Leaderboard

Popular Content

Showing content with the highest reputation on 09/04/23 in all areas

-

So I got my tools, screwdrivers, tweezers, movement holder etc and had a cheap old replica 45.5mm Omega Planet Ocean ive had for well over 12 years just sat in my drawer. "Right, you're having it" I thought. Took the caseback off, cheapy gold Chinese 21600bph movement inside, withdrew the stem, took off the hands, then the dial followed - I thought "im doing o.k here" Then it all went to rat-shit The good thing is that this watch owes me nothing, looked o.k, ran well and is now in a million bits. Im 100% sure that some of the date works flipped off when I took the date wheel off, doomed to the study carpet, I couldn't find anything - but that means bugger all. My god how tiny are some of these components?? I finally dissasembled the whole watch and all of the bits are in a parts tray. I'm getting myself a magnetic wand to sweep over the carpet then im going to sort all of the components into some sort of order and attempt to re-assemble it. Failing that, I'll chuck a 28800 movement in and enjoy it a little longer while I attempt to sort out and rebuild the movement that's more difficult than the Da Vinci Code. In fact, the more I think about it, the more it sounds like a good idea. Anyone got any spare links for a fake Planet Ocean steel bracelet?? My wrists are slightly larger nowadays How many of us lot have done the above??2 points

-

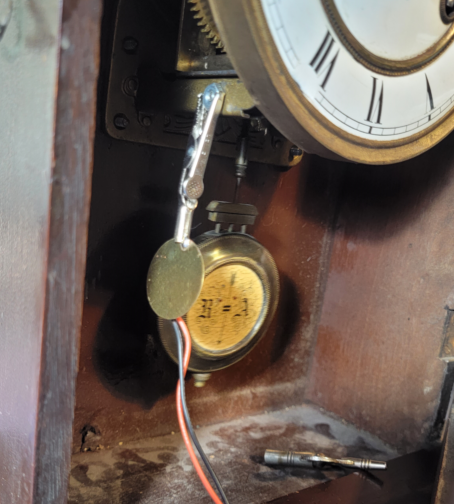

Replace the spring. Windles clock oil is the best you can use, as far as I know they only make one type. Cutting springs down when the ends have broken is bad practice, for starters you shorten the spring so the spring might not do its job in having the length it needs to run the clock or work the strike. The spring is old so it will not work so well as a new one. Priory one, never heard of it in my days that is why I always used Horolene but I think they both do the same type of job. With Horolene make sure you have good ventilation.2 points

