Leaderboard

Popular Content

Showing content with the highest reputation on 08/18/23 in all areas

-

I think our grandchildren will still be arguing about it5 points

-

3 points

-

Aw bless you Ross, you're a lovely bloke and you always inspire me. You've given me another little nudge towards giving it a go now. The BHI workshops are only 70 miles from me, so yes i do feel quite fortunate. I still haven't quite figured out why I'm drawn to the hobby, something inside me wants to carry on and become better. As for you Ross, you've come a long way since you started and you never fail to surprise me with your quest for knowledge, your ingenuity and drive to overcome obstacles, and your passion for it all. This forum would not be the same without you buddy.2 points

-

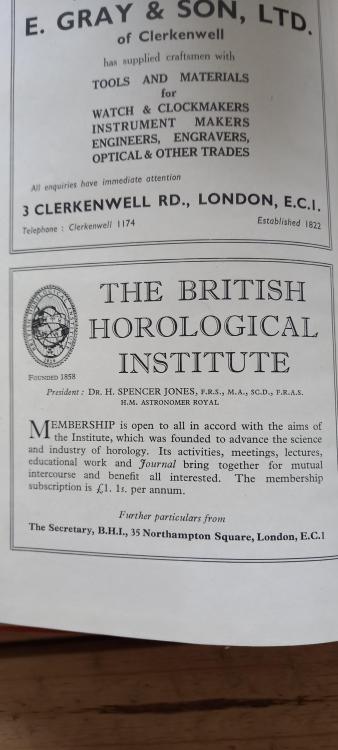

Nevereboughwatches. Envy you. However, like Tom, I also looked at this course. Discounted it quickly for three reasons. Cost, age and space. Cost. My bride would strangle me. Age. 75. But I am capable of learning visually. The written word would defeat me. Space. I live in a parkhome. One bedroom and a 6' x 9' study which has 2 tables. One for my bride's craft work, the other for my computer and watchmaking. I have no room for the required lathe, but I have purchase a 3" bench vice. Judging by your and other's posts. I think our hobby standard is far better than many of the professionals. The amount of watches I have received that are scrape marked, parts missing or even put back in the wrong place is many fold. I have gained a good appreciation of the application of care to a watch and the movements. Mark, and Alex's courses cover most bases. YouTube videos offer a plethora of information and structural advice. These make it my distance learning course. The only thing I don't have is a tutor. I do feel that I overcome this by having the members of the forum guide me. I'm still learning. But going professional? I think that the B H I is the way for recognition. As I said. I envy you2 points

-

I really hate assuming anything but it does look like shellac? As that is something used in watch repair they would have it available or it could just be some sort of really poor glue that just looks like shellac. oh I found a little history online of India making watches. I don't see any technical references to innovative methods of doing things which is what perhaps will call this. although there is a possibility that this is innovative repair done by somebody else after it left a factory perhaps https://watchesbysjx.com/2016/07/hmt-watches-the-rise-and-fall-of-indias-watchmaking-titan.html additional information https://thehourmarkers.com/history-has-it/hmt-watches-a-walk-down-the-memory-lane/2 points

-

I forgot it was a Seiko (old age is a bugger) Is that little circlip in it's place and is it flat and not bent.2 points

-

I was looking at this a while back but didn’t go for it at the time as the cumulative costs including buying a lathe at the time put me off. I have seen/heard of several well spoken of watchmakers whose professional credentials are from the BHI DLC. If I was a bit younger like Rich I would most likely have done it for an early retirement gig. Now I have a lathe amongst other things () I should look at it again, 63 can’t be too old to be an apprentice . Tom2 points

