Leaderboard

Popular Content

Showing content with the highest reputation on 08/27/23 in Posts

-

5 points

-

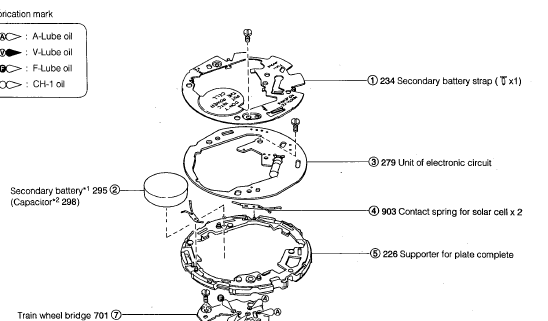

Hello again all. Back to the Bellmatic. as said above, I was so disappointed not being able to complete the Bellmatic after being sold a pup. I was looking the Youtube video with sadness, when my bride pointed out to me me, a Bellmatic on ebay that looked the same, a 4006 6040. Apart from the case, it was. Anyway, long story told short. I know have it. 'Needs a service'. Ha ha. The second one has every part bar one, and the first one has that. So, good to go, and going it is. Disassembled and cleaned, ready for lubrication and assembly. See photographs. Ross5 points

-

On a roll this weekend and did another 404, this time a Shelton Cal BF158 which came as part of a job lot so cost £2.22. It was a runner, but couldn't get a timegraph trace, but when I finished it got it to -12 s/d, 248 degrees amplitude and a beat error of 1.6. As this is a pin pallet I decided to cut my losses and be content with those figures. I used some flitz to clean up the case and it took all the gold off instantly leaving me with a two tone watch with a silver case and gold bezel which I actually prefer to the original all gold finish. The dial was made of a card almost like paper, so used a pencil eraser to clean it up and it worked a treat! Here are the before and after shots : And here is the finished watch:3 points

-

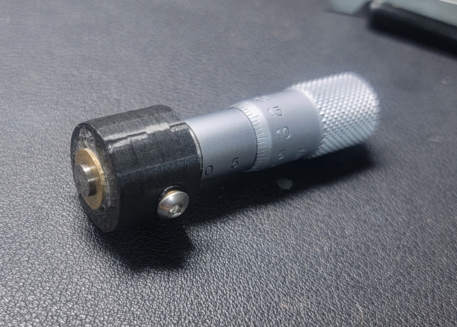

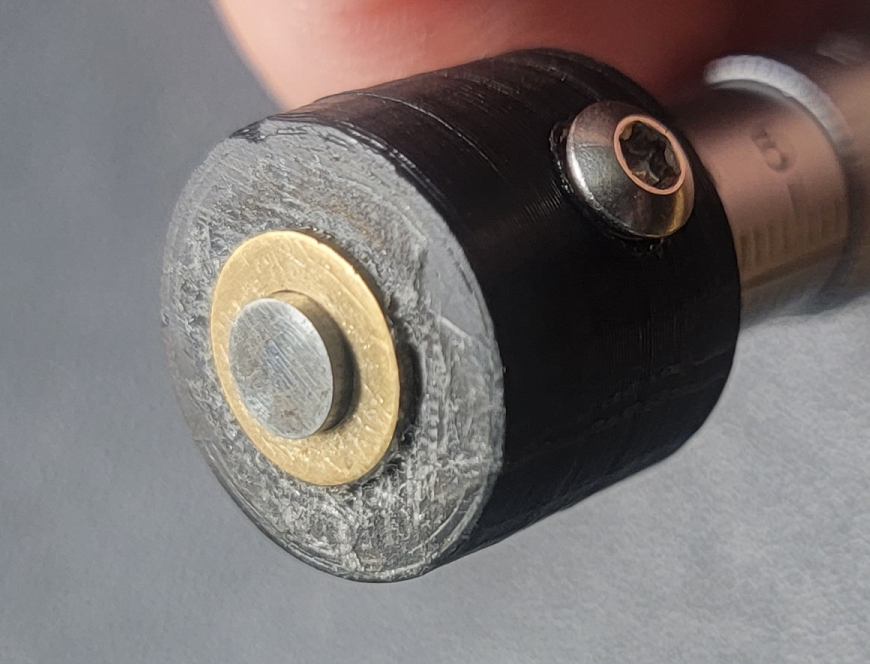

I thought I had posted about this tool I made last year, but I cannot find the post. I have been using this quite a bit lately while turning staffs on my lathe. Ugh...the watch from hell. Anyway, I snagged this micrometer off of a microscope table that has been in my scrap pile for 40 years! I 3D printed an adjustable mount with a brass washer glued on the end. The adjustment screw allows me to zero the tool. Not really zero though, because everything is backwards. It is zeroed at 10. It really works great. I only wish I could reverse the scale (left handed), because I have to count backwards!! No matter, it gets the job done.3 points

