Leaderboard

Popular Content

Showing content with the highest reputation on 08/23/23 in all areas

-

There is an old Scottish saying that: "You can't make a silk purse out of a sow's ear" Meaning that you can’t create a fine product from inferior materials. However, and just for a bit of fun, I would like to challenge all of you to show your before and after shots of the worst condition watch (swo's ear) that you have taken to a beautifully restored working watch (silk purse), and/or a current or most recent project you are working on that would qualify. To kick things off, here is my best example (to date). OK, your turn.....4 points

-

I bought the 16mp camera for my AmScope trinocular microscope, and I have to say, it's fantastic. While it is a luxury, I do post a lot of photos, and holding a loupe to my phone is less than ideal, and the ability to get close up video will be fun for the Accutron repairs I've been doing. Additionally, I bought the calibration slide to go with it, and the software lets me measure things to within a fraction of a mm. For example, trying to find the diameter and width of a flat case gasket when I don't have the original. It's just super cool and thought I'd share.2 points

-

Awwwww, you sound so dejected and frustrated. It looks like rocket science to me, I couldn't get that far. Of course, I have no advice for you but I did bring and . Wasn't sure if you wanted a so I brought one just in case. Chin up!2 points

-

ooooh- challenge accepted! Though I will place myself in the running for a participant trophy only and not part of the competition since I don't do case work, you folks are far better at me sourcing 404s and the vast majority of my achievements are making non runners slightly cleaner timekeeping runners. A couple of candidates... ...I will say however you have much work ahead as I have recently observed the work of an elderly Chinese gentleman who pulled a badly damaged Rolex from the mud of the Yangtze and using only a terry cloth towel, a rat tail file and whatever the Mandarin word for elbow grease is, transformed that mess into a gem worthy of Watches of Knightsbridge. I wish you all bon chance...2 points

-

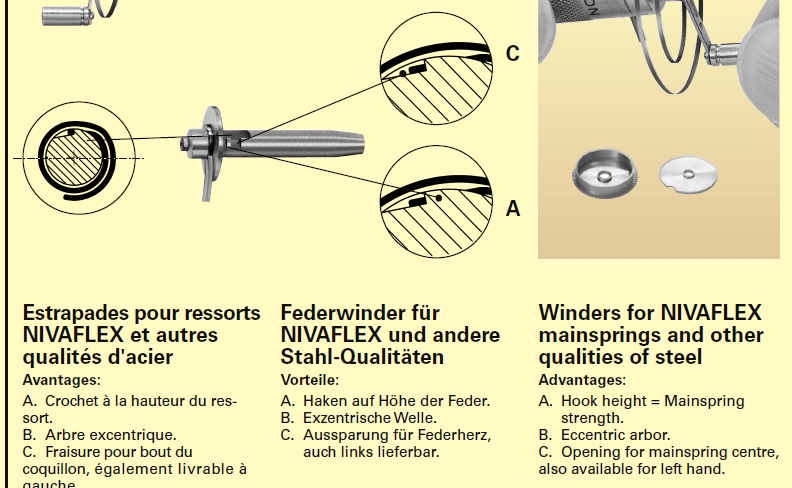

do you have the new one yet? I'm curious about how the handles compare. That's because they're actually three types a handles for these winders otherwise everything else appears to be identical over time. Actually sold by several different companies and probably not actually made by Bergeon. Because up until relatively recently they did not make anything they only sold items from other makers. so basically on the vintage ones the vintage handles will have a different kind of a hook used for blued steel Springs. The modern type is a modern type of hook and that comes in either left or right. I'm not sure if the actual vintage said had a left-handed or not. But still a good deal no matter what kind of sample you have because worst case you just buy more handles a out of to buy the whole thing. Then besides I find time to time you basically need to have everything some mainsprings will defy logic and won't go in and see need to mix and match sometimes.2 points

-

I've just got a set of these vintage winders yesterday, they look the same as photo above, the winders are marked depose with size 00 to 15, the set i got was missing the number 14, i got them at a good price so having to get a new bergeon No 14 to complete the set was ok with me. I measured the outside diameter of each winder, the sizes are the same as the new modern bergeon winders, 00 to 15 are spot on the same, i also measured the arbor diameters and compared it to the sizes on the table compiled by leo vidal on his youtube video of his new set of bergeon winders, on my set only 3 of the arbors are larger than the new bergeon set, 00 and 0 measure 1.98mm the new bergeons 1.58mm, my No 15 is 5.94mm modern bergeon is 4.99mm, all the other arbors measure the same as the new bregron ones. They are all in good condition, most look as if they haven't been used, a couple of them you can tell have been used a little more from the wear on two of the hooks but still usable. They are are still a nice set of usable winders even thought they are vintage, i'm well chuffed i took a punt.2 points

