Leaderboard

Popular Content

Showing content with the highest reputation on 08/21/23 in all areas

-

What lovely people you all are. Will let you know how successful I get. So! My new old projects. 1. Watches of Switzerland Seafarer with an ETA 1789-1 movement. Balance is not good, but I now have a donor (balance is probably shot in this one, knowing my luck) 2. I have a lovely Enicar with am AR 167 movement. No dial or rotor screw. New dial given to me from a wonderful person. Donor movement obtained. Donor, movement only, is in better condition than the original. Will clean and start the install. I've been putting both of these of until I thought I have the requisite skill. Now feel that I am there. Time to put my knowledge to the test. Thank you to you all for the push. Regards Ross3 points

-

So, at this early stage, the completed watch gains 1 minute every 10 days (at least with my pattern of use). I did the unregulated regulation (one position) as I was too excited to do more!3 points

-

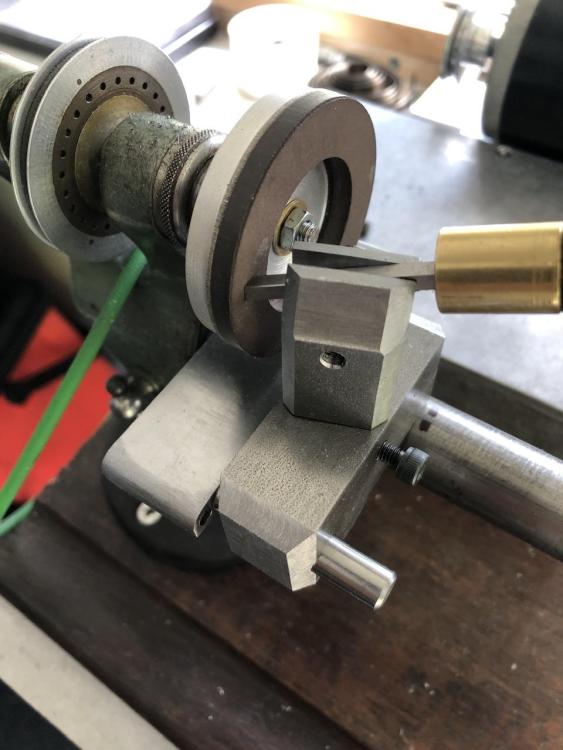

Finally got round to finish making the graver sharpener, just have to do a bit of sanding to remove some of the tool marks prior to nickel plating, I made the base so I can fit a small saw table for cutting screw slots but not made that yet. As Nickelsilver said above I should have said Levin but it’s only loosely based on the Levin one. Dell2 points

-

Different from Nickelsilver's method, I use pretempered rods for balance staffs: hardened and annealed to light blue color. In that state the steel is easily cut with HSS, not too brittle and not too soft for pivots. Frank2 points

