Leaderboard

Popular Content

Showing content with the highest reputation on 09/08/23 in all areas

-

The set has a rather strange assortment of punches. For instance the things with the plastic on top they are far too new for this set. Seeing as how they all have Springs on them they almost look like something for putting hands-on?. Then it looks like the table itself the discoloration looks like rust damage. Then usually things like the micrometer head are used for mistaking sets that are used to push jewels in but this one does not have the lever for that. Perhaps some somebody opened up the instructions it might tell but I have a suspicion that does not come with the set.3 points

-

2 points

-

Always nice to give a picture of what every working on so we know what it is and we don't have to do what I'm currently doing which is looking it up to see what it is. With the added bonus it avoids things like what I quoted below According to the link I have it looks like it's not. Oh and you're off by one digit and if you look at the link below you see the size reference of 8/0 SIZE Which indicates it some sort of American watch possibly a wristwatch but I'm not entirely sure yet. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=HAM_736 Then the only picture I would find the right now is on eBay this is not the best example it appears to be in bad condition but it now gives us an understanding of what were talking about I think background history like what was the background history of the watch before you serviced it? Then new old stock mainspring or Swiss mainspring? What are you using the time the watch in other words timing machine versus timing app on your phone?Can we have pictures and ideally we want to see dial-up and dial down and one crown position down would workfor timing or at least give us the numbers then even a new old stock mainspring when wound up tight should still run the watch at least for a little while. Oh and as you're new here and haven't done an introduction yet is this your first watch servicing? Yes I have more questions but this is enough to get you started1 point

-

Having it all complete is a big bonus, no hold ups when learning and projects. I've made this mistake with other major tools, on my forth jewelling tool but I'm happy to stop with that now .1 point

-

I asked if it was new to him because I wondered if someone had worked on it and not tightened the set lever screw.1 point

-

Let me furthure confuse you, though neverenough explained the reason why there different. Breguet stud holder and regulator are shorter that the radius of the lower ( main) coil. whereas stud holder fixed&mobile for flat spring are longer than the main coil. Yes definately the wrong balance COCK for cal 269. The question then is, would the cock of a variant for ( breguet overcoil) mount on 269 mainplate? I did go to online resources for the answer to no avail. Are you sure its cal 269. Rgds1 point

-

Have you ever bothered to read the rules of the message board? let me quote something for you Mark doesn't really have a lot of rules but it does look like promoting one's self would be frowned on. Have you noticed that I have never told anybody where I work ever? Yes I do work for somebody and I do restore vintage watches this is why grasp what somebody should be able to do. Oh look I could give you a link to somebody could make a balance staff and fix the watch except I happen to know he's thinking of retiring and would be very unhappy with me if I gave him another project. Then there's the other peculiar problem I believe that the watch is currently located in the United Kingdom. The same United Kingdom that I believe has an association known as the British horological Institute which I've actually visited at one time. Did you know they really big in making things? So they have courses where you learn how to make a lot of stuff I'm sure somewhere in that course they probably make a balance staff. so basically it seems to me that there should be somebody in the UK who could restore this watch is probably made in the UK in the first place.You just have to find somebody who does vintage restoration versus modern parts swapping.1 point