-

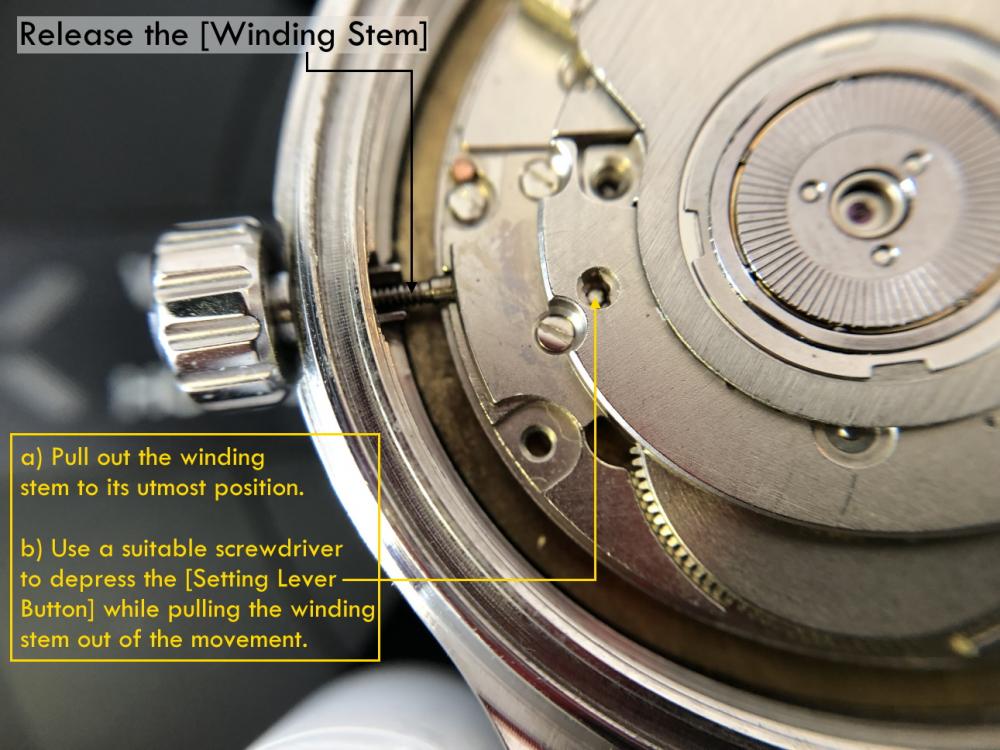

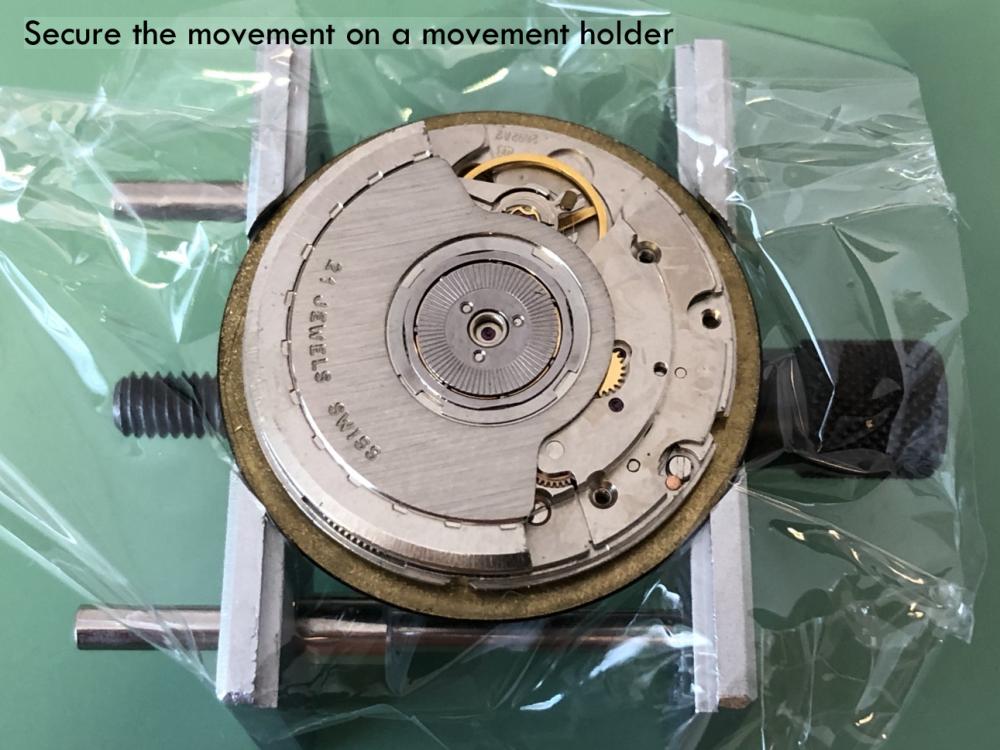

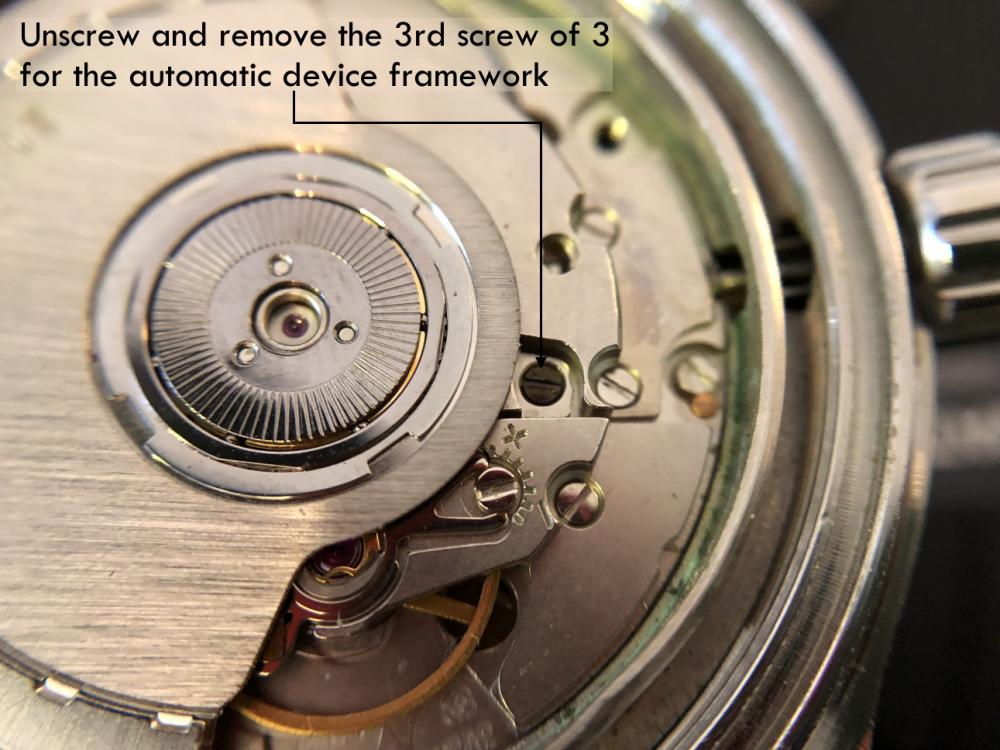

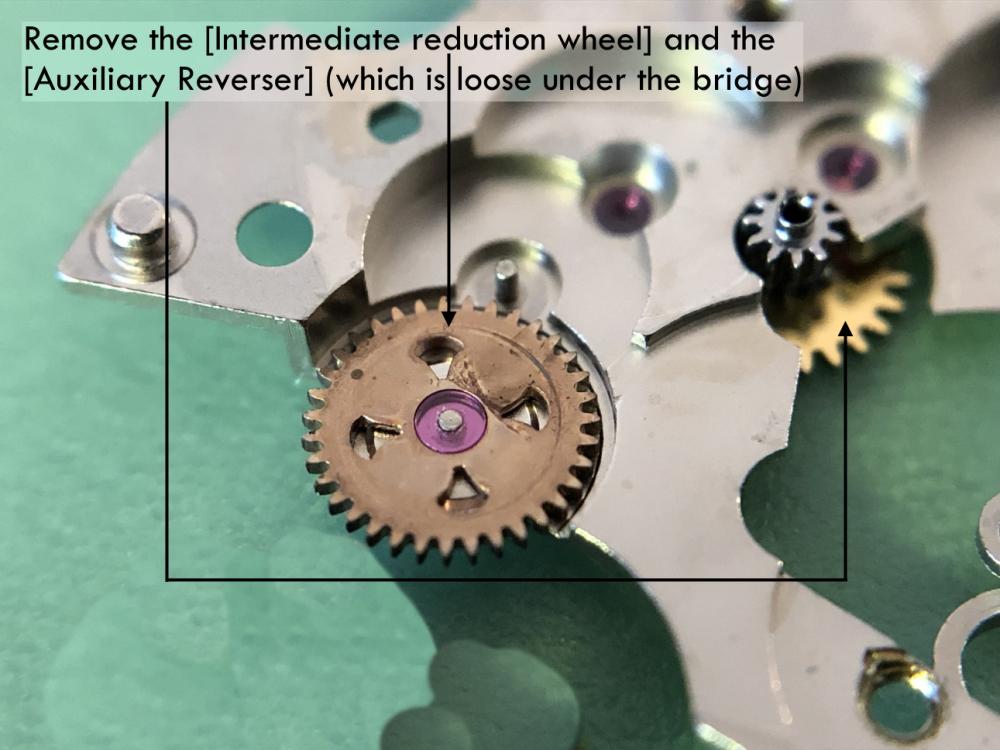

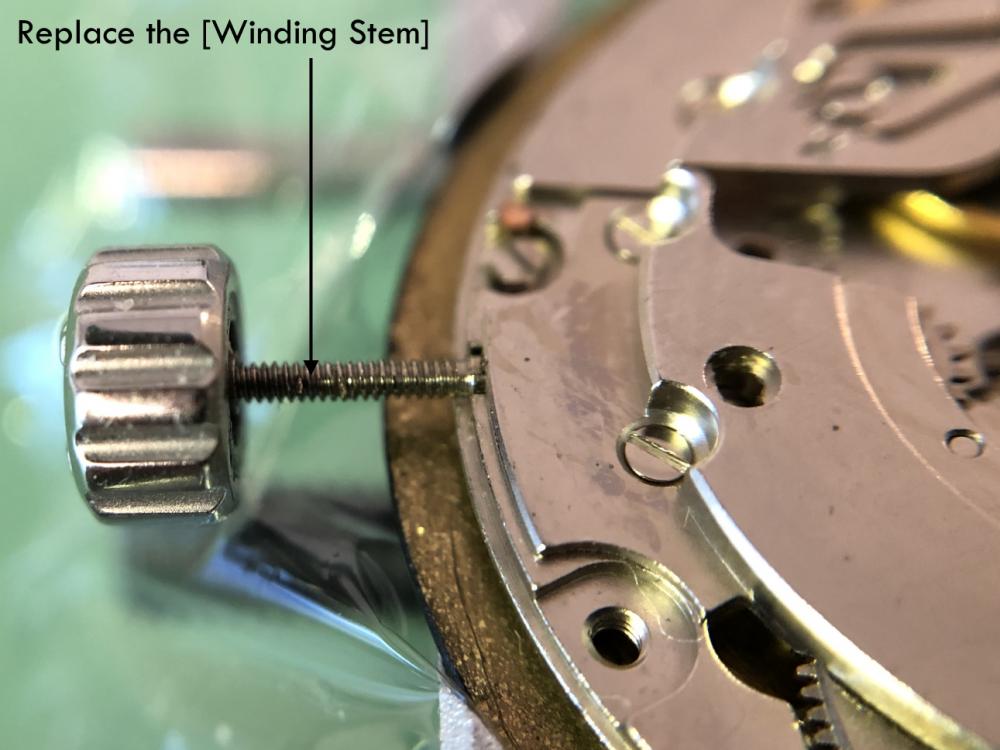

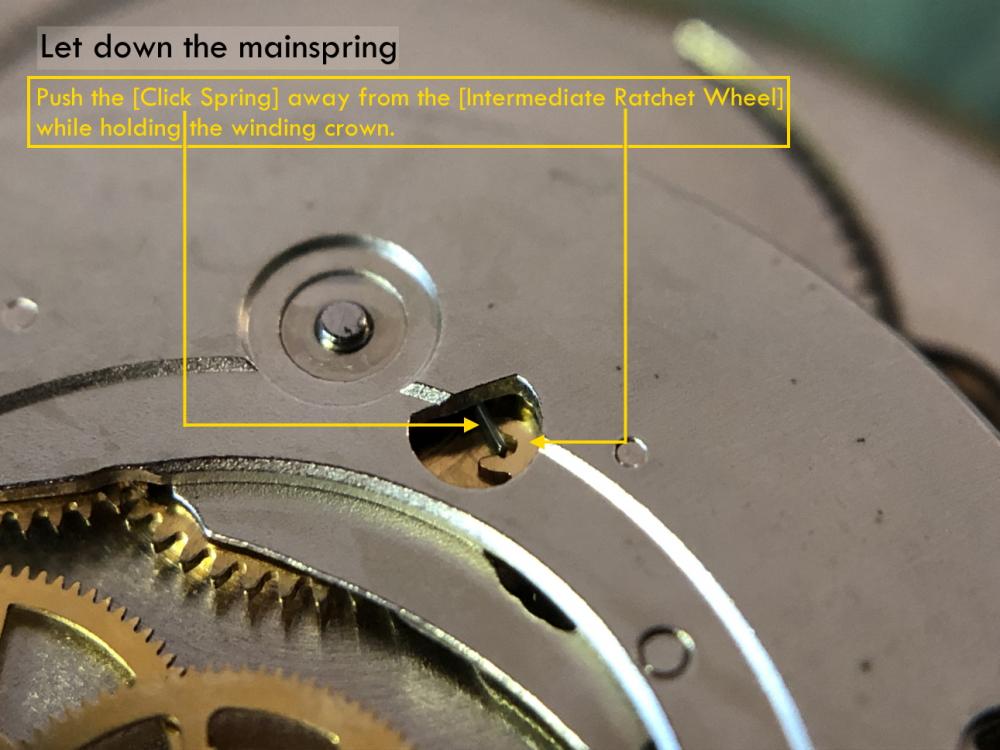

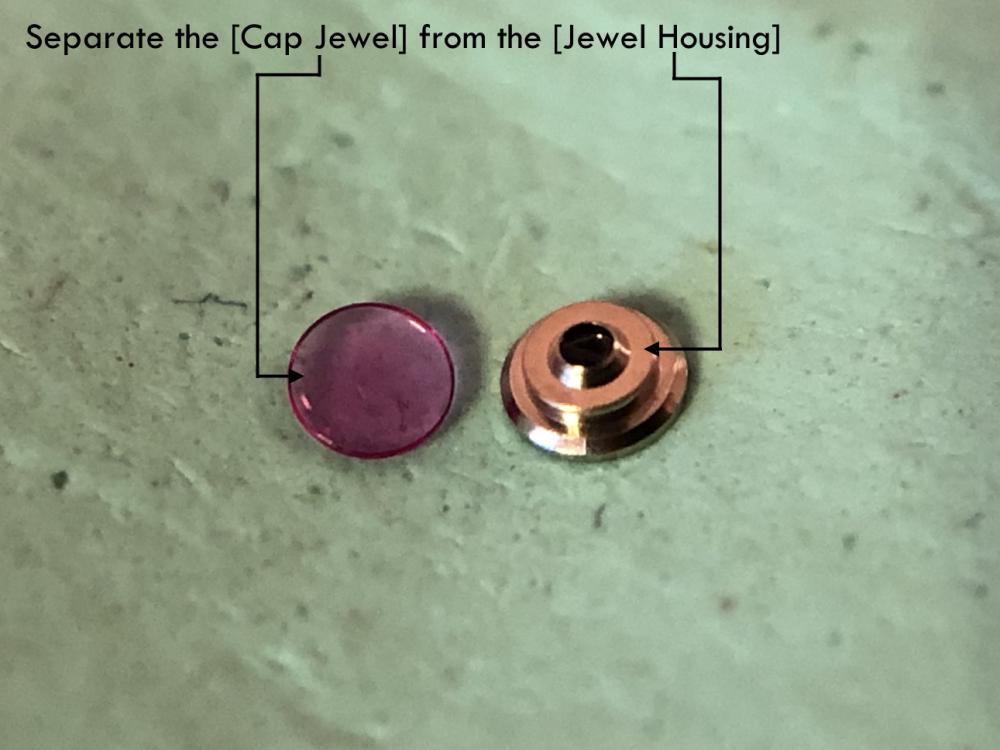

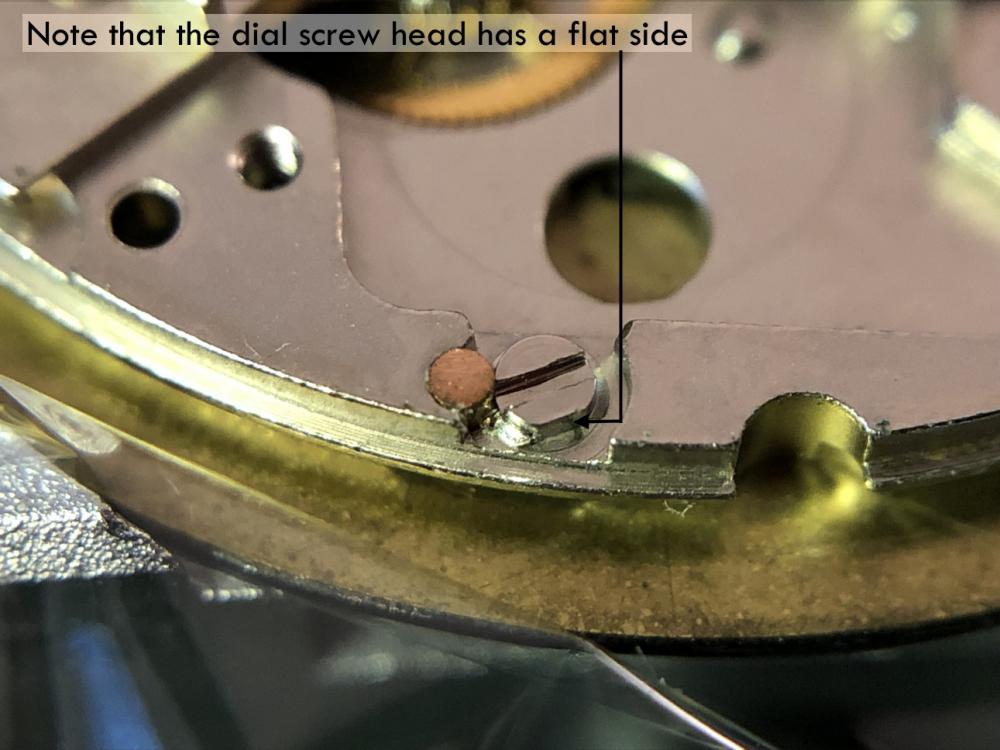

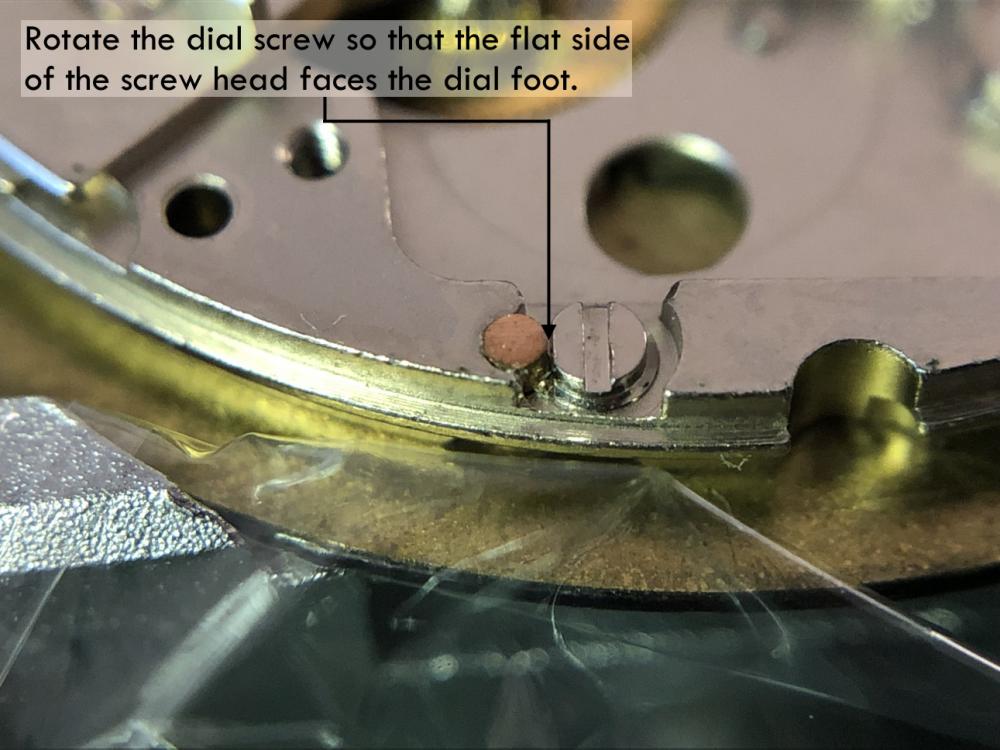

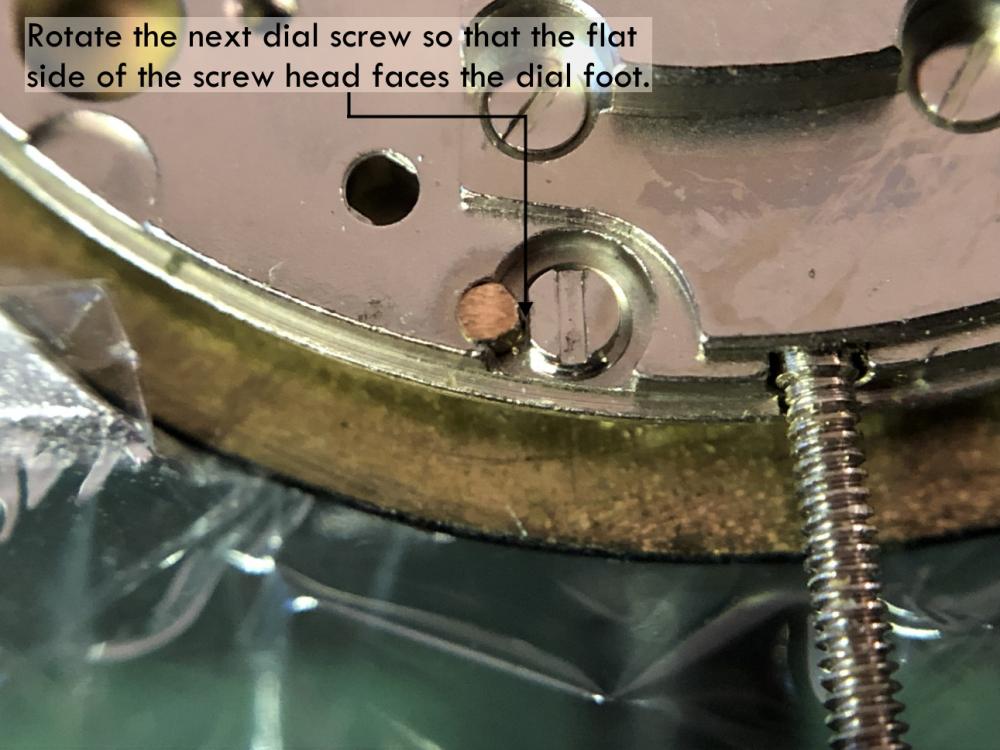

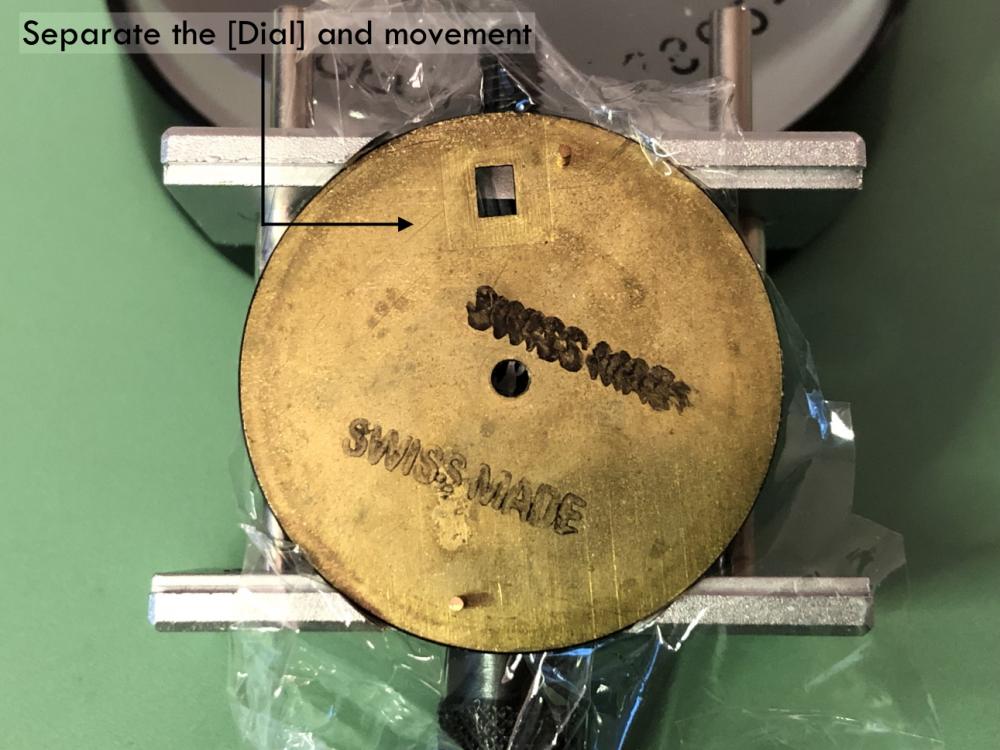

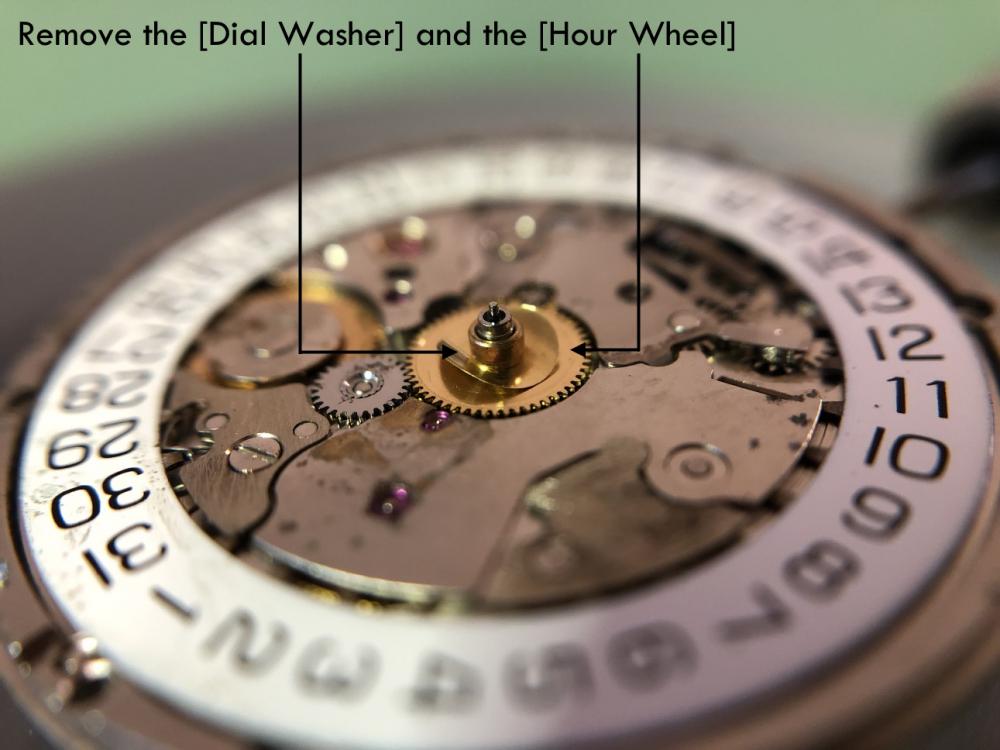

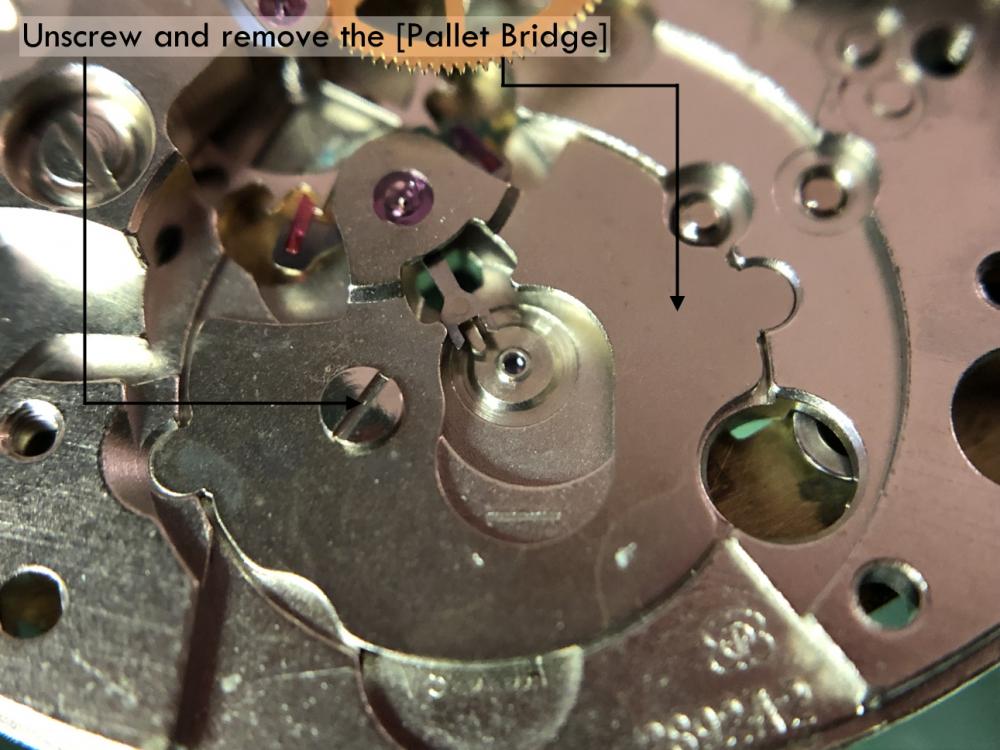

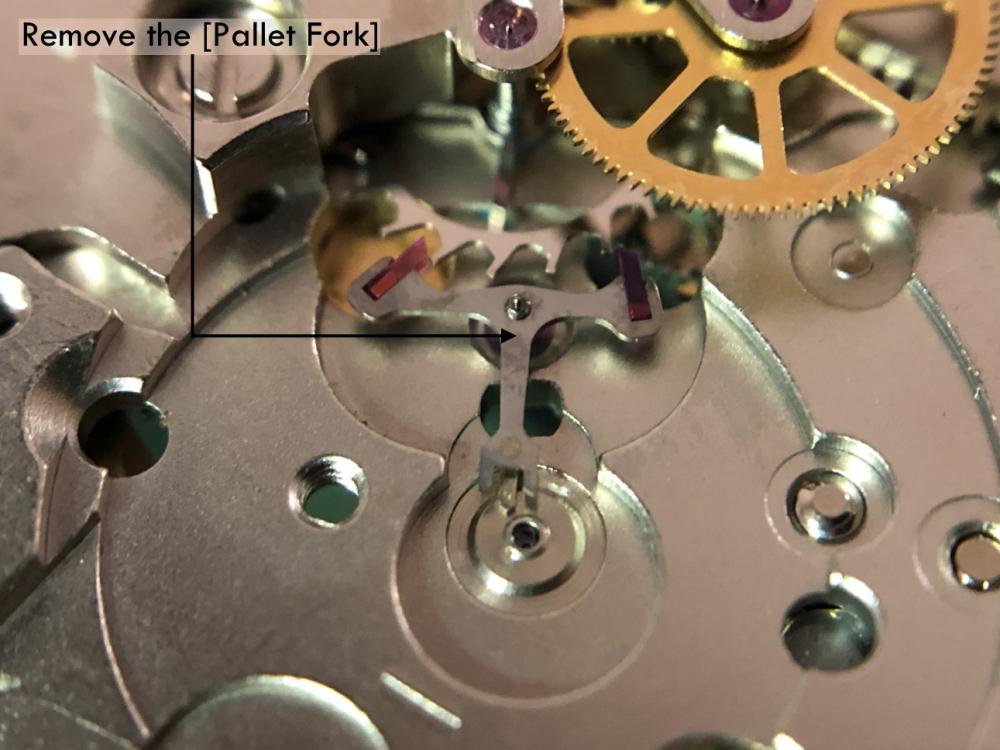

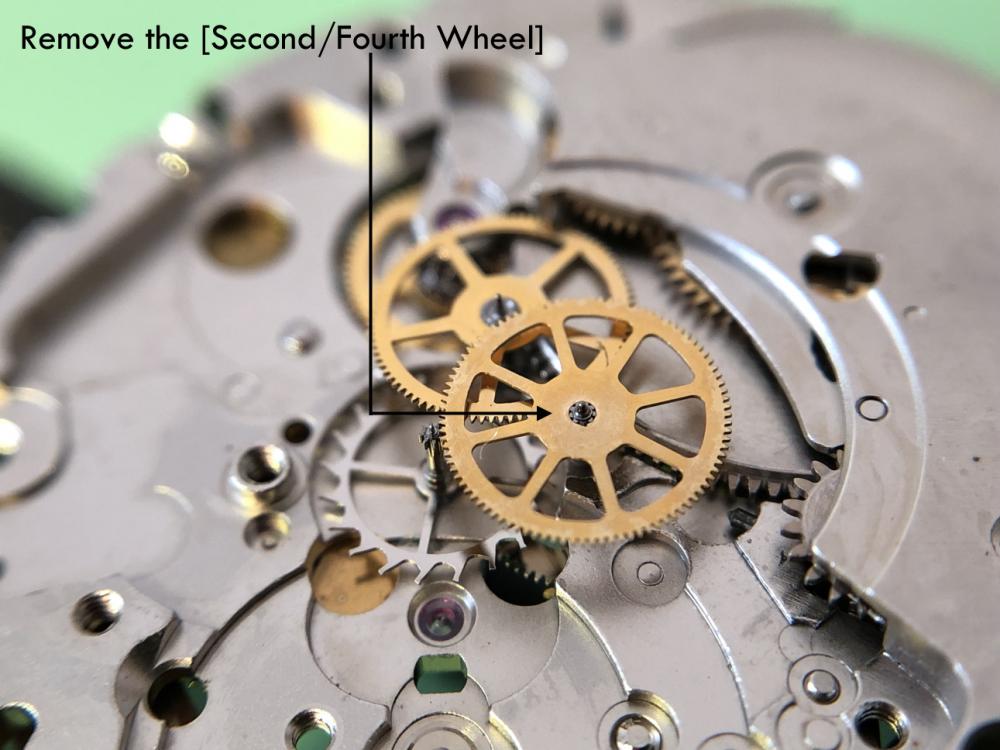

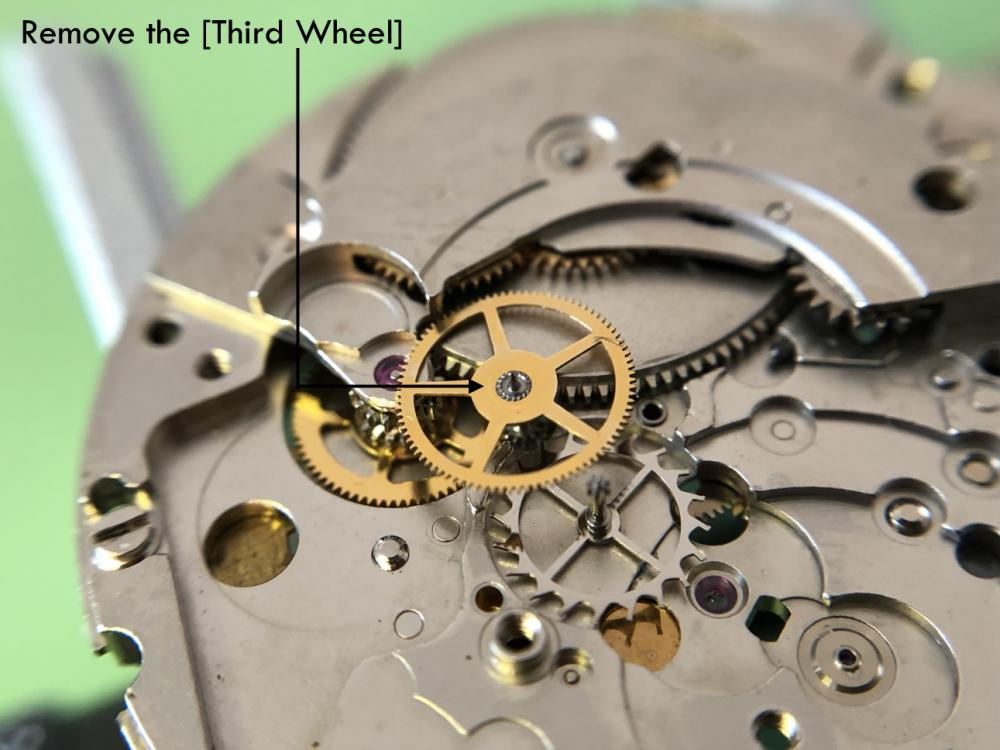

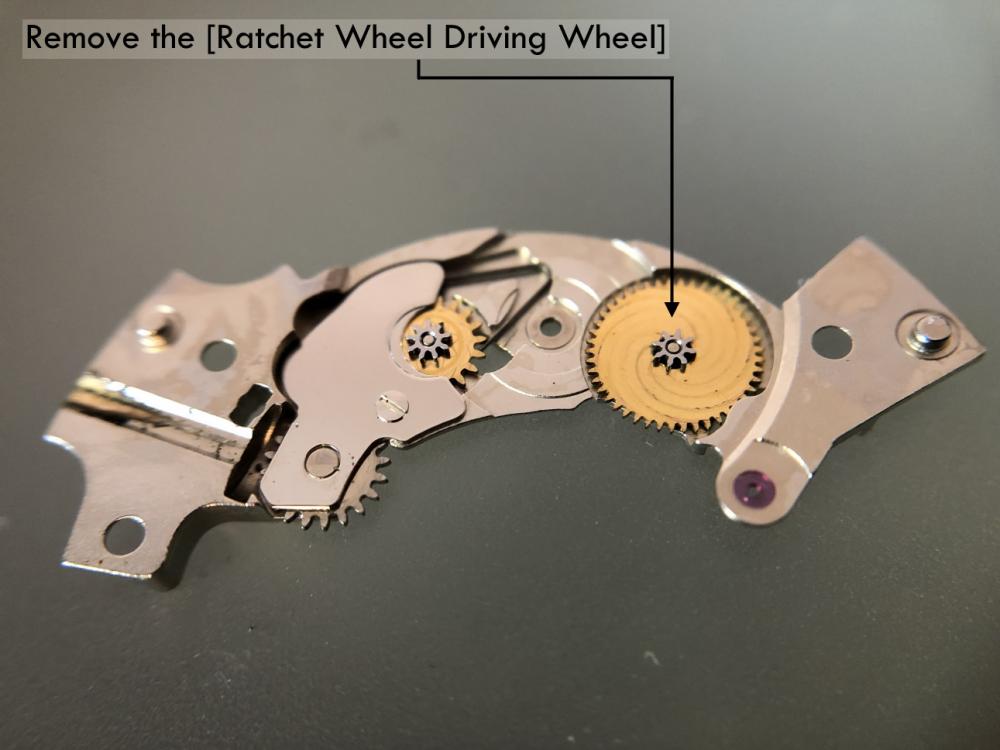

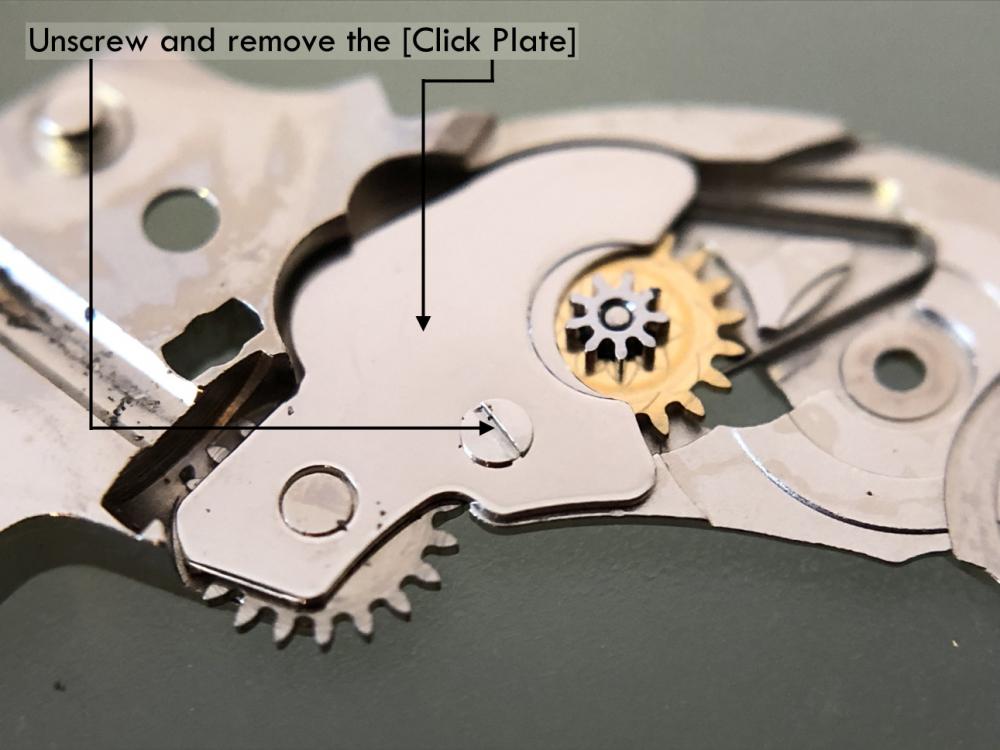

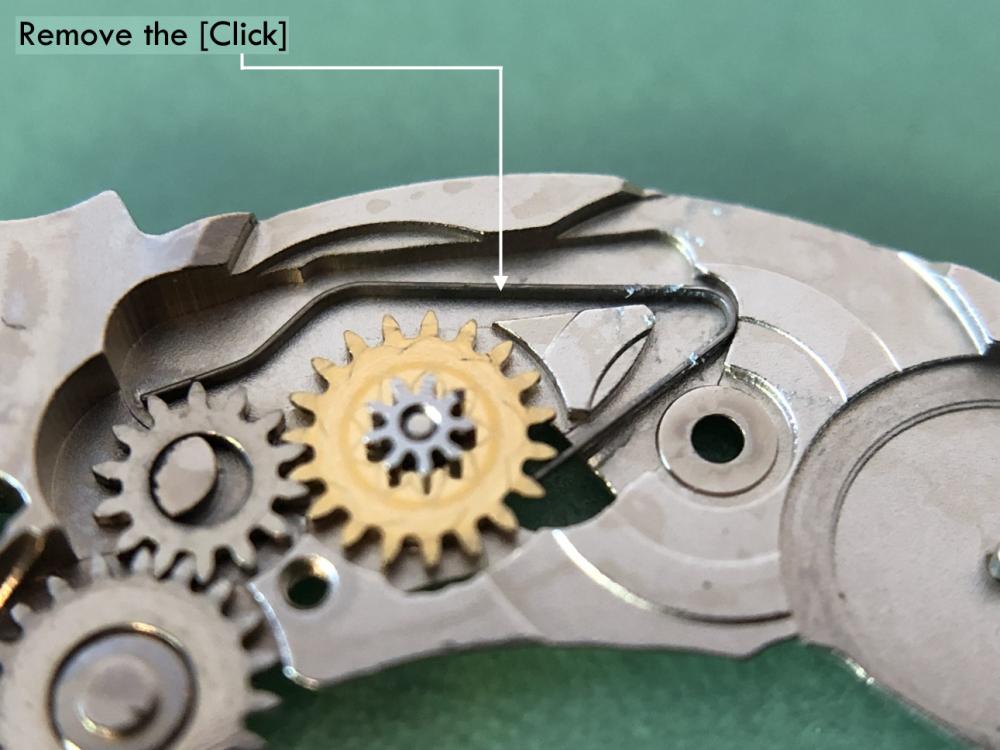

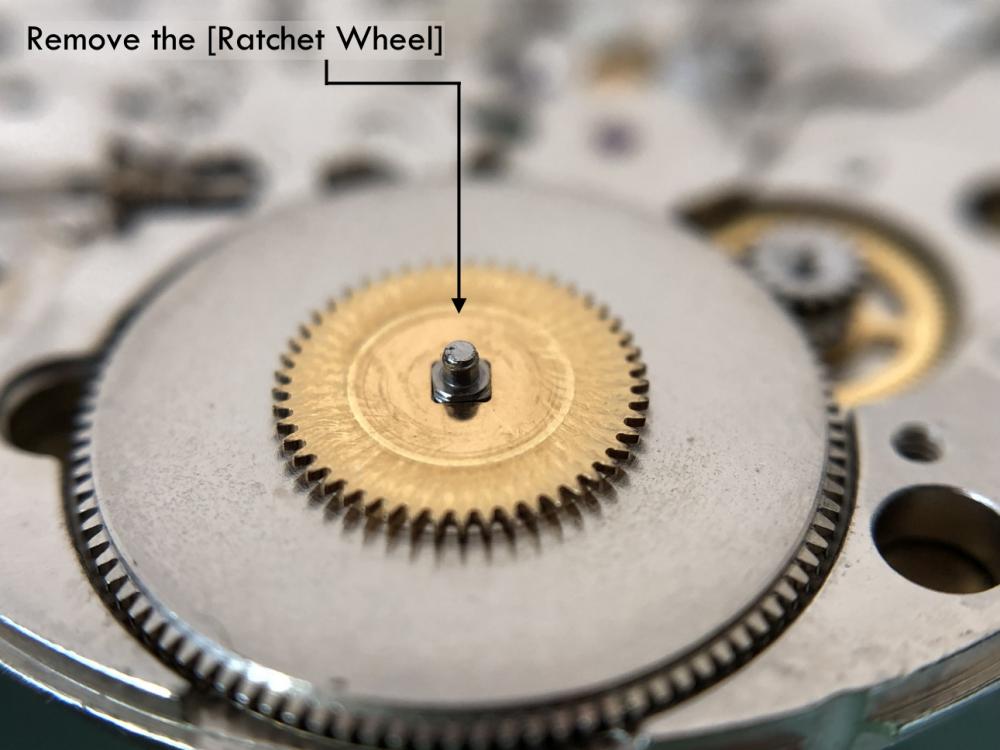

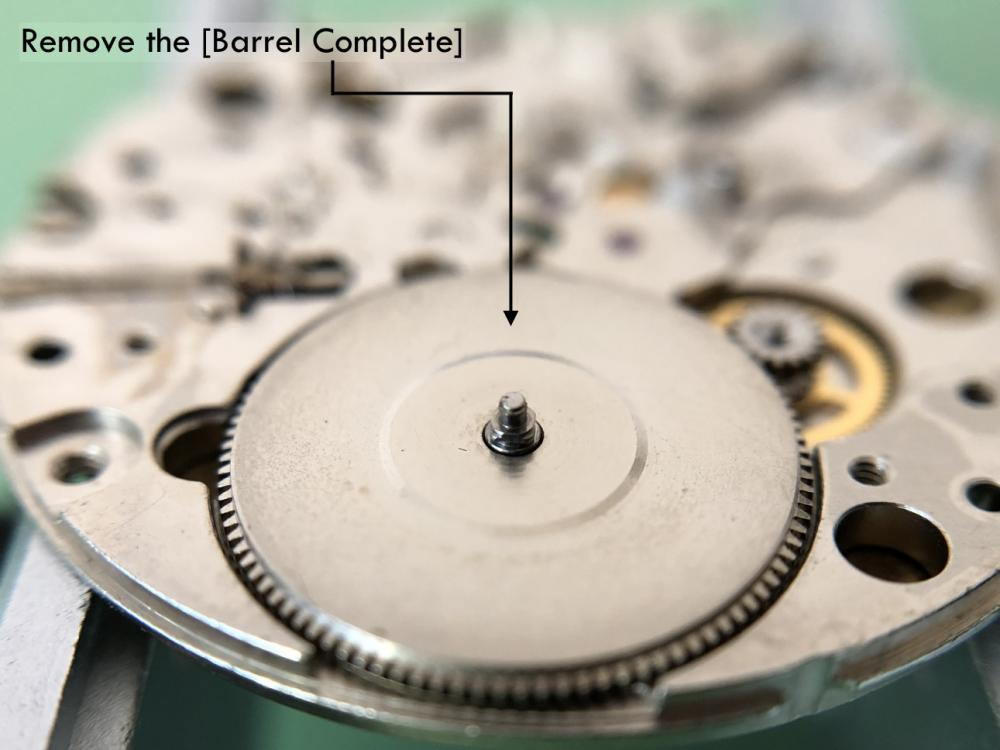

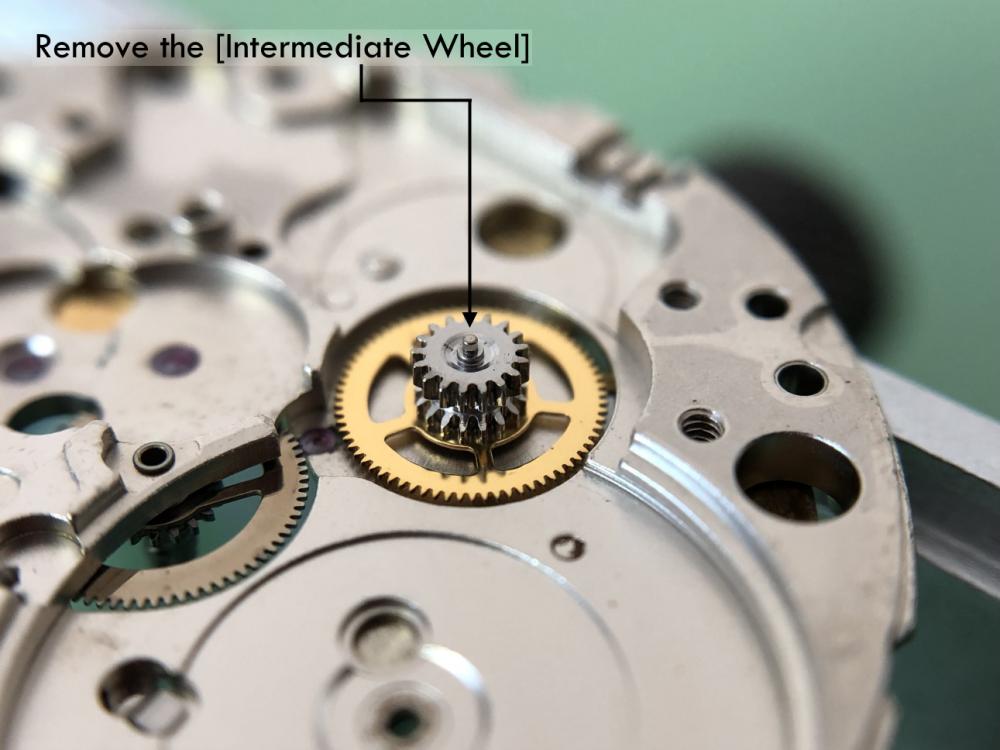

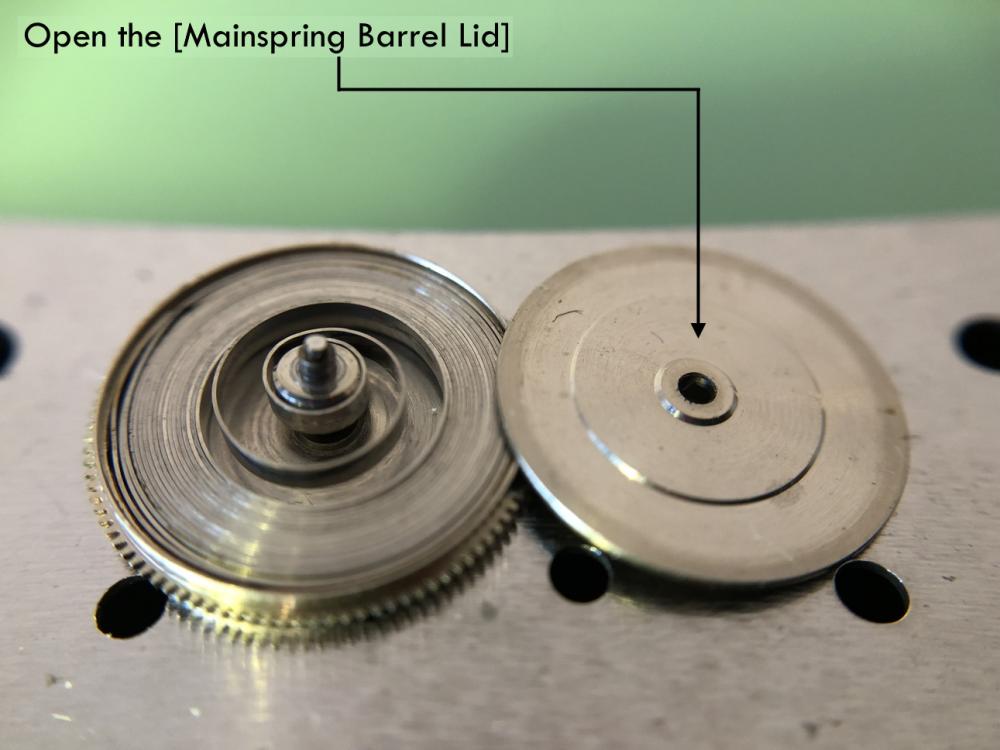

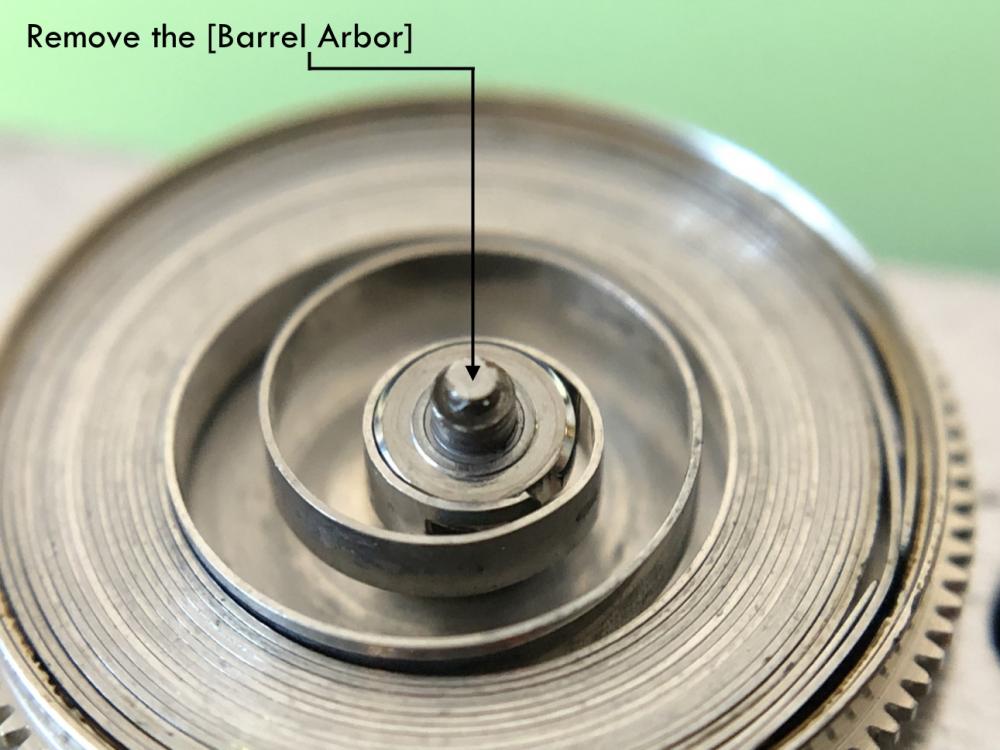

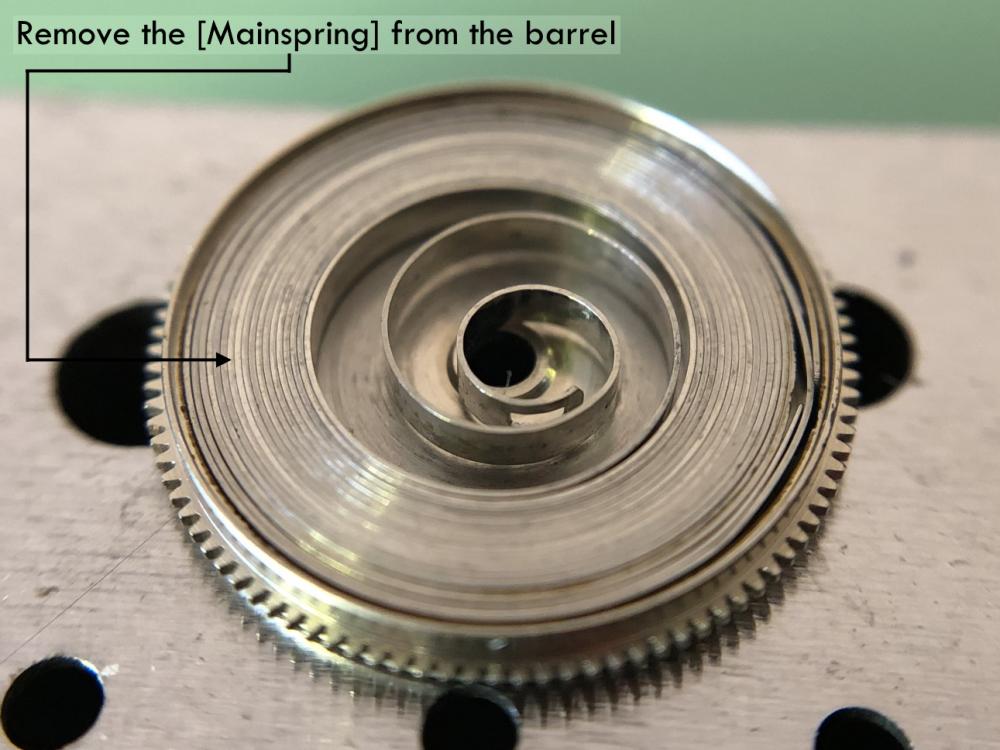

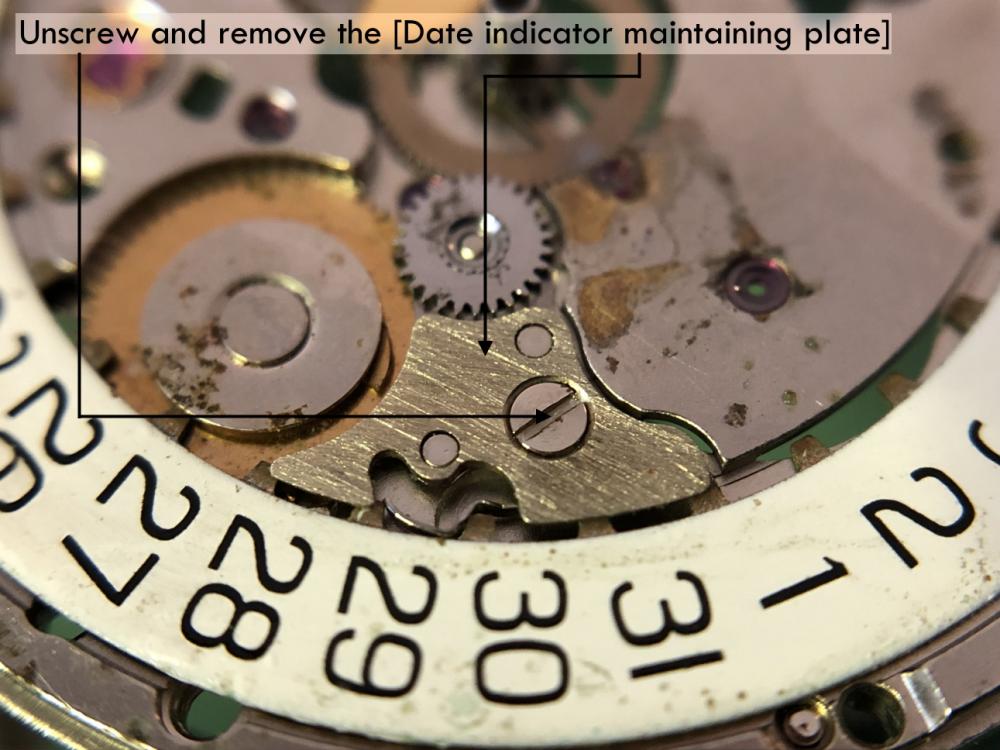

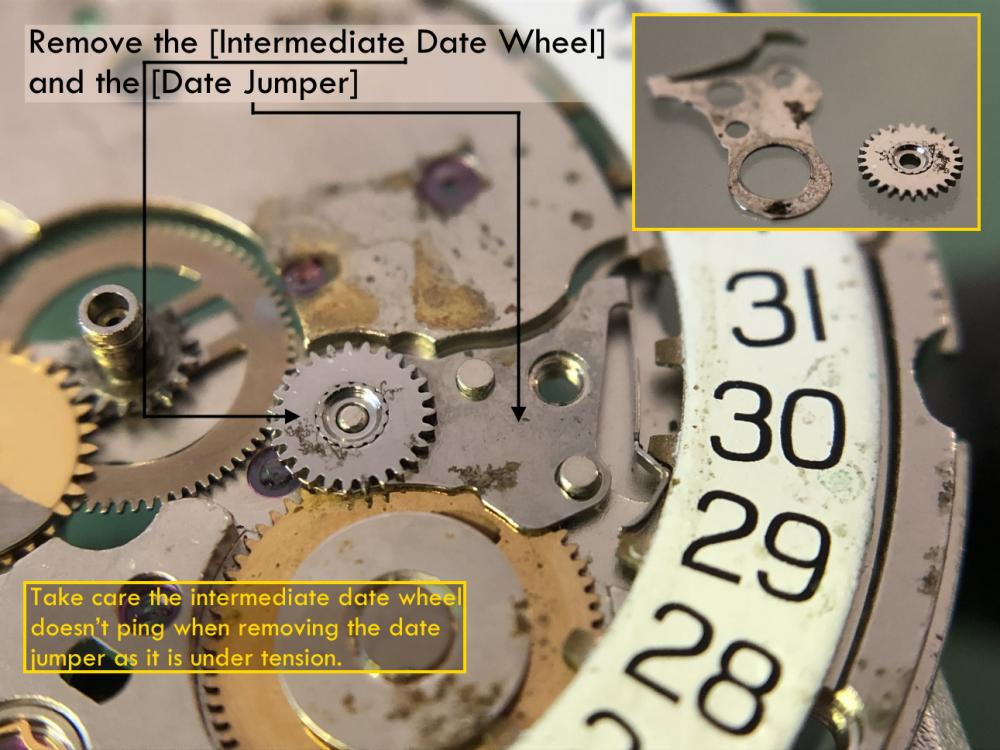

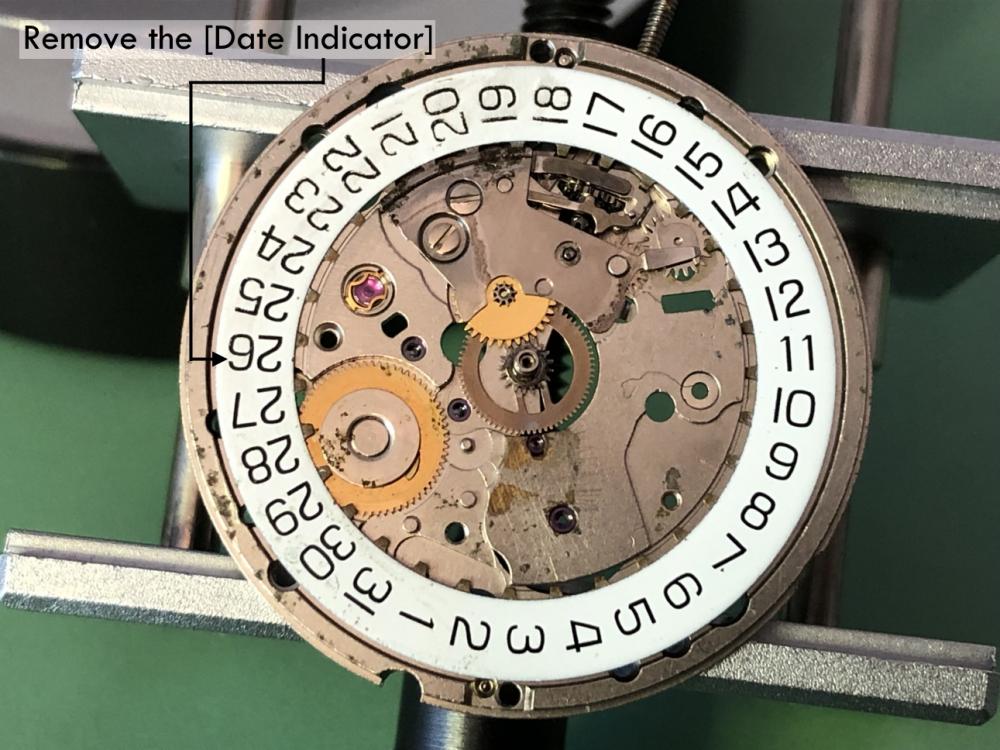

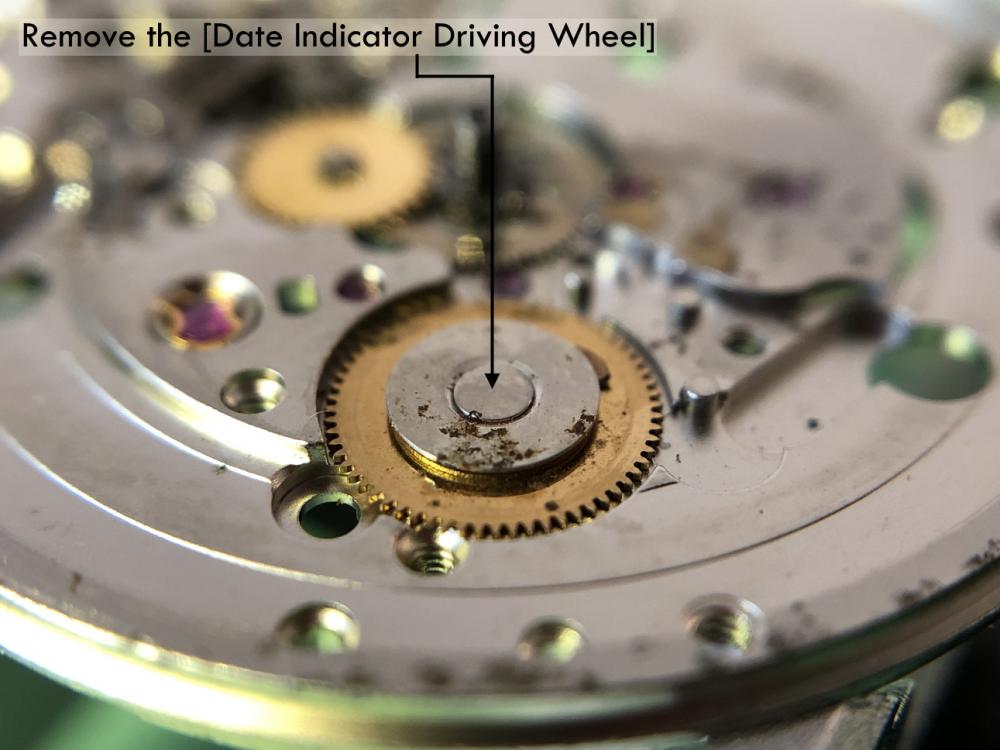

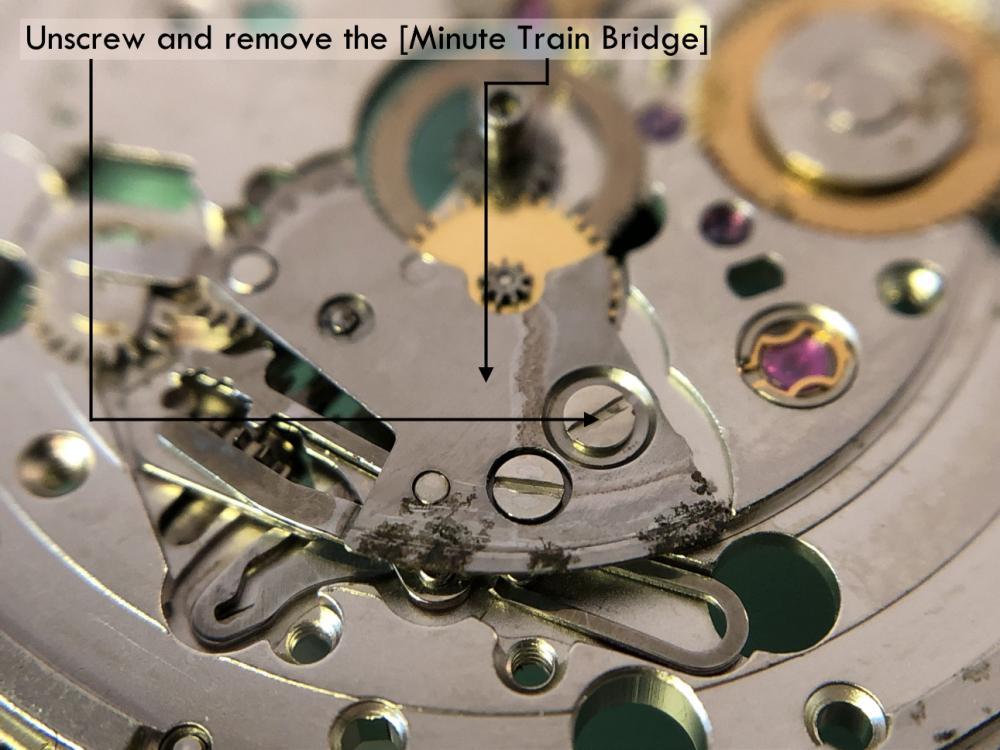

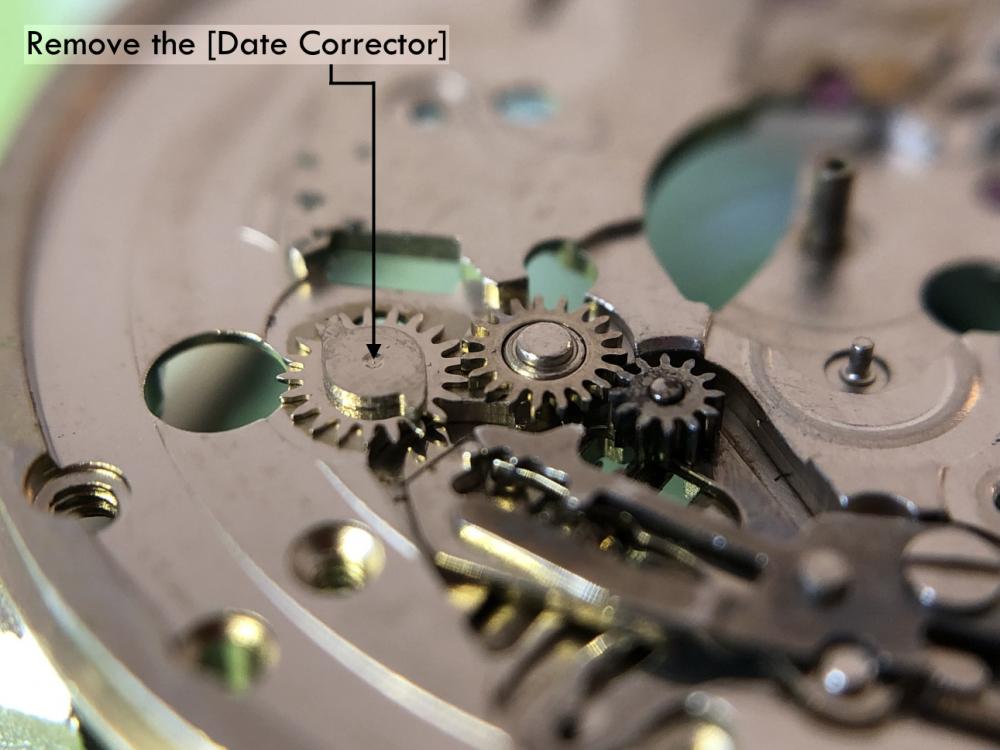

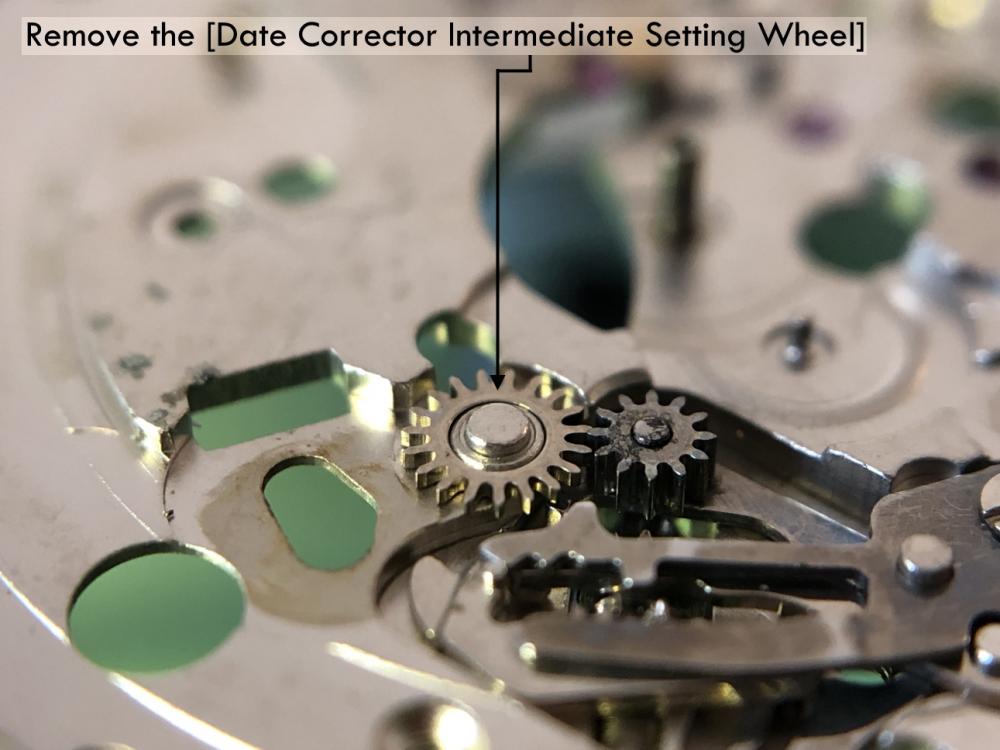

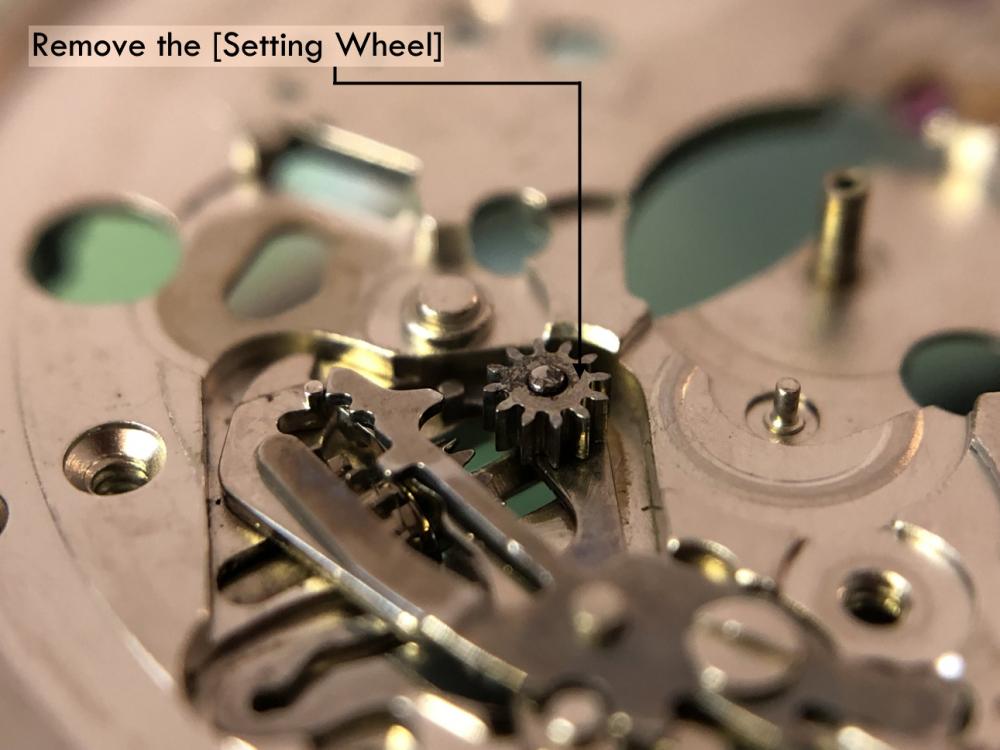

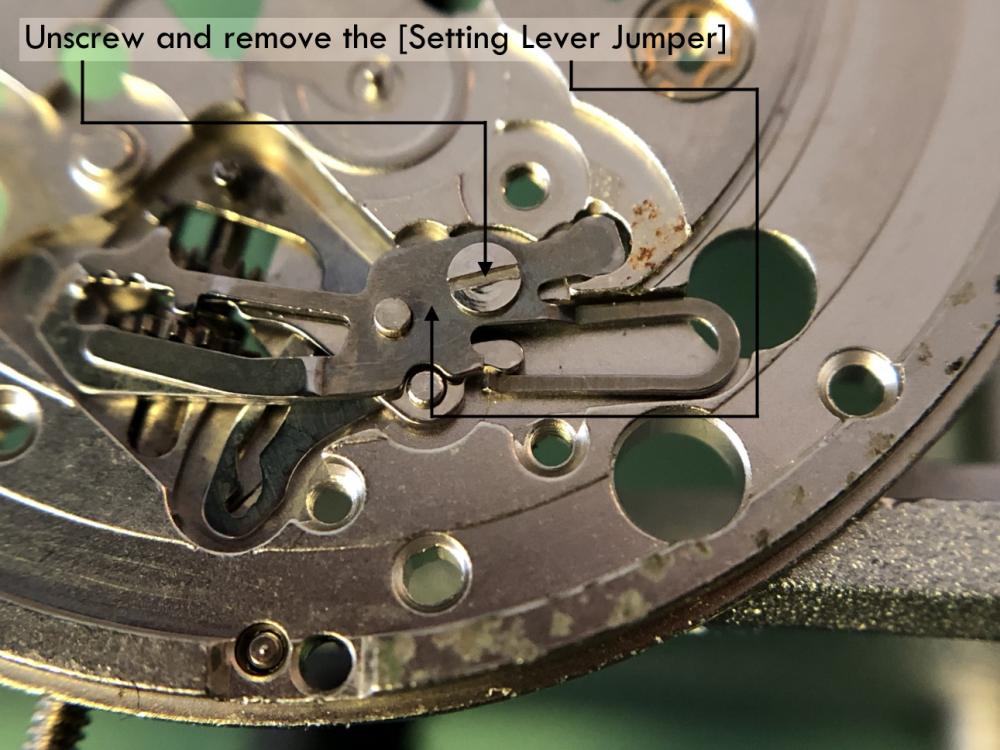

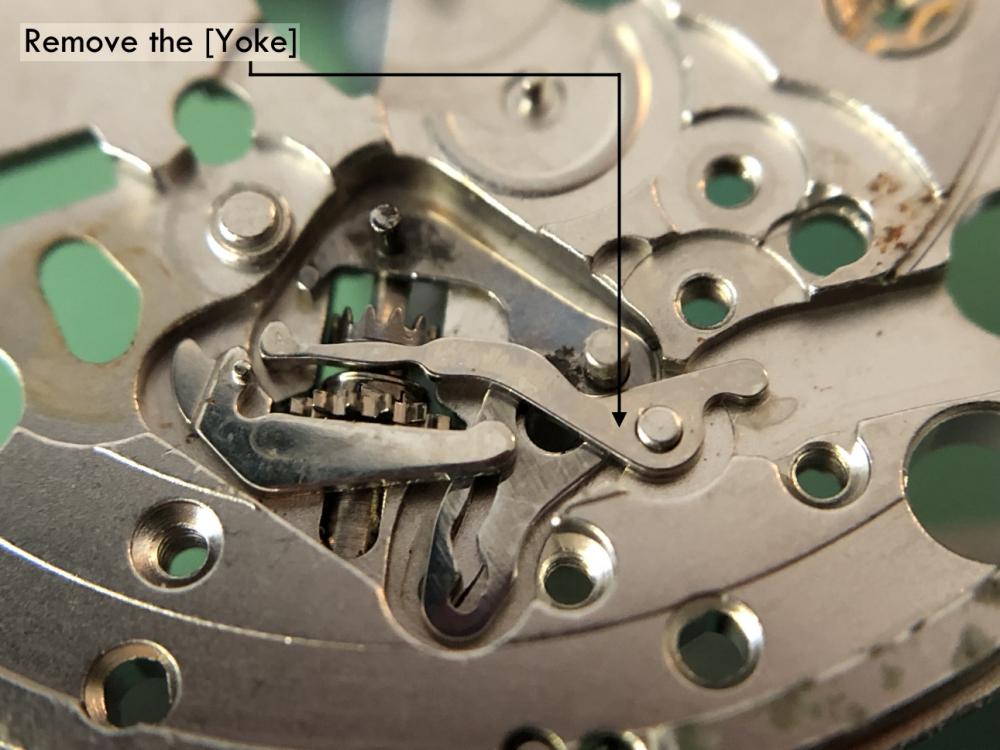

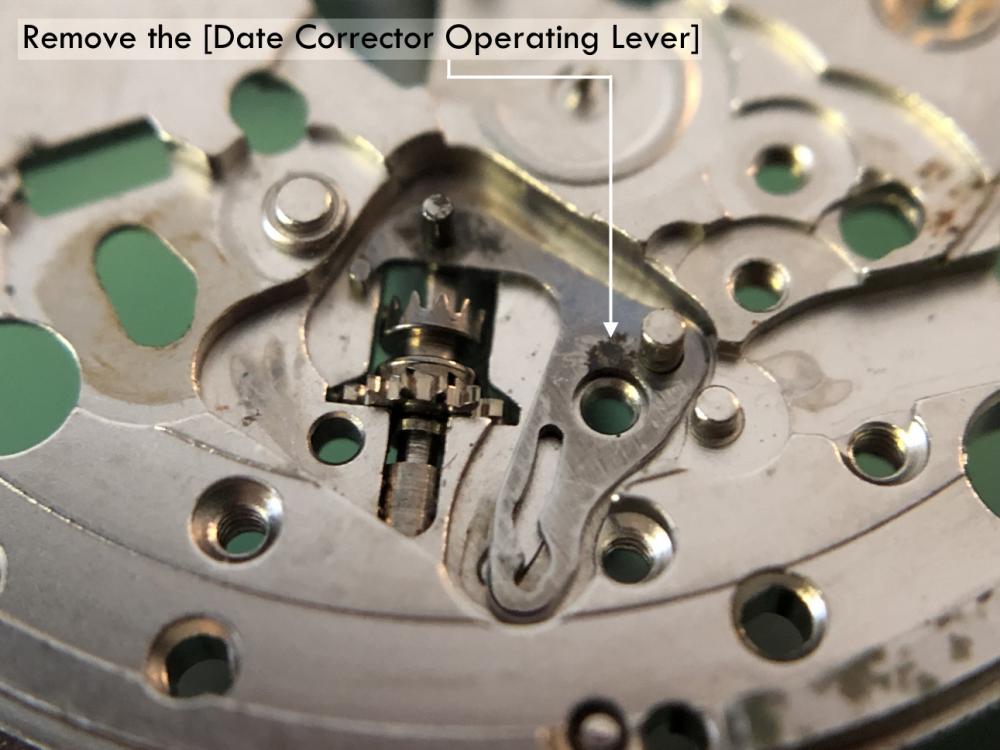

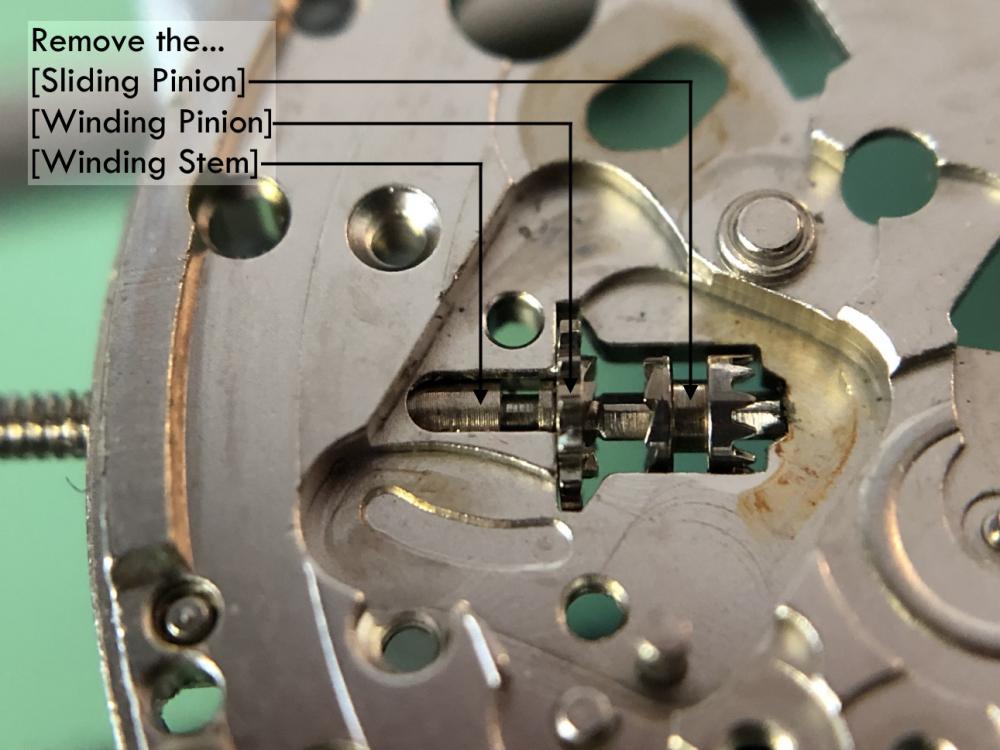

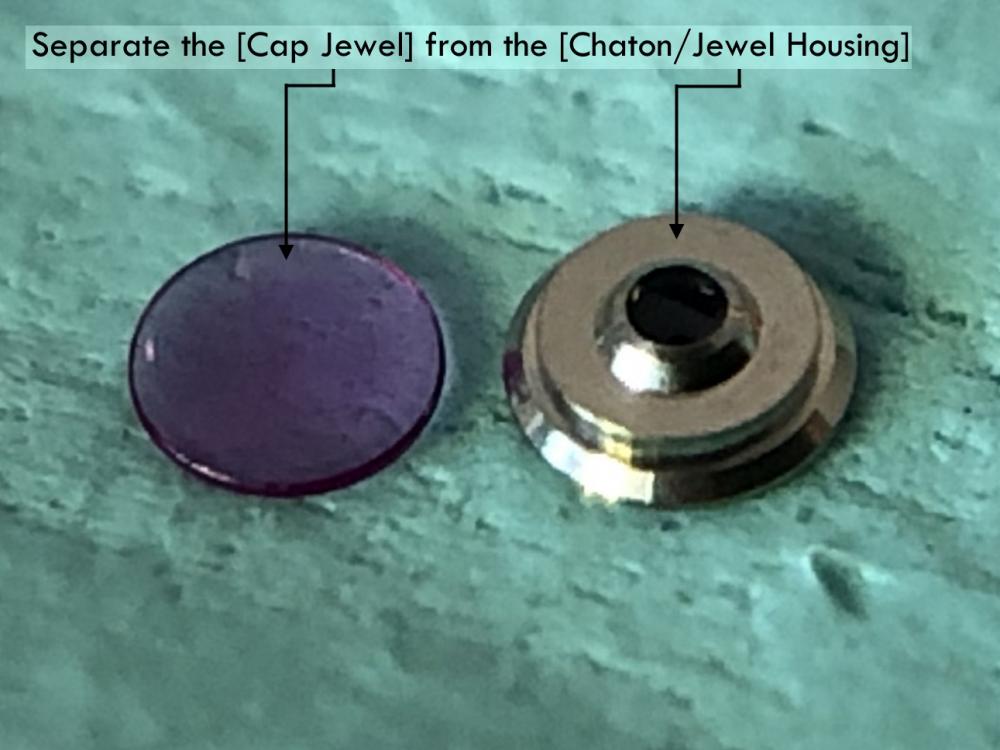

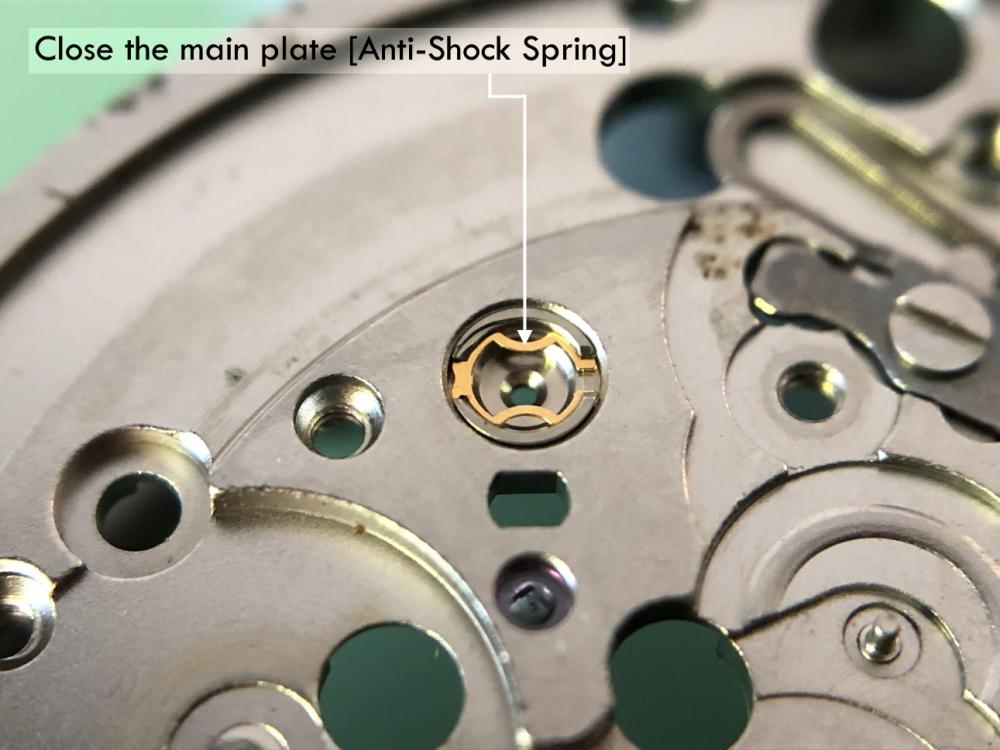

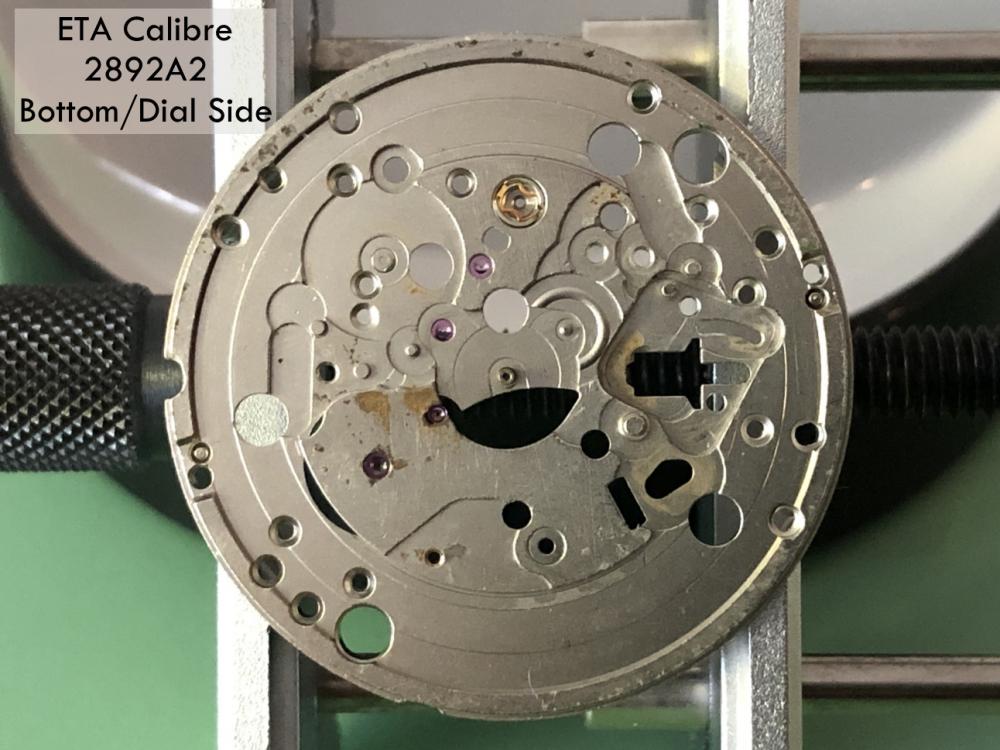

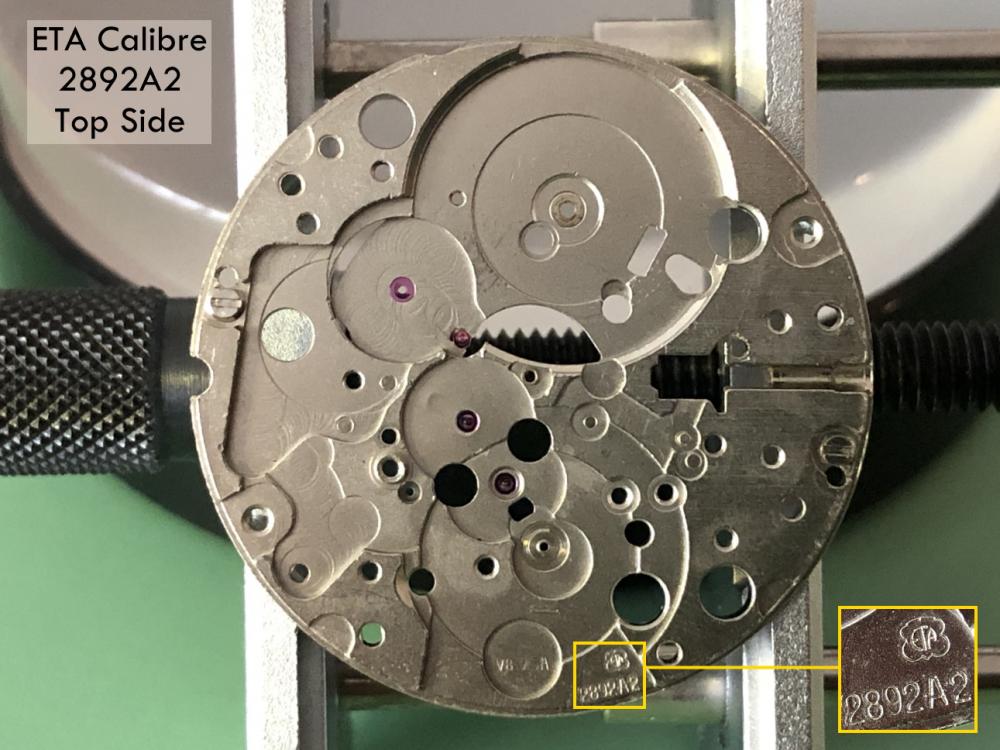

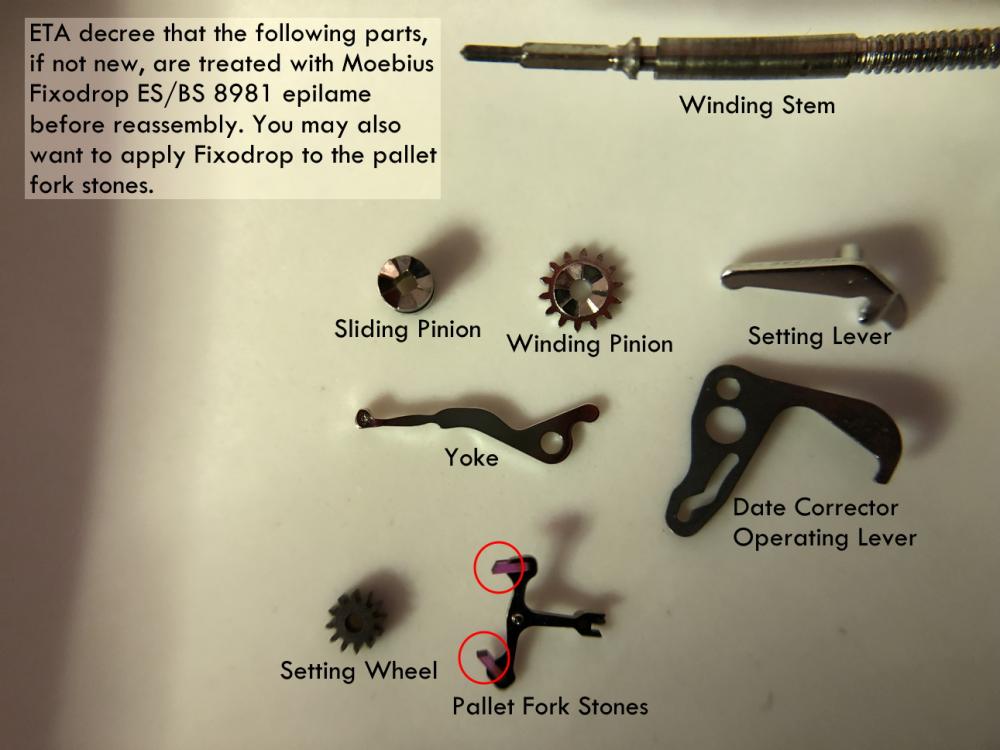

