Leaderboard

Popular Content

Showing content with the highest reputation on 08/19/23 in Posts

-

The most likely senario is that the spring might be too short, might have broken at the stud and re-shellaced like this. In such case you might could make some improvement, shape the terminal curve , sort out the coils to be parralel, etc. a fault that developes when re-shellac ing, is often the spring is re-shellaced by a wrong proceedure, which renders the coils not parralel, then the spring ought to be twisted near the stud to make coils parralel. These fault might be there but not meet the eye unless you are looking for them, in which case best to detach the sutd from the spring to sort out the coil and re-shellaced stud back on. Should you decide to go that route, let me know to provide you with a right proceedure to re-shellac the stud. Citizen did at some point sell a inferior know how to India, many watches mostly manual wind are manufactured primarily for domestic market. Rgds3 points

-

If you live in England and you are already a pensioner like me you will be getting a 7% pay rise. Are you happy now.2 points

-

How well do you want the watch to run? If you only want to see it tick again you could follow @JohnR725 advice and leave the spring alone. You could clean everything with the balance intact and reassemble. If you're enjoying this hobby you could practice on other watches and attempt a full service when competent.2 points

-

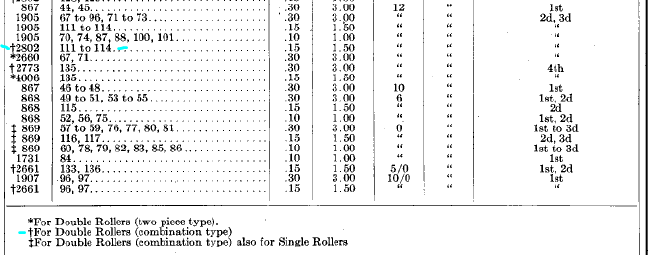

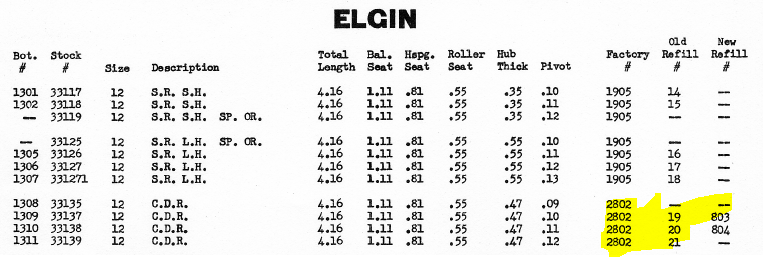

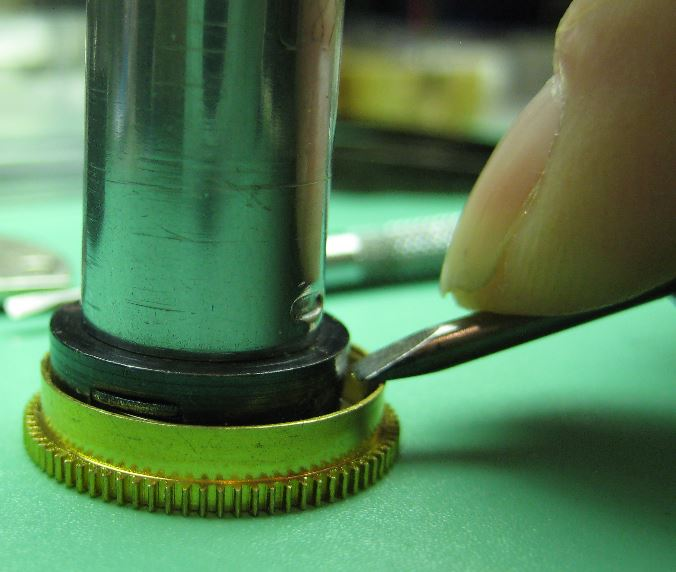

for Elgin parts link below is a better source than the pocket watch database as it tends to have a little more information so for grade 315 it is for the mainspring is actually several of them it depends upon your serial number and you have notes at the bottom of the page as to which one is which etc. This brings up one of the unfortunate problems of American pocket watches variations for the same part number. but if we look in the Elgin material guide we find out that you're supposed to have the slightly heavier spring. Another place you can look his eBay times you can find original spring is there. then as mentioned above if you're going with the modern spring it depends on the watch this spring strengths are determined by the number of jewels but if you have a high jewel watch with a modern spring you might have an issue even if it is the size you think it should be. then for balance staff out of the same parts book then no matter what if you're replacing the staff you want to measure the old and the new and make sure the same size that we'll avoid unpleasant things http://www.elginwatchparts.com/ then there's something missing from the list of staffs up above. There is a dimension that you need which would be the pivot diameter. Of course you don't always get a choice sometimes then looks like for your staff you just have pivots sizes to worry about. Notice the staff up above yours it comes in two