-

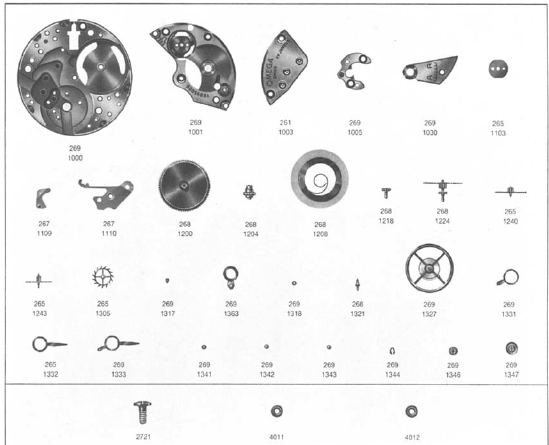

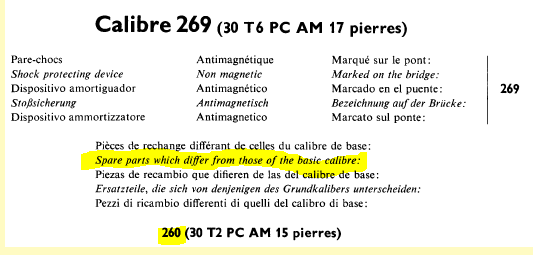

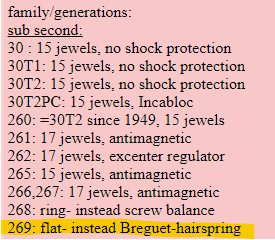

Doesn't anyone find this an odd comment? Did anyone notice that I attached the PDF of the parts list for the watch up above? If you look at the Ranfft Watches Website you'll see this watch the 269 is part of the family. Sometimes what happens is people get confused over what exactly that means like my quoted statement above does that mean we can mix and match from all the parts of the family because they're all related? Perhaps we should look at the parts list I think that might be helpful so I'll just snip out images. Reading the top part of the parts list tells us that the list has the parts unique or different than the base caliber and the base caliber is 260. One of the minor problems with the Ranfft Watches site Is it Gives us a lot of information but doesn't give us everything which is what's presenting a problem for this discussion. So for instance did you notice something that's titled family/generations:. In other words an evolution in this particular case improvements or changes made over time. So if we go down the list we get to 268: ring- instead screw balance This tells us that the balance wheel no longer has screws. It doesn't tell us anything else it just tells us the balance wheel has changed with probably still having the over coil hairspring. Then the next entry 269: flat- instead Breguet-hairspring Another evolution this would be the screwless balance wheel of 268 now has a flat hairspring. Now let's look at the parts unique to the caliber 269and how does it relate to this discussion? As you can see a lot of things have changed not just the final change the hairspring. Look at all the new parts we get is that a balance bridge I see in the parts list? Definitely looks like a balance bridge and to go with your shiny new balance bridge we have a stud holder and the regulator pins. In a course to go with that the balance wheel without screws in a flat hairspring. Conceivably the shape could be identical that's not the difference that were looking for. The breguet Hairspring versus the flat will have the stud and the regulator pins in a very different location. Now back to my unanswered question of I wonder what that actually means? For instance is somebody mixing and matching parts of the same family because they never bothered to look at the parts list to see what the differences?1 point

-

What you're looking for is somebody who works on vintage watches. They should have the capabilities of making a new staff to this watch in other words it fits this watch exactly. It basically be extremely stupid to make the staff from the dimensions and have you fit the thing which you can't do anyway. Basically somebody would make the staff to fit this exact watch. Also dealing with the hairspring collet issue and probably just restoring the watch or at least making it run basically dealing with whatever else is going on. In other words somebody who specializes in restoring vintage watches.1 point

-

Hi NEW if you read De Carles books he uses a favourite combination set which is dual purpose. Staking / jeweling but that has a lever on the head, the top unscrews and allows for inter changing of heads. I guess not made any more what with staking sets and jeweling tools made separately and readily available. Looks like a nice piece , depends on the price.1 point

-

All the pushers and anvils for the clone i have are a fraction under 4 mm. Some 3.99 some 3.98 checked on a digital vernier and an accurate bench micrometer. They all fit my seitz tool pretty well. A couple of the Seitz anvils measure 4.02 these are very tight in the horia clone base but all the seitz pushers fit the clone perfectly. Ignore the 3mm on the bench micrometer its exactly 1mm under size, the screw holding the fixed anvil is seized so i can only fine calibrate the micrometer but it is accurate. Top picture is a clone anvil at 3.98 middle a seitz anvil possibly a touch over size at 4.02 wont fit the clone base or pusher but it demonstrates that the clone will only just take 4mm at a push. What ive discovered is the clone and accessories are a good fit for a seitz tool. Only to bere in mind original horia parts may or may not struggle to fit a clone. Hope tbis helps matey. If they come a little under 4mm then should be ok. Not sure about other clones they may vary but mine finishes nicely at just 4mm both ends, you need that extra 1 or 2 hundreth tolerance on the pushers to have a good sliding fit. The clone base hole you could increase relatively easily the pusher spindle probably not. Shaving the pushers down would be a real ball ache for you, at least get that lathe of yours up and running1 point

-

1 point

-

Tap out all those bushings. As you are just starting out buy a box of Bergeon Number 4166 this will cover most of what you will need. A set of clock bushing Broaches get the best you can afford if you can afford get Bergeon they will always keep there cutting edge. German ones are also very good. A good set will last a life time. There is no reason why you shouldn't be able to handle this. There are some videos on this on youtube.1 point

-

The seller got back to me after contacting his watchmaker, the micrometer apparently is not part of the set and probably belongs as you say Ross to a combined staking and jewelling tool. The Horia clone you've linked, i have one as do a few other members. For the price they are ok but the pushers and anvils do need a little dressing up to improve their mating face finish. But all in all a fair tool for the price i consider after using it a few times. I've finally joined the seitz jewelling tool club after picking this up for a little over 60 quid, needs the accessories topping up which i hope to make and also has the reaming tool including half a dozen reamers but these are easy to aquire from cousins. So keep looking Ross something will turn up. I will keep you in mind next time i spot a potential bargain. Thanks john. My suspicion regarding the micrometer and now confirmed by the seller. I've seen these pushers as well in seperate sets for sale they are spring loaded and the seller does show them in the tool. For some reason i am think staff removing tools but maybe not. Maybe something like this.1 point

