Leaderboard

Popular Content

Showing content with the highest reputation on 08/29/23 in Posts

-

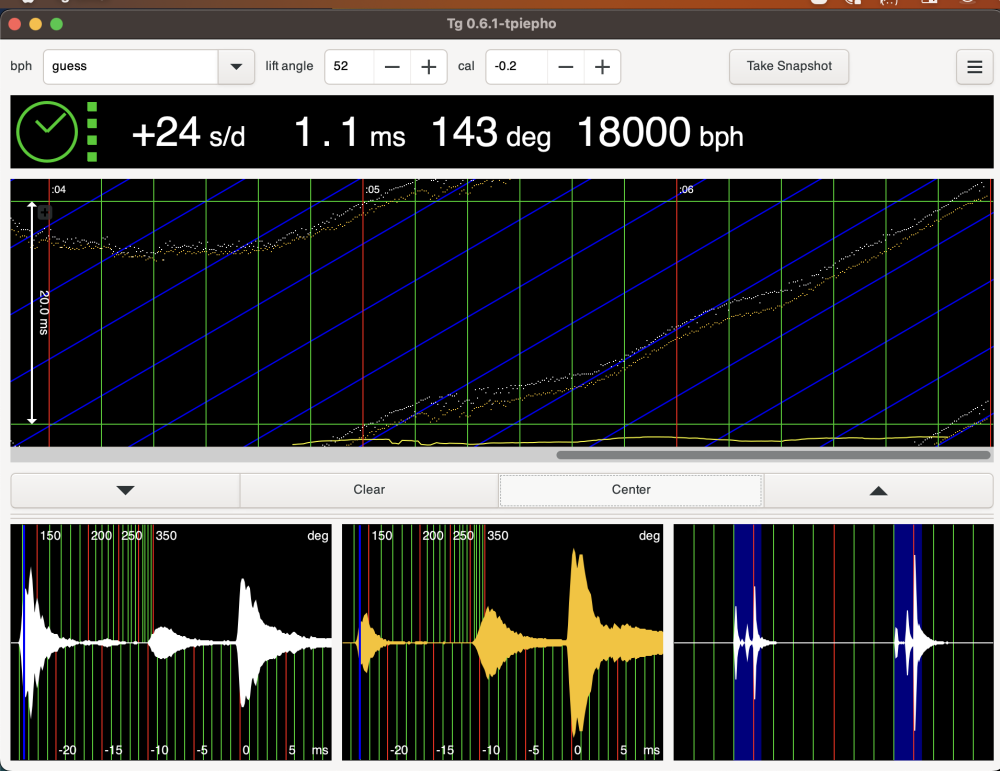

I have been buying watches to work on and putting aside the automatics until I felt I was ready for the next challenge. This weekend I managed to turn a non-working watch with a deformed (melted? crystal) into a working watch that looks pretty good! I did some research of servicing automatics and found that in addition to what I had previously done I would need to service the self winding mechanism and do something different with the mainspring / barrel. Before starting bought some 8213 breaking grease and some Lubeta V105. I then selected a watch from the handful of automatics I had bought from eBay. I was looking for one that I cared less about about but that seemed complete. The one I selected would run for at least a few seconds after being shaken, I could wind it manually, set the time and the date flipped over every 24 hours. The case was in pretty good condition but the crystal was useless. Inside the watch has an AS 1701 movement with gold(en) plates. There were a few surprises. First I found that inside the barrel there was not an automatic mainspring but instead a blued steel standard mainspring set inside a brake spring. I tried to find what to do with this and found a thread on this site discussing what oil to use on the barrel wall. I eventually followed the advice here and used D5 on the barrel wall before struggling to put the brake spring back in with my fingers. I have no idea how you are supposed to properly install the brake spring - but it is too short and has no eye for a mainspring winder to help... Later when I found the technical communication I found it says "special grease for brake spring" - guess I should have used my new 8213 grease? Anyway it doesn't appear to be slipping too early but I am measuring now how long it will run for when not worn. The eye on the old mainspring broke as I put it in the mainspring winder - so I replaced it with new (NOS) one that I had in a selection I was given. The replacement was not 100% right... The technical communication says to use one with H. 1.18 - 1.20 mm T 0.105mm L. 335mm. I found one with the right thickness and length that was 1.3mm high. It seems to fit into the barrel with some clearance and it seems to be working (perhaps I should order and replace it with the right one?!) The other surprise was the automatic device - the technical communication did not talk about dipping the pawl winding wheels in Lubeta but instead said to lubricate them with "Very fluid oil" - I used a very small amount of the thinnest oil I have which is 9010 but am a little worried that this is going to get flung all over the movement and perhaps I should have dipped them? After cleaning and reassembling I found it still did not run for more than a few seconds.... I found 2 problems. 1. The balance spring was bunching together on one side and was bent out of shape near to where the end curve begins. I loosened the screw holding the stud and with the balance wheel still attached gently stroked the hairspring back into shape so that the stud would drop straight back into place while the hairspring remained centred. This seemed to do the trick but I believe the end curve is still not right 2. The centre wheel did turn freely I discovered that the centre wheel was made up of 2 parts - a wheel that is friction fit to a pivot / tube. The wheel was not totally perpendicular to the tube. I don't have a staking set or staking block but found I could using the base plate as a staking block I could push down on the top of the centre wheel pinion with my tweezers (much like putting a canon pinion back on) and get the wheel to sit correctly. After doing this and putting the centre wheel and centre wheel cock back in place the wheel turned much more freely. With the case cleaned I replaced the crystal with a new one (without a cyclops). I wore the watch and after 24 hours it seem to have gained about 1 min. It is far from perfect but a LOT better than when I first got it. Here are some photos... Before - After - Movement - tg-timer4 points