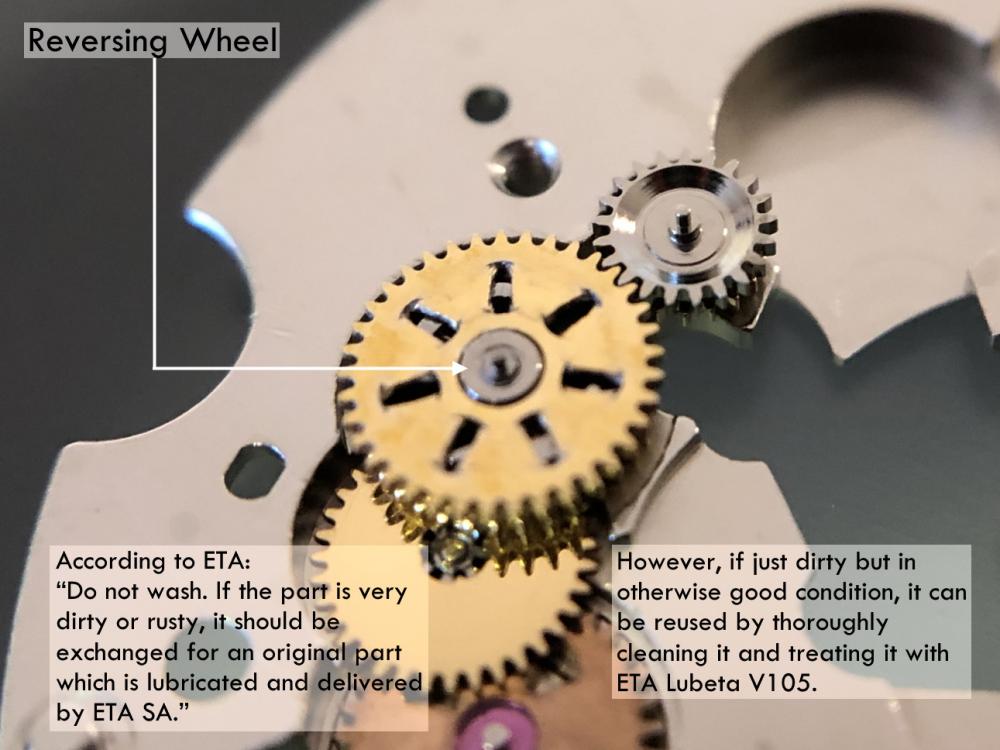

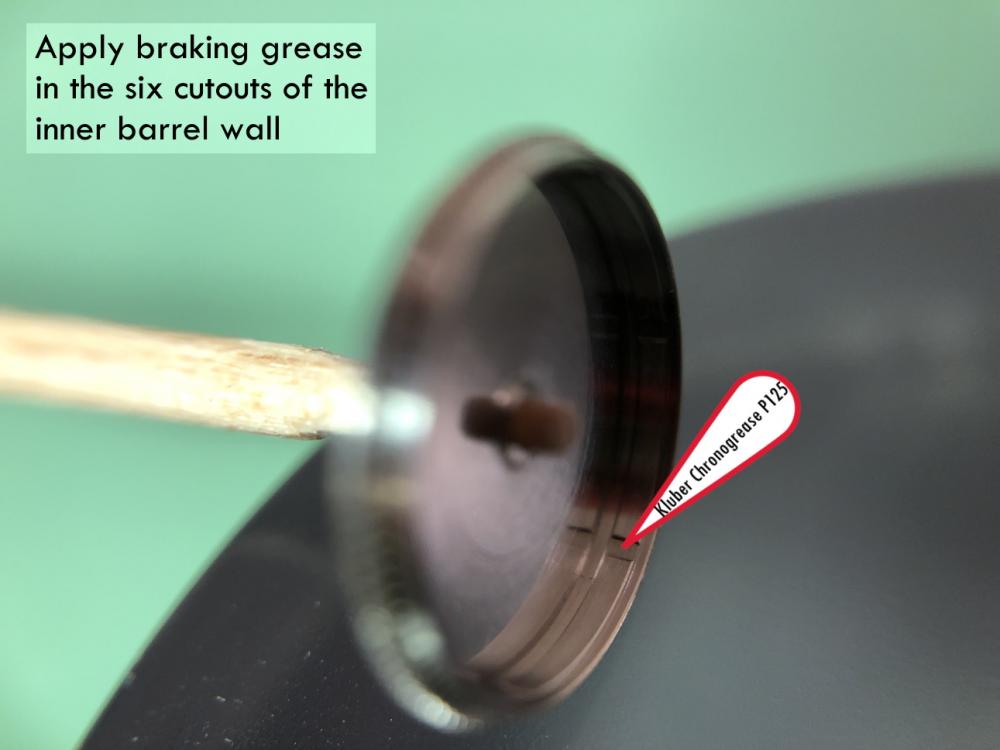

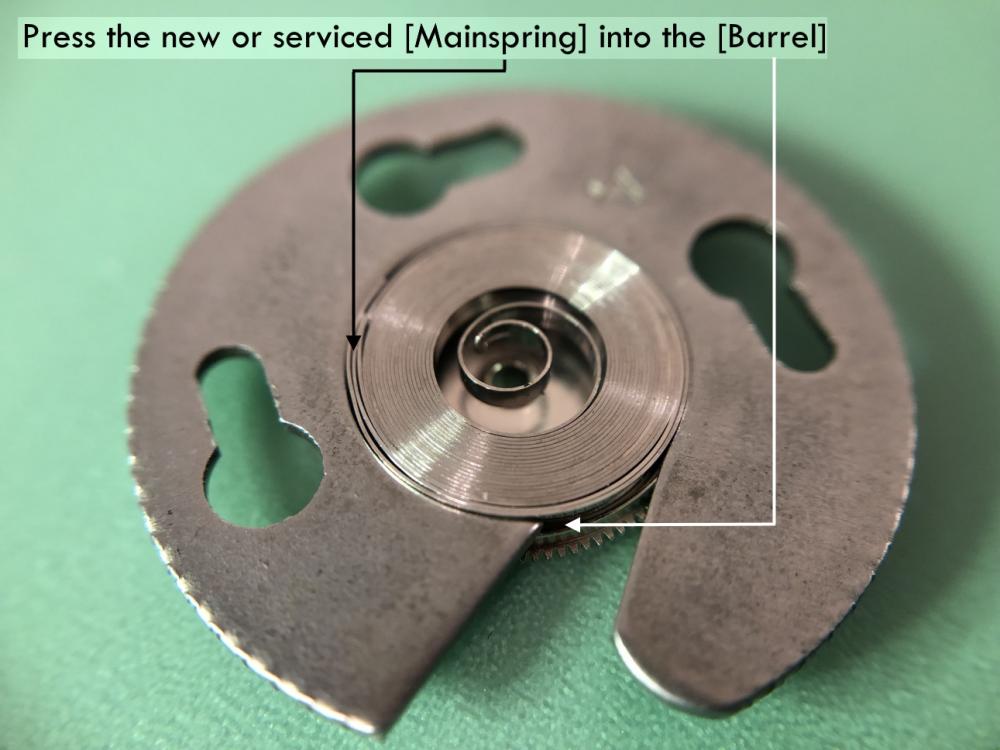

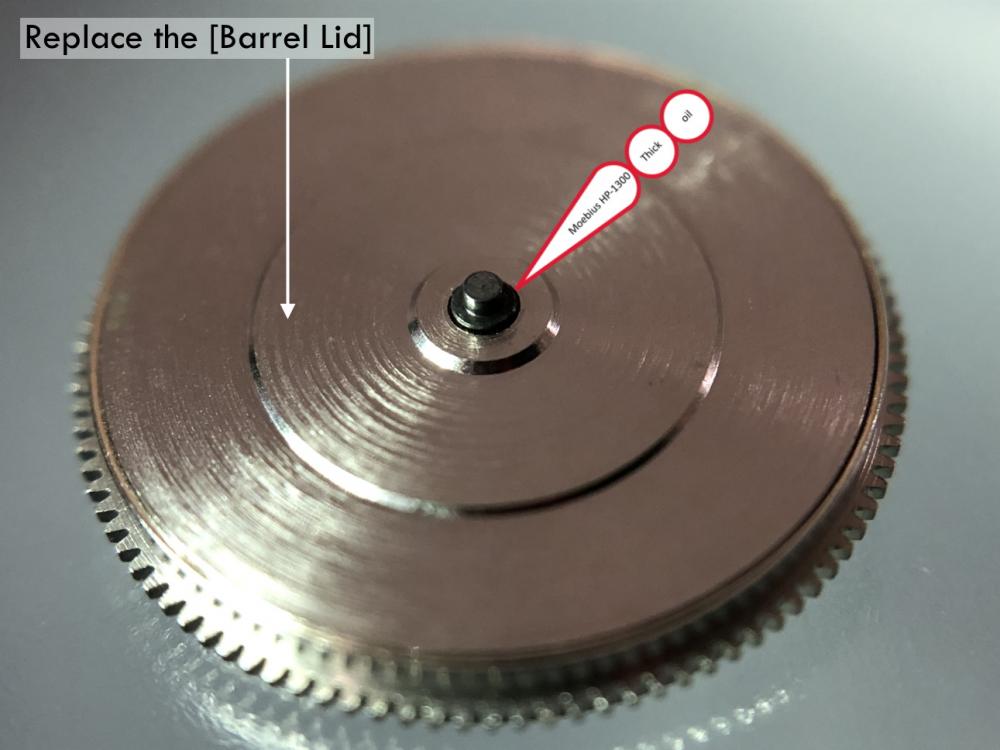

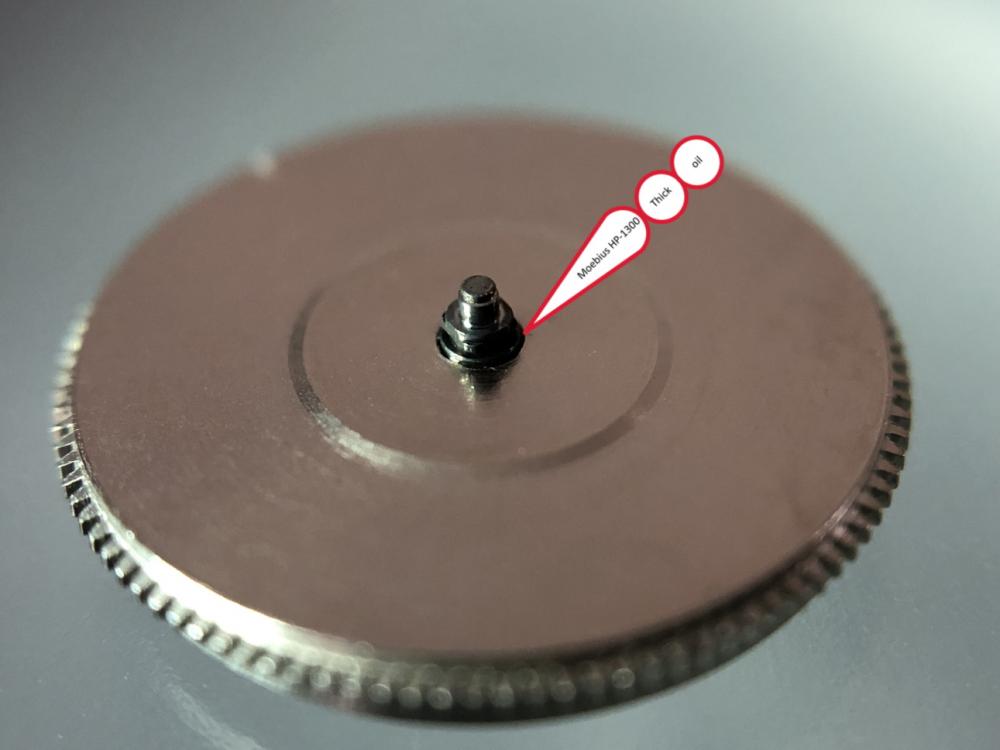

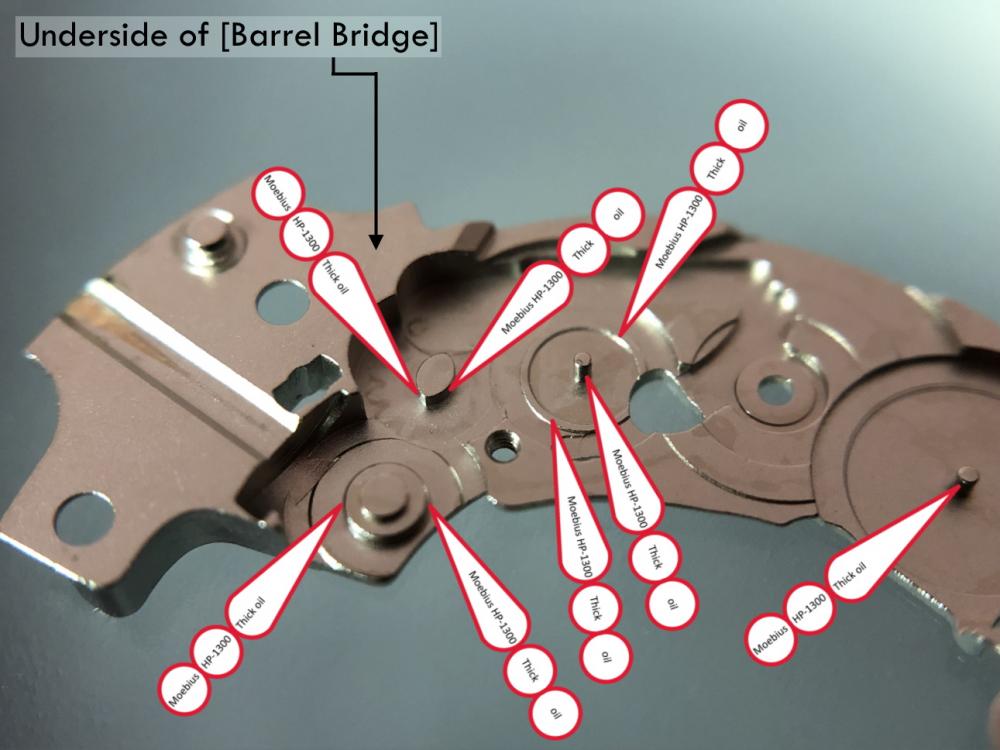

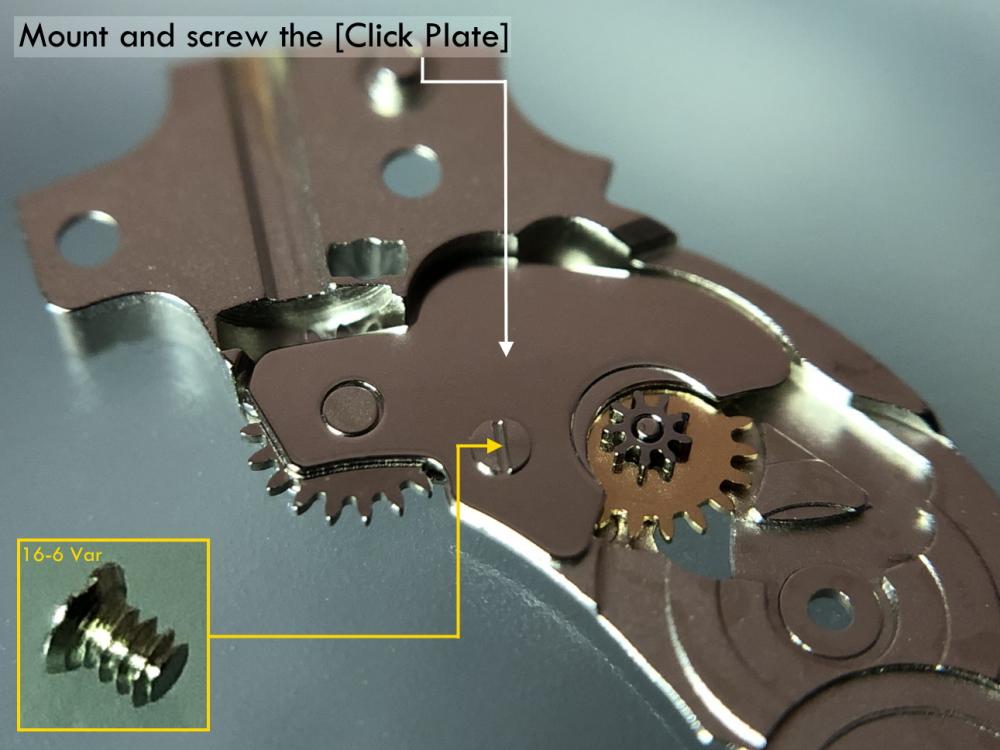

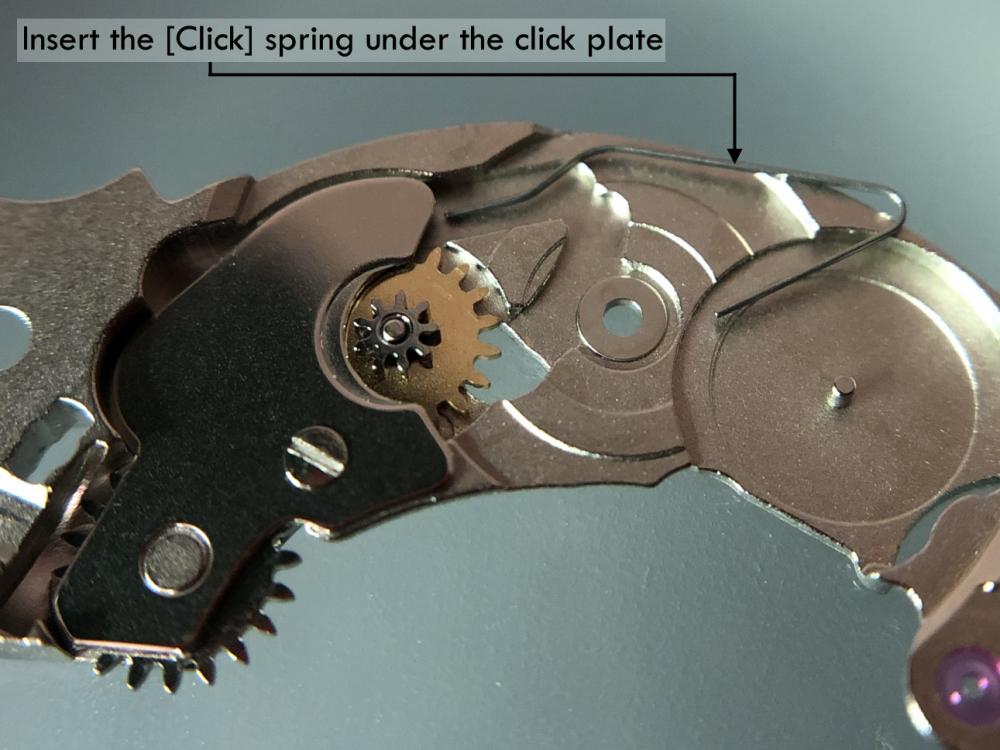

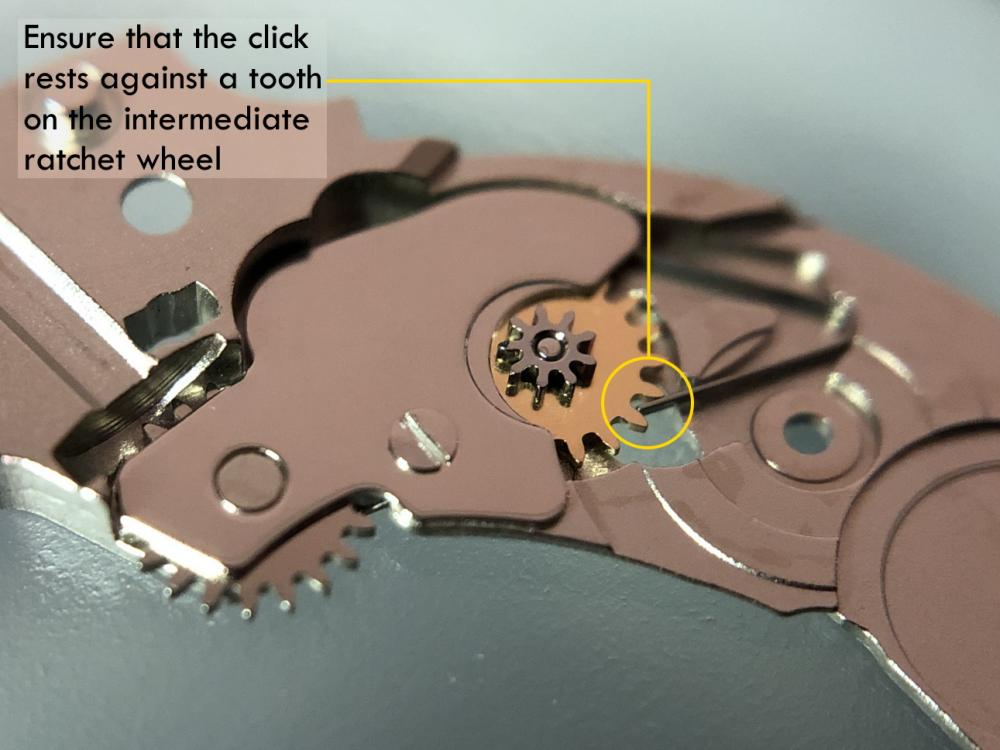

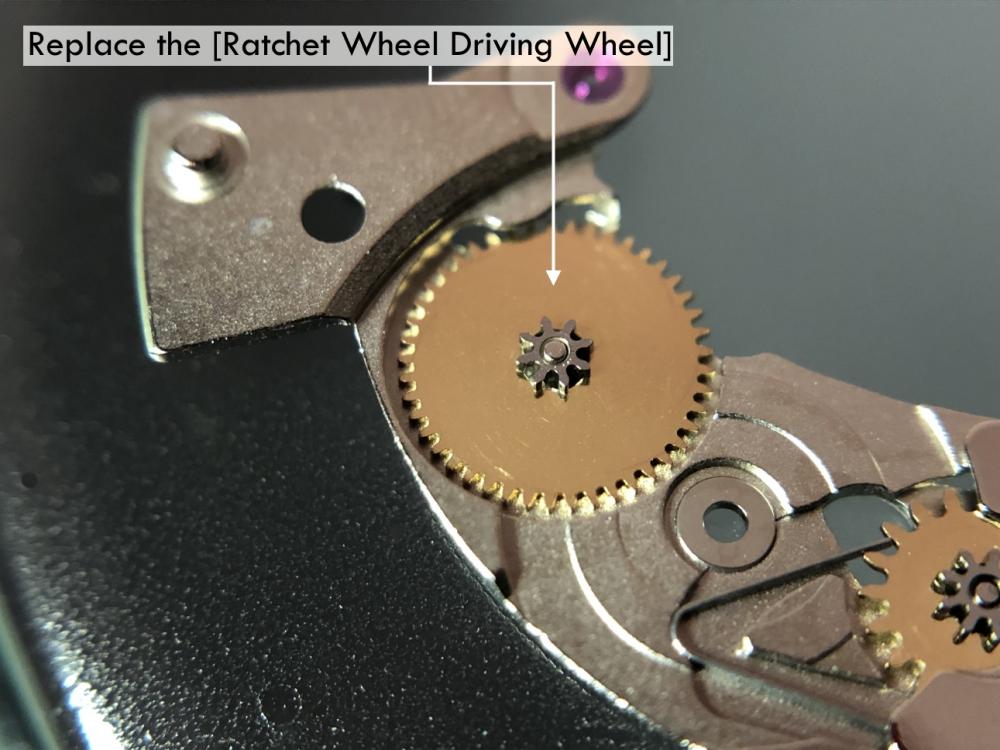

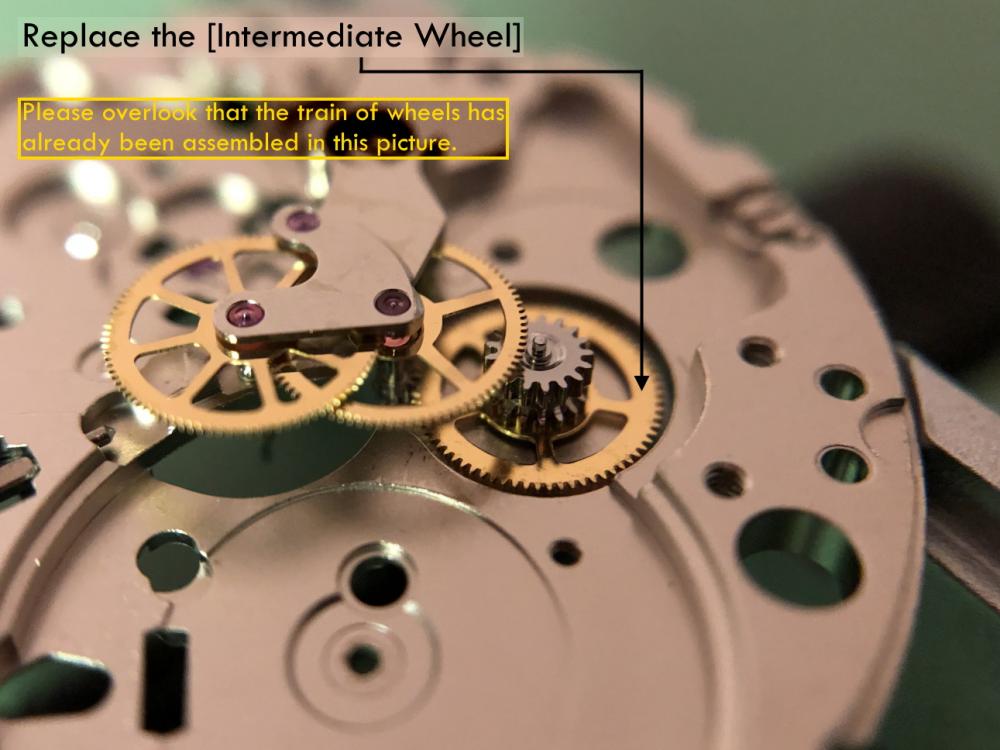

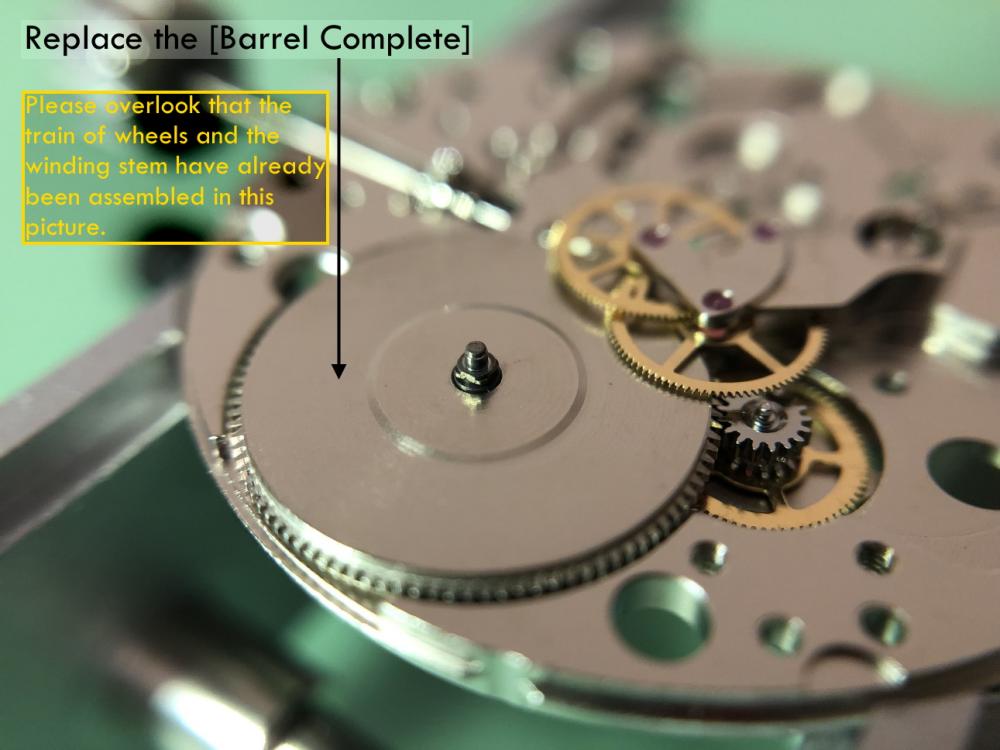

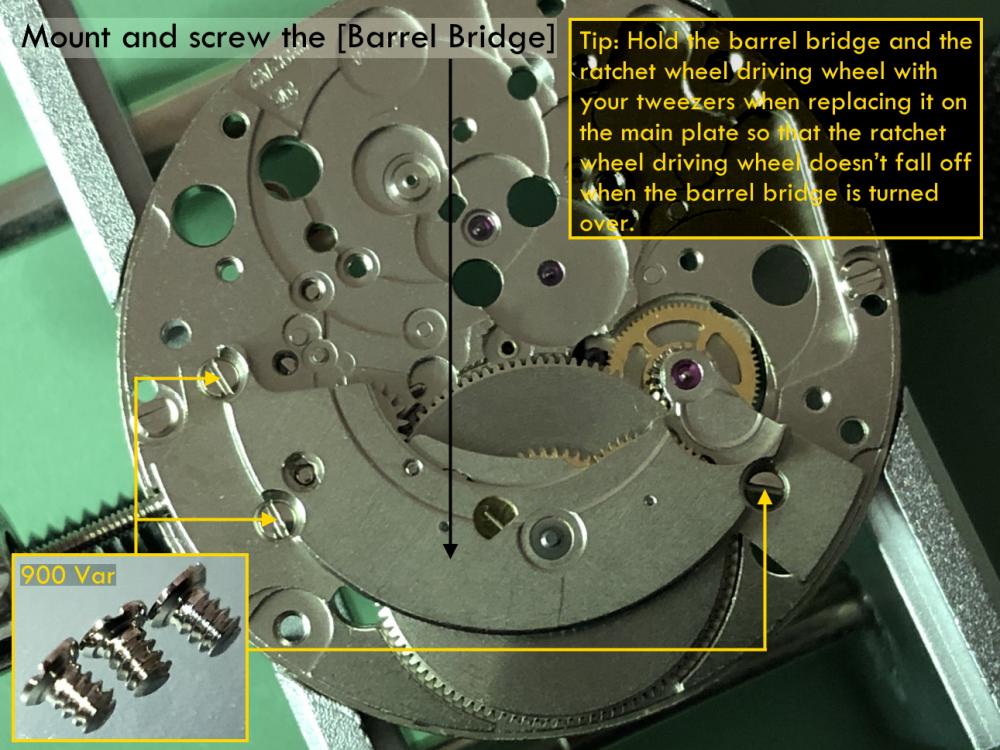

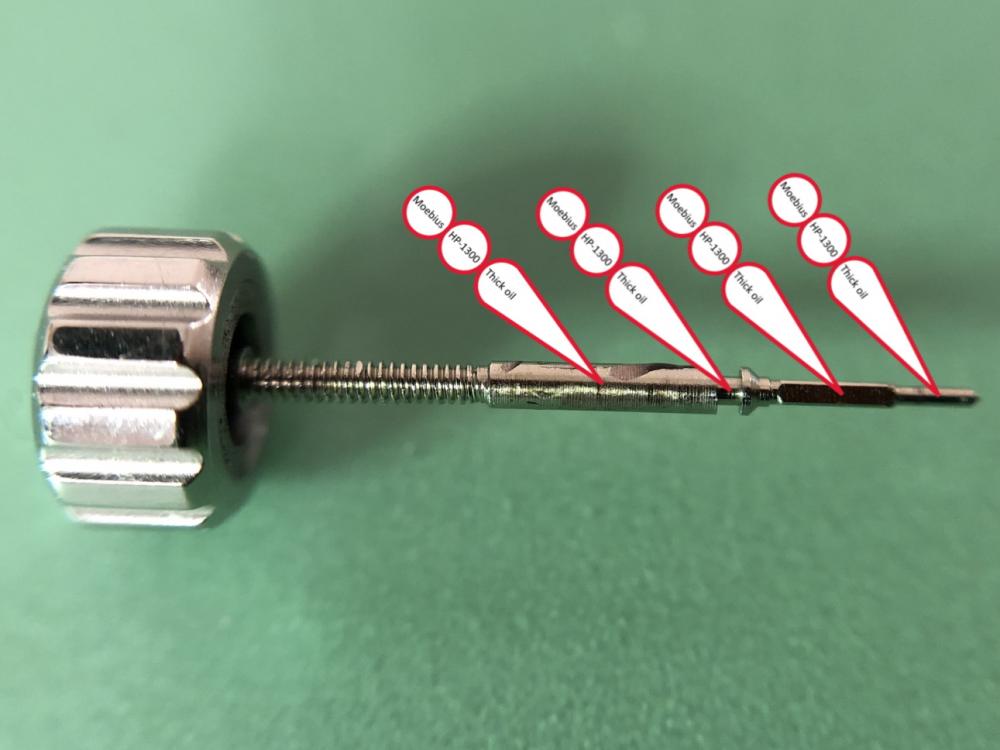

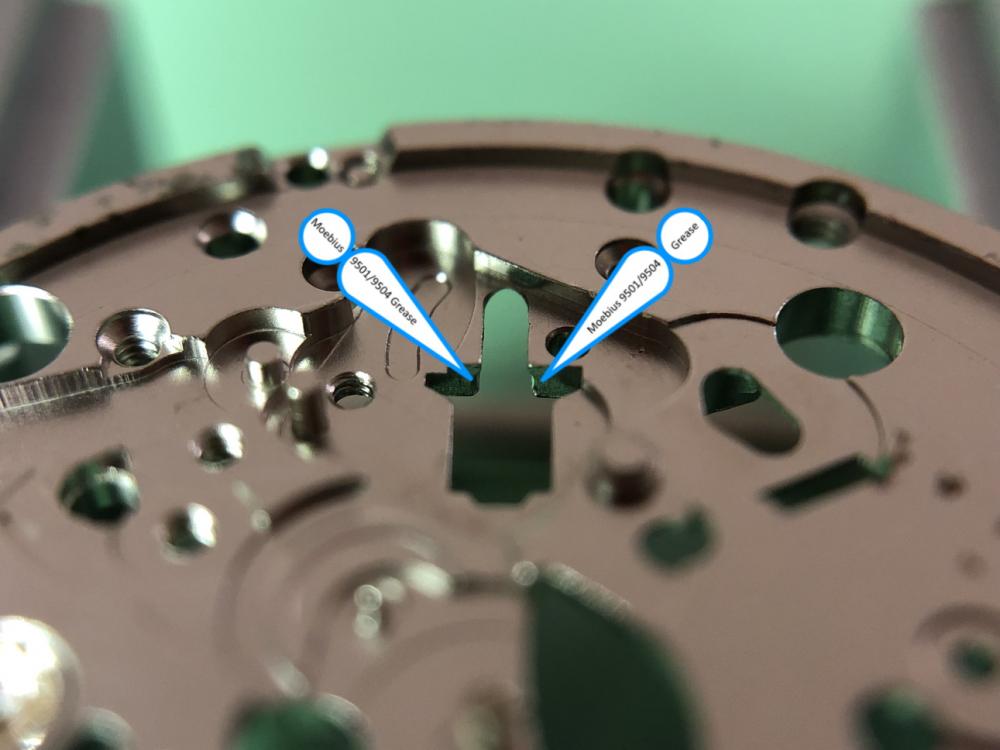

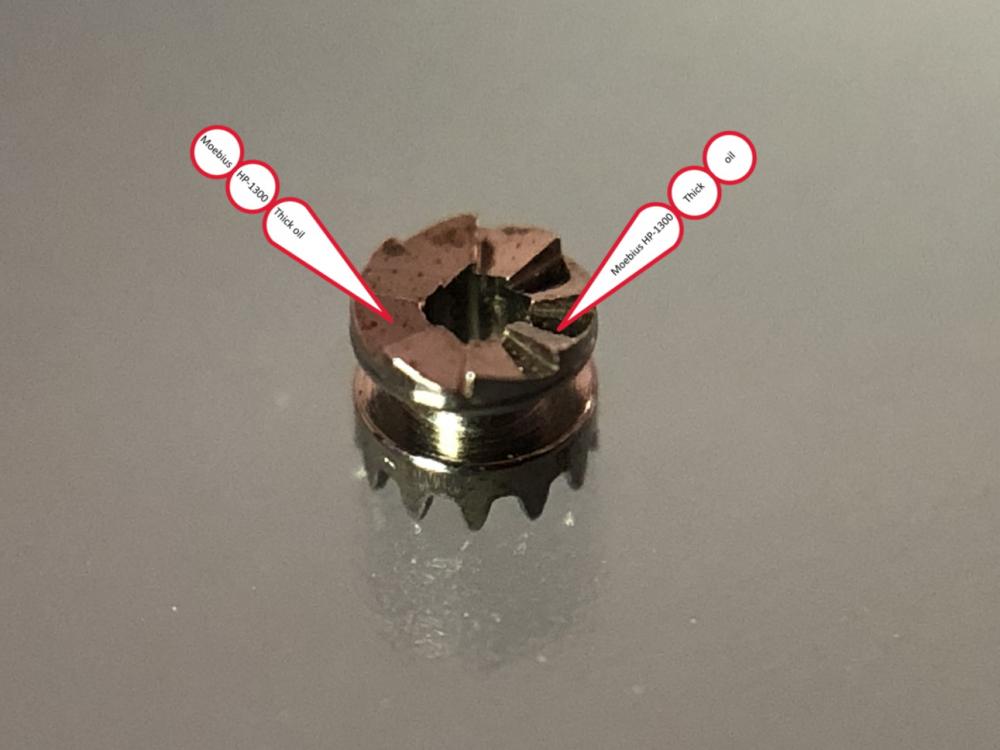

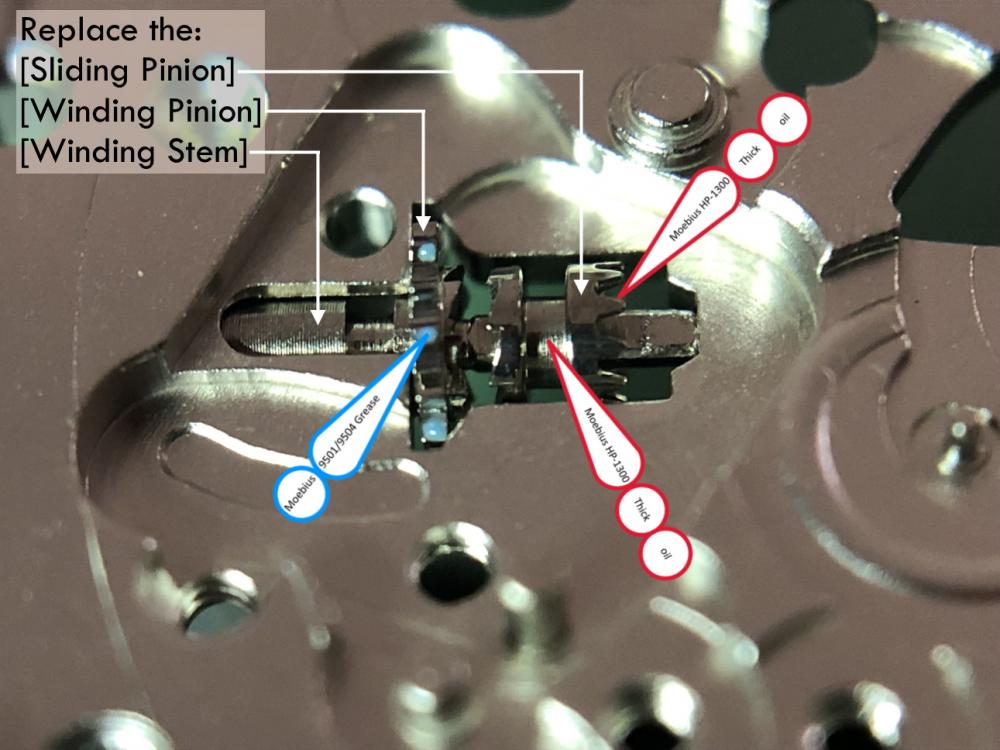

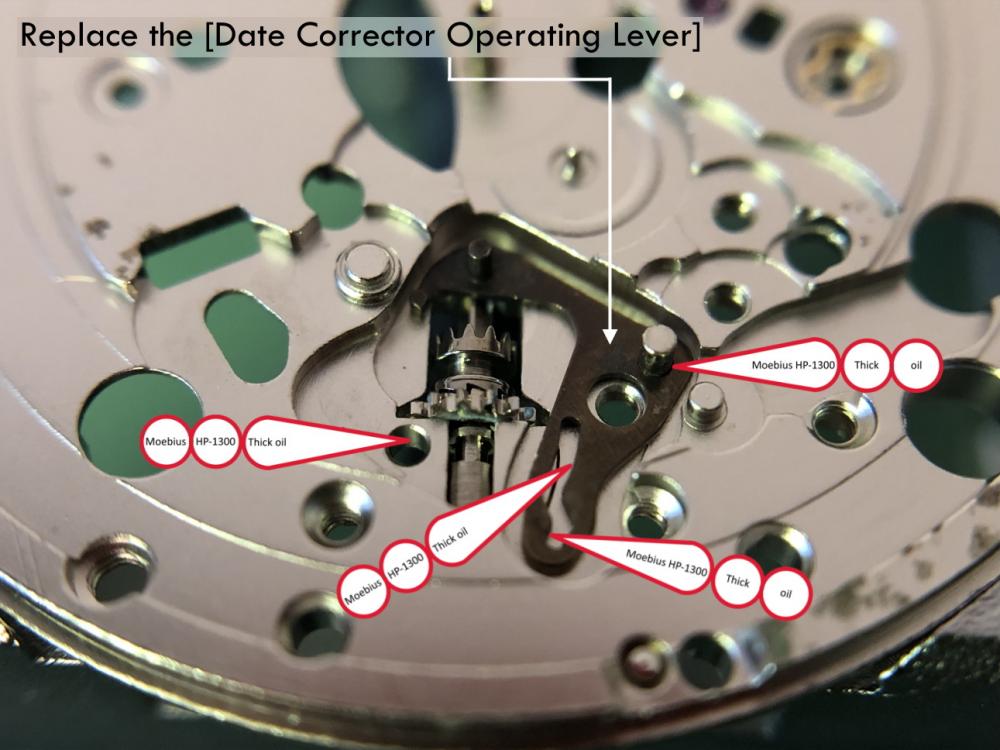

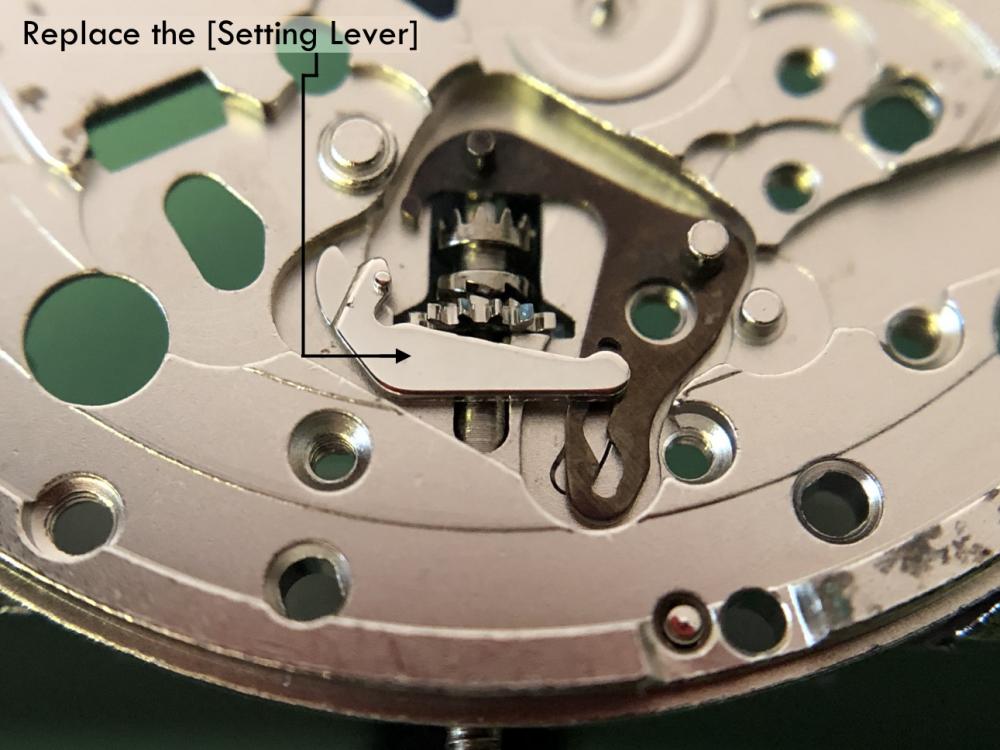

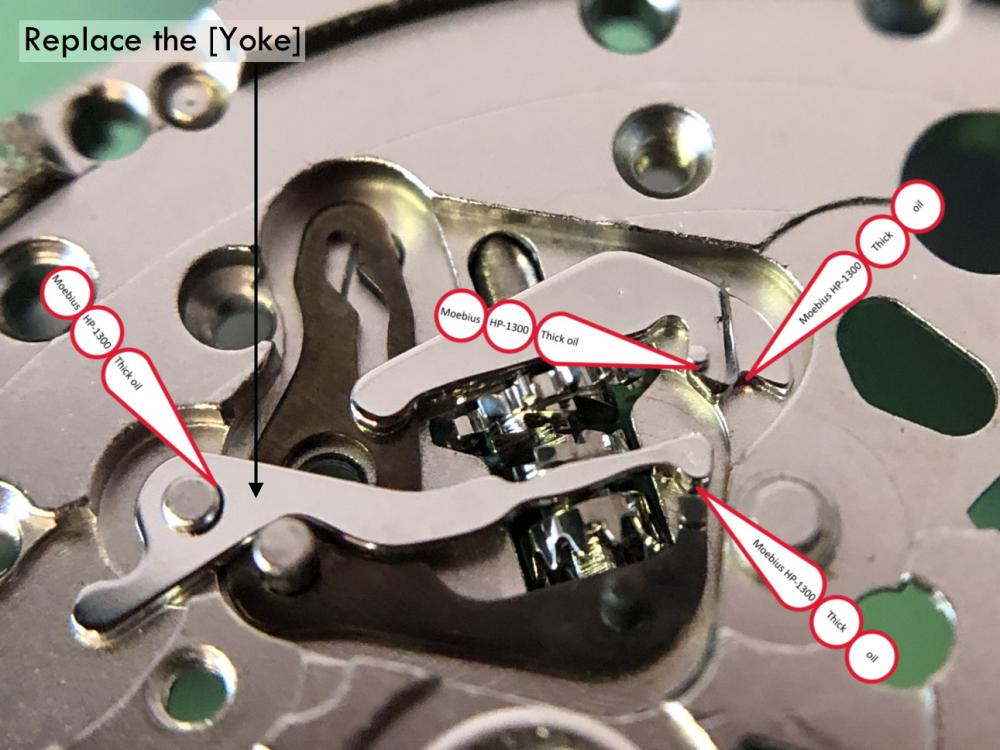

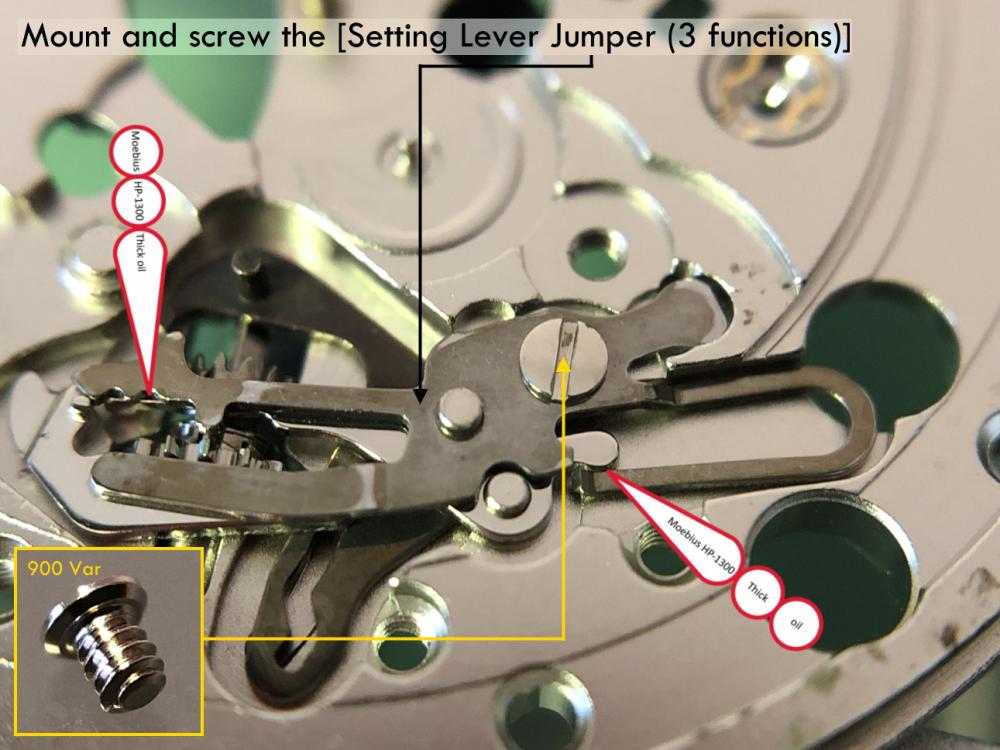

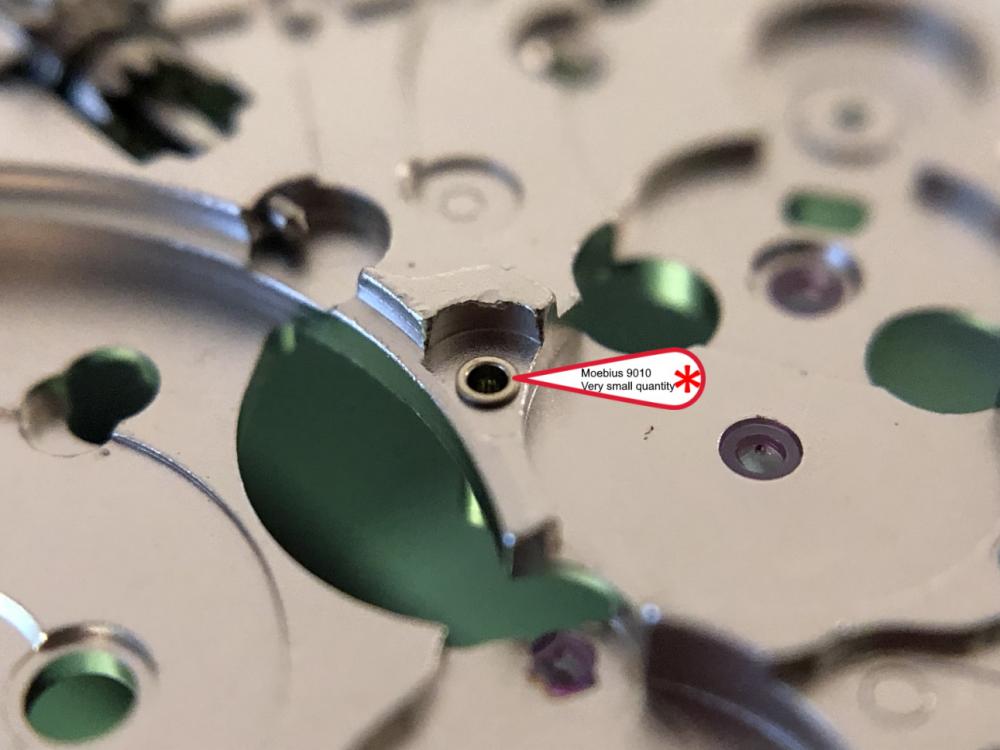

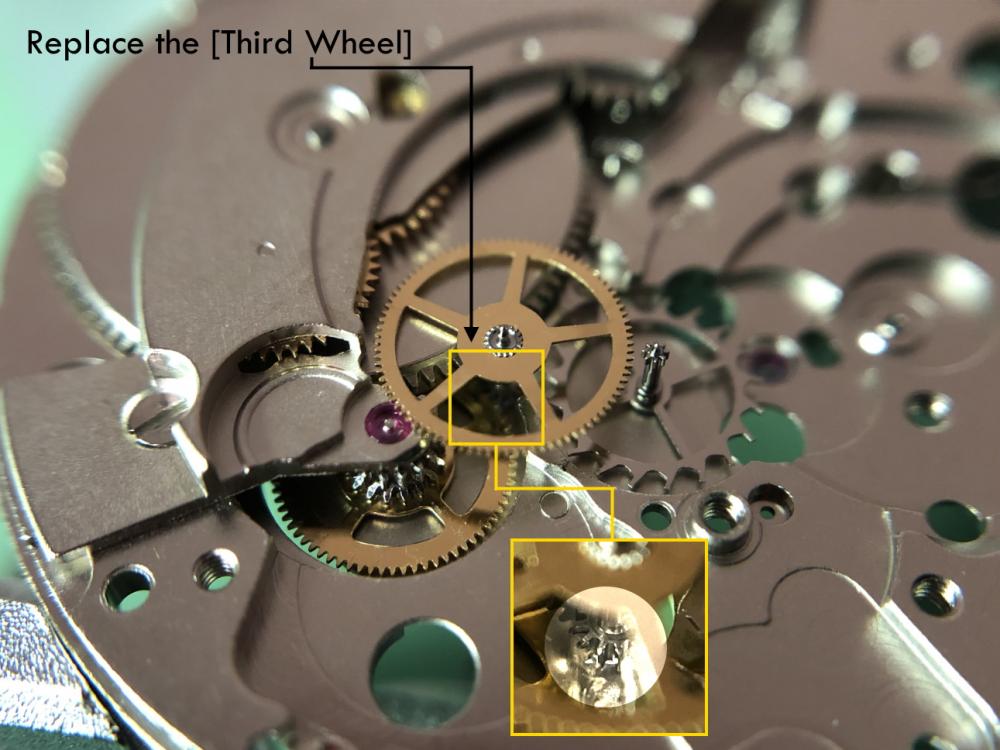

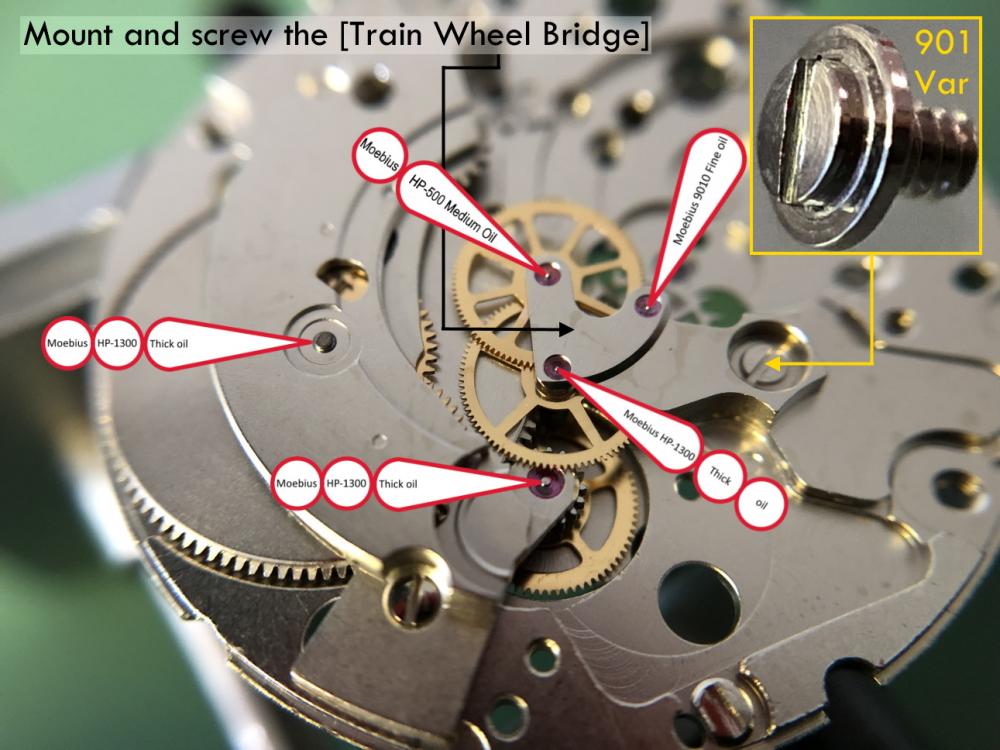

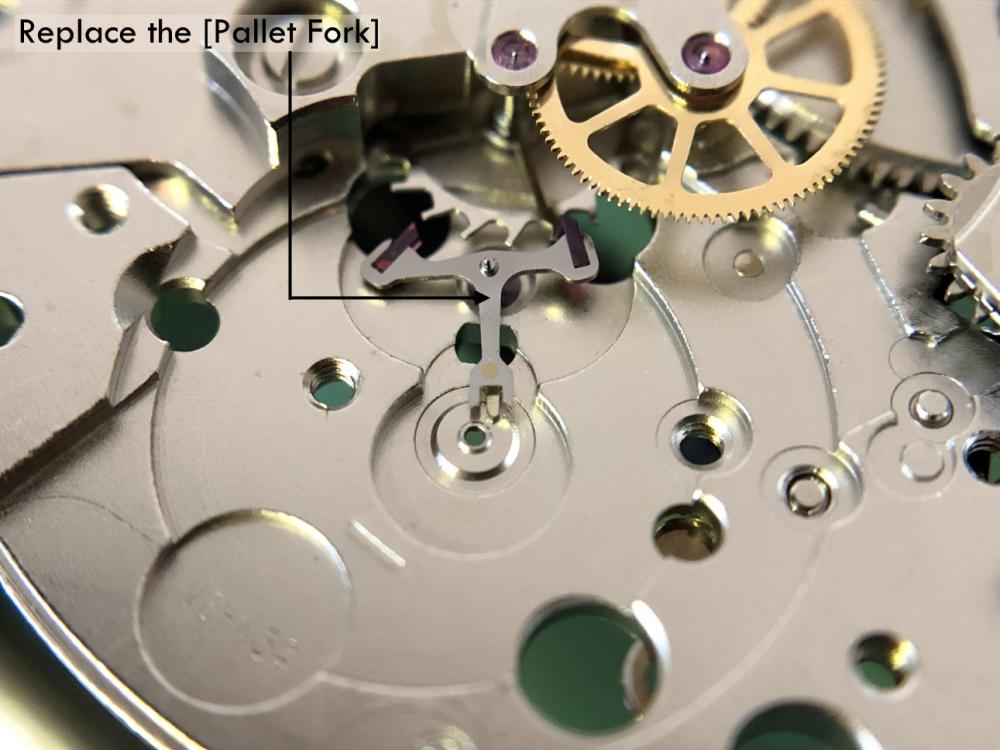

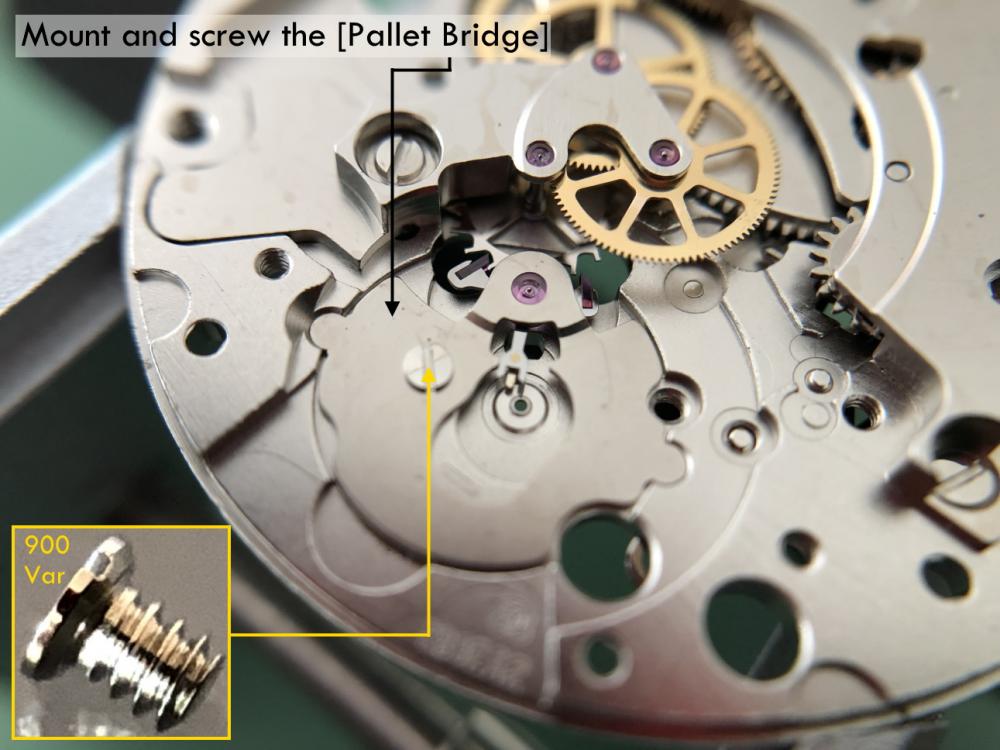

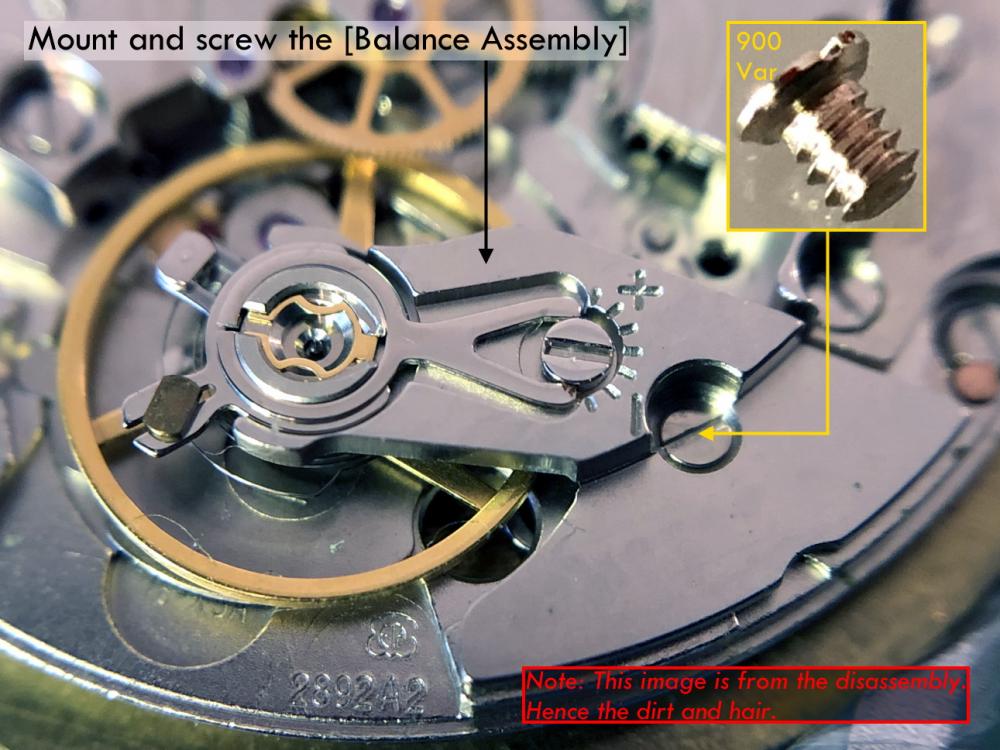

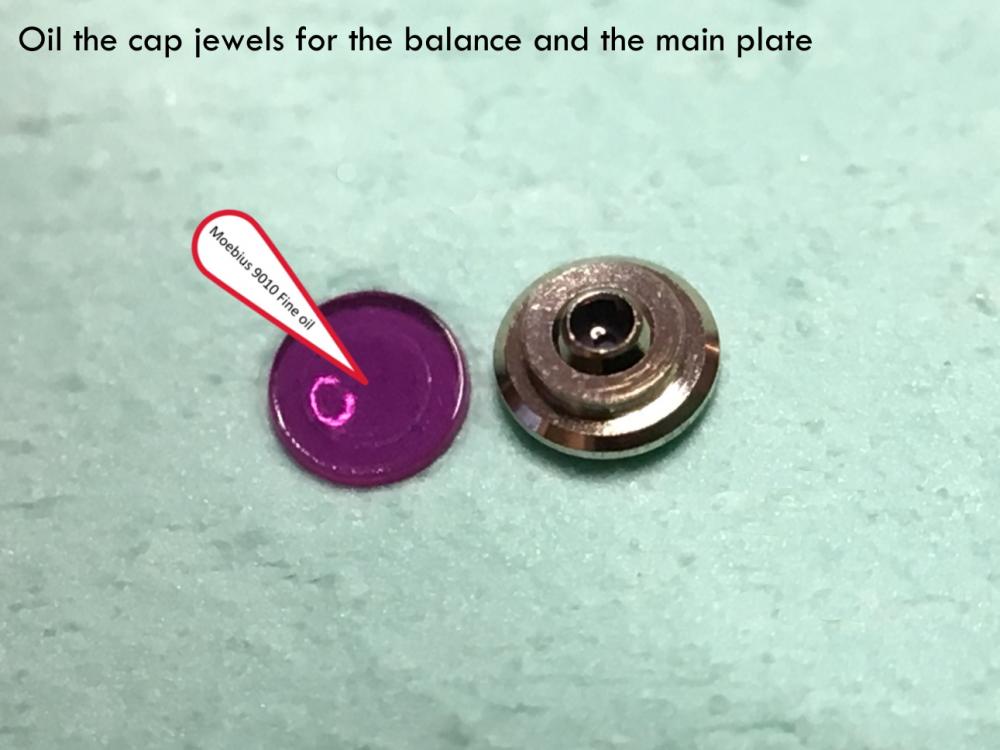

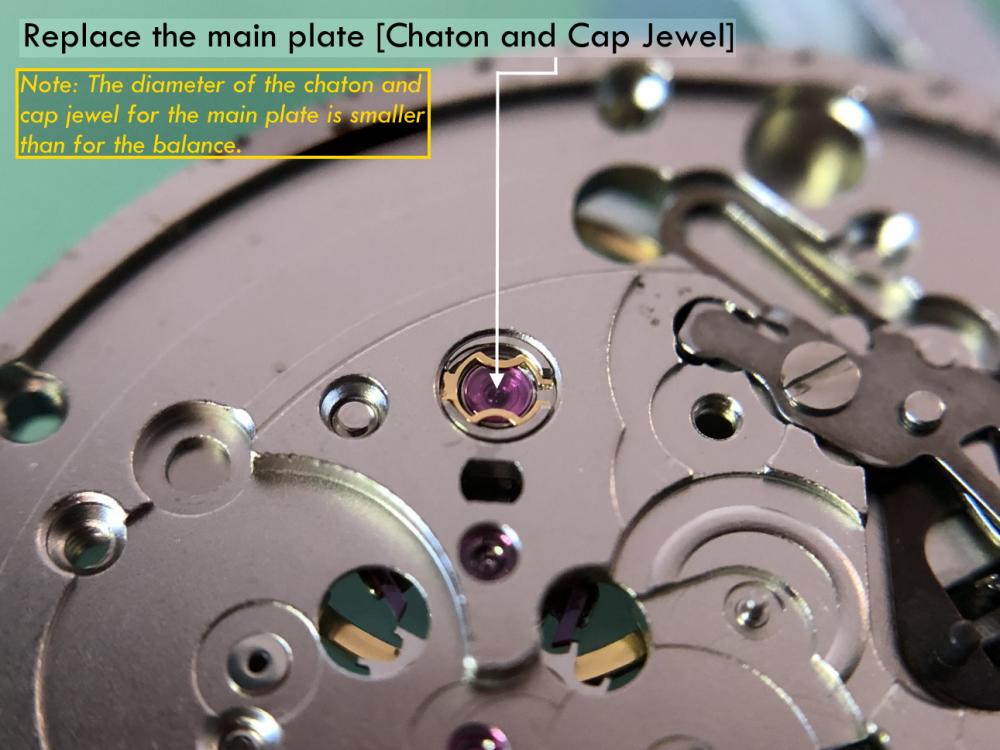

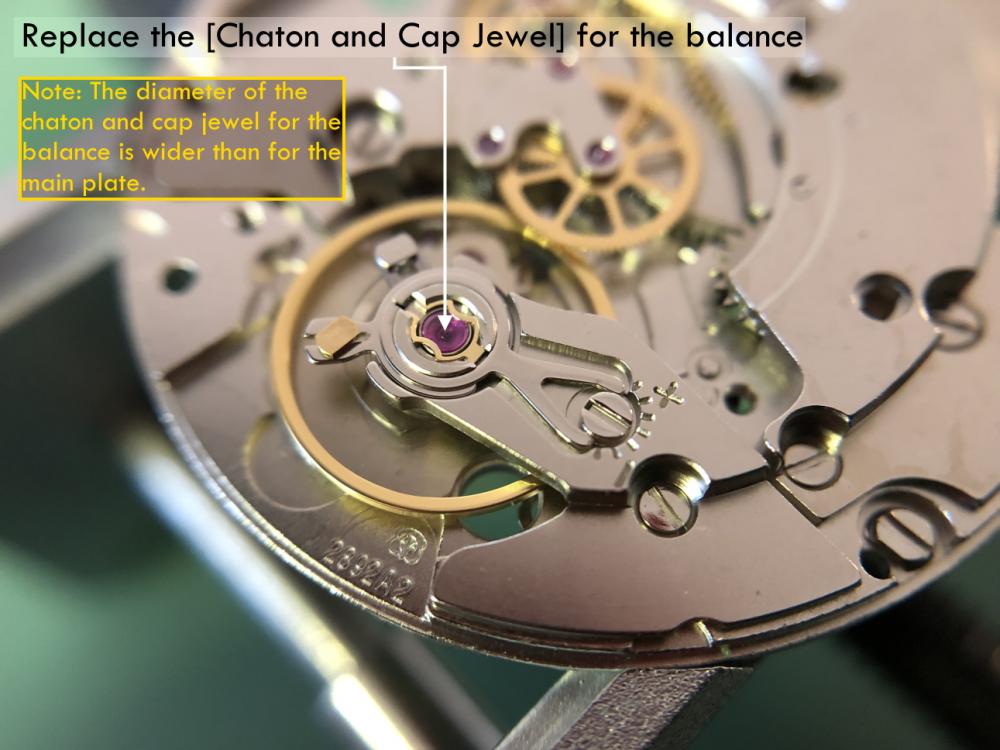

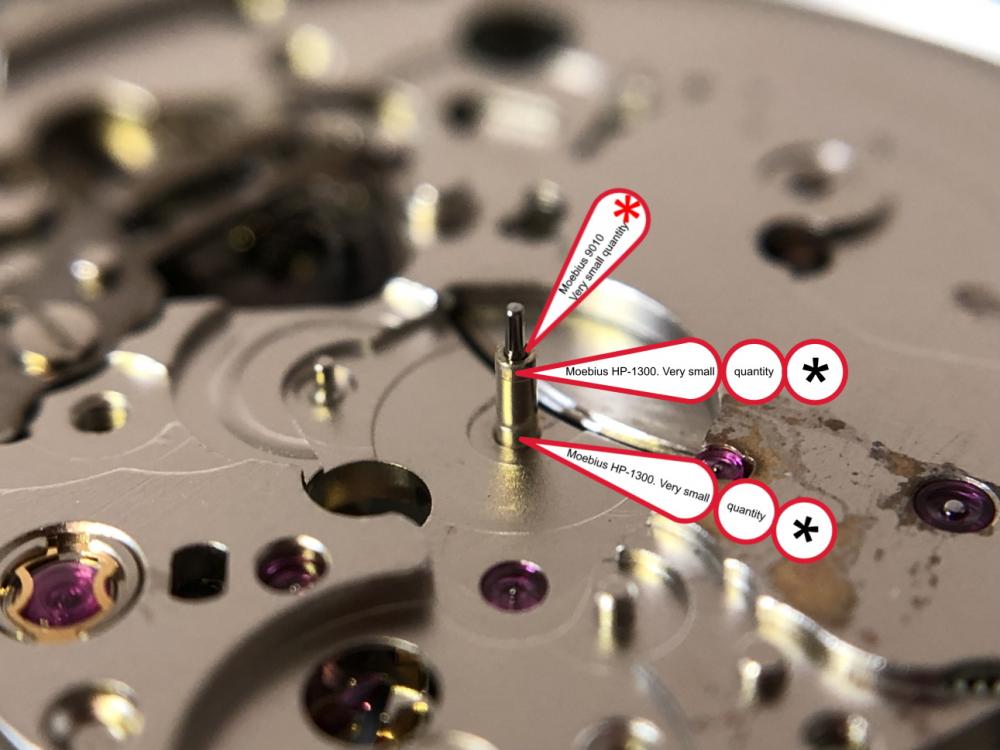

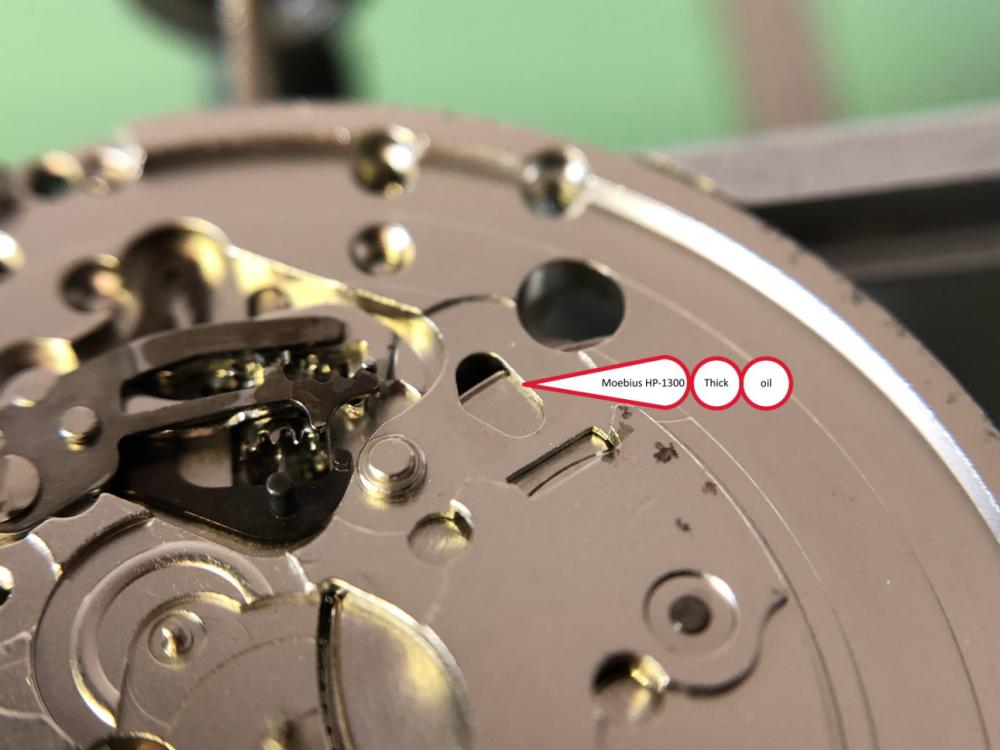

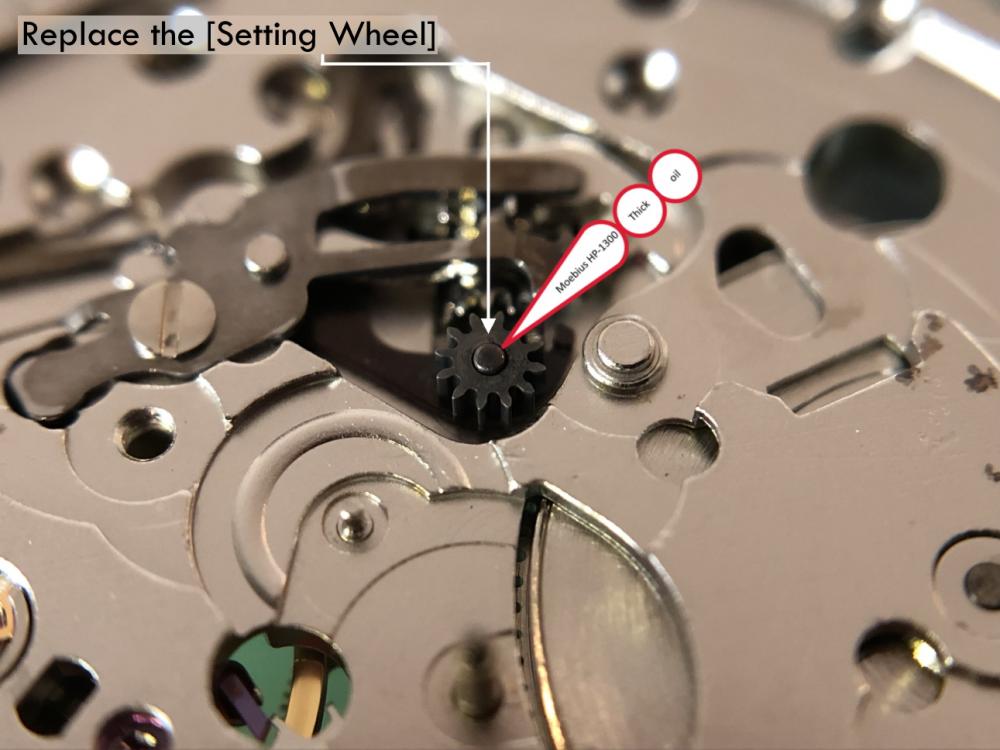

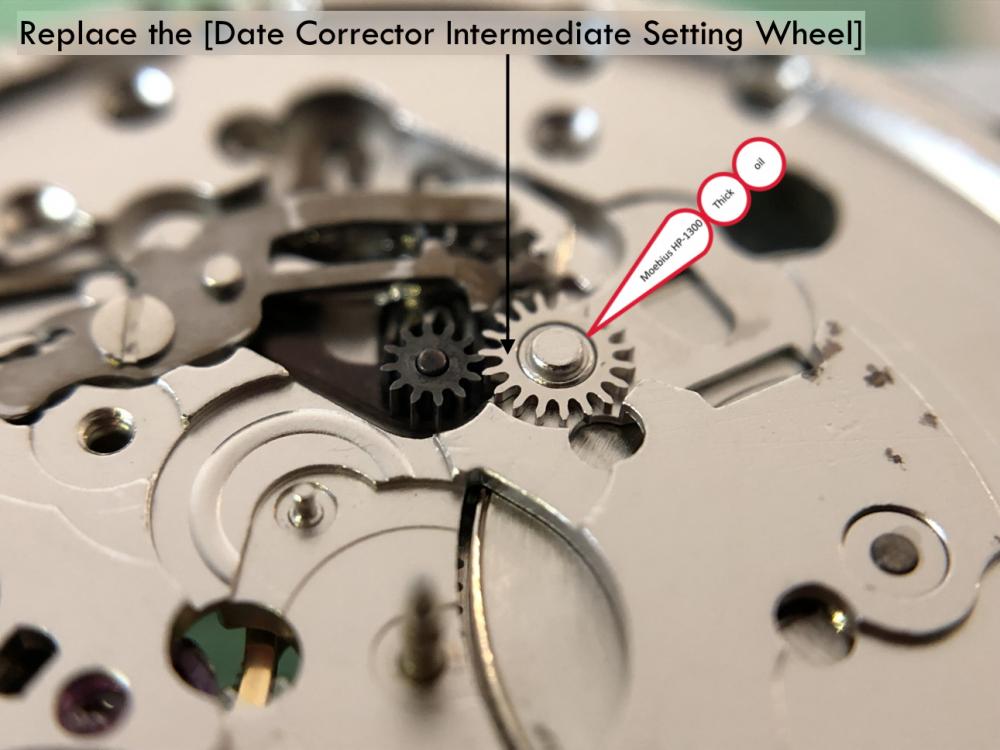

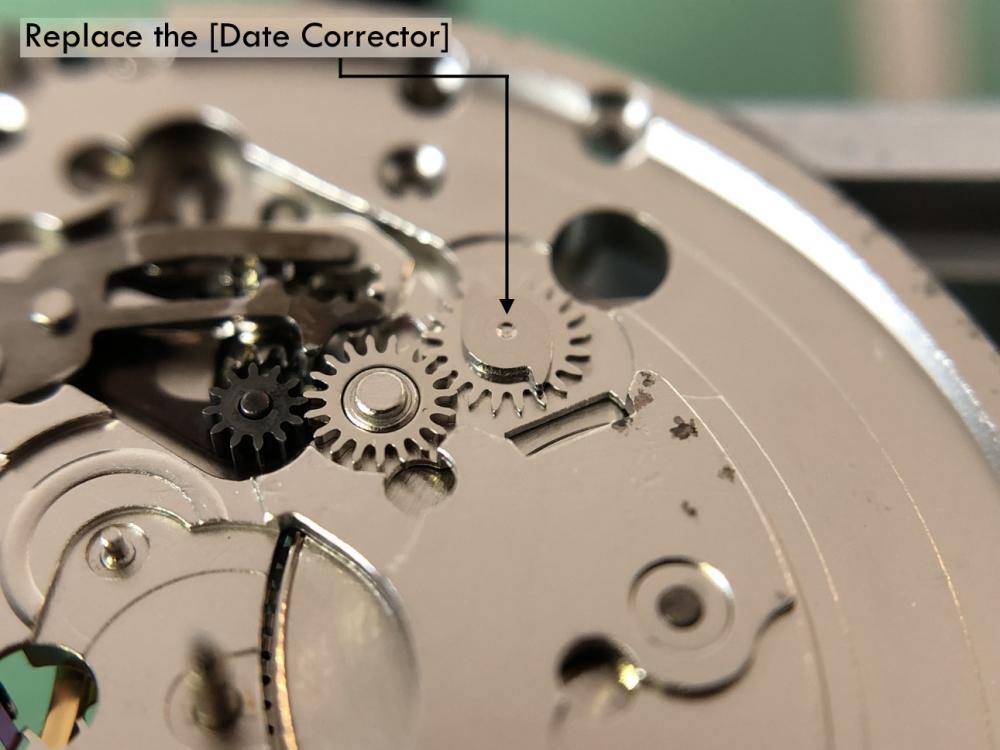

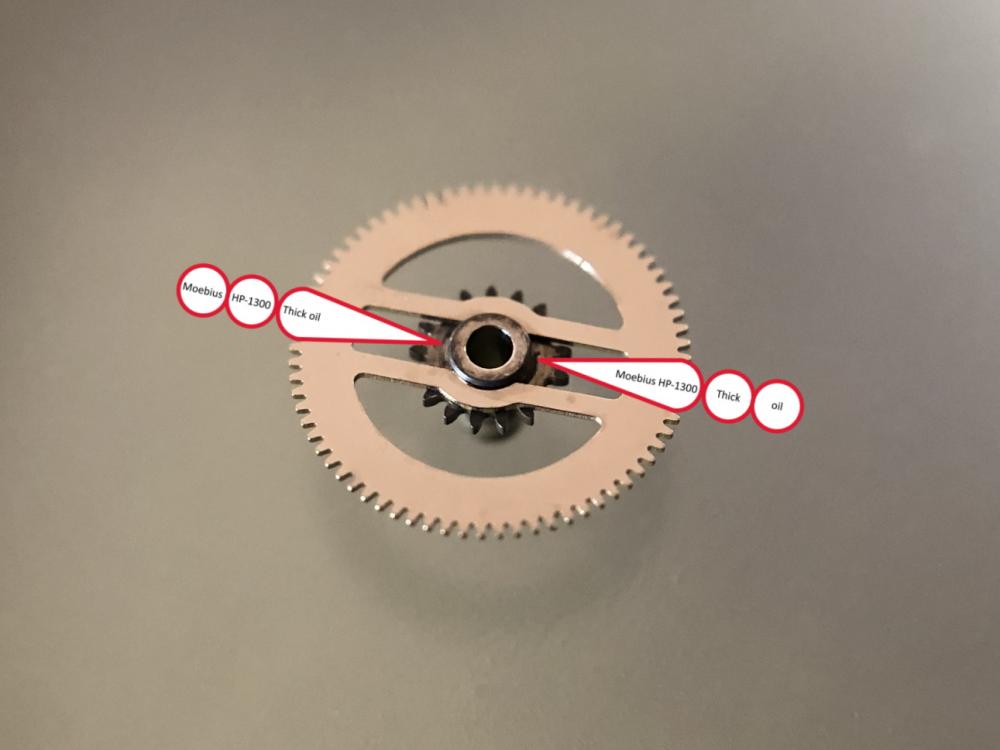

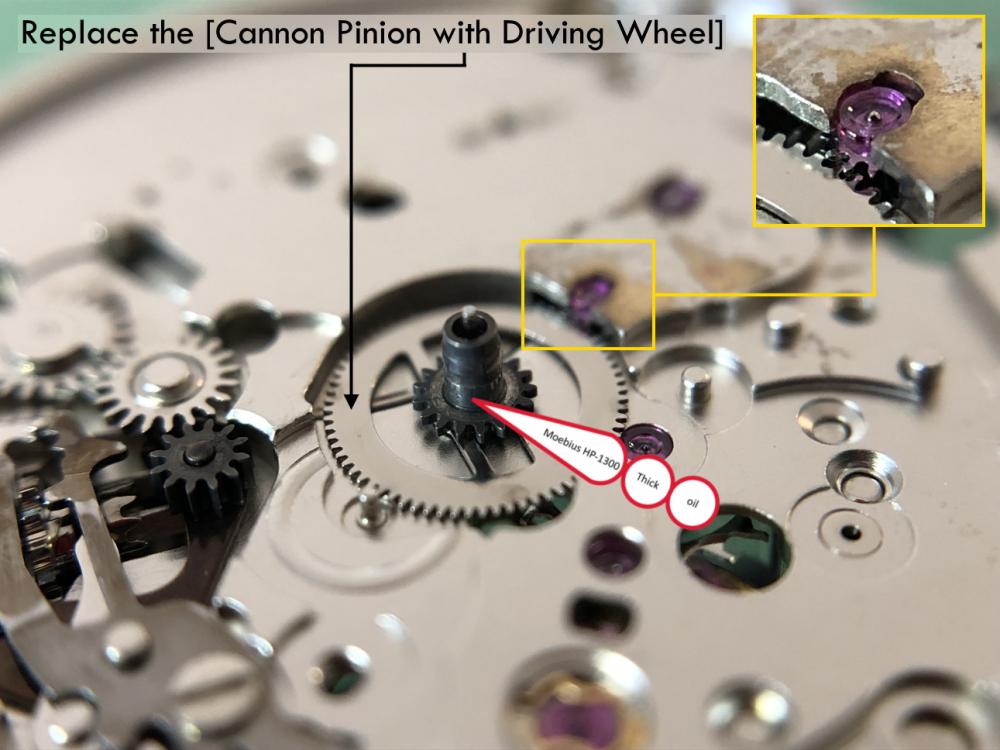

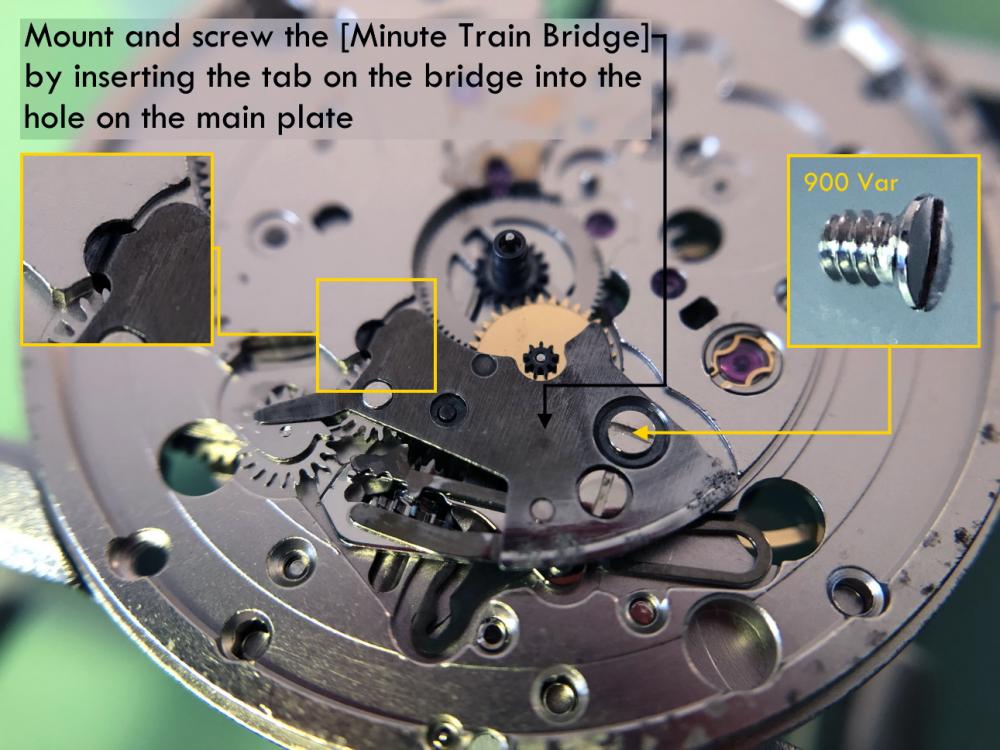

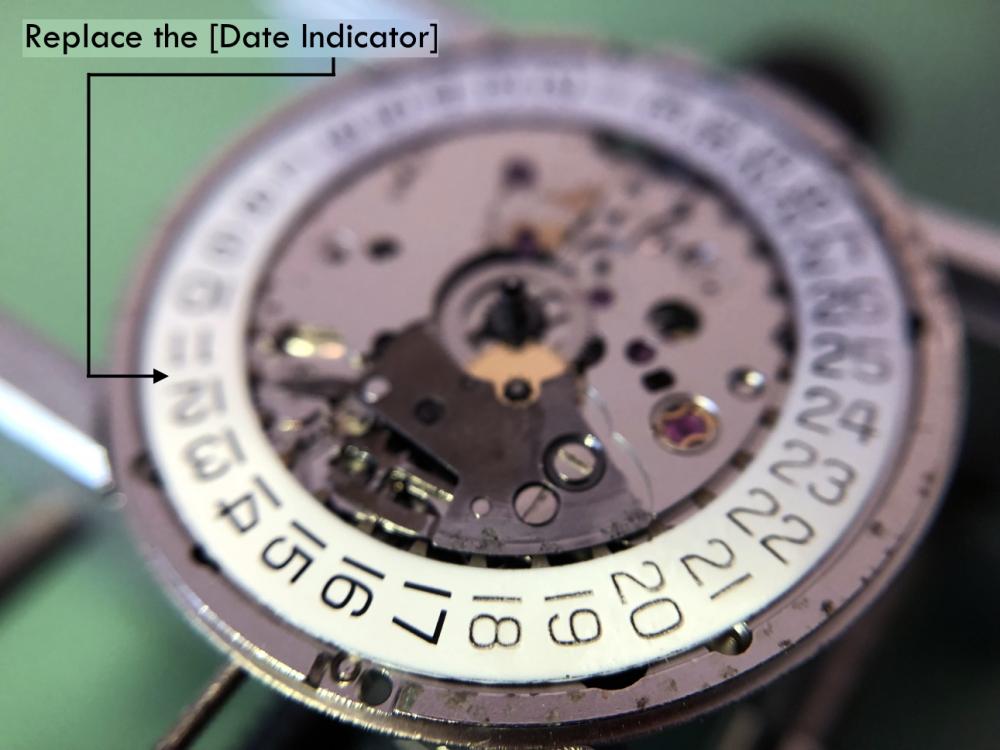

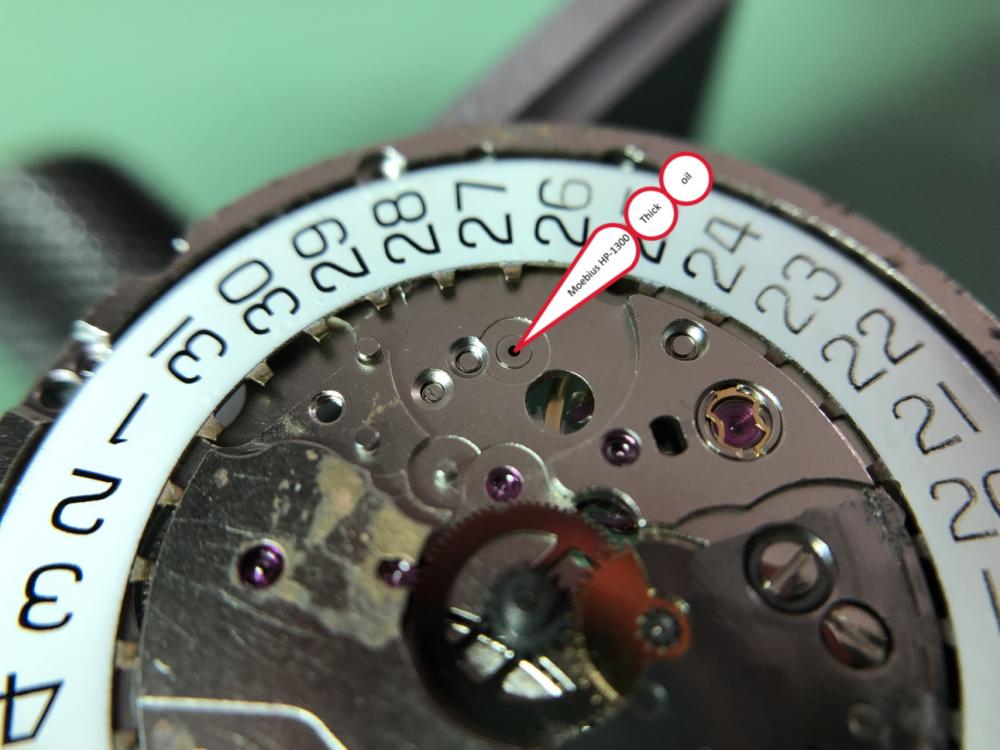

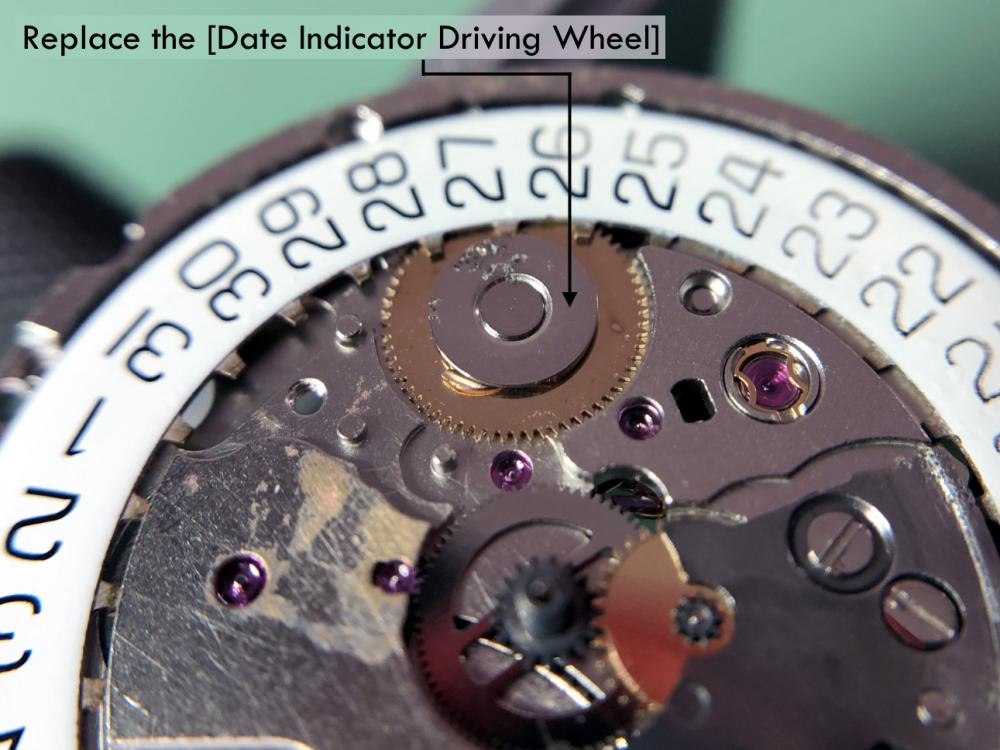

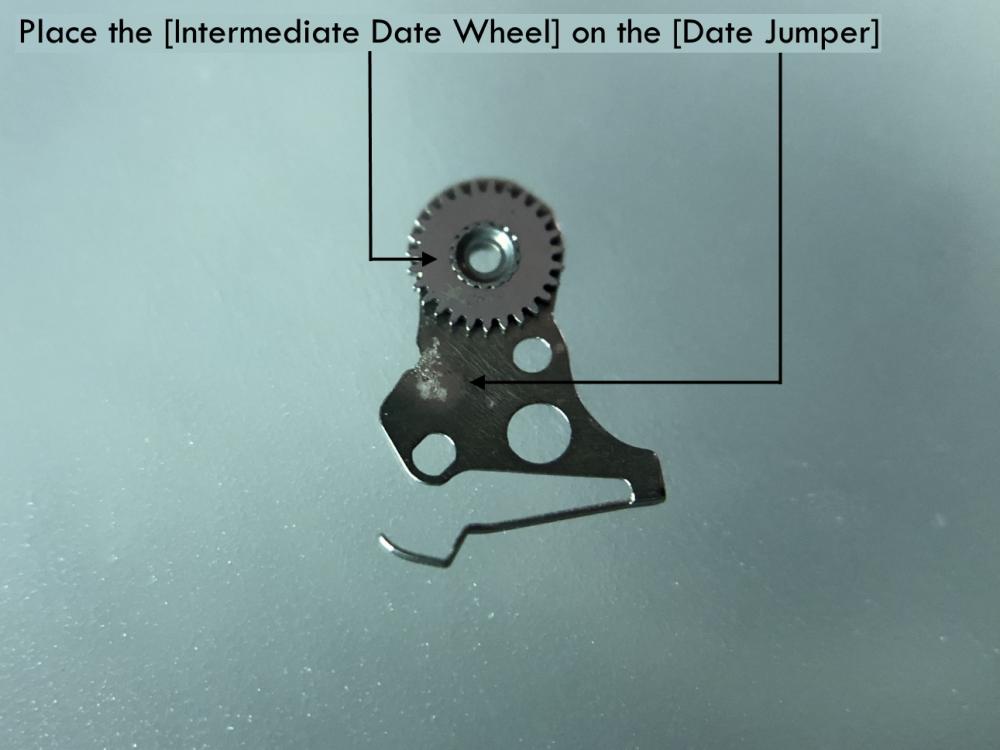

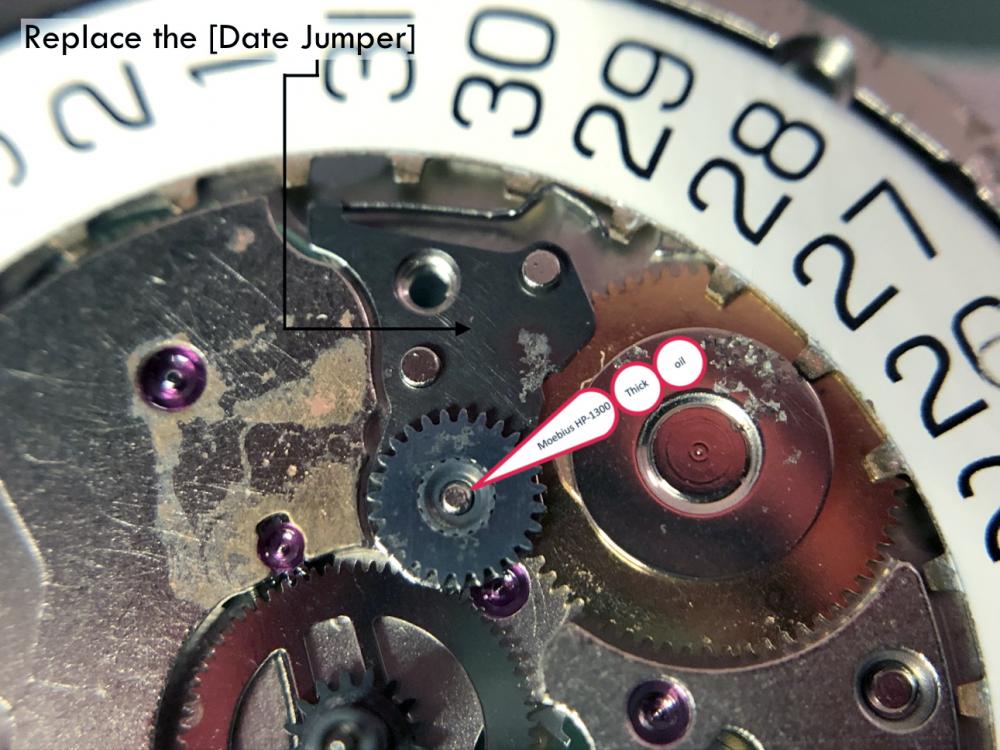