different types with one of the dimensions being different beyond the pivots size and yet it has the same part number which is why always like to check my staffs to see what sort of variations are going to have problems with did you notice how your pocket watch has a serial number on the main plate and may be serial numbers on other bits and pieces including the balance wheel? Ideally be better to change the staff if you going to look for a donor movement try to get it within the same serial number range. If you go with a donor movement you'll probably have to do some escapement adjustment may be because the serial numbered components tended to be matched together or manufactured together then for the mainspring just a reminder for this type of mainspring it cannot be shove in out of the package. It either means you hand wind it in and make sure you get the T word supposed to be or a use a mainspring winder and let me show you a picture. Otherwise you going to have lots of frustration or just shoving it in because it's never going to end up well may be at least on the T brace there is a hole in it might actually catch typically with just the T they will never go where there supposed to be you have to follow procedure. my preferred procedure is use a mainspring winder wind almost all the way in but leave a little bit out. How much out depends upon how much clearance the size of the barrel. Then rotate the winder with spring until the T is over its slot in this case. Then you do want to push it into the slot it can't just be overcast actually be in using your heavy a screwdriver of the back in your tweezers ill hold it in place when you push the spring out like shown in the image then in the case of the Elgin you'll see something like this. Then I don't know why the Elgin slot versus the tea tends to end up in the middle probably because the whole part of the braces held by the barrel. Doesn't really matter as long as it's actually in the slot and the same with the lid the lid has to go so that it slot agrees with the protruding part.2 points

-

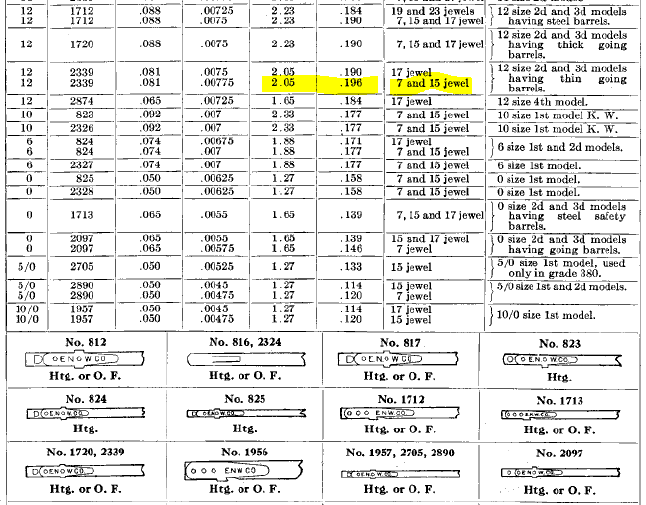

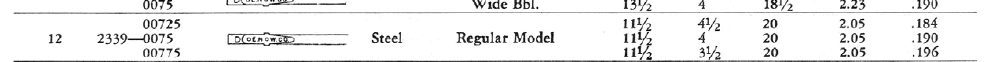

You can find info you your watch by looking up the reference number on the Pocket Watch Database https://pocketwatchdatabase.com/search/result/elgin/36478167 It's a Grade 315. If you select 'Parts' on the left, you can see that the balance and mainspring are common to lots of movements. The spring is listed as #2339, which looking in Swigart, it comes in 3 strengths : The last three columns are length in inches, and width and thickness in mm. So you need about 2.05 x thickness x 500. So the one you listed, GR5944DBH (2.05 x .185 x 500 ) is within spec. I would probably choose that strength - modern springs tend to be stronger than the old blue steel - I've had problems with re-banking. As for balance staff (part #2802), Dave at Daves Watch Parts has a huge stock - he will probably have the mainsprings too. https://www.daveswatchparts.com/2 points