-

Keep in mind too that on a timing machine you are looking at a snapshot of the running. Ideally you would check at full wind minus an hour (wind fully, let it down a few teeth on the ratchet) and at 24h (minus about 3.5 turns of wind). And in several positions, I always do 6, 2 horizontal 4 vertical. This will give you a much better idea of the actual performance.2 points

-

Pictures tell me things and with out the other parts makes it a little difficult. I think this is German from the Black Forest. I would date this around the 1870 to 1900.2 points

-

I can't think of a reason for oil to be on parts of pallet that don't come in contact with the escape teeth, so I let the escape teeth distribute oil where it does come in contact with the pallets. I just oil escape teeth a liitle and keep adding oil in small bits as I keep an eye on the amplitude, its the amplitude that tells me when to stop. Enough oil , man , it says. And when there is no extra oil, it can't migrate or aggregate where its not welcommed. Equal distribution of lubricants by the escapement itself , may take hour of running the movement. Some folks oil in reverse order, that is they oil the pallets and in small bits and let the pallets lubricat the escape teeth, then remove the fork, rinse it/ reinstall, its then the escape teeth that lubrictes the pallets. If you apply oil in small bits, you are unlikely to grosselly overlube.2 points

-

This was picked up as a non runner. The linen dial clinched it for me. Broken mainspring was replaced as was the crystal. Great movement for a beginner. Not sure if the 3600 VPH made it easier to make it look good on the timegrapher, but it was the first to come off the bench with a single flat line. Not sure how long it will last as I only had Moebius 941 for the pallet jewels, which I guess will be being splattered all over.1 point

-

reason why there's a variety of numbers is it depends upon who made the watch and the watch itself. If you have software or a timing machine they can do a time plot another way to look at timing results and you wind your watch up nice and tight you will initially see a much higher amplitude then which you really want to have. It's one of the reasons you can take set mainsprings and get them to work by widening them up nice and tight especially if they're really really set they will initially have power but they will lose it really really fast. So basically the watch companies have a time span it's not an exact number is just do not time when you wind it up tight let it run for little bit the settled down and lose that excessive energy. Otherwise you may get weird timing results because you have too much power then watch companies are not usually obsessed with amplitude like this group is there more obsessed with timekeeping. But typically it does depend on the watch companies Omega will take down to I think 160° at the end of 24 hours it depends upon the particular watch. So the watch companies at 24 hours like to see a certain minimum but what they really want to see is timekeeping does the watch keep time at the end of 24 hours. Then if they get really picky though give you and isochronal error. In other words your watch at full he wound up versus 24 hours later how close is that timekeeping. okay I believe you said you using an app and I'm guessing you just drop the watch on the phone and your often timing? Can you give us a picture of the watch on your timing device or if you can't do that can you at least tell us what apps are using so we can go and look up what it looks like what exactly are you seeing of that we can't see because we really do need to understand what it is you're using and what it looks like when it's running otherwise especially with apps were usually wasting our time at least based on past experience.1 point

-

here's an image out of the PDF on the modern and it's. Typically on the modern Springs of the part that goes on the arbor is very tightly circled and requires a hook that barely sticks out versus the old blued steel Springs where it could be just about anything and you definitely need a more aggressive hook. But the reality is you need all of these things because they're always be one mainspring that won't want to look at all even if everything looks like its right you may have to do a little bit a mix and match. let's look at some images of handles for my pocket watch set that I like that goes in either direction as you can see it's a pin that six out and you'll notice there's two of them. Though actually do two separate sizes depending upon where it is as it moves in and out. then this is what the old style handles look like for the Swiss set as you can see it's quite aggressive versus the modern then here's what the modern ones look like. Then a note especially with the older ones they may not look exactly like this depending upon how much abuse they've seen or whether somebody got desperate and file them which is not a good thing to do1 point

-

I saw orange was off- bergeon orange is 050 in my set, but I see the others are the same- nice1 point