-

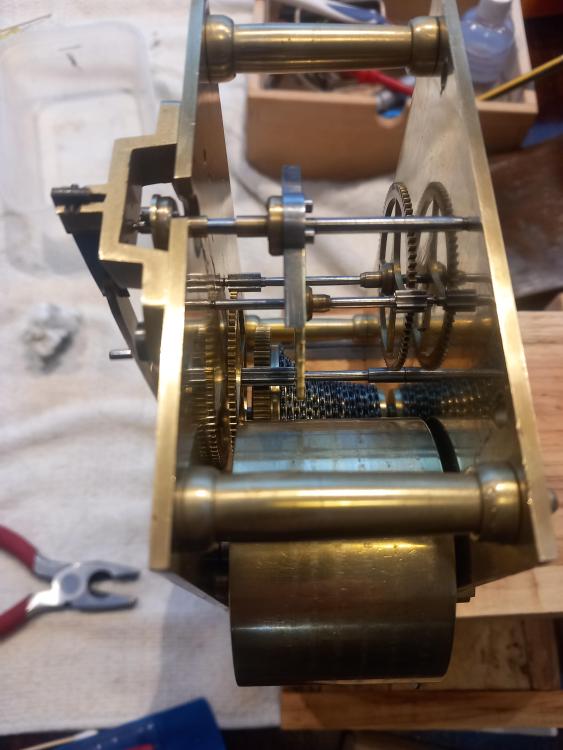

Well I took it apart and cleaned it all by hand (nowhere near the ultrasonic!) and reassembled it. Had to do a bit of research on how to reattach the chain but got there in the end. Oiled the chain, checked the mainspring (it seemed fine) and oiled the pivots, the escape wheel and the pallets. Loaded a half turn on the mainspring and secured the click. Have set it up for testing and it has been running for about 3 hours now. So far so good...2 points

-

I think the best option is a soldered bridge piece across the break then cleaned up. A thin brass piece held in place with cross over tweezers a dab of flux and thin electronic solder wire. A little heat. Job done.2 points

-

I have an Elma ultrasonic 2l (2.5?) that seems to be bulletproof, it's at least 20 years old and runs hours everyday. For watch cleaners, I used a 60s Greiner for many years, iconic model using water based cleaner rinsing in iso alcohol with built in distiller. A few years back I bit the bullet and got their industry standard ACS 900, secondhand. Mine came without ultrasonic, but a quick email and they sent me the driver board and ultrasonic tank for a reasonable fee. I asked the tech if they happened to have the schematic for my old machine and after some digging he found it and sent it. I had asked like 5 times before, just had the wrong person. Their tech I corresponded with by phone and email couldn't have been nicer, cooler. In my industry there's a lot of CNC buying, and end of the day a machine that's a little more accurate loses to a machine with better support. I'm astonished at Elma's support.2 points

-

Mine was in the original Elma box with all the original packing materials when I got it. The packaging was quite impressive actually. I did not have any damaged items, and the machine worked beautifully for several months, until the day the heater decided to stop working. When speaking to the repair shop about my machine (and kudos to Jules Borel for facilitating everything - they were absolutely great to work with), the person at the repair shop told me that the control board had failed, causing the heater not to work. Perhaps a blown capacitor or something. I didn't ask any further details about what specifically on the controller board went bad. The shop got my replacement part from Elma in Germany. Shipping took quite some time, but the shop was very consistent in providing updates and the ever changing ETA on the new part (DHL took forever to deliver it). Once received the machine was repaired quickly. The shop kept the machine for 4-5 more days and did some testing on it. He even sent me pictures of his oscilloscope hooked up to the machine, and them making sure that everything was in order. After I received the machine back, I haven't had any issues with it whatsoever. The shop told me that he hardly ever sees a part fail on these fail, outside of user induced damage. He said most of the time when he gets them in it is because the machine had been dropped when moving it. I'm sorry to see that the person in the video had such issues with their machine. I can say that I have not had anywhere near the same experience. My speed adjustment works beautifully, even at lower spin speeds and I found the packing of my machine to be very good, Mine did not see any damage. Overall I am very pleased with my purchase.2 points