-

So, the numbers are in. Fully wound: Dial up: 309° Dial down: 303° Crown Left: 281° Crown Down: 280° Crown Right: 282° Crown up: 283° Fully wound minus 25.5 hours: Dial up: 268° Dial down: 264° Crown Left: 242° Crown Down: 242° Crown Right: 251° Crown up: 247° A truly dramatic difference compared to the 260° fully wound and 130° after 24 hours in the dial-up and dial-down positions. I really don't think it was the mainspring that caused the problems although I did change it. Burnishing the pivots is in my opinion what did it, and I think it goes to show how crucial it is that all pivots are perfectly free of any impurities however small. I didn't even notice them the first time a serviced this movement.2 points

-

I used to do a couple of minutes final rinse in IPA, but now do just 30 seconds, as recommended for the watch cleaning machines. It's only to absorb moisture and any residue from the rinses, so 30s should be enough, and be kind to your shellac too2 points

-

1 point

-

what I can't tell you off I was sad. then I am going to tell you off even though you said thought to you did not read the fine print. Where exactly are you right now well you're in the safe zone and that puts restrictions on what we can say are not say. So taking out the mainspring would have all kinds of risks including because this is a vintage watch just finding another spring to put back in. Because it's nice and clean and do not going to run this every single day then you don't have to take the spring out unless? If the spring is set which it may be year probably is then you won't get 24 hours of running out of Bill depend on how badly said if it is set. So even a super badly set spring will still run the watch for while so you'll just except that it won't run overnight possibly if it does outstanding. Then yes the spring should have a small amount of lubrication you don't want to put too much because it has a habit of leaking out making a big mess. some of the jewels are held in with screws because they have end stones. Some basic is a look pretty because some viewers do not. It has to do with the evolution of how jewels are mounted basically and of course they do look pretty with nice blue screws. That's your short version of the history.1 point

-

I have also had very good luck with ofrei.com. They will actually help you with balance staves and mainsprings solely based on your Elgin serial number. The mainspring I ordered in this fashion for an old Elgin I was working on fit perfectly. https://www.ofrei.com/page298.html https://www.ofrei.com/page318.html1 point

-

All I remember is it is hard. I have removed it in the past but it screws up the hairspring. I managed to cut it off using a small screwdriver blade..1 point

-

Its a glue type of substance and it is a bugger to remove with out damaging the hairspring.1 point

-

I've started to adopt this approach more and more as well, and listening to the pros like @nickelsilver they do not overestimate the impact the mainspring has on the amplitude. As I mentioned in a previous post in this thread "upon close inspection (40X magnification) I found some very slight rust and oxidation on several of the train wheel pivots", and as I didn't find anything else looking suspicious I feel confident that it was the burnishing of the pivots that took care of the problem. Of course, you can never be 100 per cent sure about anything, but that is my best assessment. So, from now on I think I'll be using my Jacot tool a lot more often. Since we are meticulous about the condition of the jewel holes it makes sense that we should be equally meticulous about the condition of the pivots and pivot shoulders.1 point

-

Well done, those are impressive figures. I have come to realise that the mainspring is rarely the problem*. Even 'tired' looking springs can give reasonable performance. I use to change them as a matter of course, but now only change them if they are really shot. I'm still not confident about burnishing the pivots. I guess you need full magnification to see what's going on, but then you have very little working depth. ( * One watch was driving me crazy, just couldn't get it working well. Turned out that the new mainspring I fitted hadn't been hardened at all. It was just a piece of bendy wire)1 point

-

Neverenoughwatches I'm working my way through the B H I free download sample lesson for the distance course. Very interesting. Thank you1 point

-

Yes. They are called HMT. https://www.hmtwatches.in/1 point

-

If there is enough space so you can get the stud inserted into the hole like you say, why not . But such space isn't available in some calibers, in such cases you should 1- Lay the cock on bench upside down. 2- Open the regulator slot enougn for spring insertion into it, Close the slot. 3- Tighten the stud screw if you feel enough contral over the task, if not, grabe the cock and stud in your twe5ezers, flip it over to instal onto the bare mainplate, then tigten stud screw. Now is the time to make some adjustment to the coil, level it, minor adjustment for coil concentricity, check if balance swings freely, so on. This all comes before reassembly. Make a habiit of always doing adjustment to the coil, check the balance swing etc so you are sure balance and coil are OK before you instal it. Rgds1 point