-

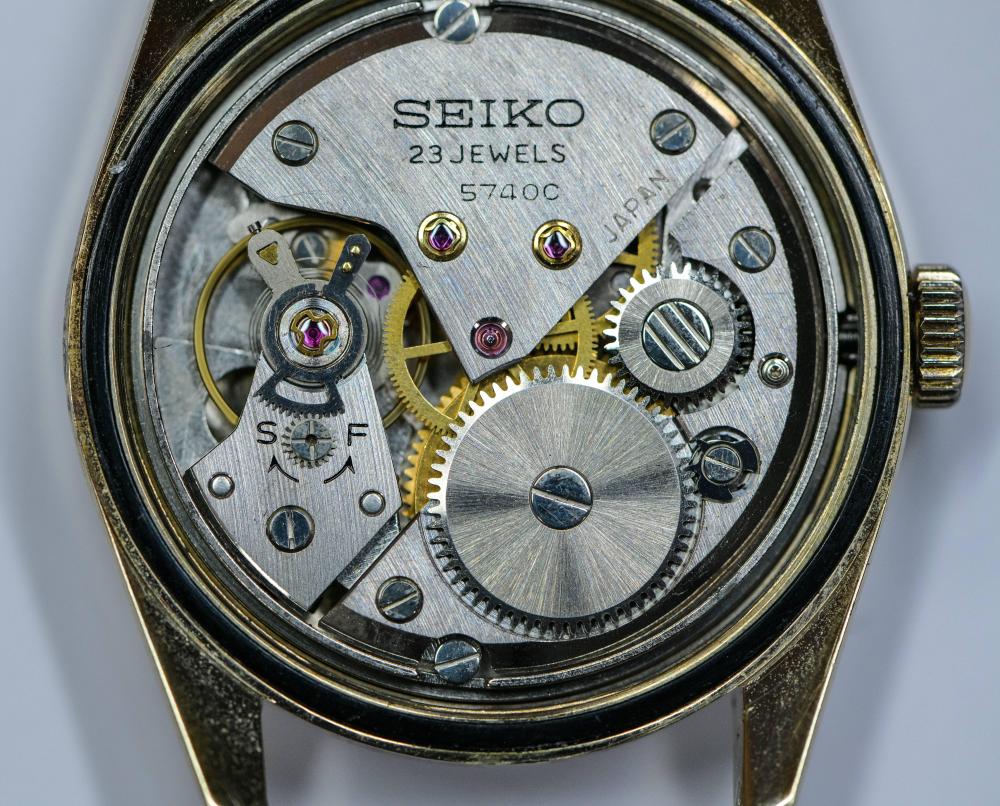

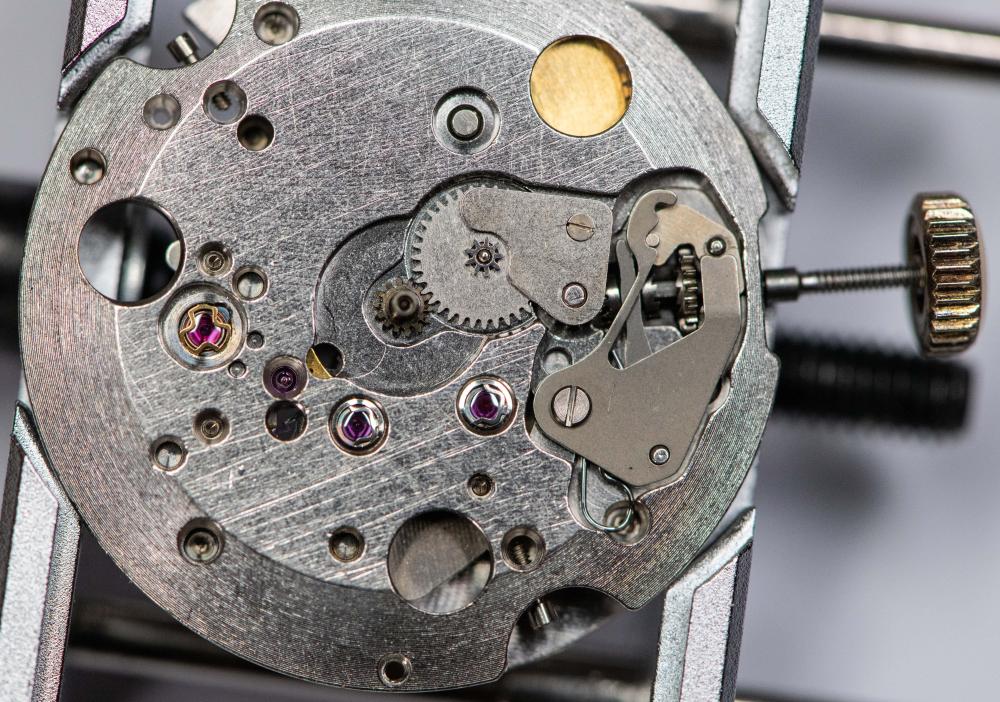

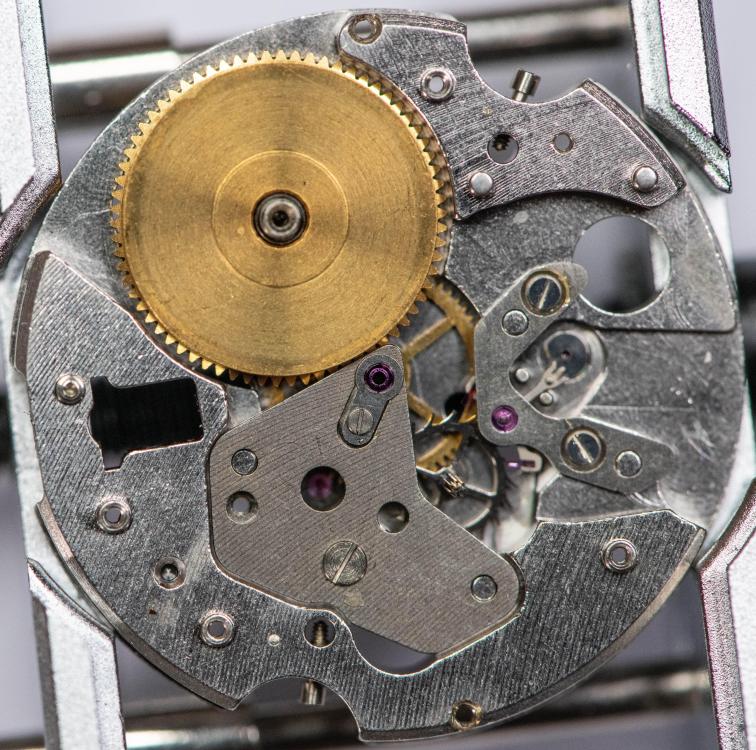

a lot of the early Seiko's are rather interesting because they do seem to be a very nice quality. Not quite a grand Seiko quality but not far away either they do tend to be very good timekeepers.yours has that micro regulator for fine adjustment also. Then escapement lubrication I've seen on other discussion groups for the high frequency watches there is a concern I don't know if anyone ever came up with a good recommendation. After all your running twice as fast as a regular watch. Ideally you should use some epilam on the pallet fork stones to help to keep the oil in place. Otherwise the 9415 wasn't exactly invented for this higher frequency but would've been a better choice. out of curiosity what mainspring did you use? I'm not sure I'd recommend it for the typical beginner because beginner will usually have accidents things happen undesirable things. Then I'm not sure how plentiful these watches are or the availability of spare parts. I found link with some additional information https://calibercorner.com/seiko-caliber-5740c/2 points

-

This was picked up as a non runner. The linen dial clinched it for me. Broken mainspring was replaced as was the crystal. Great movement for a beginner. Not sure if the 3600 VPH made it easier to make it look good on the timegrapher, but it was the first to come off the bench with a single flat line. Not sure how long it will last as I only had Moebius 941 for the pallet jewels, which I guess will be being splattered all over.1 point

-

As I said. What lovely people you are. Balance staff repair. Maybe after Christmas when I have saved enough to get a Chinese staking set. I'm getting there with using the microscope to repair a hairspring. Still don't work, but they do look better. Regards Ross1 point