-

My grandmother would add to that “and simple ones seldom differ” Tom1 point

-

I can’t remember where I saw it VWatchie but I have seen a graph of mainspring delivered torque where you see very high torque for the first hour reducing rapidly till the one hour mark. Around the one hour mark the curve flattens out and remains pretty flat until sometime after 24 hours. It will then drop off fairly precipitously when it is getting close to the power reserve limit. Maybe one of the cleverer than me folks on here can confirm or maybe even have a copy of a similar graph. Tom1 point

-

Waggy. You are training me well. I read the post and thought it might be upside down intermediate wheel. Then lo', on next post you stated the same. Feel pleased to be in the same honoured place as you.1 point

-

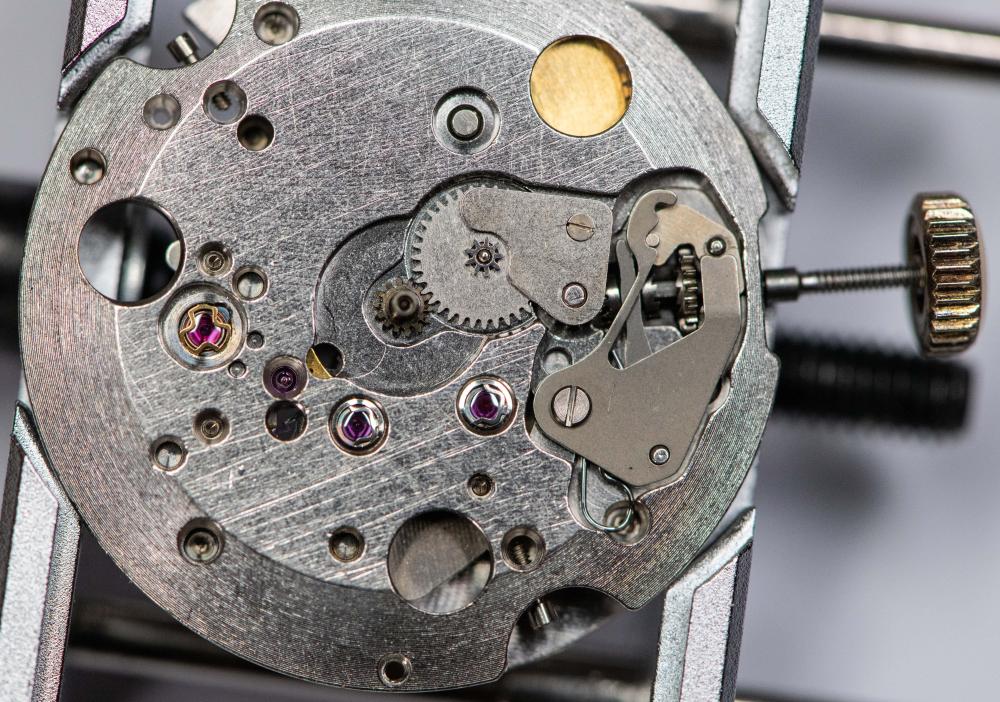

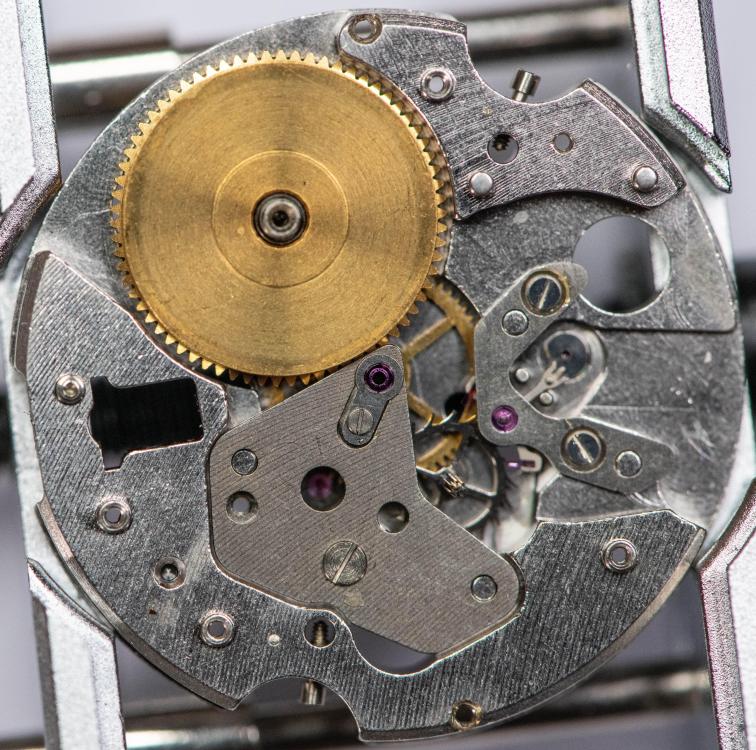

The automatic works interacts with the spring barrel/ratchet wheel mechanism to tighten the spring. Similarly the winding pinion also interacts with the spring via the winding mechanism. If one side is locked up, you may see it on the other side. You may see that the rotor weight does not rotate freely is stays in one position when rotating the watch, which would add weight to this theory (pardon the pun). Quick way to check is to remove the automatic works module (usually removable as an entire module) and see if the problem remains. The reason I thought of this is that a recent video on My Retro Watches has the exact issue you are describing, and this was down to the automatic works. I think its part two (re-build) of the Roco video, the most recent one.1 point

-

Is the intermediate wheel chamfered on one side, if so there is a possibility that you may have installed it upside down, generally the chamfer goes down (but there are always exceptions of course). I once did this and the winding felt 'crunchy' when winding, but didn't lock up like you have experienced. If you change the stem to the date setting position, you would temporarily disengage the sliding pinion from the wheel and