Leaderboard

Popular Content

Showing content with the highest reputation on 08/22/23 in Posts

-

I used to work for Tandy Leather right after high school and got pretty good at it, but never made myself a watch strap. Tandy's tools are more suited to western leather craft like saddles, boots, belts etc. Finer tools for fashion items like purses, wallets and, of course, watch straps might be better sourced from sewing supply houses. So, your most basic watch strap -- a strip of leather with no backing -- still need to accommodate a buckle or clasp at one end and spring bars at the other to attach to the watch lugs. This means you'll need to thin the leather from the back and fold it over on itself. For this you use a skiving knife or a splitter. The knife is hand held and you just shave the leather until you get it to the right thickness. The splitter can be set to a specific thickness for repeatability, but as everything else it will be be much more expensive. Both are razor-sharp, so practice carefully. One of your most used tools will be something called a bone folder. They used to be bone, but they are made of nylon now. This will be used for folding (obviously) and edge burnishing, smoothing and forming, if you are going to pad the straps. You'll also need some sturdy needles, but not too heavy. Upholstery needles work pretty well, and you'll also need some beeswax for the thread. While you can buy prewaxed leather stitching thread, it will most likely be much too heavy for a watch strap. Buy a good quality cotton thread and pull it through the beeswax. You'll also need a marking wheel and/or stitching chisels to properly cut evenly spaced holes for the thread. And make sure you get a leather palm and some thimbles for stitching or on day one you'll at least get some very painful blisters, or worse, puncture your hand with a needle (that's experience speaking). You have plenty of leather choices such as calfskin, alligator, snake, ostrich, etc. You just need to consider comfort, strength and appearance. Textured leather is almost always prefinished in some way from the tannery and therefore less forgiving. Make sure it's vegetable tanned so you can work it, otherwise your edges will be pretty ragged. Glue should be a strong, thinnable contact cement. You'll want to apply it in layers for an even seam. Nothing worse than a blob of glue showing under fine leather. Of course contact cement is a you-get-one-shot-at-it deal so slide a piece of waxed paper between the two pieces and then align the end and slide it out.3 points

-

I can't think of a reason for oil to be on parts of pallet that don't come in contact with the escape teeth, so I let the escape teeth distribute oil where it does come in contact with the pallets. I just oil escape teeth a liitle and keep adding oil in small bits as I keep an eye on the amplitude, its the amplitude that tells me when to stop. Enough oil , man , it says. And when there is no extra oil, it can't migrate or aggregate where its not welcommed. Equal distribution of lubricants by the escapement itself , may take hour of running the movement. Some folks oil in reverse order, that is they oil the pallets and in small bits and let the pallets lubricat the escape teeth, then remove the fork, rinse it/ reinstall, its then the escape teeth that lubrictes the pallets. If you apply oil in small bits, you are unlikely to grosselly overlube.2 points

-

Hi Richard. Commonly called the postman’s clock. They were similar but had an alarm feature. Might take some time getting bits although a dose of woodworm juice wouldn’t go amiss. I have repaired two of these one sits in the workshop. Interesting old clock probably Black Forest in origin. The bushes in the woodwork wear or come loose but will clean up ok Good luck.2 points

-

Hello All; I managed to get the little booklet originally supplied with a Boley's staking set. It shows where the punches belong, their numbers & sizes and a cross-section of the tool. Minor detail; it's in German, but that's to keep the excitement going I scanned and converted it to a PDF file. Perhaps it has been uploaded before but better one time too much than nothing at all Boley set.pdf1 point

-

Ooo, sneaky. #13 drill size, 0.185", McMaster has O1, W1, & M2, all just a few dollars.1 point

-

I wanted to share this one I've asked about here quite a bit. Hat tip to all who contributed assistance- Thank you! A Smiths W10 non-runner I acquired as an add-on at auction- I thought the price was great so I went for it. I hope the bloke recovered from the spill... The movement was dirty but otherwise in fine condition. It had been serviced by a considerate repairer given the conservative use and placement of...Molykote DX perhaps? The pivots still had some lubricant as well... . ...of course, the obligatory broken detent on the set lever bridge. There really is very little room to remove the stem. Thank you oldhippie to sort a replacement... ...with the exception of a new bridge it only needed a crystal but it was certainly worthy of a new mainspring, so added to the Cousins basket! It really was enjoyable to work on especially since I haven't seen a moveable stud in a while. The only problem came in the last step- how to secure the movement in the case? No ring or gasket, only the floating dial back and the inner anti-mag case back. Tightening the case back yielding no improvement- the movement shakes inside like broken glass. You got me- playing a joke on the yank...ha ha, very funny... ...after much 'navel gazing' protrusion improvement seemed the only logical step. A couple raps with a round punch and ready to try again- Success! Mr. Merrens at smithswatches warns they are prone to snap off dial feet if the movement is not 100 percent secure in the case. I'm not certain I've reached his certainly but I'm hoping for the best... Thank you Canada for the sticky-type Hirsch strap...1 point