-

Just to update, I managed to broach out the old pendant tube to the threads and then managed to clean out the threads well enough with a tap and then screw the new pendant tube in without any issues. A bit scary but it certainly works and it looks really nice(:4 points

-

On my wrist. This was the first watch on which a managed to do a full service. It was advertised as a 'Sekonda'. On arrival the dial displayed 'Quest'. The indexes were damaged. Non runner. The case is from the 'Quest'. The Slava 2427 movement is from the 'Quest'. The dial is as you can see, is from an automatic Sekonda. This is my 'wear most days watch'.3 points

-

3 points

-

Tissot calibre 781 Disassembly (Please sort the images by name in ascending order) Tissot calibre 781 Assembly (Please sort the images by name in ascending order) Tissot calibre 781 ranfft facts Some time ago my brother handed me this Tissot dress watch from the mid-1960s housing a Tissot calibre 781. My brother collects watches but doesn’t tinker with them (yet). Anyway, I thought it would be interesting to give this Tissot 781 an overhaul (you always learn something). It did seem to run and being a 17-jewel manual wind watch I thought a service shouldn’t take too long or pose any challenges in particular. Anyway, when I removed the case back, I noticed to my surprise that the balance had stopped. I thought “that’s funny”, as it was fully wound and had been ticking along fine while I was looking at the dial. Going deeper I realized that the one of the balance staff pivots was broken off. So, I called my brother and told him the bad news and that I had no experience replacing balance staffs. Well, my brother didn’t become too upset about this but simply told me to keep the watch and possibly repair it in the future if and when I would learn how to replace a balance staff. I wasn’t sure I was ready for it, but life is unpredictable so I thought that it was now or never that I would learn how to replace a balance staff and get the necessary tools to do it. Long story short, I did learn how to replace a balance staff and the watch is now ticking along just fine. In the process I got first class help and illustrations from my fellow Swede @HSL, and if you are in the process of learning how to replace a balance staff, I do recommend reading the following thread where you’ll find HSL’s (and other helpful) posts about this “Staff replacement, balance wheel wobble”. To call this post of mine a “Service Walkthrough” is perhaps a bit of a stretch as the pictures don’t include any oiling suggestions and/or tips/instructions. Nevertheless, I’m thinking that the pictures still might be useful to anyone servicing this calibre and perhaps pondering in what direction the main spring should go and/or what screws to use where, and so on.1 point

-

You are on a roll, no stopping you now! Soon be bringing dumpster Rolex back to mint condition with car polish and an old toothbrush!1 point

-

VWatchie, I have to agree Frank's software is pretty badass. I'm using it with a Vibrograf mic and his preamp (simple, cheap, effective in-line thing) and calibrated with his again, simple, cheap, effective calibration stick. It tracks spot on with my 7500 buck witschi. But will also do odd escapements (cylinder, duplex, clocks). My Witschi is on my bench but I often have an oddball piece in my computer that would have formerly been on a paper tape machine, as the PCTM just picks up everything. Not trying to make an advertisement but it's really good stuff. I don't know what version you have but the full one will tell you the heavy spot when doing dynamic poise- brilliant.1 point