-

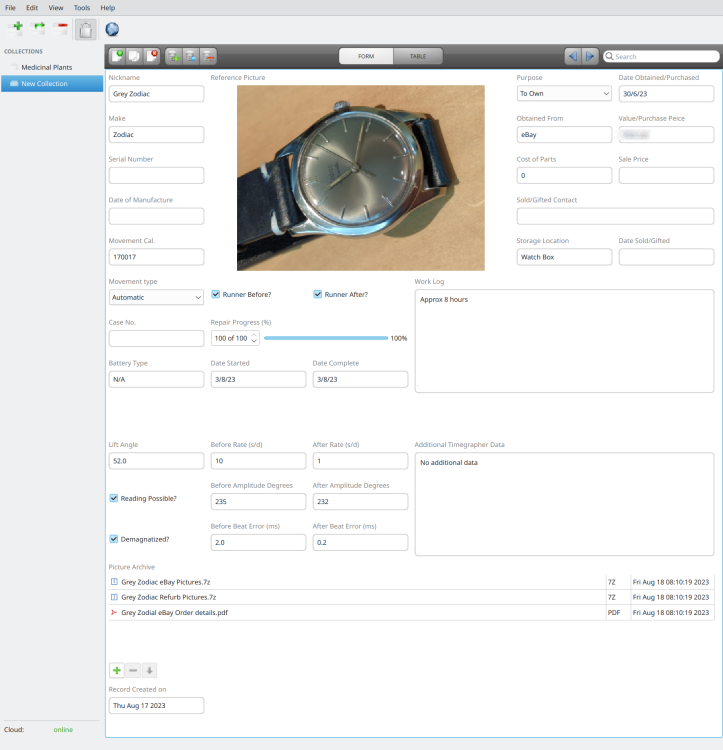

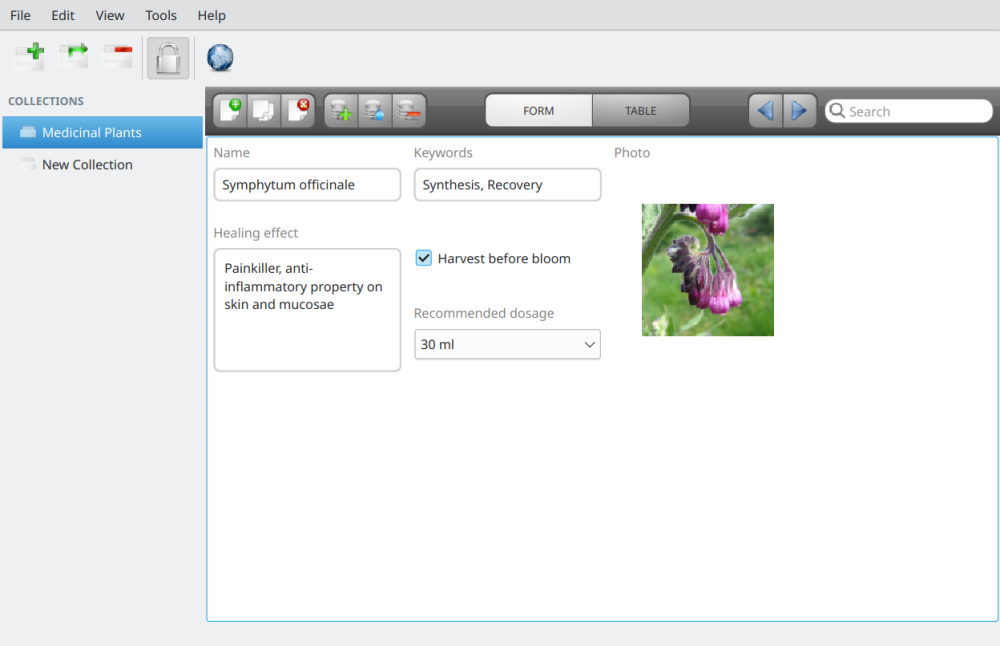

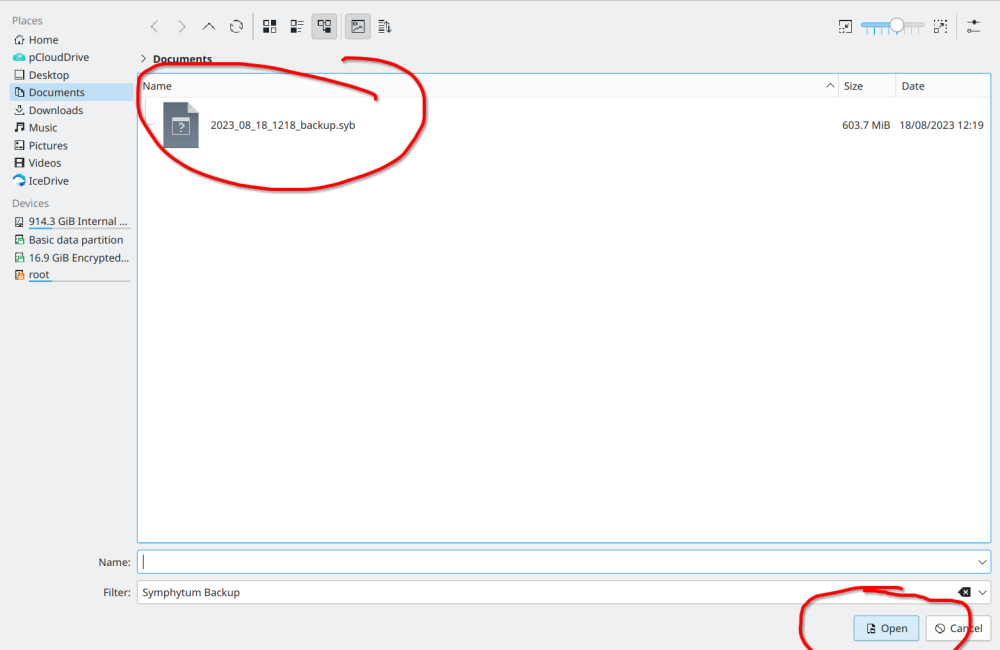

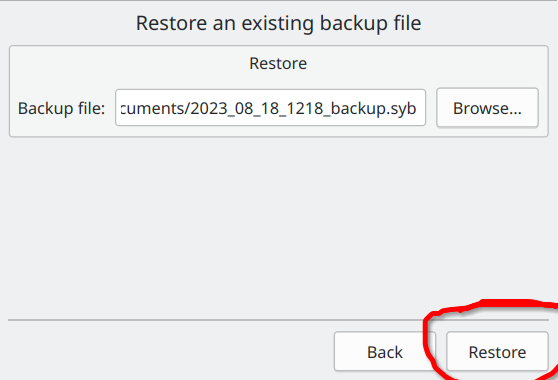

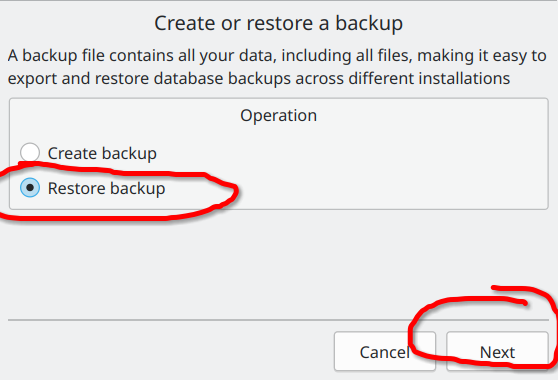

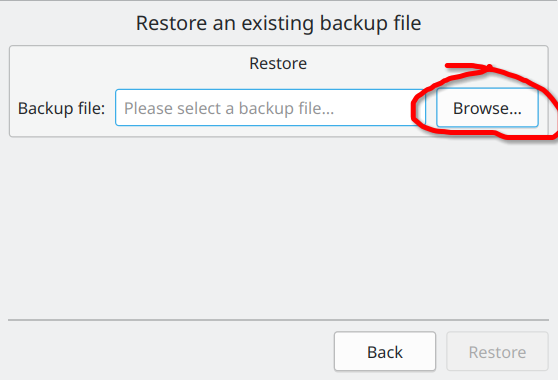

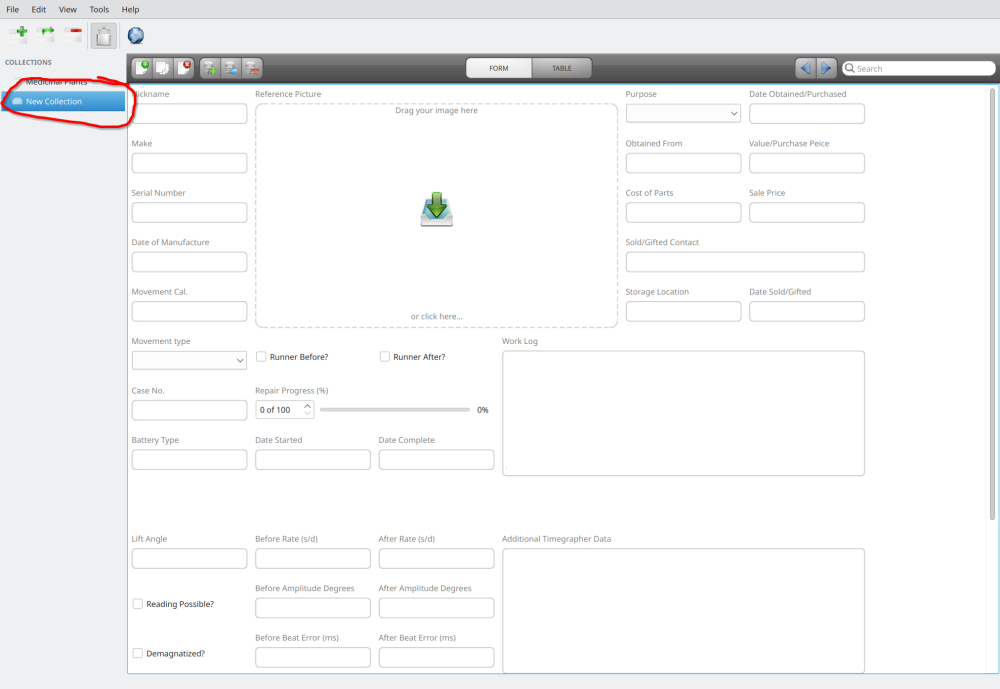

So here is the updated version - I have abandoned the Libreoffice version as this was buggy and pretty ugly - would have taken a lot of work to iron out the kinks and make it look pretty, hence I have switched to symphytum which is a stand alone database application which is free and open source (yay!!!!). The versions for Windows, Mac and Linux can be downloaded from this link. The watch database I have created can be downloaded from the link here - completely free to use and re-distribute...etc. I think this is much more stable and looks a lot better than my previous attempt. Steps to use: Download the software (link above) and install on your machine, latest version is 2.6 Download the database file - I had to do this as a data backup, so you will need to restore as if it is a backup of your data Use and enjoy! Steps to install the backup: Start symphytum, you will get a screen that looks something like this: Go to file (top left menu) and select backup, then you will get another window (below) and select Restore backup, then next Now navigate (press the Browse... button) to the location of the backup file that you downloaded on your computer: Highlight the file and press open Then Restore int he box above You will need to re-start the program and you should now see in the left hand side a new database, click on it and you should have your first record input sheet. as below: You can now right click on the plant database to delete it, unless you like it Here is an example of one of my records: Any pictures I took during the service I simply zipped into one file and dragged into the file storage area (picture archive: bottom of record sheet) I'm also keeping my eBay receipts there etc. Hope you like!2 points