-

Not sure what you're trying to say, but I guess I wasn't very clear about what I was trying to explain, so perhaps there was a misunderstanding Anyway, I'll try to illustrate the feature of my Weishi 1900 which is helpful when adjusting the beat. At least when the balance has a moveable stud and you're adjusting while measuring. In this picture, we're out of beat. But as you can see the two beats have different colours (blue and yellow). Now, after having moved the stud we can see that the direction was correct but shot over the target. If the lines had been the same colour, it would have been a little more difficult to tell. Admittedly, you can sometimes see the lines crossing each other while adjusting, but the colours still make it easier. Not critical, but nice to have. So, perhaps a feature you could implement in the PCTM app!?2 points

-

Exactly my thinking. Think I will try slotting that tiny tab into various Speidel bands and see what fits. In all my spare time, right?1 point

-

Somewhere along the way the insider bits of a 68 marlin were cased into mercury. So I decided to right this wrong. With the help of an NOS 1970 dial, the correct case, and even the date stamp. This now is a period correct 1970 Marlin. full service of the M25 movement, crystal buffed and polished, etc.1 point

-

I'm a big fan of Seiko watches/movements too. Unfortunately, some of the smallest (Diafix) springs for the third wheel and the escape wheel can be extremely tricky to handle. Pretty nerve-racking even for a somewhat seasoned enthusiast like myself. Also, it seems near impossible to get hold of mainspring replacements and the Swiss Generale Ressorts springs just won't cut it. For this reason, I stay away from the Seiko/Orient movements, but someday I'm determined to return to them. Best of luck!1 point

-

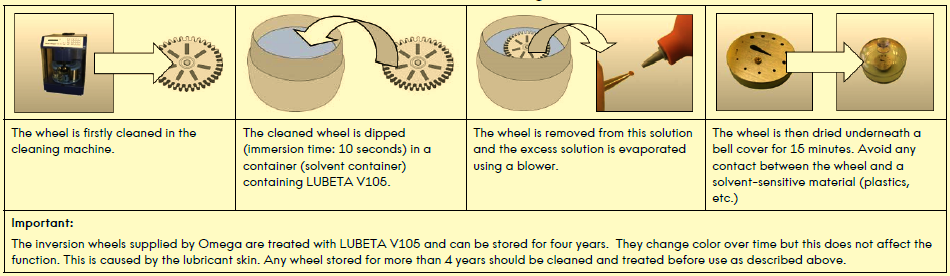

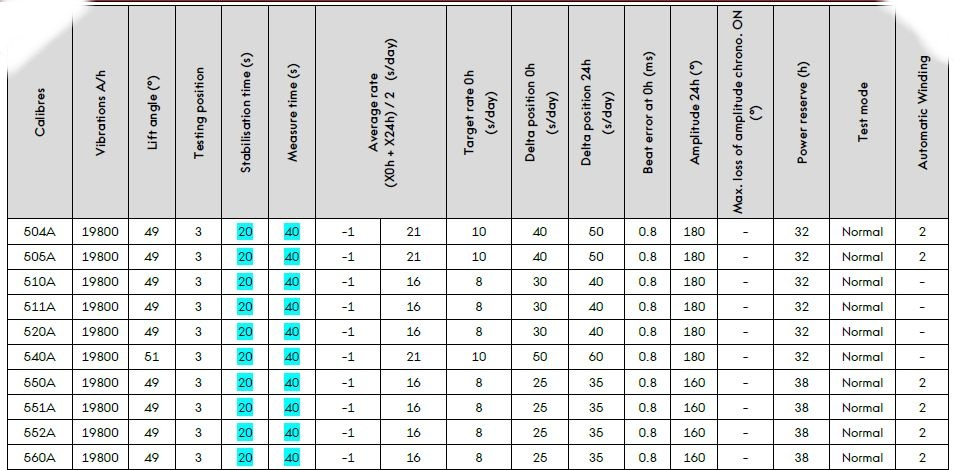

so on the group we've discussed this before but obviously you didn't see it Omega does have a procedure for the reversers if you don't have the tools which no one does and even if he did have the tools and probably still prefer the procedure of lubrication assembled as it's a better procedure. oh thinking of the specs here's the specs for timing for your watch what sort of problem were you having? The reason I ask is if you look at the automatic assembly and the spring itself I don't suppose it pushes on that at all does it? what's interesting is when you look at the timing trace amplitude is fine as soon as the automatic goes on the amplitude drops and I seriously doubt it has to do with any of the wheels at all because you're not turning. If it was pushing on the setter second assembly that would cause additional friction or if it was somehow bent and maybe twisting the plates I don't even think of a screw was too long it would be an issue?1 point