-

I think taking a non-runner and making it work is a win. Yes, we all strive for perfection but sometimes it's not possible. So well done, it looks great.1 point

-

I'm well aware of that. I once had an argument in another group for somebody absolutely insisted that you could tell the difference the top line was always and the bottom line was always and some arguments you just walk away from but let me quote the whole thing and rip it apart to make sure all on the same page as I'm still confused by what is quoted below. okay let's look at the quote which I'm having a problem with. Then I highlighted one of the lines in bold so we can see the problem. Notice it says the sounds are different and if we had the waveform which we don't it claims you can visually tell the difference. This by the way I was under the impression was impossible but it is quoted above as yes it's true. Then notice it goes on to say it uses the sound to tell them apart rather than just assuming which once again implies an absolute. Then we get to the confusion the risk of if you take the watch often put it back on again. Which is the reality of the situation if you take a watch often you put it back on the machine as far as I know there is no way of telling one from the other by listening. It may be possible with witschi and their newest or one other machines that uses an optical method it would obviously know which direction the balance wheel swinging in so that it would no but only because of that not because of the waveforms being different because as far as I know they are not accept I will comment on the waveforms in a moment then continuing on and I've made that bold the loudest is first. Then the last line is a contradiction to what I've already commented about in the same paragraph which is why have a confusion as far as I know there is no difference in the sound from one to the other except. Yes this is watch repair that always seems to be exceptions. If you have access to something with our oscilloscope and you can look at the waveform like the witschi we have at work I can see 4 waveforms unless of course you're running a higher frequency watch which I typically never do that I've noticed we can get six. So what I've noticed when you look at the oscilloscope is it's not an exact science there is variations for a whole variety of reasons. Then I have noticed were sometimes some of them the loudness does seem to very but that's only occasionally I was interpreted to something else. So as far as I know there should be no difference between exit and entry as far as audio sound goes for analysis but the above paragraph indicates that I'm wrong. But also confusingly indicates that I might be right which is why I'm confused1 point

-

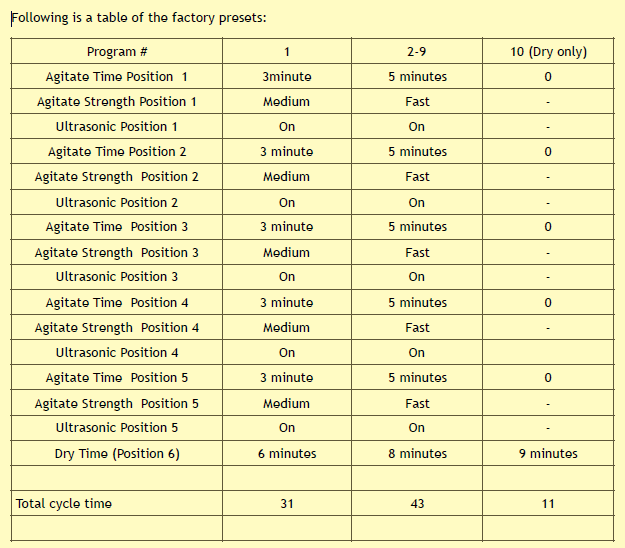

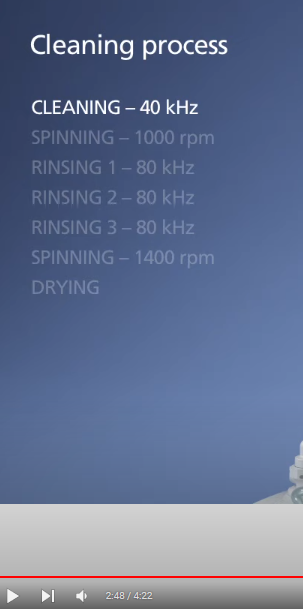

it probably depends upon a lot of factors including personal choice. it also of course depends upon the cleaning machine. for instance at the links below to separate cleaning machines that have ultrasonic. Notice in the specification it says ultrasonic for every cycle and for documentation you can download the manuals for these so out of the freedom manual we get recommended or the preprogram cycles. You'll notice that they use ultrasonic and every cycle. http://lititzpp.com/freedom.php http://lititzpp.com/matador.php here's another cleaning machine where it's easier to figure out about the ultrasonic if we look at the video and I just snipped out an image. then yes this is an incredibly complicated machine with as far as I can tell everything is programmable in it. https://youtu.be/4F67g_F_L14?si=-MszC1okUv-BmlZg1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