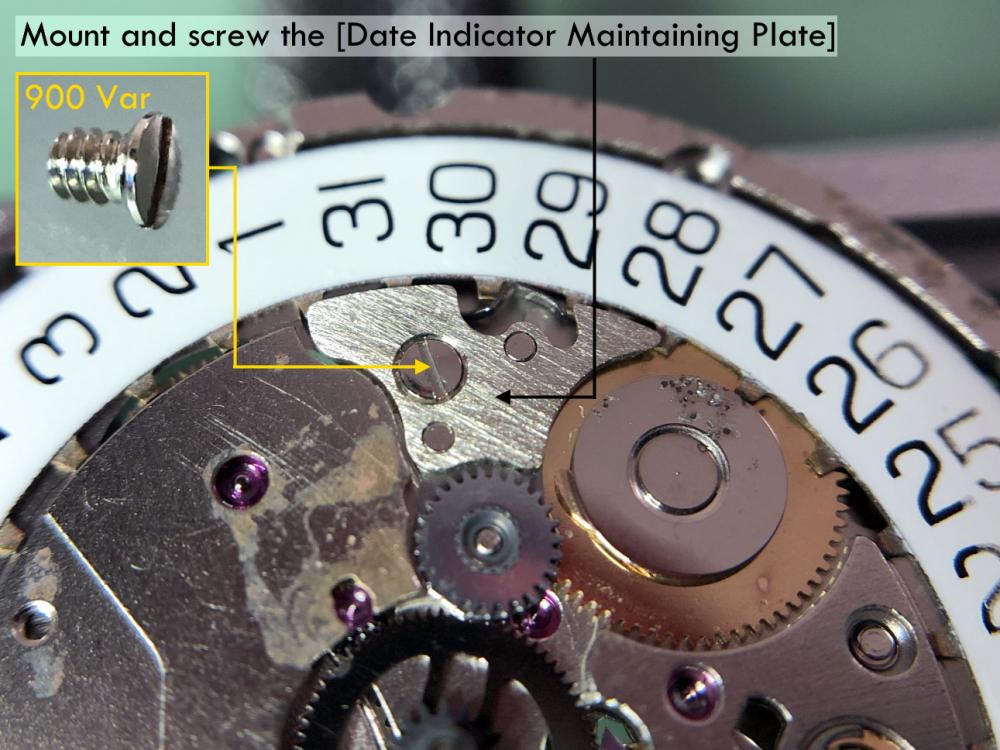

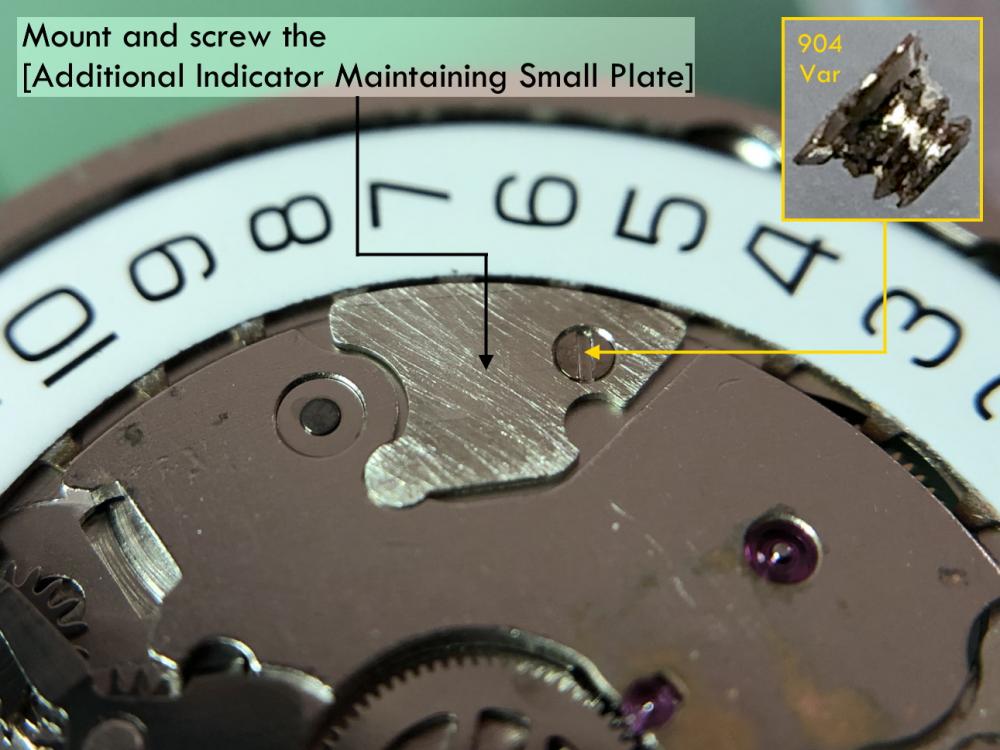

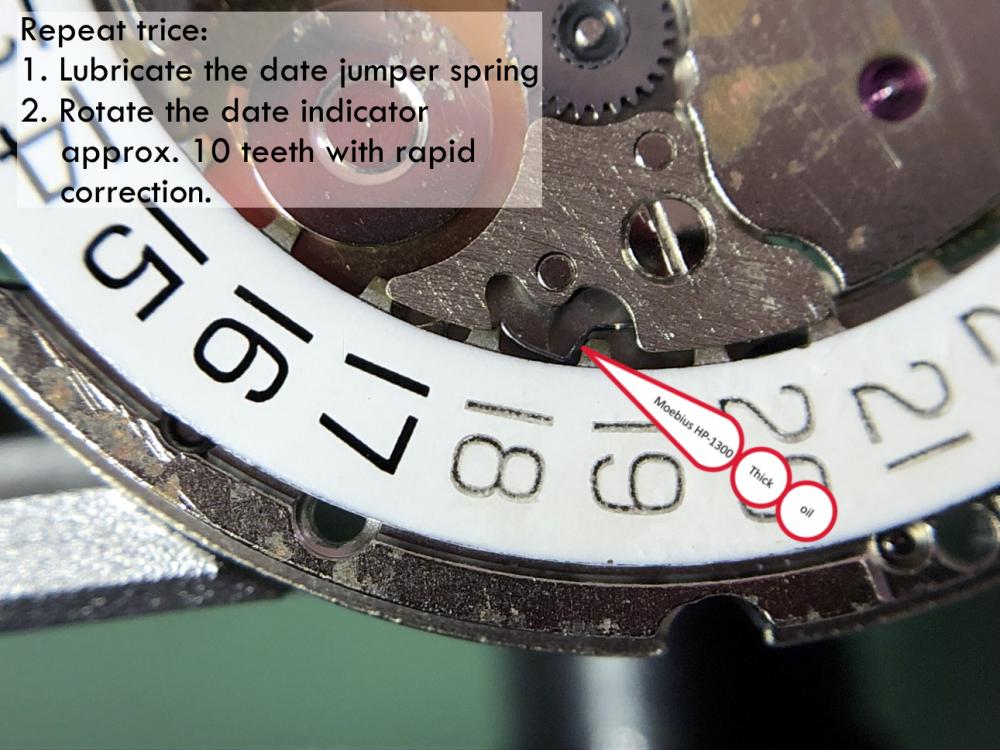

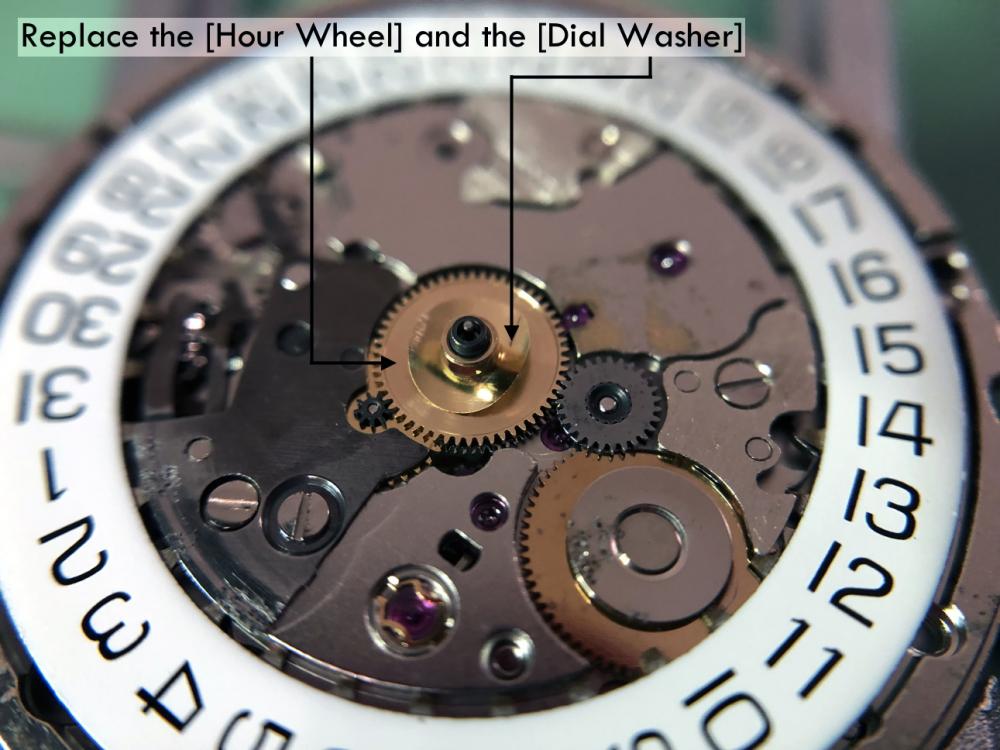

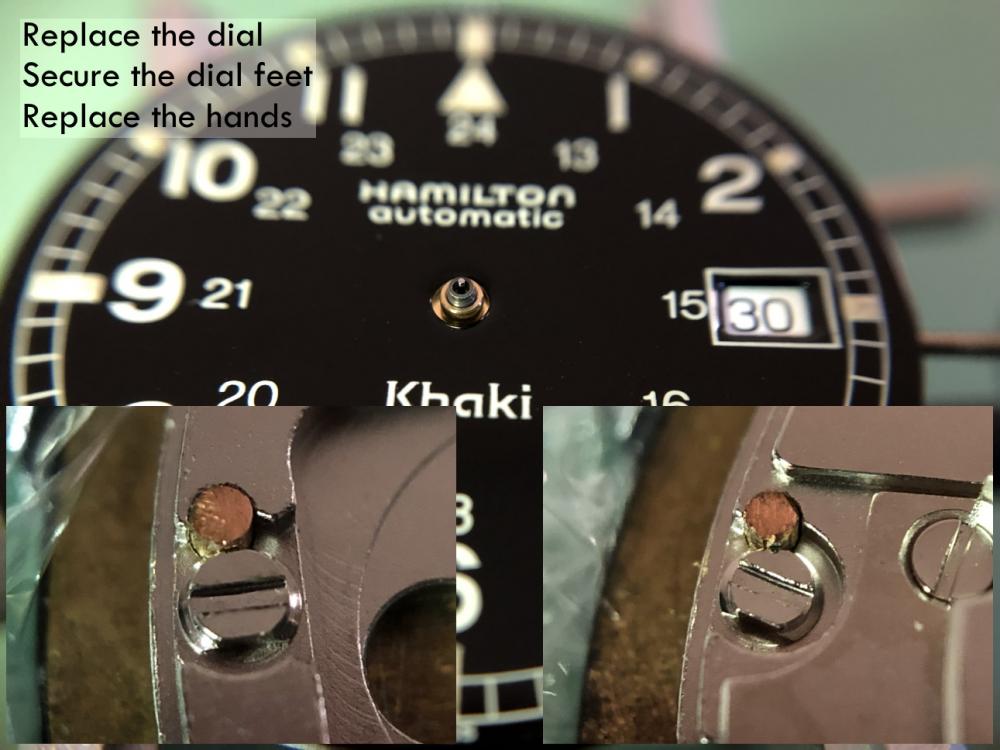

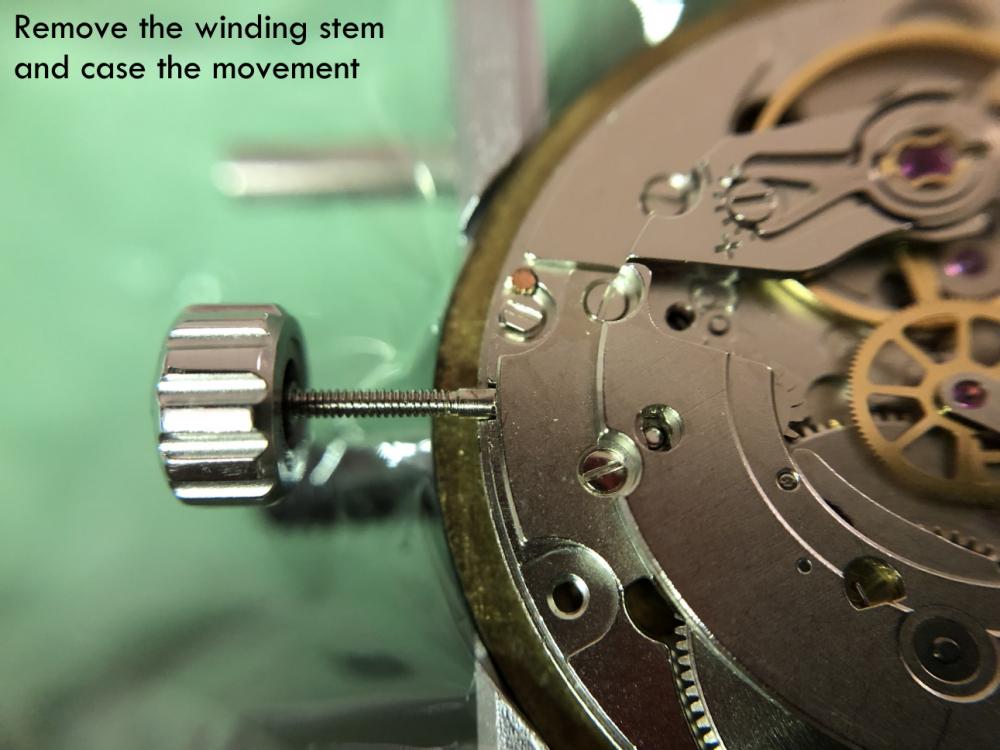

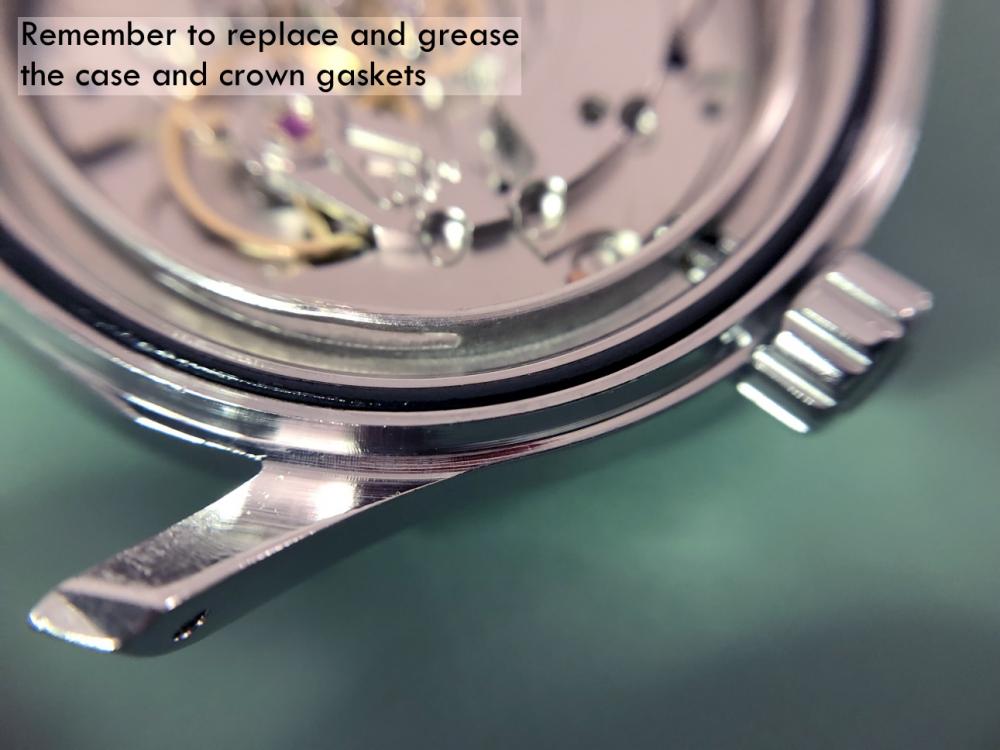

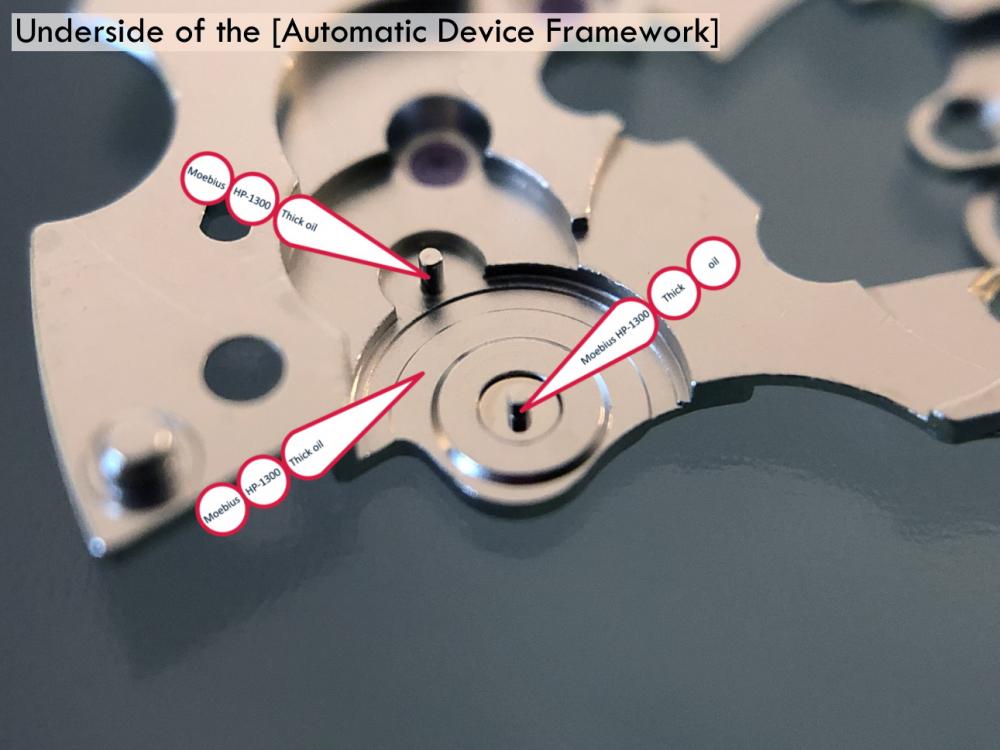

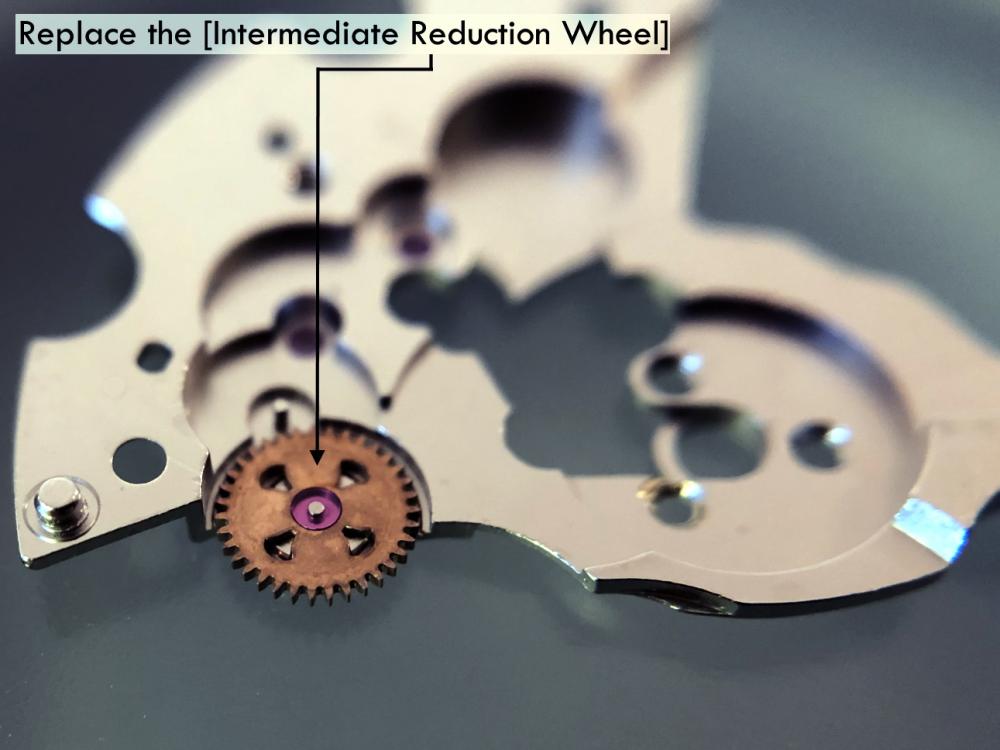

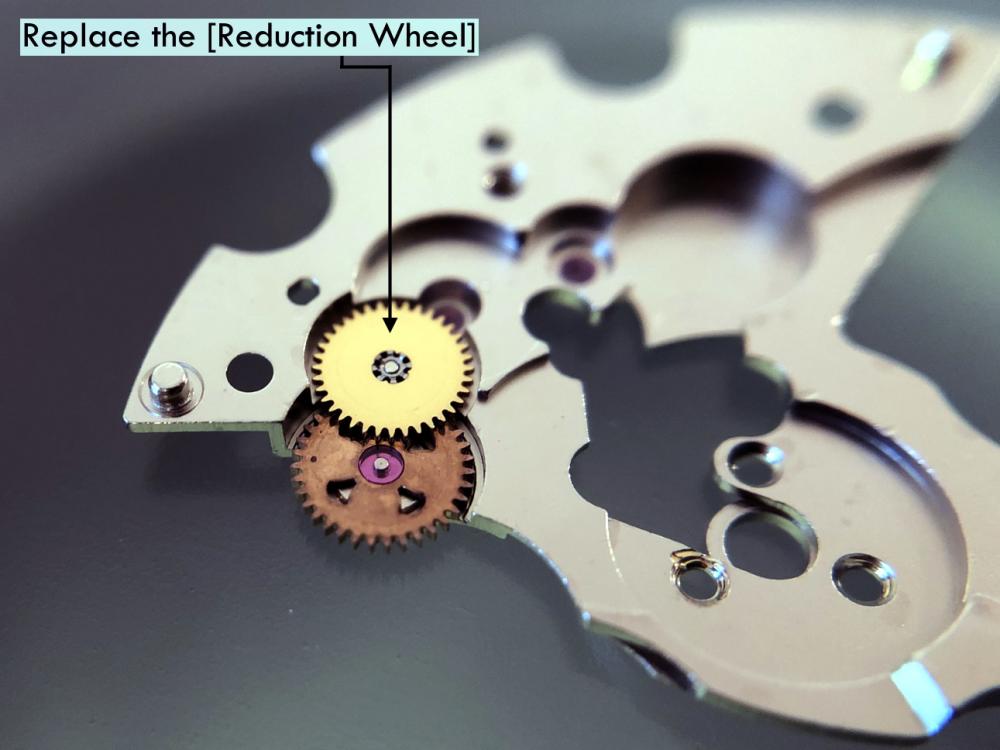

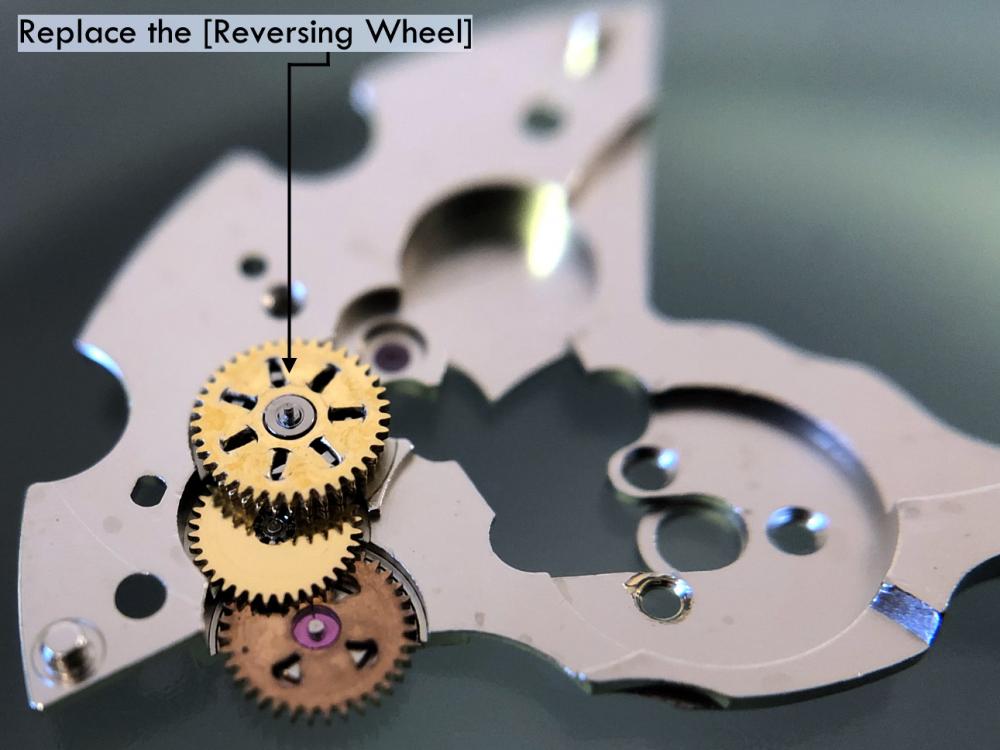

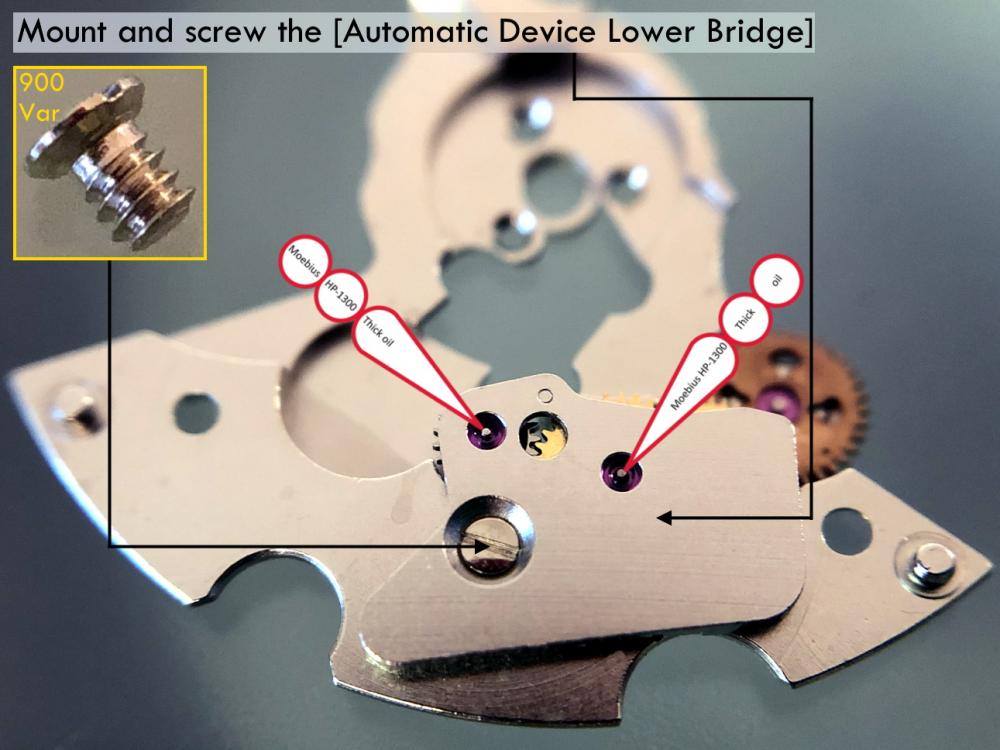

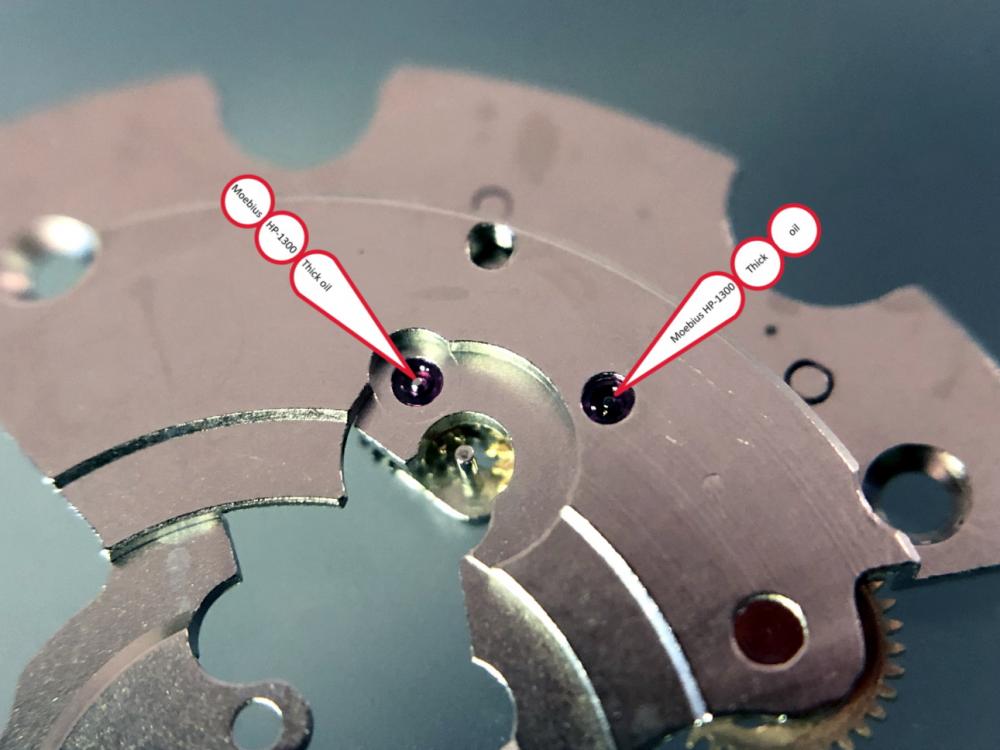

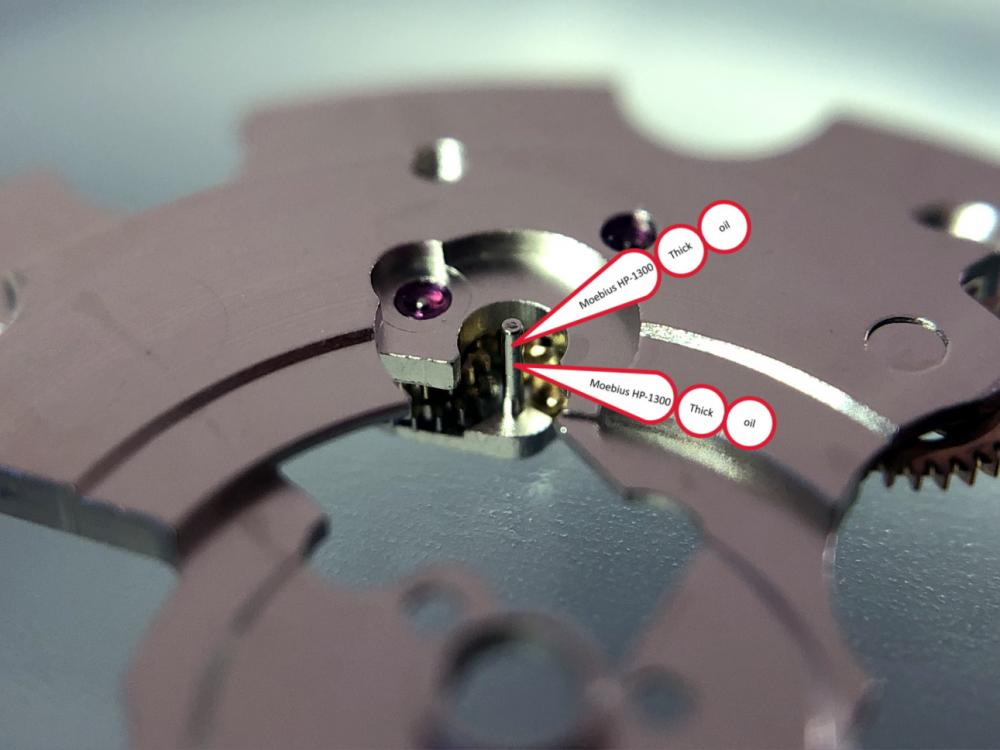

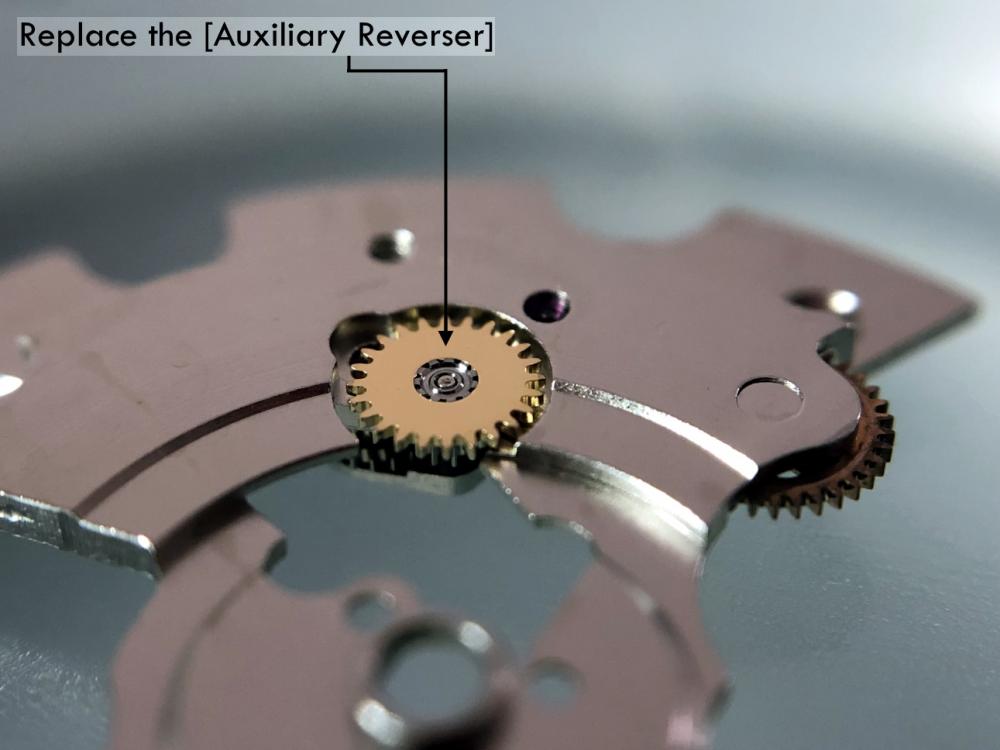

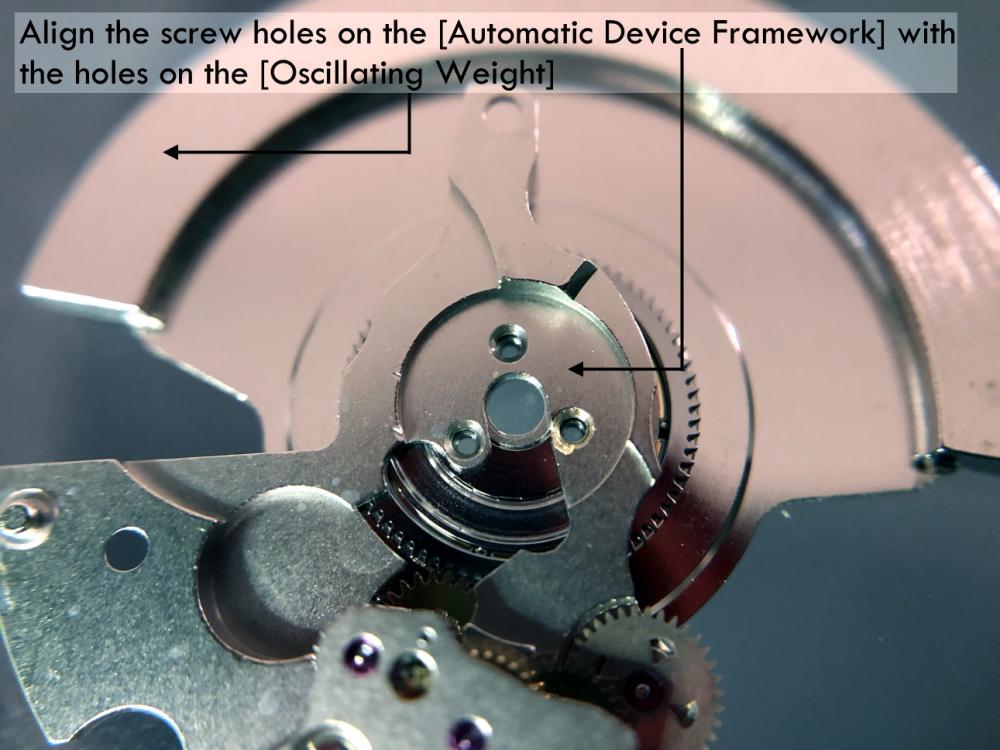

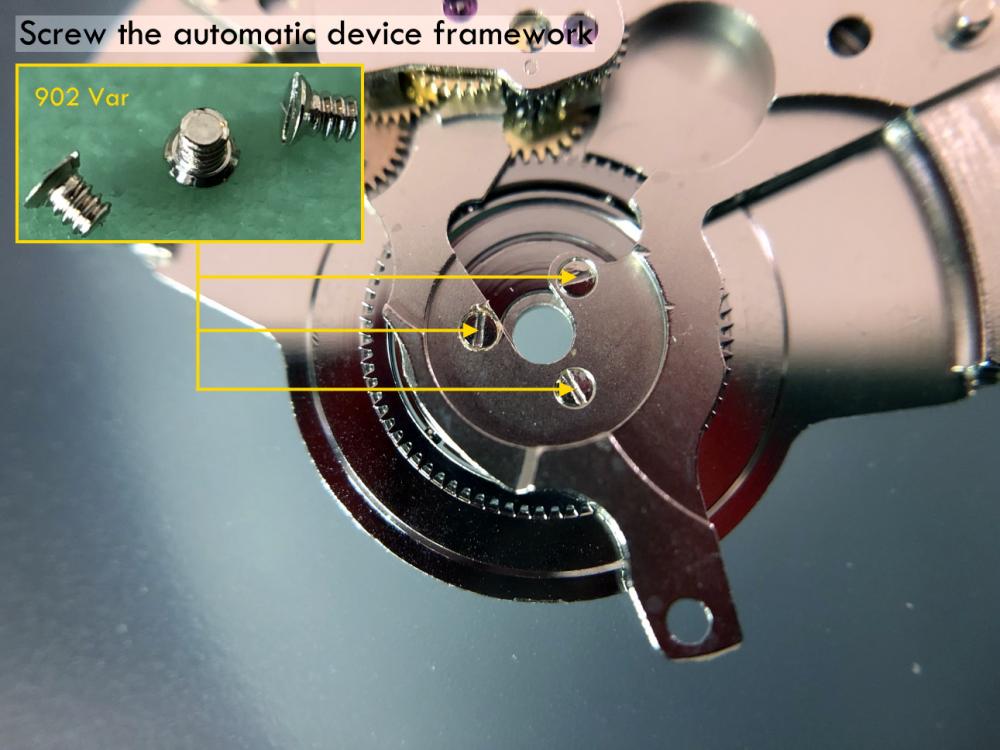

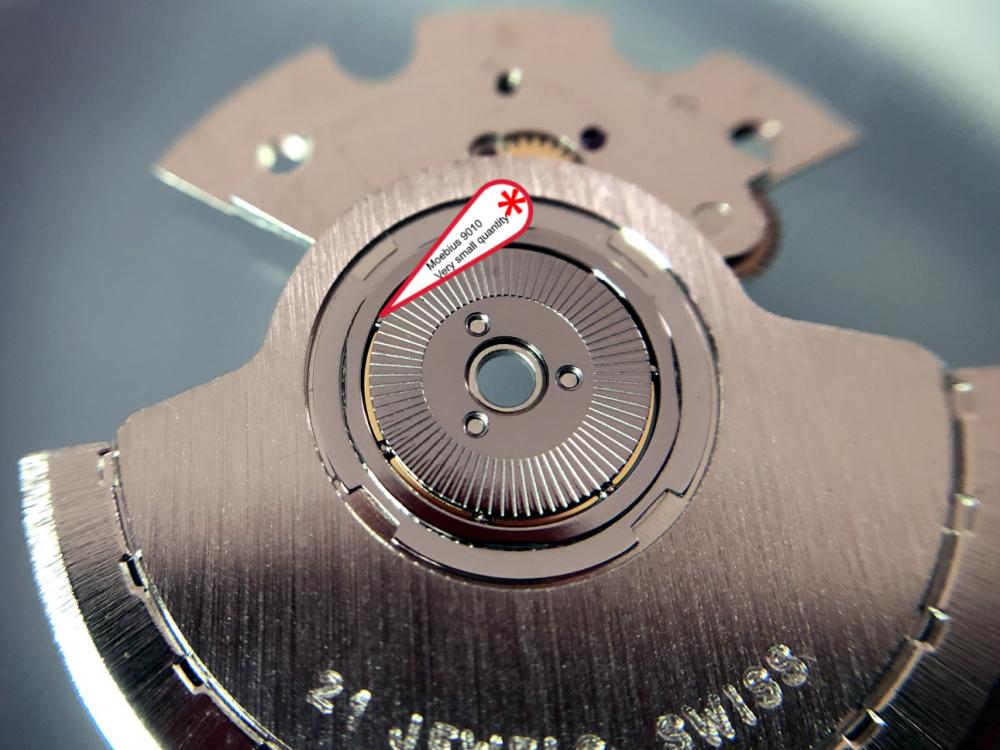

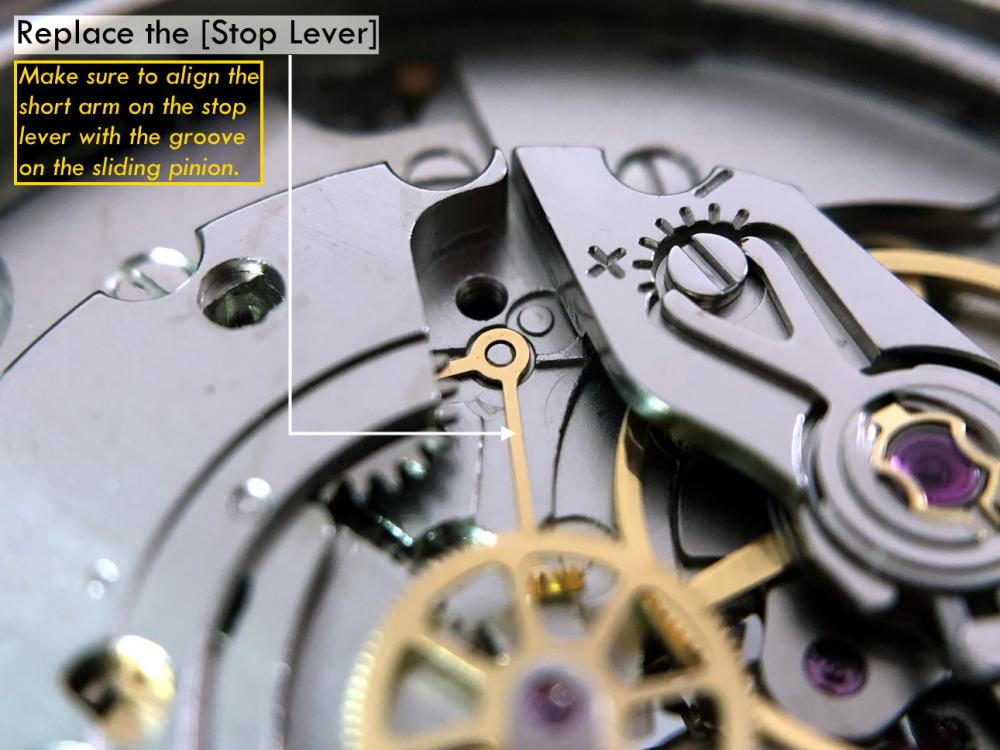

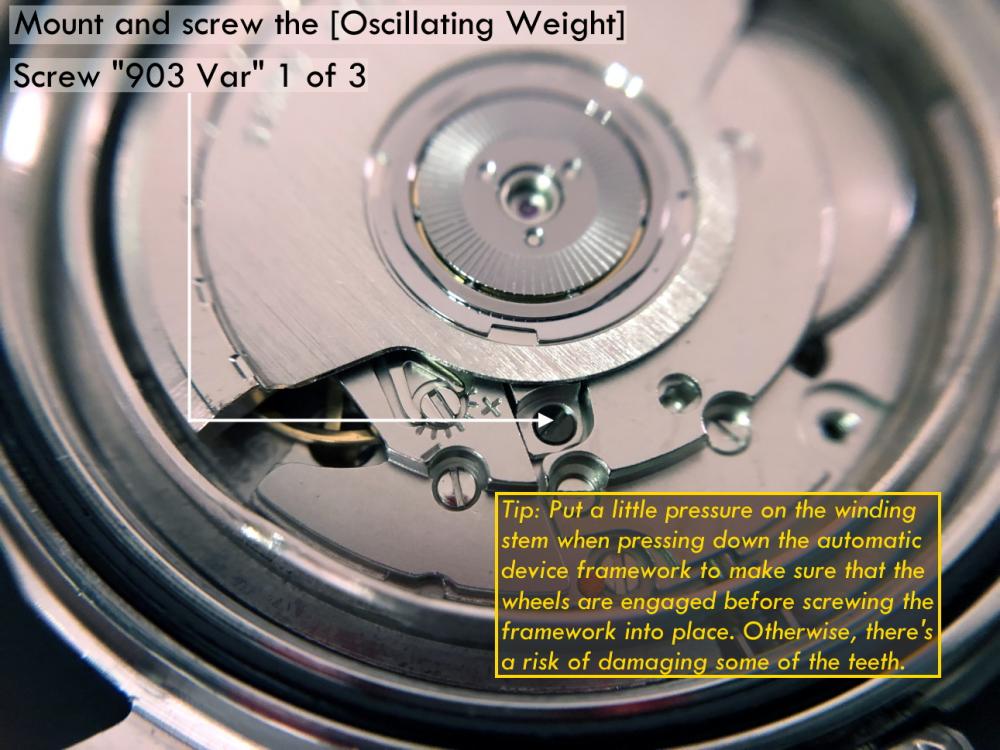

It is my impression that ETA's calibre 2892-A2 is usually found in more expensive watches and in luxury watches where oftentimes the movement has been modified. Mechanically, I don't think the 2892-A2 is superior to ETA’s classic 2824-2. Both movements have the same diameter (11 ½´´´ Ø 25.60 mm), the same frequency (28’800 A/h), and the same date complication. The decisive difference is the thickness where the 2892-A2 is one-millimetre thinner (3.6mm). That, combined with being a reliable and well-functioning movement, has made it popular for additional complications and alterations such as moon phase, power reserve display, co-axial escapement, chronograph modules from Dubois Depraz, and so on. The Swiss Sellita Calibre SW300-1 is, as far as I understand, an excellent clone of the 2892-A2. There is also a Chinese clone, the Seagull Calibre ST1812 (reviewed by @Markin the video “Chinese eta 2892-A2 Clone - Service and Review - Seagull ST1812”), and possibly others. Mark has made a playlist of videos that excellently demonstrate how to service the ETA 2892-A2 movement. The playlist is named: "Omega 2500 Co-Axial Stripdown and Service (ETA 2892-A2)" I recommend Mark’s playlist for several reasons. Among other things, he shows how to mount the barrel bridge safely and how to hold the minute train bridge with your tweezers to easily get it into place on the main plate (which I found a bit fiddly). In addition, he shows and compares the parts that are all too easy to mix up. One thing that is not shown in Mark's service video is that the Incabloc setting (chaton and cap jewel) for the balance and the main plate have different diameters. The main plate Incabloc setting diameter is smaller than that of the balance. The reason this is not shown in the video is probably that Mark removes, cleans, and lubricates the Incabloc settings one at a time after he reassembles the balance, so he wouldn’t notice. Anyway, don't mix up the two sets! Something that I appreciate about Mark's videos in general and that sets him apart from basically all other watch repairers on YouTube is that he doesn't continuously babble in his videos but mainly talks to make clarifications. I enjoy those segments of silence where I can just focus on the work being done. When I started my service, I decided to follow Mark's disassembly which worked perfectly. But for the assembly, I made up my mind to follow ETA's technical documentation to the letter. It turned out to be a mistake. In ETA's documentation, the assembly of the movement begins with the keyless works, then the train of wheels and then the barrel bridge. The crucial problem with this arrangement is that it is physically impossible to mount the barrel