying flat during the rivetting process. My take on your situation is the staff was a snug fit in the plate, and you used a close fitting punch, and things literally went sideways when the hammering started.2 points

-

I've been learning this wonderful hobby for 21 month. Still learning. However, I now feel confident enough to tackle my first major project. Seiko Bellmatic 4006. Just arrived form the seller. Started the disassemble. Need parts. Beginning the source. Stem, crown, pusher and stem, setting wheel holders and may be a new alarm setting wheel. Phew! But as said, I do feel confident enough to start and complete the restoration.1 point

-

I like to keep the ultrasonic to a minimum. As you have found, it can be destructive. Maybe you could reduce the rinse times? I use Elma cleaners. The Elma product info sheets recommends 2-10 mins cleaning, and about 3 mins rinse. In the ultrasonic, I do jar 1, 5 mins clean, then jars 2 and 3, 3 mins rinse in each, and a final 30s rinse in IPA. This gets everything nice and clean for me, and I've never noticed any plate damage.1 point

-

The illustration John showed illustrated it perfectly. Anyway, thanks for clarifying! I'll edit my post now or I'll never stop thinking about it.1 point

-

1 point

-

I see, that's the setting bridge and detent spring. I've seen plenty of these broken.1 point

-

Thanks Richard. I'm actually starting to enjoy this. By amazing coincidence, Lidl are selling ultrasonic cleaners tomorrow . Mike1 point

-

Thank you everyone for the advice! I guess I will keep it (the dial) as is and just do a service on the movement, and leave it. I do really like it, just such a pity that there is that small dot there. All the best!1 point

-

Nah mate don't touch it. Its not just painted, you have a sunburst dial there. No offence but you dont have a hope in hell of patching that up yourself to improve it. Any pro restoration to the same standard would be very expensive and if you did decide to sell it any serious collector would almost certainly know and walk away from a non original dial. It is what it is and is its history. I love collecting and originality is at the top of my list when considering anything to buy.1 point

-

The ones I have repaired many years ago were always countersunk. Nearly every one that came in the set lever would be brokeen so I had a good stock of parts for this movement.1 point

-

Awesome illustration, thank you. To be honest, this is exactly what I thought I had in my set up, but it’s pretty clear now that the crap I had not cleared out of the staking base plate holes was a major contributor to my failure. Wow, Thank you!1 point

-

1 point

-

I suppose technically we still need to figure out what the problem is. for instance what exactly is this? the white is printed on but the spots look like they're on top of the surface unless their chips? So there on top of the surface up off of their might remove them or they may make special well basically fancy cotton swabs you maybe would just gently nudge them slowly come off. Providing there actually something on the surface and not in the surface now for these ones it's hard to tell I think all the white stuff is probably something extra what's on top it may just wipe off or blow off but the others spots just can't tell. then those images are a pretty high magnification in the sections I snipped out or even bigger. If the white specks would just go away maybe you'd be happy. Traditionally any form of cleaning cleaning products can have undesirable results on the dial. If you had a spare dial to play with but then a few disparate dial you just swap. So traditionally any form of cleaning painted dials has the potential of making things worse. then we have this. Notice the T stands for Tritium safer than radium but it does present a challenge for someone trying to replace anything that was florescent because ideally they have to use that. I was at a lecture a little while back and is about restoring hands slack she talked about buying hands that use this for the luminescent material salvaging the material in making a new stuff to put on the new hands that they had not recommended for casual use because yes it's still radioactive. the problem is when you're dealing with a painted surface anything you do will probably make it worse unless it's something external like residue left behind from the fluorescent markers if you're lucky oh just blow off. The problem is if the wife is actually a gouge or something filling it in matching the color would be impossible. Anything you do will probably make it worse. But maybe somebody on the discussion group will tell you some thing that I don't know and fix the problem.1 point

-

From my days many moons ago doing chemistry all the chloro carbons are carcinogenic to a greater or lesser degree. So, distilling it all down, it would appear that one-dip (Trichloroethylene) is not ok with shellac based on the communication with the people who make the stuff as reported in earlier posts in this thread. But B-dip (naphtha) is ok.1 point

-

Just to make certain I understand. So do you mean that when the punch is resting on the balance shoulder there should be a bit of freedom between the hole in the punch and the collet seat? EDIT: Now, that didn't come out right . What I meant was: Just to make certain I understand. So do you mean that when the punch is resting on the collet seat there should be a bit of freedom between the hole in the punch and the collet shoulder? (@HSL drew this picture for me when I was learning)1 point

-

1 point

-

I busted a pivot the other day because I grabbed an unchecked punch that was blocked. Grrrr...I was mad. Such an easy thing to avoid.1 point

-

corset punch sounds interesting- if it's for removal I'm all for it!1 point

-

1 point

-

What is a “lump hammer”? Never heard that term before. I don’t know what a corset punch is either. I used a round nosed punch that fit very close over the shaft of the staff.1 point

-

It's vintage so part of the enjoyment. Leave alone I say. It's another thing if a dial is completely shot but this is far from it.. A shiny new crystal hides those minor imperfections- lost in the highlight1 point

-

Most Seiko dials I have seen are 28.5 mm in diameter irrespective of case size. If you could provide pictures and the movement number we might be able to help. Tom1 point

-

I assume this is a vintage staking set? Based on the fact that the pivot is also broken, I'm going to guess that there was some debris inside your stake that put enough lateral force on the staff to snap it off. I know my set had bits of metal stuck in all the holes of the plate, so I wouldn't be surprised if there was debris in your stakes.1 point

-

i haven't played poker for years and i never give anything away1 point

.thumb.jpg.2238215abb0bc0183061297482ba237d.jpg)

.thumb.jpg.45c97b5e8961bd24ce4d2efb37292a9b.jpg)

.thumb.jpg.5e949b9ea0c27242835579a5bae70599.jpg)