-

Eyup SpringMangler, at 56 going to full time watchschool is not an option, though i nearly considered the one year 1800 hour schooling. The BHi courses at least have exams and some qualifications at the end of them. The two courses are just over a grand which i thought wasn't bad and for the same again includes tutor feedback. There are only 2 serious repairers in my town one of them is the only member of the BHI in my county of Yorkshire. He lives about a mile from me, works from home and has been a watchmaker for over 40 years. A visit to see him might be a good move.2 points

-

@rossjackson01 I think that for me and @Neverenoughwatches we seem to have a common drive, we need to know all the things when we hit a new venture. I can quite happily build you a custom watercooled PC, custom computer keyboard or a watch I can get parts for. The first two are easy, I spent time as an electronic engineer in the dim and distant past and also time as a computer service engineer working down to components. So for me I think this is the same mindset of problem solving and maybe a bit of going back to my childhood working with my granddad on mechanical things like steam engines. Tom1 point

-

If there is enough space so you can get the stud inserted into the hole like you say, why not . But such space isn't available in some calibers, in such cases you should 1- Lay the cock on bench upside down. 2- Open the regulator slot enougn for spring insertion into it, Close the slot. 3- Tighten the stud screw if you feel enough contral over the task, if not, grabe the cock and stud in your twe5ezers, flip it over to instal onto the bare mainplate, then tigten stud screw. Now is the time to make some adjustment to the coil, level it, minor adjustment for coil concentricity, check if balance swings freely, so on. This all comes before reassembly. Make a habiit of always doing adjustment to the coil, check the balance swing etc so you are sure balance and coil are OK before you instal it. Rgds1 point

-

Eyup peeps , i have an update on my experiment with perc. Tetrachloroethylene. Two pallet forks from movements approx 50 years old were soaked for one hour. Removed and then poked at the shellac with a sharp needle. The shellac wasn't especially soft but the needle point could be pressed in, and if pushed the shellac would shell off. I didn't test before hand how hard the schellac was so i tried on another six dry pallet forks from the same test bunch. The result was the just the same, the needle point could be dug in and shellac could be shelled off with the same general force as the soaked pallet forks. My conclusion from this is that Tetrachloroethylene ( supposedly a similar chemical to one dip ) doesnt have much if any effect on shellac. But secondly shellac is not really the superglue adhesive that some folk may think it is, but more than adequate to keep stones in place during the forces they undergo go perform their function.1 point

-

I think somewhere in the history of citizen watch company they moved or sold or something of factory relocated to India. one of the companies that pioneered gluing hairsprings was the Elgin watch company. It's done because then there's no stress on the hairspring versus using pins. Of course today they laser weld a lot of the stuff. I case in the Elgin literature whatever they use is not available to us so they recommended shellac which is sort of what that looks like. In the case of the Chinese they use some sort of substance like a glue that usually disintegrates after one or two times through the cleaning machine. Then if you're careful with epoxy you can put it all back together again. So basically if you don't want to deal with the hairspring floating free of it stud you can't run it through anything that resembles cleaning fluid because if that's not shellac who knows what it is.1 point

-

Thank you @oldhippy and @tomh207 I'll reset the hands over the weekend. Hopefully it'll do the trick, will post and let yous know. Thanks again folks1 point

-

Not if your tutor has 20 years on you. Watchmakers live well into their 80's Other things ? Two different sized eyes and a tongue that permanently sticks out ? now i come to think about it thats exactly how i look when I'm tinkering at my watch bench.1 point

-

Anyone can join the B H I. I know from previous experience with the first course there is a lot of technical drawing, filing and making parts so you will need a good lathe to make parts on such as balance staffs. Being just a member doesn't hold any weight apart from getting a reduction in price of there monthly mag.1 point

-

1 point

-

I know that the lighter fluid i use has never affected the shellac on any pallet stones even after an overnight soak. The percentage of naptha isn't stated on the label. Pharmaceutical grade naptha ( 99.99 %) is readily obtainable in the Uk through ebay at 22 quid per litre. Who knows we might one day have a concisive list of what to use for cleaning all watch parts which everone agrees upon .1 point