bridge if the train of wheels is already mounted. It is also very fiddly and difficult to baste the end of the winding stem into the winding pinion hole because the hole for the winding stem in the main plate is both open and tapered and therefore does not hold the winding stem. Mark takes a considerably more hands-on approach. He begins the assembly with the barrel bridge. He then mounts the keyless works whose constituent parts (the winding stem, the winding pinion, and the sliding pinion) are supported by the underside of the barrel bridge, making it considerably easier to get the keyless works in place. After I revised my strategy, this service walkthrough now follows Mark’s approach. It surprises me, but it seems like no watchmaker has proofread ETA's technical documentation. Alternatively, ETA follows an established practice and expects those using the documentation to understand that the assembly order in the document is not significant. I am also somewhat sceptical of ETA's recommendations regarding lubrication. Where we traditionally use grease, for example in the keyless works, ETA chooses mainly oil (HP-1300). I guess that ETA treats all parts of the movement with epilame (Fixodrop) and that oil may then be a better alternative. For better or for worse, my service walkthrough follows ETA's lubrication recommendations. As usual, I would like to remind those of you with no previous experience in watch servicing that this service walkthrough should not be seen as a tutorial on how to service a watch movement. A lot of tools, consumables, training and know-how are required to succeed. Fortunately, there are several excellent resources and watchmaking schools online. When looking through the pictures you’ll see that a few screws and plates are