-

1 point

-

Those are push pins. Push on the end in the bottom picture. The end that looks like a screw slot is wider and will not go all the way through the bracelet.1 point

-

Aw Ross that really sucks mate, I'm bloody miserable for you . But defeatist you are not, and the MAN you most certainly are my brother i would not like to get on the wrong side of you just now Ross, i know your hands are lethal weapons lol. Yep SM, these watchbreakers have the same movements going round and round on ebay until some decent bloke cops for the motherload of it. My opinion of the lot of them, stewards working behind bars .1 point

-

Ross, I've been stung a number of times with people being 'economical with the truth' on eBay. Not just on watches but other items I've bought over the years. It does appear these days that a number of people have taken up horology, then find it's not easy or they've bought a dud and dump it on eBay. I'm starting to see 'mumbai specials' being sold from the UK, mostly from people who've been conned into buying them. Had it lately with an Oris Super that had the dial glued on with the glue having dripped into other parts of the movement and, as with yours, there were screws missing. Had to buy another movement which arrived in better condition than the one I had to end up with a working watch. Seems to be par for the course these days and, as parts get scarcer, we are going to see more of it. Look at it as a long term project, and get to know how the movement and its complications work whilst waiting for the parts. Silver cloud and all that. I'm sure a few of us will be keeping an eye out for a movement or parts that you need.1 point