-

Eyup peeps , i have an update on my experiment with perc. Tetrachloroethylene. Two pallet forks from movements approx 50 years old were soaked for one hour. Removed and then poked at the shellac with a sharp needle. The shellac wasn't especially soft but the needle point could be pressed in, and if pushed the shellac would shell off. I didn't test before hand how hard the schellac was so i tried on another six dry pallet forks from the same test bunch. The result was the just the same, the needle point could be dug in and shellac could be shelled off with the same general force as the soaked pallet forks. My conclusion from this is that Tetrachloroethylene ( supposedly a similar chemical to one dip ) doesnt have much if any effect on shellac. But secondly shellac is not really the superglue adhesive that some folk may think it is, but more than adequate to keep stones in place during the forces they undergo go perform their function.1 point

-

I've run across these in a Wakkman (Unitas movement) and another movement where the name escapes me. Both dissolved in cleaning fluid, so you might want to err on the side of caution. Luckily, there was a little bump left on the spring that showed me where to attach it again, which I did so with epoxy and they both worked fine afterwards.1 point

-

I really hate assuming anything but it does look like shellac? As that is something used in watch repair they would have it available or it could just be some sort of really poor glue that just looks like shellac. oh I found a little history online of India making watches. I don't see any technical references to innovative methods of doing things which is what perhaps will call this. although there is a possibility that this is innovative repair done by somebody else after it left a factory perhaps https://watchesbysjx.com/2016/07/hmt-watches-the-rise-and-fall-of-indias-watchmaking-titan.html additional information https://thehourmarkers.com/history-has-it/hmt-watches-a-walk-down-the-memory-lane/1 point

-

normally this is wonderful advice except. The normal and modern watches one of the complications that comes up is how to get the old mainspring back into the barrel either people do it by hand or they need mainspring blinders. But the end of your mainspring is a T end and mainspring winder is the best as it's a brand-new mainspring and you are to shove it out of the ring the little T part will never stay in the whole and when you get there also give you a picture on how to put it back in with mainspring winder. Because otherwise a great quite a challenge and lead to a lot of frustration which occurred recently on another discussion group until we told them how to do that. yes one of my amusements is if you actually look at the breakdown of the message board and you come to the board with I have a watch that needs servicing ideally if you followed the categories your watch would get discussed a whole bunch of different sections which is nice for people that are obsessed with things going in little boxes but as long as nobody rocks the boat nobody cares in a discussion as long as this related to the discussion and doesn't go off in the other silly things. What's interesting though is your mainspring barrel is nice and clean inside is no signs of lubrication at all? This is a vintage watch and there's no vintage lubrication I'm assuming that maybe it's been serviced in the last quite a number of years? Typically with modern mainsprings there's considered to be free lube at all actually say that some of the packages but usually we do put some lubrication on. usually used for cleaning the watch case band parts etc. probably not what I would recommend for the watch itself. They do make water-based cleaning products for watches but I have a problem with water-based cleaners for watches but people do do it on the group. Then as you're discovering one of the problems is if you were to purchase anything resemble commercial fluids you end up with a lot of commercial fluids. Which tend to be expensive although in this country you can order watch cleaning fluids from Amazon which I do find quite amusing as it's an easy way to get the cleaning fluid and the cleaning rinse if you do a search of the group they do talk about alternatives to lighter fluid on the other hand since you're going to do a follow-up rinse with I PA then it probably won't be an issue. Lighter fluids can have additional products which aren't always desirable in other words not bad from a cleaning point of view except if you didn't do a rinse they would leave residue behind that would help oil the spread possibly. Except of course lighter fluid is the universal choice of cleaning products on the discussion group.1 point

-

1 point

-

This a project I did over the weekend, a Lucerne. Watch was a non-runner due to dire need for a service, gummed up with old oil and a damaged balance hair spring. This is the first time I have taken on rebuilding a hairspring was was smiling all day when I got it not only working, but working well! Before and after pictures: Finished watch1 point

-

No i haven't visited yet John, i didn't know about the museum until i looked at joining. Its on my list to do now. The library will be worth a visit. There are also day courses on site available Shame that everything has gone up 70 %0 points