-

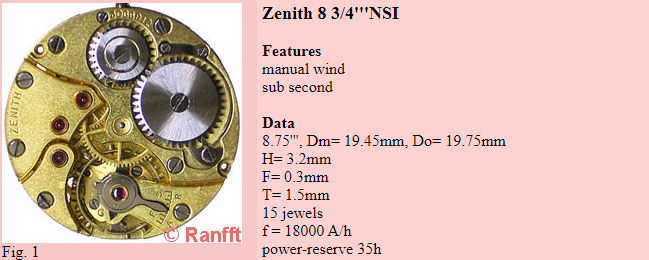

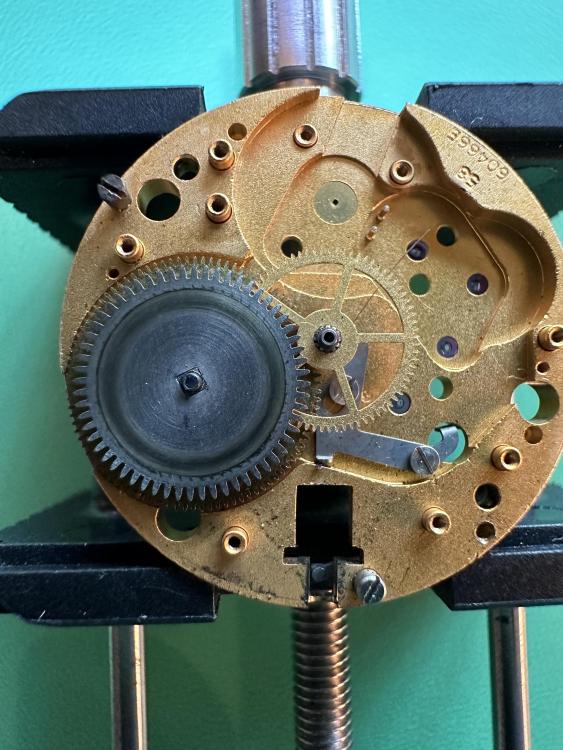

1 point

-

It was on the Bulova 23 jewel 10BPAC movements that I noticed the difference, but it could be just me. When I use 9415, I put it right on the pallet stones, covering 1/3 to 1/2 the end of the stone, very minimal amount. I could see trying 9415 on a pocket watch movement, everything is much beefier and I'd guess that the escapement is less sensitive to the type of oil. Cheers!1 point

-

That ratchet is to set the tension for the chain on the fusee. The ratchet, the sort of thing you have on a clock is as I have said in the fusee cone. You expect to see all sorts of thing when you are working on on something as old as this.1 point

-

I've found that 9415 can rob amplitude on a low beat watch, I don't use it much anymore, as I don't work on hi-beat movements very often.1 point

-

Another effective and safer way to close a hairspring collet is to put it in a close fitting wire chuck in your lathe and then just slowly and carefully tighten the chuck as far as you judge necessary.1 point

-

Lol Ross, see me for excuses mate, when John catches me out if i overlook something, i generally have something up my sleeve and blag my way out of it .1 point

-

Hey, good to see you on the forum. Make sure you're checking all the positions, the watch could have very different rates in each position. Dial up, dial down, crown up, crown down, etc. Cheers!1 point

-

1 point

-

I can't find the video where balance staffs are cut, but this video shows some of the bar stock used (at 1 min)1 point

-

And look in "job lots" of watches for repair - you can sometimes be lucky. I waited 2 years for a part for a ladies Omega I was repairing to appear on ebay, and I'm currently waiting for a part for a rare Zenith - could be another long wait. As @Neverenoughwatches says, turn on "notification" so you get an email when a new item is listed - saves you checking all the time.1 point

-

As N. suggested: I cut pieces of 5 cm or so length (silver steel, have to look up the steel #…) and heat treat. As said, light blue, not dark like available „blue steel“. Frank1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. This looks like an Austrian Wag on the Wall. Do you have the pendulum, weights, hands and dial. Ca you post other photos as I'd like to see the other side and between the plates.1 point