when you return the stem to the winding position it would re engage for a few turns until it locks up again... Could explain what you are seeing? Hopefully this is a reasonably quick check as you may not have to take the keyless assembly apart and fight the yolk spring Other thing that came to mind is the automatic works, if this has an issue it can sometimes lock up the winding mechanism, but not sure if your movement has an automatic works... Worth a try.1 point

-

Hello All; I managed to get the little booklet originally supplied with a Boley's staking set. It shows where the punches belong, their numbers & sizes and a cross-section of the tool. Minor detail; it's in German, but that's to keep the excitement going I scanned and converted it to a PDF file. Perhaps it has been uploaded before but better one time too much than nothing at all Boley set.pdf1 point

-

Good reminder. I need to hang a sign above my bench saying "Yo, doofus, slow down and pay attention!"1 point

-

And even though MSC/ MCMaster et al don't stock 4.70mm steel, you can find inch equivalent for making staking punches .1 point

-

9415 grease is the only escape lubrication i have, when i made a choice my thoughts were it would be easier to place than the 941 oil, but did not really consider that the extra thickness of a grease might slow down the escapement of a low beat. John then mentions that the properties of the 9415 make the grease become quite fluid and slippery on impact. Impact of the jewel impulse face on the escape wheel teeth. I wonder how fluid and slippery compared to the oil. Without epilame used on the escapement the grease might be a better choice anyway as once the escape teeth have carved a groove through the grease's surface on the impulse face of the jewel any remaining oil either side of the groove would remain unimpacted and hopefully stay put . Does that make any sense ?1 point

-

The 9415 grease is thicker so one would expect it to stay put a little longer. Those poor little rubies are flicking to and fro at double the pace of a standard bph movement.1 point