-

Metal polish by hand, it won't fix the area's without plate but should look better.1 point

-

Are we voting? My vote is a hand buff with a sunshine polishing cloth or equivalent then leave it be- it is too hard to fake authenticity. That’s a lovely clock btw. I see lots of travel clocks but have not seen the likes of it at auction…1 point

-

1 point

-

1 point

-

Quick update: With 4min cleaning and 2x 3min rinsing in the U/S and respective L&R products, the plating on the Omega T12.6 has stayed intact.1 point

-

Thanks VWatchie! They are very interesting time pieces, both Russian and Soviet. It's a part of History that makes them special, not because they're particularly good. They're easily modded and somewhat reliable and won't break the bank. I took one to the pool and it survived (a new Russian, wouldn't dare to do that with an old Soviet one). Besides Vostok, I've had a Strela chrono. Lovely piece for under 500 €. Now, I'm into Seikos, learning disassembling and identifying each piece.1 point

-

How much do you charge per bush? I include bushing in my service costs, just done a Hermle with 19 bushes1 point

-

That's not proper cider. You need the proper farmhouse stuff, which we call gut rot. 3 pints and you can't walk.1 point

-

Holy heck, I have learned never to buy one of those, lol. .1 point

-

technical sheet is attached always nice to attach one when talking about it then if you Google the part number well the first link I found was this one so it does look like it's available just probably not from citizen https://www.smallbattery.company.org.uk/sbc_298-177.htm then for how to get the battery out that's with the technical guides for it looks like you have to remove the plate. 1023_Citizen 7810, 7820, 7860, 7870.pdf1 point

-

Looking at the service sheet for 7817 movement the battery part for the 78** series is 298-177 GC970. Cousins UK list it but as being discontinued. You could try searching for suitable replacement.1 point

-

What we have here is what is known as a Marriage in the trade. That means a clock case and movement that never started out as one. The case and movement have been altered to fit. But this has a slight difference. It is a three parts marriage because the dial never started out to fit the movement this is because of the two winding holes. 1 The case as you can see has part of the bottom cut away to accommodate the length of the pendulum. This tells you right away nether were made to fit each other. The top of the case has been altered, instead of signs of a handle it has had a piece of wood put inside the top you can see the grain doesn’t match. 2. Movement this in unfinished, It is more likely an apprentice piece. It is easy to see the intention was for the end result to be a strike. If it was to be just a timepiece the design of the train would have been different so the winding arbor would have been at 6 o’clock and not at 3. 3 Dial this is a very nice dial and dates around 1760 the hands are also in keeping with the dial. Due to the lack of photos I cannot see how it has been adapted, but I can assure you it has been altered. See what I mean by the top. Thanks for participating and I think you all deserve a bag of peanuts each.1 point

-

@Waggy somehow this popped into my YouTube feed, it’s not a tutorial but does show the end to end making of a strap. Tom1 point

-

uusually on watches that say push that's to give you a clue where to push to get the stem out. is that actually went citizen says? Usually if you look at the rechargeable batteries that is one of the common batteries then the watch companies usually weld on various things to hold it in place so you do need to get the specific battery for your watch as opposed to a generic battery because it's not going to have the bits and pieces welded on exactly right. yyes I remember when I go to work tomorrow I'll ask if anyone has experience with this. They change a lot of these things so maybe they've seen this one before I typically don't do these things.1 point

-

one of the problems with visual observation is that it also depends on the safety features. In other words there is a procedure to verify things are correct you check various clearances first and then you look at the pallet depth so even though the depth may look outstandingly huge for that particular watch it may be just fine depending upon the safety features.1 point

-

Here is my latest. A Tissot Seastar with a 2571 (US 2591 actually) automatic with day-date complications. Actually came in pieces (as pictured below) and I managed to complete a reassemble and source several parts needed. I will write up the restoration on another thread soon enough. Still need a thorough clean and lube service. The 37mm case is pretty large on my small wrist. 42mm lug to lug. With this movement and the dial-hands types I think this is a late 70s model. Really like the bezel...maybe a little Rolex-ish style wise? then after pix...1 point

-

This a project I did over the weekend, a Lucerne. Watch was a non-runner due to dire need for a service, gummed up with old oil and a damaged balance hair spring. This is the first time I have taken on rebuilding a hairspring was was smiling all day when I got it not only working, but working well! Before and after pictures: Finished watch1 point

.thumb.jpg.381f622fd349d5d8f1b7b8ecbc436c44.jpg)

.thumb.jpg.dc9a4120bc428412a335b91599cfd9b9.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)