-

From Frank's post I understand he heat treats his own steel prior to turning. I used to do that too. In school they do have you do a lot of hand turning from "blue" steel; but I find the rods available to be of questionable quality, both old stock Bergeon* and other that I have found and tried. Doing it yourself gives better results. *I had some old Bergeon steel that was so strange, like inconsistently hardened, that it would only turn ovals. One of my old students makes his living making components for other watchmakers, and he went back and forth and finally settled on pre heat treated steel he makes, and makes the staffs directly from that. He might have to touch up the lathe tool/s a time or two during the process, but he still takes about the same amount of time for a staff that I do. I often do batches of components, so being able to rely on a tool to make it through the batch is more important to me. Plus, I won't cut threads on blue steel (stems), or cut teeth (pinions), so everything gets a post-heat treat.1 point

-

You can have saved searches on Ebay Ross, that way whenever a part you are looking for is listed you will receive a notification for it.1 point

-

The ratchet is inside the fusee which is that cone shape. So you will have to take it apart to check. If you followed what I said about the hairspring, that is the way to go about it. You will be able to lift the balance up enough after un pinning it to remove screw S1. After you have removed all that is under the balance you will be able to remove the barrel and then the top plate. Just be very careful how you go about it. Take note of the screws as they are all different and they properly will not fit snug in other places you can see how crude they are all individually made.1 point

-

1 point

-

In addition to always doing what Mike suggested above in making sure the movement is visible, I also check Cousins, other suppliers and eBay for parts availability before buying a watch or movement. If the parts are like hen's teeth or ridiculously expensive then I pass. It's simple things like a stem that can be a right pain to find for some watches. Seiko are interesting. Either there is a surplus of parts for particular movements or the square root of nothing. I had to repair and service a 6117 Navigator Timer and what few parts could be bought were very expensive.1 point

-

Indeed a small world. I actually fly to London for two days next month. Hoping it will be cooler there than here in Florida.1 point

-

The 9415 grease is thicker so one would expect it to stay put a little longer. Those poor little rubies are flicking to and fro at double the pace of a standard bph movement.1 point

-

Ross, I probably have all of those parts. I have a 'donor' movement that is basically complete, but it is in pieces right now. If you need I can try to assemble it and if everything is there, ship it to you (might take a while with it being international). I know I have a NOS case spring because my recent project was missing one as well, and so I ordered two of them so I'd have a stock for future use. Let me know if you need any help sourcing these items.1 point

-

If you have a hankering for one of Harrisons clocks, but you are short of the odd million, but you do have a few grand to spare, Comitti of London may be the place to go. Fascinating to see that there are still fusee clocks being built in this day and age.1 point

-

the history of lubrication for lever escapement's is interesting at one time basically it was just a light oil like 9010. Then they came up with 941 specifically designed for lever escapement's. Then 9415 which is a really interesting grease in that on impact it becomes fluid and is extremely slippery and the rest the time it's a grease and stays wherever you put it. So for a while you would have a transition of 941 for low frequency watches 9415 for high-frequency watches and now the recommendation is 9415 for everything. Then as a reminder this watch is running fast really fast instead of the normal 18,000 or 21,600 or even 28,000 for a fast modern watch this one is running at 36,000 beats per hour which is why it be nice if the lubrication would stay in place. then I'm attaching a PDF which covers lubrication and you'll see they recommend 9415 as the escapement lubrication. Even watch companies tend to be cheap and just defaulted on one lubrication for everything. this is what makes some of the early Seiko watches interesting as they were made to very high standards. But even the ones that are running in 18,000 beats per hour some of them are still capable of very good timekeeping almost as good as a grand Seiko is my understanding of what I've read online. Omega 8645_WI_40_rules for lubrication cousins UK.pdf1 point

-

I do find it's interesting is the collection and the library are now a separate entity wears before they were all one thing. But no matter what you should take the time to go and visit it's a interesting place to visit. Even I visited there once one summer got to see everything but I had a VIP visitation I knew the people in charge at that time. Another thing you want to keep an eye on is the calendar for events not just the classes because I think in the summer or sometime once a year they have some sort of big event and that would be well worth visiting to not just one class possibly lots eyeglasses I then one year Roger Smith was coming for instance to give a talk. Like that always looked really interesting also if you had a chapter nearby might be worthwhile to go to those don't know how welcoming and they are to hobbyists just tell them you taking a course you're at the beginning level and maybe they'll be okay the reason why joke about how welcoming of they are is in this country will be American watch and clockmakers Institute. We used even have a local chapter that we got annoyed with them and split and were still functioning and very happy. But some of the chapters made it very clear that they do not like hobbyists and others like us we didn't care and I don't know how the British chapters are with people that are obviously hobbyists whether they look down on you are not even nice of Summit give us a report as to what happens chapter meeting because it is a nice opportunity to meet other people that are doing watch and clock repair and learn additional stuff. It looks like you just have to join and then probably join the local chapter1 point

.thumb.jpg.e1737221d1bb91b37331a627546ff250.jpg)