-

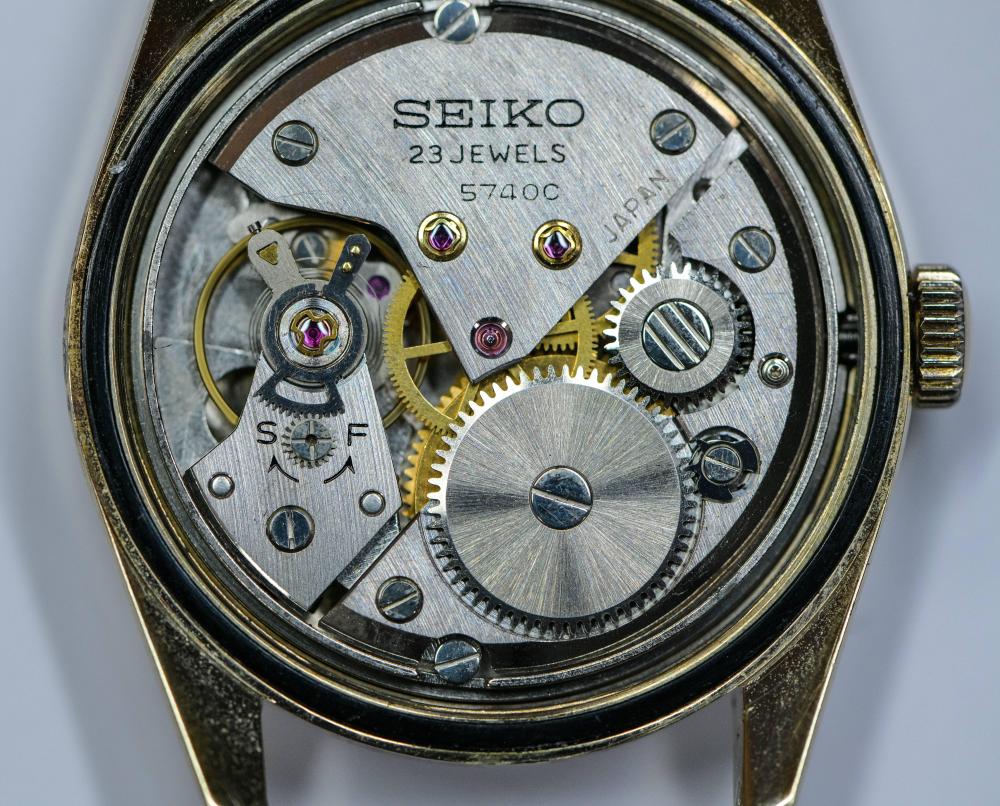

Congrats! MARVELlous Watch! Any challenges in particular handling those Diafix springs? If you need spare parts you can always have a look at this: https://www.chrono24.se/seiko/lord-marvel-lm5740-36000-bph-vws-2190--id29461007.htm1 point

-

the history of lubrication for lever escapement's is interesting at one time basically it was just a light oil like 9010. Then they came up with 941 specifically designed for lever escapement's. Then 9415 which is a really interesting grease in that on impact it becomes fluid and is extremely slippery and the rest the time it's a grease and stays wherever you put it. So for a while you would have a transition of 941 for low frequency watches 9415 for high-frequency watches and now the recommendation is 9415 for everything. Then as a reminder this watch is running fast really fast instead of the normal 18,000 or 21,600 or even 28,000 for a fast modern watch this one is running at 36,000 beats per hour which is why it be nice if the lubrication would stay in place. then I'm attaching a PDF which covers lubrication and you'll see they recommend 9415 as the escapement lubrication. Even watch companies tend to be cheap and just defaulted on one lubrication for everything. this is what makes some of the early Seiko watches interesting as they were made to very high standards. But even the ones that are running in 18,000 beats per hour some of them are still capable of very good timekeeping almost as good as a grand Seiko is my understanding of what I've read online. Omega 8645_WI_40_rules for lubrication cousins UK.pdf1 point

-

I watched your video on youtube showing your homade mainspring winder, your write up gives the bergeon dimensions if anyone wants to have ago at making one or even a full set themselves. If it's ok with you i've added a link below to your flickr page. https://live.staticflickr.com/65535/51890412256_d0f66b7f21_b.jpg1 point

-

I get quite upset and disgusted by it. Quality brand names that were around for over a hundred years to have their reputations completely destroyed and their names attached to something that bares no resemblance whatsoever to what that company actualy stood for.1 point

-

I have several of these, some marked Bergeon, some no name (depose' is French for "patent pending"). These older sets have larger winding arbors than the newer ones marked "Nivaflex", but you can use a smaller arbor in a larger winder- the hole difference doesn't really matter, and if the cap on the winding arbor is really too small you can cut a hole in thin plastic sheet and fit it over the arbor under the cap. On all of these, often, the winding hook is sticking out too far- it's good to trim it down with a file so it's about as high as the thickest mainspring it might see (the hook can damage the coils as you wind if it's sticking way out). Sometimes the hook is too wide too, again, easy to trim up with a file.1 point

-

Hi Remembering where the bits go comes with experience, also photographing as you go and keeping parts and screws together with their associated plates etc. So its a combination. and also having to hand tech sheets and manuals. I have attached a couple of PDF's to get you started. cheers TZIllustratedGlossary.pdf TimeZone Watch School Home.html1 point