either marred or have pits and grooves in them. None of this is my doing but is either the result of rust (that I removed) or the doings of a less scrupulous repairer than myself. Finally, someone may ask, “Why to bother to do a service walkthrough with pictures when there is such an excellent video?" The main answer to the question is that I find it interesting and fun, and I see it as a complement to Mark's service video. Using this walkthrough, you can quickly scroll through the pictures to read what the different parts are called and where and in what order they should go, what the screws to be used look like, and to read ETA's lubrication recommendations. So, I hope you’ll find this ETA 2892-A2 service walkthrough useful, now or in the future. *** ETA Calibre 2892-A2 Disassembly *** ' *** ETA Calibre 2892-A2 Assembly ***1 point

-

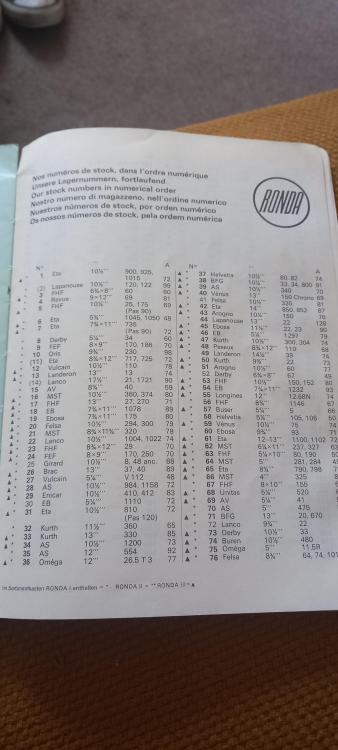

Eyup watch peeps. I have just received another useful book addition . There are sites containing this information, one in particular is the balance staff and stem .com site. A very handy database when searching for information on sizes. But it is an actual retail site so may not be around forever. If you google ronda catalogs there are also pdfs that you can download, i will add a link, but the stem pdf are not complete to the book. Everything is there but only is alphabetical order of make. Not grest if you have a stash of stems by ronda number order which i happen to have. This book will save days if not weeks of searching and identifying ronda numbered stems also unknown stems. https://vintagewatchparts.net/ronda-winding-stem-catalogue/1 point

-

1 point

-

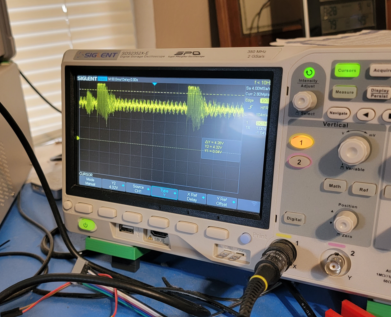

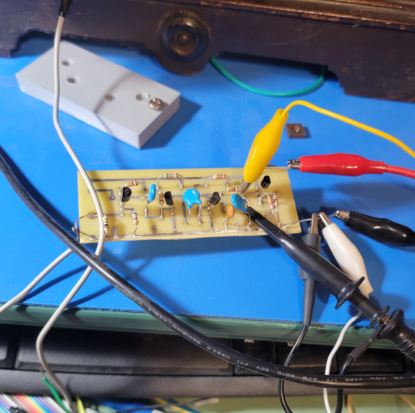