-

I'm even older than you, so not looking for a new career. Whatever hobby I'm into, be it photography or watches, I want to know as much as possible. Must be a bit of OCD. Looking at the various options the BHI looks well structured and, as you say, relatively well priced.1 point

-

1 point

-

Seiko NH movement so no dial washer. As oldhippy says the hands need to be reset for the date change to happen at midnight, as it is NH36 it has a day wheel as well, iirc the day on these changes around 4am. Tom1 point

-

did you notice on the image I sliced off the PDF that on the left-hand side there is a red symbol that probably is a on the website click this and get a parts breakdown. So conceivably there is a parts breakdown for all the components which means by theory you could get just what you need. Like if somebody probably on eBay needed just the button and didn't need the other part. Otherwise at least here I can see what you're getting it looks like the whole thing. https://www.watchmaterial.com/omega-speedmaster-professional-mark-ii-145-014-push-button-stainless/1 point

-

Cousins item # S15720. Seiko crystal part number is 325T02ANS0. You can use Sternkreuz XAC326.534. It also comes with the tension ring. https://www.cousinsuk.com/product/special-profile-chrome-ring-xac?code=S157201 point

-

Here's a link to the post where I got the picture of the balance staff naming its various sections. That post, with its additional illustrations, was very useful to me at the time, and even though it doesn't add much to this particular discussion I thought it might be appreciated nevertheless. If you look closely, @HSL (where are you these days?) has indeed added a bit of space between the hole in the punch and the collet shoulder, but that was not discussed or even noticed by me at the time. So, another piece of important information gained!1 point

-

1 point

-

1 point

-

One more update: While I was getting ready to phase the watch, I noticed the finger jewels had skipped under the index wheel. Turns out there was an absurd amount of end shake. After some quality time with the Horia clone (and a lot of practice aligning pivots in a bridge), I got the shake down to an acceptable level. Phasing was actually super interesting. I used the method described here. Started at 1.05v and turned the pawl adjusting screw until it ran smoothly. Jumped up to 1.75v, and the train started spinning noticeably faster. The method above says, "See if the index wheel is running normally or fast." I thought there was no way I'd be able to tell, but looking at the speed of the second wheel it is completely obvious. I was able to get it to run smoothly up to 1.80v, and I called that good. Re-cased, popped in a Renata 344, gave it a little tap, and off she went!1 point

-

It is indeed a Smiths movement Mike. Ingersoll Smiths Services and i also think Newmark all had same calibre movements at one time or another. These were the cheap end of Smith's market made in Wales, hence GB labelled, at the Ystradgynlais factory as opposed to their Cheltenham factor. I have this same calibre in a Smiths diver, a rather expensive watch to buy for what it is. I'm sure you've seen all the Smiths Empires knocking around Ebay all made in the same Welsh factory . The 17 jewels in yours is not a common find though, must have been towards the end of their production. Smiths started to source out their watches to Switzerland around late 70s early 80s.1 point

-

I can tell you its British made, so not a swiss movement. You can get them with calendar as well.1 point

-

This a project I did over the weekend, a Lucerne. Watch was a non-runner due to dire need for a service, gummed up with old oil and a damaged balance hair spring. This is the first time I have taken on rebuilding a hairspring was was smiling all day when I got it not only working, but working well! Before and after pictures: Finished watch1 point

-

Watch of today. I've finally finished the Seiko 6119. Thank you folks. Not the 6119a I was recently posting about. Still haven't got the correct crown. However?..... I obtained a 6119 which was a 'b'. I did a teardown. Clean and full service. It came without a strap, so I've found a strap from another Seiko purchased last year. Not a great photograph, but, thank you to all. I'm on the way, getting there. Great fun this hobby.1 point