-

You are in the position to find the answer to some of your questions. The cock is the right one if it fits on the mainplate plus upper&lower jewels align. Balance can work if it fits and roller engages with the fork and escapement escape nicely. This spring might have the proper strengh to match with the balance at hand. Screw balance can work even if not the original and original was modern. I reinstal this balance/cock assembly on the movement and check if it fits with no problem and properly engages with the fork, next check how nice the escapement escapes, if alright, you can have tons of fun rebuilding a balance complete out of this existing balance, perhaps with the same spring, cut, repin .... so much fun so you run away fast. Regards1 point

-

Beautiful it is. Can't afford it. But. Beautiful it is Seems to be two in one Staking set and press set? https://www.ebay.co.uk/itm/Watch-Repair-Tool-Watch-Case-Closer-Set-Kit-With-48pcs-Dies-Jewelling-Tool-/1341591720941 point

-

I agree with all @Neverenoughwatches said, my lathe is a long work in progress collecting accessories and collets as they come up is a frustrating and expensive process. If you can afford it go for the star as it is the most complete. I think star lathes are still made so maybe possible to get spares, they were sold by cousins until fairly recently. Have a look at lathes.co.uk for lots of information and history of the lathes you are interested in. Tom1 point

-

1 point

-

1 point

-

Hi. To press out the old bushes I would use the same method as putting them in. As I don’t own a Bergeron tool I would use a small diameter punch in the drill press over a holed plate or a big nut. The watch makers staking set, of which I have two I feel are a little delicate for that type of work and may get damaged. There are clockmakers sets which are a bit more robust. As to setting end shake the bush needs to be flush with the inside of the plate only and is not as critical as in watches. If you have an old movement all the better to practise with. Hand broaching and drilling out worn holes Just takes care, there is plenty of guidance notes etc on the net to look at.1 point

-

Just waterproof 17 jewels and Incabloc. No printed brand. Nice quality inside but only a calibre number of 1035. It will need disassembly to figure out what it is .1 point

-

1 point

-

1 point

-

Holy dumba$$ Batman... There IS a circlip. I had another closer look from the side, and lo and behold.... It's a tiny silver clip at the base of the brass collar. I couldn't see it from above. Boy do i feel silly. Thanks @mikepilk and @RichardHarris123 Still, i'm glad i posted and did NOT try to force the wheel. Another problem solved thanks to you guys and this forum!1 point

-

I'm a watchmaker, so Essex is the way forward. You would use a clock bushing/reaming/pressing tool. You could do it with a watchmaker staking set, or even with small hand punches, although when pressing them back in you have to get the correct end-shake. You could use a watchmakers jewelling tool, as you have a micrometer setting to get the depth of the bush perfect.1 point

-

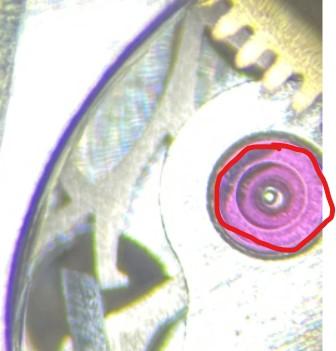

From the photo, the pallet fork arbor jewel looks massively worn to me creating a big side-shake and a much deeper and shallower lock in vertical positions because of the excessive side shake reducing your amplitude because of that deep lock. A shallow lock may cause mislocking There should be no discernable or visible side shake, so if you give the pallet a wiggle and see the arbor visibly moving sideways, that is far from acceptable. There should be about 0.01 mm to 0.015 mm side shake of the pallet fork.1 point

-

Grip the stem square with smooth pliers, and unscrew the crown. The stem should now pull out from the inside of the case.1 point

-

Closing off this topic (thank goodness you all say!) I got my response from Aliexpress about the fact they shipped the wrong item. It says "Judgement from Ali Express - not valid - reason - not enough evidence supplied - no refund". It goes on to say; Notice: If the seller makes a counterclaim against your claim/evidence during the dispute, you may need to test the product according to the seller's instructions/advice and record the process! Needless to say I am looking forward to their instructions on how to install a set of screwdrivers into a pocket watch and make them function as a balance wheel! I'm quite new to all this but even I think that might be difficult... Thinking about it it was worth wasting $USD5.00 for the entertainment value. Cheers...Jules1 point

-

It is a Breguet hairspring. What you see is no touching but the coil in 2nd level (over main level). It needs to be centered without balance wheel, hairspring mounted in cock. However surely not recommended for unexperienced repairers! Frank1 point

-

Take the balance wheel off from the balance bridge. And look again. Is he centred, is he flat, and work from that point onwards on the spring. But first I would correct the bend you showed on the picture to perfection again. All withe balance removed from the bridge. Do not remove the spring from the balance itself.1 point

-

typical with watch repair especially vintage is variations. Because you have so many variations is usually best to not to play with things until you discover they don't work. So this lever looks fine to me as the ones I've seen all have the jewels well some of them some stick out and some are parallel just like this.1 point

-

On this type of lever with the slots "the other way" it's normal for the jewels to be set essentially flush with the slot opening, and it's very difficult to move them.1 point