one of the minor issues with having a 6497 is variations. So for instance if it's a modern 6497 putting it in beat is easy because it has the etachron system as you'll notice in the attached technical sheet for this watch. I think this is the last one they printed from 2016. So putting it in beat is easy just nudge the stud holder. To be really careful and go really slow though because it's really easy to go past and then get hopelessly lost as to where you are. CT_6497-1_FDE_482160_11.pdf1 point

-

here's a really good website for looking up watches with in need of parts and also handy because you can find out cross references and when the watches use the same parts http://cgi.julesborel.com/ then jumping ahead to your watchhere's the parts list http://cgi.julesborel.com/cgi-bin/matcgi2?ref=TIS_2581 then once you get a part number you can go back to the main page that tells you how to go to the normal sites we can enter in your part number and quite a few times the part is available. and because I like pictures of watches plus bonus information like the watches that are related. Often times you won't find a tech sheet for specific version but you might find the base caliber http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&69&2uswk&Tissot_25811 point

-

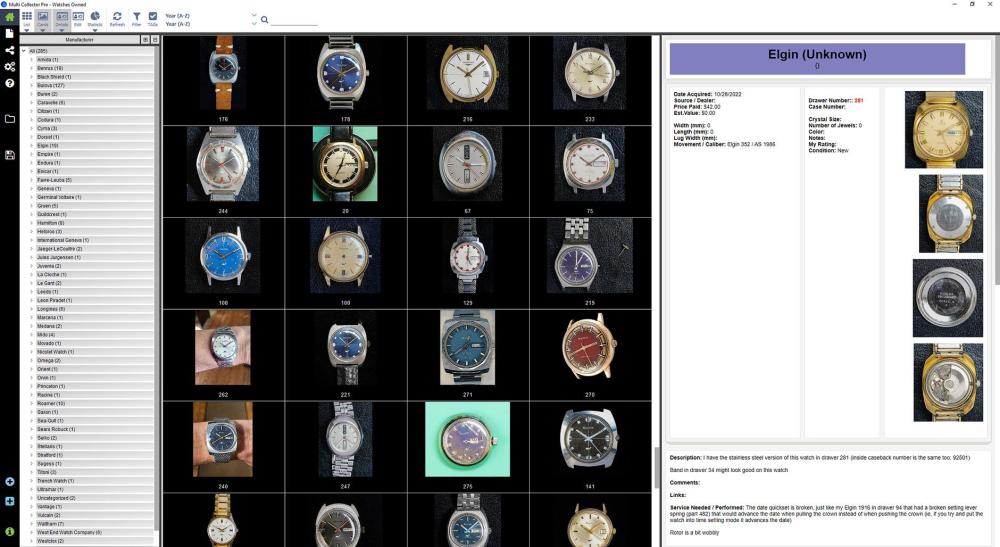

I use the program 'Multi Collector Pro' to keep track of my collection. You can customize the templates to look the way you want and can edit templates to add fields you would like to track. For example, I added a "Drawer" field. I keep my watches in plastic parts containers and number the drawers. That lets me easily find a particular watch by looking at what drawer it is in within the program. All of the fields are searchable which is very handy for quickly finding things. For example, if I get a watch that has a nice strap I will put "nice strap" in the description field and then later if I am looking for a strap to put on a watch I will search for "nice strap" and get a list of all of those watches. It's basically a database program and you can do normal database things with the data. In the screenshot I have it sorted by "year" and I use that view a lot and I also sort by "drawer" a lot too, depending on what I am trying to do. You can sort on most any field, including caliber, # of jewels, date acquired, etc. You can also include web links (and local links to things like service sheets) and when you click on it, it will open the linked webpage/PDF. Handy for when doing research on a movement and you want to remember what website had the info on the watch in question. When I first started using it I found a review that had a template the person customized which I used as a starting point and then customized it further.1 point

-

1 point

-

0 points

.thumb.jpg.60a30970b7ceed2a9e26e863021d78d0.jpg)

.thumb.jpg.4f4f45149566cdebb9fcb3dfd1c13f26.jpg)