-

Tom and Mikepilk. I note your comments. Part harvest. I'd like to harvest their parts. Parts. I am able, using the information from members, to locate all of the parts from various locations. As stated, the cost of those parts individually exceeds the sot of purchase. Nearly double in fact. Looking in depth. My new watchword. Regards Ross1 point

-

I replaced a PW manual wind MS the other day. It did not use a "bridle" in the automatic wind sense, but had the reverse catch welded to the end. I was winding in my trusty K&D winder and got close to inserting it into the winder at that last stage and it just popped off. I think it was a bad weld, frankly. Easy fix. Annealed the end and bent it back.1 point

-

You will have to unpin the hairspring take note of how much of the hairspring tail is left and mark or these days a photo. You say you think the spring is broken so are you saying there is no power? Are you sure the fusee chain is in tact. 51 needs to be unscrewed. Do you have the skills to undertake the balance work. Many watchmakers do not touch fusee P/Watches because they are very troublesome to work on and hardly any spares, chains and verge blanks are around, it is not that difficult to make a verge.1 point

-

So true, I had a friend who used to say "sometimes it has to hurt to learn" I have found this to be true on so many occasions, just part of the human condition I suppose.1 point

-

Wow, it's been a while since I started this! In the intervening months I've still been active in this hobby. This particular watch continues to be a ridiculous journey in discovery and spending. It turns out that "6309 turtle" case I bought was specifically designed for the newer 4R (NH) movements, so the 6309 would not in fact fit in it. Also, the case had a slope in the crystal which annoyed me greatly, it did not sit flat. I ended up pulling the case apart and discovered it's because it's just cheap garbage, the plastic "gasket" for the crystal was poorly manufactured. I managed to destroy the cheap crappy bezel when removing it (managed to bend it), so the whole case is completely worthless to me now. I did learn that I need a proper bezel remover, so one of those is on order now. Of course, by that stage I'd already bought an NH36 and all the accessories to fit in that case, so I needed a new case to fit that movement. It was at this point that I discovered the NH series comes in 3, 3.8, and 4.1 crown configurations. I discovered this by somehow managing to purchase the exact wrong thing every step of the way. I now have a bunch of various cases, dials, and hands to fit all configurations of the NH36 movement. The one I was most excited about was a Tuna style case, but it leaks like an absolute seive. I'm going to have to work out how to remove the outer part of the case so I can get the bezel and crystal out and check/install gaskets, as water goes straight through the crystal it seems. These two I'm quite happy with, especially the "Red Special", being the giant Brian May fan that I am: There's also a case with a GMT bezel that I bought by accident, one day I might get an NH34 to fit into it. In the meantime, the 6309 is not dead! The movement came together great and works really well. I bought a new crystal for the original case I had, but managed to smash it to pieces and also break the plastic seal. I can get another crystal, but not another seal, so that case is going to sit in a storage box forever. I've just bought an old beat up 6309-7040 case with movement, and some bit and pieces to fix it up, so hopefully in another month I'll have everything I need to get a working vintage 6309-7040.1 point

-

Ah yes, I know that *snap* when I hear it. Heard it at least twice, possibly three times. I think the time that we really start getting good at using watch winders (and other tools) is when we get to the point of realizing we will never *believe* we are that good, so we go even slower and more carefully that we used to. It hurts to have to pay out of pocket for parts that I, myself, broke (or lost, like click springs) so some tools I become very mindful of, very cautious with, and may always be on "high-alert" when using. Perhaps that is the way it should be. I think that is how we learn sometimes.1 point

-

I think you should be fine with 941 on the pallet jewels, my understanding is that it is the oil for those jewels; might be different for Seiko, but for Swiss 941 is it.1 point

-

I'm sure it won't be difficult to come up with some hold down tool made from scrap pieces of brass, plastic or hard wood. It would be interesting to see what designs member could come up with.1 point

-

I have started writing a book entitled "How to Become a Millionaire in Watchmaking." Spoiler alert: start with two million!1 point

-

Its to help with fine adjustment of the regulator its not actually connected to anything you line the slot up with a gap in the teeth on the regulator then use a screwdriver blade to turn the regulator it stops the balance cock getting marked when adjusting and keeps the blade in the slot so it cant slip.1 point