They exist but where is the challenge if you're going to buy one versus you could make your own? Plus maybe could be improved upon. This is an extremely popular one https://www.bmumford.com/mset/ This company's been around for a very long time multiple generation of clock and watch machines. https://adamsbrown.com/wordpress1/timetrax-timers/ The problem with bookmarks I accumulate a lot of them even searching for timing machine is a really helpful as I have too many. Not finding what I'm looking for but this was interesting that should never seen one of these? Yes I know this is a discussion about clock machines and know this is not for clocks but still it's a timing machine. https://www.td-timer.ru/catalog/snyatye/ppch-1e.htm1 point

-

I picked up this 033 75 Timex automatic at an antiques fair this morning in a lot with 2 other watches. This one is completely original and other than the broken strap, in great condition. Some DNA that took about 20 minutes to clean up with rodico including a quick crystal touch up with polywatcn. It seems like it was worn for a bit and when the strap broke it was put in a drawer. Put a temp rubber strap on and for £8 can't really beat it. Runs OK on the timegraoher but probably can be adjusted...1 point

-

There's a good walkthrough here : And this is the Service Sheet for the 2892-2, which has all the part numbers: ETA 2892-2.pdf Cousins stock a range of date wheels (part 2557.1) for this movement : https://www.cousinsuk.com/product/eta-2892a21 point

-

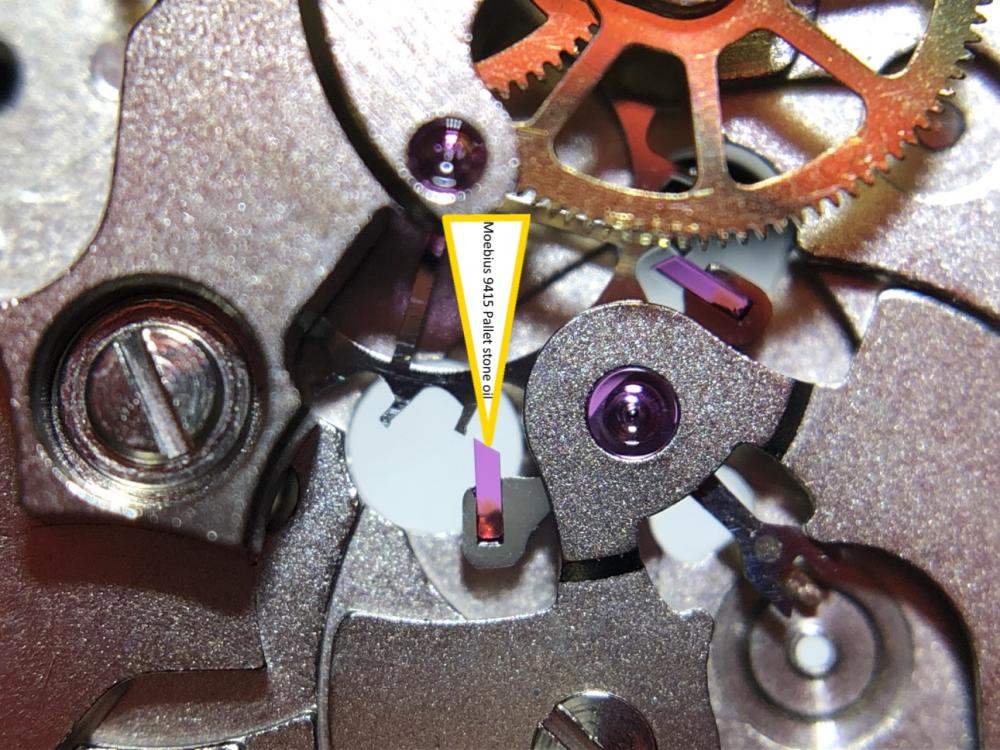

Yes you should oil. The trick is movements like the one showed do not have oil wells. So be careful not to over oil, You do not want to flood the plate, so make sure it doesn't come out over the pivots circle. The tiniest amount of oil on the pallet pivots.1 point